hydrostatic rotary table factory

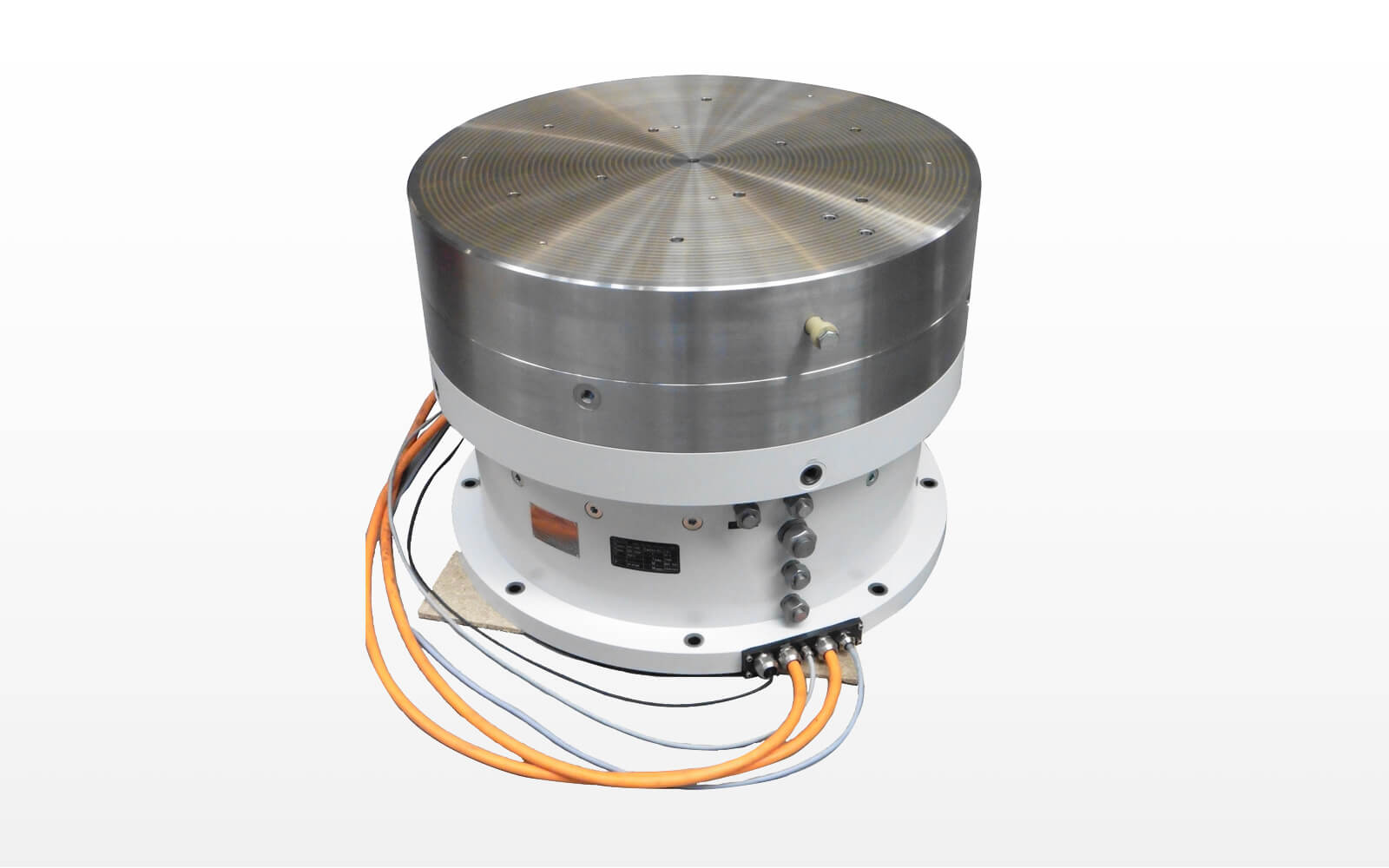

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure is set automatically and independently of production tolerances. The freedom from friction at low speeds prevents slip stick and therefore allows maximum positioning accuracy.

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.

