hypoid gear rotary table factory

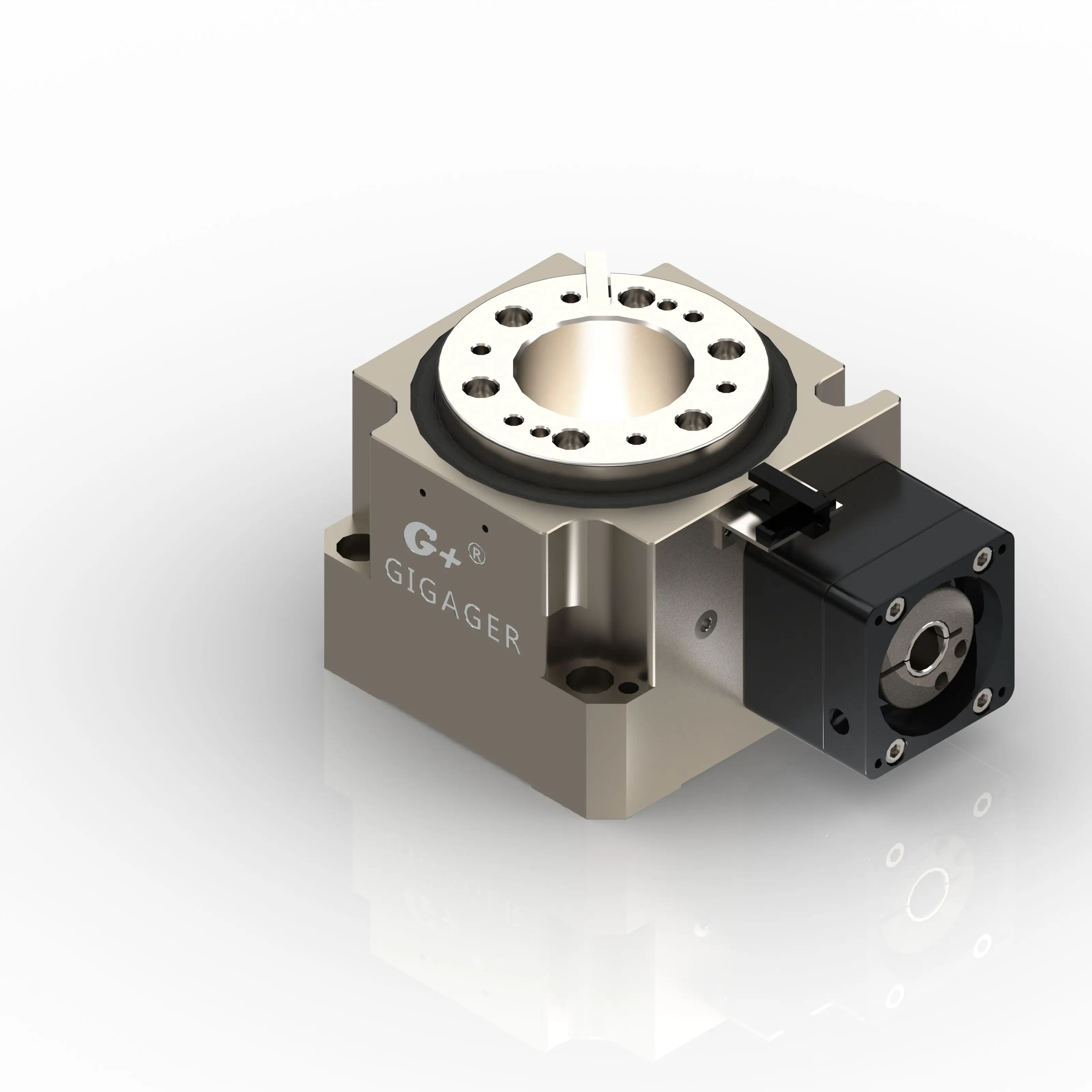

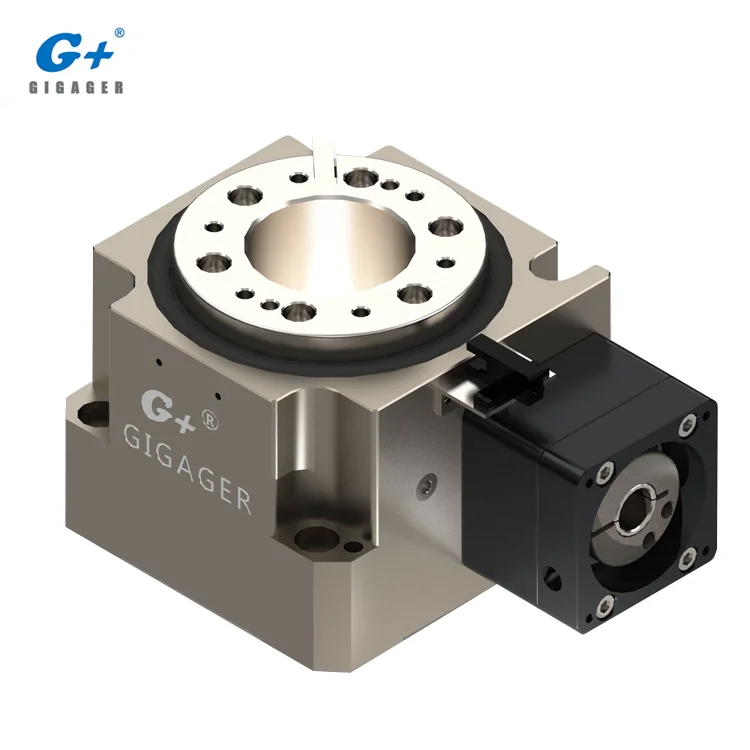

Hypoid Hollow Table is a kind of gearbox integrated right angle gearbox and Hypoid gears, featured with high torque, high gear ratio, high IP grade, high precision, low wear.

There are many types of rotary tables in the market, for instance, the hypoid gear rotary table, all of which essentially work positioning devices widely used in metalworking applications. It allows work to be cut or drilled at identical intervals around a fixed axis (normally horizontal or vertical).

Some of the key advantages of a rotary table include the repeatability, short time of indexing, flexible indexing positions, as well as the tolerability of exceptionally high axial and radial torques during rotation and stopping.

Systems based on rotary tables are generally very durable, and will not require a repair until a longer period of time. Depending on the applications, the rotary table may be complemented with an internal or external clamp. In this article, we’ll specifically address the hypoid gear rotary table.

A hypoid gear rotary table is a kind of rotary table with the hypoid gears and right angle gearbox integrated into it. This type of rotary table is characterized by high gear ratio, high torque, high precision, high IP grade, and low wear. It employs a sliding mechanism to rotate, and the transmission precision can reach as high as 30 arc seconds with transmission efficiency up to 96%. A hypoid gear rotary table also has the gear geometric tolerance of ≤ 0.002mm.

The high IP grade allows hypoid gear rotary tables to work in environments with high humidity, and to be both waterproof and dustproof. The housing of the hypoid gear rotary table is also typically made of robust alloy steel with a large modulus root design, making it one of the most rigid rotary tables for rotation of large inertia load. Hypoid gear rotary table is also known for its long lifespan, having been made with high rigidity and high density gear materials that can reach up to 30,000 hours of precision life.

Hypoid gear rotary tables are also referred to as the high torque rotary stage, hypoid follow rotary stage, right angle hypoid gearbox, etc. This type of rotary tables is widely used in several automation-emphasized industries, namely transmission system, CNC and robot arm fields. Hypoid gear rotary tables can be installed horizontally, suspended or side installation. To elaborate better, we’ll talk about what exact hypoid gears are in the following section.

In this section, we’ll illustrate what exactly hypoid gears are and where they are used complementing the rotary table. A hypoid gear is essentially a type of spiral bevel gear with an axis not intersecting with the meshing gear axis. The shape of a hypoid gear is a revolved hyperboloid while the shape of a spiral bevel gear is usually conical. The reason that we mention this here is that they are usually mistaken as interchangeable terms.

