hypoid gear rotary table in stock

Hosea provides a diversity of Hypoid gear rotary tables for customers to choose from, our Hypoid gear rotary tables with stable index accuracy and high transmission efficiency. Moreover, they are easy to adjust. Please feel free to contact us as you are interested in our products detail!

Guangdong Saini Intelligent Equipment Technology Co,Ltd. is a professional manufacturer integrated with production, R & D and sales for more than 10 years in China. We supply high precision hollow rotary actuator, harmonic drive gearboxes, high precision planetary gearboxes, 90 degree gearboxes ( for servo motors and stepper motors), right angle hollow reducer, high precision alignment platform, etc.

Guangdong Saini Intelligent Equipment Technology Co,Ltd. is a professional manufacturer integrated with production, R & D and sales for more than 10 years in China. We supply high precision hollow rotary actuator, harmonic drive gearboxes, high precision planetary gearboxes, 90 degree gearboxes ( for servo motors and stepper motors), right angle hollow reducer, high precision alignment platform, etc.

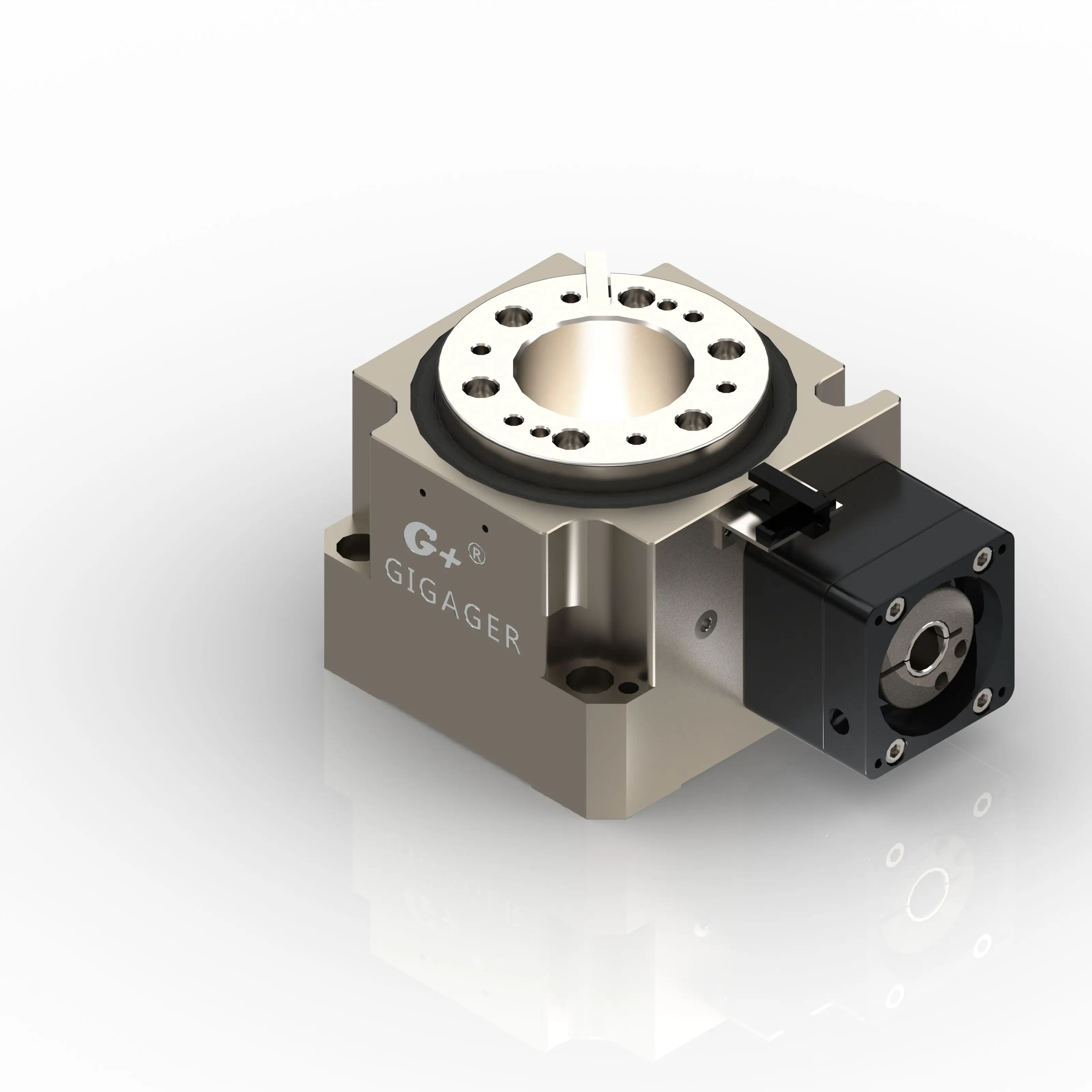

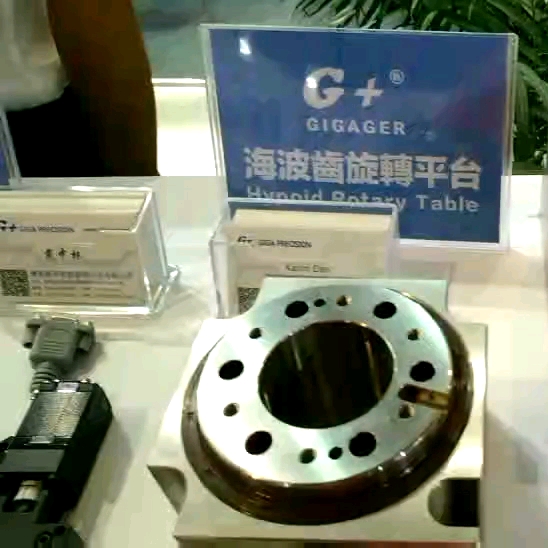

Hypoid Hollow Table is a kind of gearbox integrated right angle gearbox and Hypoid gears, featured with high torque, high gear ratio, high IP grade, high precision, low wear.