• Gleason-Pfauter of Ludwigsburg, Germany built the world’s largest machine for gear grinding. One of the engineering highlights of this machine is the use of a hydrostatic bearing system for the rotating table. This table design makes it possible to very

The high table load and machining forces are not a problem for the hydrostatic bearings. Dampening of the hydrostatic system is 10 to 100 times better than with roller bearings, resulting in better surface quality of the gear. The round table floats – independent of speed – on a number of 20 micron hydrostatic bearing pockets. The end result is a totally wear-resistant system with very high stiffness. The accuracy of the machine can be expected to be unchanged over many years of operation since no wear takes place. With the use of a HYPROSTATIK PM controller system for the oil fl ow, the

hydrostatic pockets are so stiff that a 40 ton gear load will change the bearing gap by only a few microns. The mechanical PM fl ow controller employs a unique and patented design and is manufactured by HYPROSTATIK of Goeppingen, Germany.

The achievable roundness accuracy of the rotating table is much better than that of tables with comparable roller type bearings. At low RPM, friction is virtually nonexistent. In fact, friction is so low that one person can easily move the table with a 40 ton workpiece on it by hand. This low friction allows the table to be positioned second angle movements without backlash or high initial friction. Such slow and accurate positioning is only possible because of the hydrostatic bearing.

The typical oscillating motions used during gear grinding cause wear when using ballscrews. This results in loss of accuracy and can lead to failures over time. When using hydrostatic guide ways and hydrostatic lead screws, oscillating machine motion does not cause wear or loss of accuracy.

In addition, to further reduce friction and wear, hydrostatic bearings from HYPROSTATIK are installed on the table drive worm gear spindle and on the ways for the machine column.

The engineering calculations required for implementing the hydrostatic system were made by HYPROSTATIK. Since the hydrostatic pockets are machined directly into the frame of the machine and the table sits directly on the frame, there is no need for

Hydrostatic systems that improve machine accuracy can also be used on machining centers, grinding machines, lathes, and spindles for rotating tables, guide ways, bearings, and threaded spindles. For more information, contact Transatlantic Connection, Inc. – US Representative for Hyprostatik.

The hydrostatic rotary table is a large machine tool that utilizes hydrostatic bearings, it is used in a wide range of machining for large gears. Hydrostatics provide the rotary table substantially better load capacity than aerostatic bearings. Therefore, hydrostatic tables are commonly used to produce precise components for mills and other large gear applications, typically applied in a grinding system.

Hydrostatic Rotary tables nowadays are commonly applied on grinding machines, especially surface grinding. If extreme stiffness and high load capacity are the factors that the operators are considering, the hydrostatic rotary table will be an ideal choice.

The hydrostatic bearings provide a pressure supply in order to maintain clearance between the rotating and stationary elements. Between the moving surfaces, the lubrication is constantly supplied under pressure with the bearings.

Hydrostatic rotary tables are supported by oil film between guideways. The bearing surfaces are always separated by a thin lubricant film at static pressure. There is no friction between two contact surfaces when using a hydrostatic guideway. With the flow controller, a hydrostatic fluid film of the guideway, the hydrostatic rotary table can achieve high stiffness, high stability, great precision, and control without gear wear.

However, the accuracy can still be improved by regulating the oil film thickness of the hydrostatic rotary table. The oil film thickness can be controlled by the pressure control and the speed control via a variable hydraulic motor.

The hydrostatic lead screws are used to translate the rotation from a servo motor into linear motion. Compared to ball screws, lead screws have substantially smoother, cleaner, and quieter motion. The hydrostatic lead screw of the rotary table is self-lubricating, totally wear-free while the hydrostatic nut floats on a thin oil film.

Hydraulic motors are mechanical actuators that are designed to convert hydraulic pressure or fluid energy into mechanical power. A hydraulic pump, on the other hand, converts mechanical power into fluids or hydraulic power. Hydraulic motors can provide the driving force for the rotary table, supporting the motion to move an external load.

The oil filter, the pressure relief valve, and the throttle are also required in hydraulic machinery. Oil filters are designed to remove the contaminants from the hydraulic oil in hydrostatic rotary tables. The dirty oil would pass through the filter when pushed by pressure and return to the central hole, then the oil would re-enter the system. Most pressurized lubrication systems work with pressure relief valves, controlling oil to bypass the filter if the flow restriction is excessive. If the oil is thickened or the filter is clogged, pressure valves will also regulate the oil to bypass.

High Accuracy: During machining and grinding, generally, oscillation motions can lead to lower accuracy or even failures over time. However, a hydrostatic rotary table that utilizes hydrostatic guideways and hydrostatic lead screws creates little wear and little loss of accuracy in oscillation motions. With the arrangements, the machining and grinding run in maximum positioning accuracy.