In a hypoid gear, the pinion is positioned off-axis to the ring gear, which enables the pinion to be greater in diameter and to have more contact area. For the design of hypoid gear, the pinion and the gear are virtually always positioned opposite of each other, and the spiral angle of the gear is usually smaller than that of the pinion. It’s also worth noting that the hypoid pinion is greater in diameter than that of an equivalent bevel pinion.

Equipment that incorporate hypoid gears, namely rotary tables, are typically used in power transmission products which are more efficient than the traditional worm gearing. Hypoid gearings are significantly stronger because the load is conveyed through multiple teeth at the same time. Conversely, bevel gears are loaded through a single tooth one at a time. With proper lubricants, multiple contacts of hypoid gearing can be made silent as well. Specialized gear oils are also imperative for hypoid gears due to the fact that the sliding motion of the gear requires proper lubrication under extreme pressure among the teeth.

Hosea provides a diversity of Hypoid gear rotary tables for customers to choose from, our Hypoid gear rotary tables with stable index accuracy and high transmission efficiency. Moreover, they are easy to adjust. Please feel free to contact us as you are interested in our products detail!

Hypoid Gear Rotary Table is a kind of gearbox integrated right angle gearbox and Hypoid gears, featured with high torque, high gear ratio, high IP grade, high precision, low wear. It adopts sliding mode to rotate, the transmission precision can reach 30 arc seconds, the transmission efficiency is up to 96%; the gear geometric tolerance ≤ 0.002mm, up to JIS0 level standard. Hypoid Rotary Table also called High Torque Rotary Stage, Hypoid Hollow Rotary Stage, Right Angle Hypoid Gearbox, etc.

The turntable is a rotating plate at the bottom of the rig that turns the drill string clockwise. The rotary table has four or six-sided bushings and a drill string attached around a keel drive that transmits power from the platform drive system to the drill string and drill bit. Since the power supply connects the rig to the rotary table and the drill string, it can be described as a coupling. Most drilling rigs have a rotary table as the primary drive of the drill string, but overhead drive systems that provide continuous rotation of the drill string replace rotary tables, keel bushings and general drives through a trenchless conversion. Construction requirements. The drive bogie is used on top-drive platforms, meaning the drive motor is on top of the platform. Drill string segments are first attached to the bottom of the well. As the drill string segments enter the well, additional drill string segments appear

Guangdong Saini Intelligent Equipment Technology Co,Ltd. is a professional manufacturer integrated with production, R & D and sales for more than 10 years in China. We supply high precision hollow rotary actuator, harmonic drive gearboxes, high precision planetary gearboxes, 90 degree gearboxes ( for servo motors and stepper motors), right angle hollow reducer, high precision alignment platform, etc.

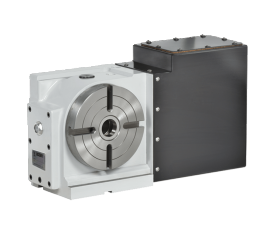

Rotary tables are used for precision metal work. They are usually made of a solid base that can be attached to another bracket. The table is a disk that rotates freely or with the help of a spiral (hand crank).

The rotary table is a disk-shaped metalworking device that enables precise positioning of the workpiece. It allows the metalworker to cut or drill the workpiece at precise intervals vertically or horizontally around a fixed axis. The turntable can be controlled both manually and digitally by computer. Some types of rotary tables are designed to be used with indexers or separators for special operations. A rotary table used with one of these positioning plates is often called a dividing or indexing head.

The Rotary tables is usually a sturdy base that can be attached to a separate stand or table. This device is basically a rotating disc that holds the workpiece in place while cutting or drilling. The disk portion of the rotary table can be freely rotated or rotated for indexing operations by means of an attached control lever known as a worm wheel. Tables used in precision operations are usually turned with a duplex type helical wheel to compensate for clearance. Rotary tables used in automated metalworking processes are connected to a digitally controlled computer.