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

Swing head is suitable for any spindle from any brand, the clockwise and counterclockwise for swing angle and multi-axis elliptic arc machining application.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines, however, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continual load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right angle attachment is available (P/N 3701) to mount the table in the vertical position to further increase its versatility. With the table mounted vertically, an optional adjustable right angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

A ghost view of the rotary table drawn in SolidEdge® by John Costello shows the internal mechanism so you can see how the worm gear drives the table. Ball bearings are shown in dark blue.

The rotary table has a unique table locking mechanism that is positive and does not move the table as it is locked. To maintain accuracy and frictionless movements, ball bearings are used. Worm gears are factory greased and the drives sealed to keep out chips and dirt. An oiler is easily accessible to facilitate lubrication of the table. The appearance is instrument quality with a black oxide base, precision ground finishes, and laser engraved markings.

As with all Sherline tools, the illustrated instructions are very useful. The 8-page manual covers the basics of rotary table use and takes the user through a typical project.

Any machinist desiring to take his capabilities to the ultimate levels should consider purchasing and learning to use a rotary table. The Sherline rotary table is an extremely precise and well-built piece of equipment that is sized to fit with our product line. It can also be useful on larger equipment when its compact size is called for.

The rotary table is also available with a stepper motor mount attached ready for the application of a stepper motor and CNC controls. See P/N 3700-CNC.

NOTE: Because components of the table are ground as a set during production, the P/N 3700 rotary table cannot be upgraded to the P/N 3700-CNC version later on. A new rotary table with stepper motor worm housing must be purchased.

Hosea, a professional CNC rotary table manufacturer in Taiwan, providing quality 5 axis rotary table, hydraulic rotary table, and precision index table.

At Hosea, precision quality comes first at every stage of the production process. Our rotary tables have been sold and widely used in the European market and have an enormously high reputation among our customers.

In March 2015 Hosea Precision created the independent brand「 HOSEA 」, to make it a household name for high-quality rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our CNC index table and other products.

With a Hosea pneumatic rotary table, you always know what you get: a quality product that was manufactured in a quality production process - from start to finish. With this attitude and as a member of the Taiwan Machine Center Alliance, we continue to provide the best products for the high-tech machine tool industry of today and the future.

Many rotary index table end users need the flexibility afforded by having a fully programmable tool. A seemingly simple way to achieve this is by using a gear head coupled to a servo motor or an AC motor with an encoder. In reality though, while this seems simple and cost-effective, because of the physics described above, high inertia, combined with a goal of high accuracy can create a problematic mis-match.

With a servo-driven barrel cam rotary index table, it’s possible to deliver a wide range of table sizes, with zero backlash and unparalleled accuracy. Servo driven rotary indexers allow heavy inertial loads to be rotated in a very smooth and controlled manner.

Cam-driven rotary index tables can have significant advantages over other types of rotary index table drive systems such as gear drives. Cam-driven rotary index tables provide extremely high accuracy because they operate with no backlash. There are several types of commonly used cam-driven rotary index table systems, each is best for a specific application.

Barrel cams represent strength in indexing. Primarily found in rotary index tables, indexers utilizing barrel cams feature the greatest strength/size offering available.

Cam driven rotary table indexers are sometimes call "fixed indexers". With a fixed indexer, the cam drives receive constant power input from the motor. This rotates the cam which then rotates the output. Based upon the design of the drive, the output will have "dwell" periods (when the output is stopped) as well as acceleration, deceleration and peak velocity. Cam-driven rotary index tables have a number of advantages, however, they won"t meet the needs of every application.

Rotary index tables can also be "flexible". Flexible rotary index tables use a cam that has a constant lead, that is the output is at a constant velocity if the motor is running at a constant velocity. Constant lead cams provide a high-precision mechanical transition of power to the output and since acceleration and deceleration are still necessary, the logic controller for the index tables motor provides the necessary control.

Saini Intelligent provides wide ranges of Hollow Raotay Table and their Combination Axis. We provide the following Hollow Rotary Table and its combination.

For some application, the bigger gear ratio are needed, it can be achieved by combination of Hollow Rotary Table with Planetary Reducer or Right Angle Gearbox. Below is a combination list for different gear ratio.

The Hollow Rotary Table could be applied for many application like Rotating Platform, Laser Marking machine, Gyro Test, Gravity Sensor Test, Electronic Compass Test of mobile phone and other precise electronic product. It also can used for robot arm joint, automation production line, testing device, laser cutting, etc.

8613371530291

8613371530291