Almost Frictionless Motion: Hydrostatic bearings provide hydrostatic rotary table significant advantages over tables that use mechanical bearings or other approaches to the rotation. Without mechanical attaching parts to wear or generate friction drag, the bearings of the hydrostatic rotary tables provide almost frictionless, smooth, accurate, and repeatable rotation.

Stiffness and Durability: Remarkable stiffness and durability of hydrostatic rotary tables provide the machine almost unlimited life. Even when it is exposed to harsher environments or an accident happens, often the bearings only need to be repaired but no need for replacement.

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

Hosea offers hydrostatic rotary tables, our hydrostatic tables with a high-quality, user-friendly display and record function, which can satisfy the need of our customers. Design flexibility is the reason our hydrostatic rotary tables are meeting the ultra-precision motion demands. If you are interested in our hydrostatic rotary table, just send us an inquiry to know more detail!

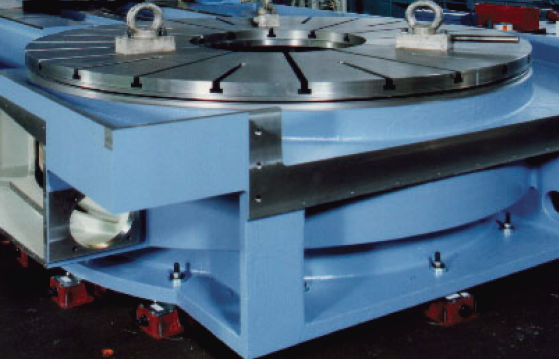

Fully Factory Rebuilt, Factory Refurbished Rotary Tables, to as new factory specifications: Horizontal, Weight approx 2100kg, Loading capacity approx 18,000kg/39,600lbs, . Refurbished October 2017 by Rusach International. Fanuc Alpha 30 motor, Heidenhain ROD800C +/-3.5 Arc Second encoder, Siemens hydraulic pump. Table Top is set up for a pallet receiver. Need it modified, please let us know!