Rotary tables are mostly used in a flat position with the table axis vertical. Sometimes they are installed with the shaft pointing horizontally so that the suppository can be used to support the free end of the workpiece. When this device is attached to the secondary table, the workpiece can be centered on the axis of the rotary table, which is then centered on the axis of the cutter. In this configuration, the axes of the rotary table, secondary table and cutter are coaxial to facilitate concentric cutting operations. This configuration also allows the secondary table to be moved to drill evenly spaced holes in the workpiece.

Rotary Table offers an unparalleled combination of good accuracy and high load capacity. These rotary stages utilize a precision worm gear with the worm “flexed” against the gear to ensure a proper mesh. This feature provides high repeatability with very smooth operation. Additionally, the rotary stages incorporate an oversized pre loaded cross roller bearing, offering exceptional stiffness and load capacity.

The HD housing and gears is produced by the high rigidity materials, with excellent load capabilities, high endurable, motion accuracy and ultra low-noise. The design of Angle Tapered Roller Bearings, which also effectively strengthened. A rotary indexing table has basic moisture resistance, protection level, and can reach water IP65 grade.

American Block offers a complete line of drilling rotary tables that range from 17 ½ to 60 ½ . These tables are designed to withstand the harshest drilling conditions. All rotary tables feature a fabricated frame, heavy duty main thrust bearing and precision machined spiral bevel gear that results in superior strength, toughness and durability.

American Block can also provide unitized rotary table assemblies (IRD). Our unitized skid packages are ideal for new builds or can be retrofitted to existing rigs. Featuring a heavy-duty oilfield skid and an extend life transmission. The rugged design ensures that when the equipment is mounted it remains rigid during operation and rig moves. Other rotary table options include hydraulically operated tables and high torque tables (25% more torque), which are ideally suited for top drive operation.

Hypoid Rotary Table adalah sejenis gearbox terpasang gearbox sudut kanan dan gear Hypoid, dilengkapi dengan tork yang tinggi, nisbah gear tinggi, gred IP tinggi, ketepatan tinggi, pakai rendah. Ia menggunakan mod gelongsor untuk berputar, ketepatan penghantaran boleh mencapai 30 detik arc, kecekapan penghantaran adalah sehingga 96%; gear toleransi geometri ≤0.002mm, sehingga standard tahap JIS0. Hypoid Rotary Table juga dipanggil Peringkat Rotary Tork Tinggi, Hypoid Hollow Rotary Stage, Sudut Kanan Hypoid Gearbox, dan sebagainya.

Saini Intelligent provides wide ranges of Hollow Raotay Table and their Combination Axis. We provide the following Hollow Rotary Table and its combination.

For some application, the bigger gear ratio are needed, it can be achieved by combination of Hollow Rotary Table with Planetary Reducer or Right Angle Gearbox. Below is a combination list for different gear ratio.

The Hollow Rotary Table could be applied for many application like Rotating Platform, Laser Marking machine, Gyro Test, Gravity Sensor Test, Electronic Compass Test of mobile phone and other precise electronic product. It also can used for robot arm joint, automation production line, testing device, laser cutting, etc.

Many rotary index table end users need the flexibility afforded by having a fully programmable tool. A seemingly simple way to achieve this is by using a gear head coupled to a servo motor or an AC motor with an encoder. In reality though, while this seems simple and cost-effective, because of the physics described above, high inertia, combined with a goal of high accuracy can create a problematic mis-match.

With a servo-driven barrel cam rotary index table, it’s possible to deliver a wide range of table sizes, with zero backlash and unparalleled accuracy. Servo driven rotary indexers allow heavy inertial loads to be rotated in a very smooth and controlled manner.

Cam-driven rotary index tables can have significant advantages over other types of rotary index table drive systems such as gear drives. Cam-driven rotary index tables provide extremely high accuracy because they operate with no backlash. There are several types of commonly used cam-driven rotary index table systems, each is best for a specific application.

Barrel cams represent strength in indexing. Primarily found in rotary index tables, indexers utilizing barrel cams feature the greatest strength/size offering available.

