magnetic rotary table manufacturer

The chuck is a specialized clamp-type used to hold objects with radial symmetry like drills or perforators. By fixing magnetic rotary table on the front part of your rotary tools, you will be able to fix various tools and parts such as screws, nuts, drills, and cutters. Having a chuck in your toolkit will allow you to finish your jobs quickly thanks to its versatility and practicality.

magnetic rotary table can also be used to fix a workpiece. This small tool facilitates the transition between different activities, like going from drilling to screwing. Furthermore, you can also use it as a rotating element in drawn glass manufacturing. Some chucks are composed of retractable keys, which give you more freedom in your work and improved performance.

You will find various types of wholesale magnetic rotary table in our online collection. The jawed chucks are one of the popular types, and they often have three jaws. They are ideal for gripping circular or hexagonal cross-sections. The four-jawed chucks are also available, and they are generally suitable for gripping square or octagonal material.

We also have other modern types of magnetic rotary table. For example, the collet chuck is perfect for small-sized bar stocks, and you can operate it by hand or by power. Another modern type is the magnetic chuck, which is perfect for holding ferromagnetic workpieces. Without forgetting to mention the vacuum chucks that you can use to hold non-ferrous materials such as plastic, aluminum, and stone.

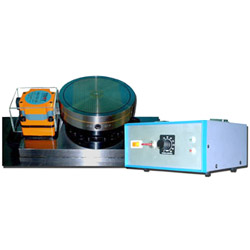

Rotary Grinding Tables and Roto Inspection systems can be designed with multiple axis, CNC systems, feedback options, and more. We commonly provide grinding solutions to numerous industries in the United States and around the world:

Roto-Grind standard precision rotary grinding tables are great for inside diameter, outside diameter and surface grinding, lapping, inspection and assembly applications. We have proudly manufactured Roto-Grind Rotary Grinding Tables in the United States since 1958. Standard models from 7" to 15" diameter.

The Heavy Duty Roto-Grind Rotary Grinding Table can be used on those difficult applications where additional rigidity and power is required. Standard models from 7" to 24" diameter.

A series of Heavy-Duty Rotary Grinding Tables specially configured for a China manufacturing plant for working silicon carbide, quartz, ceramics and other hard materials

Roto-Grind is the industry leader for precision rotary grinding applications. Roto-Grind Rotary Grinding Tables are available in three models in a wide range of sizes and configurations to provide superior results for your specific applications.

See how Roto Tech Rotary Tables can enhance your precision milling applications. View the new Roto Tech corporate video promoting our rotary grinding table products and rotary grinding services. Also visit our YouTube channel.

Total flexibility – easily moved around the workshop and suitable for a wide area of applications, inclusive of Precision seals Discs and Rings and Prototype Components

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Rotary tables have slots on the surface for jaw installation. They may also use a magnetic mechanism to clamp magnetic conductive workpieces. The table consists of a circular work surface mounted on a base. Its movement is driven by a motor. Compared to the conventional work table (stationary), the rotary table has more flexibility in positioning workpieces.

A typical machine tool usually comes with three axes, X, Y, and Z-axis. These axes refer to the directions (left-and-right, front-and-back, up-and-down) the tooling or the workpiece moves. Rotary tables can equip the tool with two extra axes, rotational, and tilting. The machine equipped with the extra axes is called the 3+1 (3+2) machine.

The rotational axis can be A, B, or C-axis (usually C on a vertical platform), depending on the orientation of the table. A-axis refers to the rotation on X-axis, B on Y-axis, and C on Z-axis. It is subject to the machine tool’s working mechanism. The tilting (swing) axis is granted by the swingarm or another rotational axis on the table base. It is also called a tilting table.

using a rotary table is hassle-free because the motions are under the control of the CNC system. That said, there are still takeaways to consider in order to preserve the best quality of its performance.