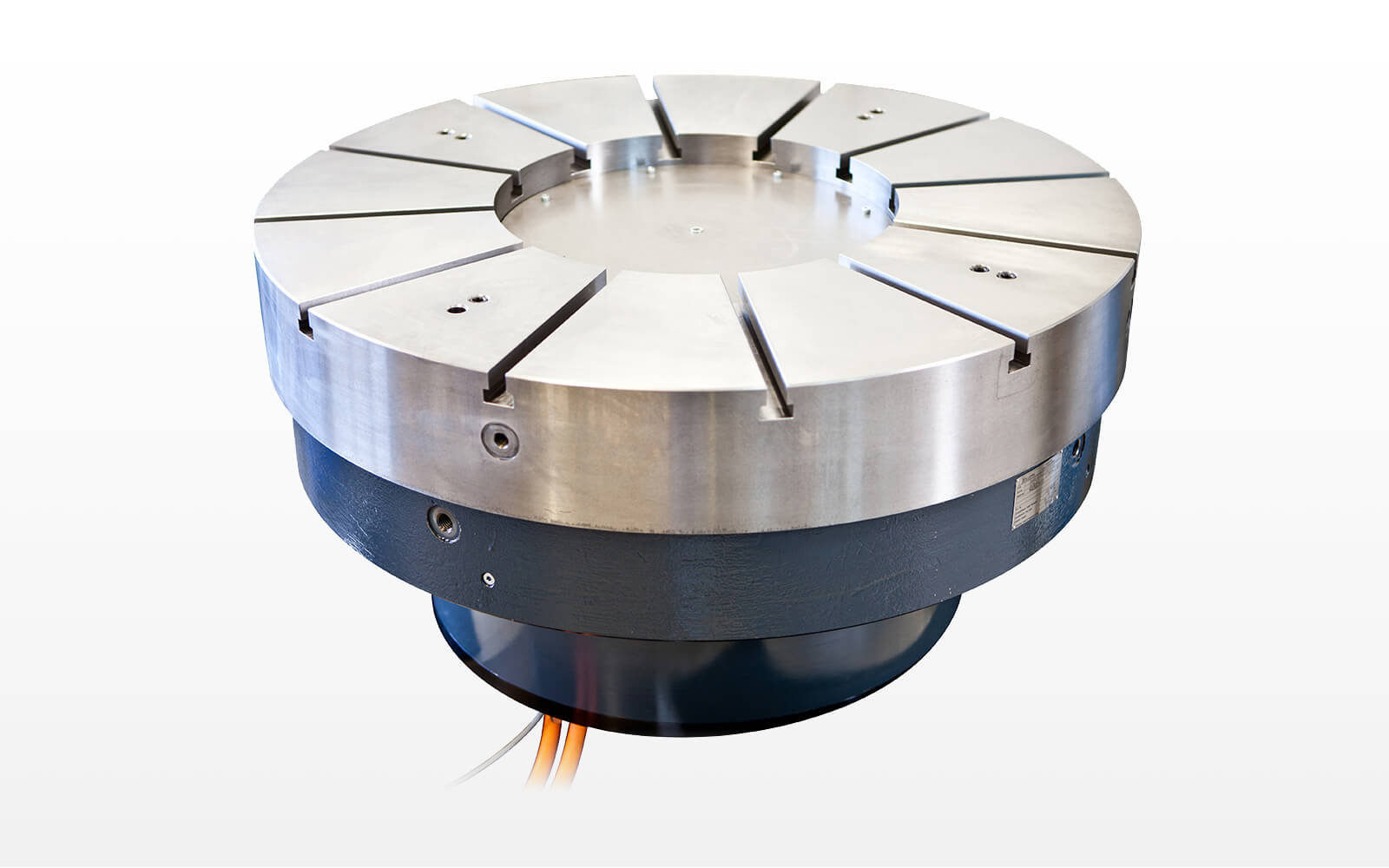

Our rotary, tilt and carousel rotary tables set a clear mark due to the extremely robust design as well as a high level of precision in the micrometre range, speed and repeatability. A suitable solution can be designed for every application case. We speak with our customers about requirements and work pieces, which are to be processed on the rotary tables. We create the right solution based on our experience from more than 600 projects. Our high-precision rotary tables can withstand a bearing load of up to 500 tonnes. If such masses are being moved, this requires high torques. If these masses need to be accelerated quickly, then they need to be braked quickly, and they need to be precisely positioned with accurate repeatability.

Whether a hydrostatic linear or rotary axis, roller bearing axles or also a combination with both, we have all the solutions in our portfolio. Hydrostatic guides help to avoid wear surfaces, for example at very high loads, and the tables are thus suitable for processing with the highest requirements and the highest accuracy. The best damping properties allow for longer tool lives and high-precision work piece processing. The decisive factor for the durability and precision of the rotary tables is not only the possible loading, but the largest possible bearing diameter in relation to the worktop size. The machine bed itself is very compact and space-saving. It is well-protected under the steel cover. All the necessary regulation and control elements are easily accessible in an power box located in the rotary table. Thanks to the standardised, plug-in-ready interface, the rotary table can easily be connected to all machine tools.

In addition to rotary tables for positioning work pieces for milling work (also in interpolation operation), patented tilting tables with additional axes, for example, are among the repertoire. Due to the standard angular adjustment of up to 10°, these are suitable for milling large an heavy components and, for example, are used in wind energy technology. Pallet changing systems are used to automate machining centres due to the multiple pallets and the ability to set up during main working hours. Thanks to a powerful drive train design, our carousel rotary table achieves very high machining torques, which makes a very good machining performance possible. In addition to the milling, it is also possible to turn and grind work pieces.

The Aries milling-boring machines can be equipped with a wide range of roto-traversing tables with complete hydrostatic bearing both for the rotating B-axis and for the linear V-axis.

In general all the tables can be equipped with a clamping system on the rotating B-axis. The system is designed in such a way that it does not modify the angular position of the table during the clamping phase.

The Rotary Tables of the VTL Blansko, a.s. Company’s own production, comprise a clamping plate which is provided with T-grooves for mounting four or more clamping jaws and the actual shears. The drive of the plate is solved by means of a pinion drive cabinet with two motors in a Master-Slave arrangement. The table plate is mounted on an axial hydrostatic bearing and radially on the rolling bearing. The power for the hydrostatic bearing is supplied by a hydraulic unit with the integrated cooling of the hydraulic oil.

In 2012 the VTL Blansko, a.s. Company became involved in the “Research and Development of a new generation of the RT6300-C rotary table” a grant programme for the promotion of Science and Research, announced by the Ministry of Industry and Trade. This departmental project is entitled TIP.

8613371530291

8613371530291