Cam driven rotary table indexers are sometimes call "fixed indexers". With a fixed indexer, the cam drives receive constant power input from the motor. This rotates the cam which then rotates the output. Based upon the design of the drive, the output will have "dwell" periods (when the output is stopped) as well as acceleration, deceleration and peak velocity. Cam-driven rotary index tables have a number of advantages, however, they won"t meet the needs of every application.

Rotary index tables can also be "flexible". Flexible rotary index tables use a cam that has a constant lead, that is the output is at a constant velocity if the motor is running at a constant velocity. Constant lead cams provide a high-precision mechanical transition of power to the output and since acceleration and deceleration are still necessary, the logic controller for the index tables motor provides the necessary control.

The worm shaft is made of case-hardened steel. It is a specially designed and profile-corrected gear arrangement for higher efficiency, higher load carrying capacity, and precise accuracy. The worm gear is made of a special non-ferrous alloy with high anti-wearing. A unique profile on worm gear ensures improved gear engagement between the worm gear and worm shaft while guaranteeing improved accuracy, lesser wear & tear, and uniform load distribution. This transmission mechanism is used in all standard 4th axis and 5th axis worm gear rotary tables.

Manufacturer of spur Gear, spur gears, automobile Hypoid gears, diesel engine gears, automobile gears, motocycle gears, car transmissions, springs, spring raise suspend frames, metal products, forgings. It has passed ISO9002:9004 certification.

Hangzhou Ocean Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, bearings, Gear, gear rack, belt, sulzer loom spare parts, rapier loom spare parts and other loom spare parts.

Hangzhou Xingda Machinery Co., Ltd. specializes in the development, manufacture and sale of metal machining. Our main product, MNRV worm Gear speed reducer has reached the advanced techique index of the congeneric European and Janpanese products. We also accept orders of non-standard products, such as gears, shafts, punching parts and so on according to customers" drawings or samples.

Ningbo Kingbell Powder Metallurgy Co., Ltd. specializes in manufacturing various of powder metallurgy components, which have more than 1500 items, including structure parts which have complex shapes, high mechanical & physical performance and accuracy demands, gears, oil pump rotors and so on.

Founded in 1995 and renamed in 2006, Shenzhen Chaojun Plastics and Mould Co., Ltd has been working as a well-known plastic gears, Gear boxes ( speed reducer), plastic parts & products manufacturer for more than 11 years in China. Now we own precise Gear machining, tooling and testing instruments like Japan Sodick EDM machine , Japan OKK CNC machines, Mitsubishi EDM machines,laths,milling machines grinding machine for making the mould and and 3-D vision measuring system and Gear rolling test for checking the moulded products, advanced brand injection machines like battenfeld do injection etc. If you are a design engineer searching for a development partner or a corporate purchaser researching price competitive plastic/ mould supplier, we provide total solutions which are cost-effective, manufactured...

Zhejiang Dafa Gear Co., Ltd. specialized in producing the engine gears of automobile and motorcycle who found in 1988. During these more than 10 years, we are always persist in taking the market as the guidance and set up company"s system for independence, innovation, science and technology. It makes DAFA developped continuously and quickly so that have today"s splendid success.

Zomax Group has gone through the attestation of ISO 9001:2000 and ISO/TS- 16949:2002 quality system. It has the authorization to import and export products independently. The business covers car transmission car Gear, motorcycle Gear, car spare parts, garden machinery, real estate, foreign trade and so on.

Hypoid gearing combines the space and configuration advantages of worm gearing with the high efficiencies of bevel gearing. The result is the Dyna Series gearbox is able to achieve ratios up to 15:1 in a single stage and ratios up to 100:1 in 2 stages.

For the most demanding motion control applications that require high angular accuracy, choose our new DSX gearbox. It offers extremely low backlash, extremely smooth torque transmission and extremely low noise. Angular accuracy test data is available upon request.

We’ve taken the highest-performing gearbox on the market and redesigned it for greater durability, smoother gear rotation, improved bearing life, and reduced noise.

8613371530291

8613371530291