When setting up the rotary table, the alignment of the table is important. As mentioned above, the primary goal is to provide additional machining axes. The alignment of the table to the base has a major influence on the accuracy and precision of the process. You should carefully align the table and the base and test it with the program before running it.

The rotary table is dynamic in use. Its motions always pair with the cutting tool. The correct installation of jaws is vital for it exerts the clamping force on a workpiece. It ensures the stability of the workpiece and the smoothness of the process. If the jaws are not installed firmly and properly, it results in workpiece distortion under high compression. It may also lead to displacement during operation.

Almost all moving parts in a machine require proper and adequate lubrication. As the moving parts contact and collide with each other directly, the smoothness declines, and unwanted wear occurs. As a result, before and after using the machine tools that come with a rotary worktable, remember to apply lubrication on the contacting surfaces of the components.

The multi-axis machining capability reduces the production cycle time by eliminating the need for repositioning and transferring workpieces from one machine to another. In addition, performing machining processes on the same platform prevents the risk of deviation. In other words, the rotary table guarantees optimal precision and accuracy when machining a workpiece from multiple angles.

Rotary tables are widely applied for machine tools that are compatible with CNC systems, such as the machining centers. With this component, both simple and intricate procedures can be easily accomplished.

Rusach International & Innovative Rotary Table Solutions are a leading worldwide supplier of small to medium sized compact CNC rotary tables, standard and application oriented designs, high accuracy, compact rotary tables. Thru bore rotary tables, horizontal rotary tables, vertical rotary tables, combination/convertible H-V rotary tables, multi spindle rotary tables, 2-axis tilting rotary tables, direct drive rigid and flexible rotary tables. Production style rotary tables to fit any machine.

Innovative Rotary Table Solutions has a full line of accessories like tail stocks, magnetic plates, rotary supports, steady rests, rotating tail stock supports and controllers, all designed to fit your application. Contact Rusach International today with your application.

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

... rotating units of the DT series comprise of stainless steel and aluminium. They are available in many different designs. The rotary tables DT 80/100 or DT 100/140 are designed for motor-powered operation. ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

The DTS is a compact cantilevered tilting table consisting of two sets of roller gear cams and a servomotor. It ensures high rigidity by designing compact devices with a smaller stress path and employing dedicated large ...

... precise results for 5-axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables feature high acceleration and tilting ...

The table top center bearing is extremely precise: concentricity is less than .0004 inches, typically as small as .0002 inches. This gives you ultra center positioning, makes ...

The ZAS 160 is a CNC tilting rotary table that is constructed with a faceplate possessing a minimum diameter of 160 m. The axis is capable of rotating in either a vertical or horizontal ...

Boasting a 1300 mm footprint, the TO1300 suddenly makes larger scale applications possible that previously seemed out of reach− as current direct-drive tables are relatively small and limited to a diameter of 750 mm. Additionally the TO1300’s high-tech drive operates predominantly without mechanics or gearboxes.

For challenging tasks of this nature, a mechanical heavy duty table is typically the logical choice. Due to their gearing ratio, however, these tables don’t fare well in service life calculations for use at such high speeds as the needle bearings simply suffer from too much wear.

The correct alternative is a direct drive; which inspired the development of the TO1300. With a direct drive, only one bearing is under load which is virtually free of backlash. The table is low-wear and easily capable of delivering the desired dynamic performance requirements.

Unique to the TO1300 is that customers can customize it to their individual requirements. For example; they can make a modular selection between bearings, encoder and motor, and thereby alter the following table characteristics:

A specialist in automation, WEISS also offers many sizes for the TO series direct-drive rotary indexing tables; ranging from small to very large. Optimal solutions for specific application challenges can be achieved from the series wide range of options. Each TO model is also available in a version with a cleanroom certificate.

Corporate Profile: An integral part of the Weiss global network, Weiss North America (ISO-9001 Certified) leverages over 45 years of reliable world-wide expertise to comprise an integrative, customer-specific approach to its vast array of electromechanical products. Our 100% vertical range of manufacturing ranges from rotary indexing tables, handling systems, and linear assembly systems−providing flexible technology for turnkey solutions that incorporate electronics, mechanical systems, software, and comprehensive engineering support. This enables us to provide pre-installed, intelligent, and highly convenient solutions for the entire field of kinematics.

The A-688 direct drive rotary table with air bearings provides extremely high resolution and geometric performance. The angular resolution of this high precision air bearing spindle is 0.0015µrad (0.00003 arcsec), and flatness and eccentricity are specified better than 175nm and 300nm, respectively. This is made possible by high resolution, absolute measuring feedback encoders, and low-cogging frameless and slotless torque motors. The A-688 rotary table can be used in any orientation. Air bearing spindles guarantee a virtually unlimited service life with no wear, and zero required maintenance. As with all PI air bearings tables, the A-688 spindle is clean room compatible and requires no lubrication.

PI uses EtherCat based, high performance motion controllers ideally suited for closed-loop control of the rotation tables. Advanced algorithms are available to deal with changing load conditions and to suppress external disturbances.

Rotary Milling Tableoffered comes in quality metal construction finish and is made available at competitive prices. These full size milling tables come developed using high strength resin sand casting as well as feature 3-axis line rail and high speed spindle unit. Some of its features include separate hand wheel support; turntable style tool magazine; pneumatic broach system; adjustment support for shim and screw; automatic intermittent lubrication.

A rotary desk is the revolving plate at the rig"s drill ground that turns the drill string in a clockwise course. The rotary table surrounds the 4 or six-sided kelly bushing and kelly force to which the drill string is hooked up, moving the strength from the rig"s force device to the drill string and bit.

The rotary table hyperlinks the rig"s strength deliver to the drill string, it may be described as a capture. most rigs have a rotary desk due to the fact the top mover for the drill string, however, top strength structures that permit continuous rotation of the drill string have changed the rotary desk, the kelly bushing and the kelly strain in a few rigs, because of changes in trenchless construction requirements.

The rotary force table is familiar in pinnacle-pressure rigs, that is, those who have their pressure motor at the top of the rig. Drill string sections are first linked to the bottom hole assembly. As drill string sections bypass into the bore, extra sections of drill string are connected to the pinnacle strain motor and to sections inside the bore, constructing the drill string from the top. the ones sections of drill string screw collectively the usage of a clockwise movement. The rotary desk -- which turns clockwise -- is used to tighten the segments of the drill string.

Rotary Milling Tableoffered comes in quality metal construction finish and is made available at competitive prices. These full size milling tables come developed using high strength resin sand casting as well as feature 3-axis line rail and high speed spindle unit. Some of its features include separate hand wheel support; turntable style tool magazine; pneumatic broach system; adjustment support for shim and screw; automatic intermittent lubrication.

A rotary desk is the revolving plate at the rig"s drill ground that turns the drill string in a clockwise course. The rotary table surrounds the 4 or six-sided kelly bushing and kelly force to which the drill string is hooked up, moving the strength from the rig"s force device to the drill string and bit.

The rotary table hyperlinks the rig"s strength deliver to the drill string, it may be described as a capture. most rigs have a rotary desk due to the fact the top mover for the drill string, however, top strength structures that permit continuous rotation of the drill string have changed the rotary desk, the kelly bushing and the kelly strain in a few rigs, because of changes in trenchless construction requirements.

The rotary force table is familiar in pinnacle-pressure rigs, that is, those who have their pressure motor at the top of the rig. Drill string sections are first linked to the bottom hole assembly. As drill string sections bypass into the bore, extra sections of drill string are connected to the pinnacle strain motor and to sections inside the bore, constructing the drill string from the top. the ones sections of drill string screw collectively the usage of a clockwise movement. The rotary desk -- which turns clockwise -- is used to tighten the segments of the drill string.

8613371530291

8613371530291