lehmann rotary table pdf for sale

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

Our customers live in different time zones, speak a variety of languages and need information at different times of the day and night. In the Download area, pL LEHMANN offers a wealth of information at no cost – 24/7 365 days a year.

pL LEHMANN holds the copyright for all data available herein. The brand name pL LEHMANN is internationally protected by copyright. Pictures and diagrams are only intended for the use in promotional documents and technical documentation and only for OEM customers (original equipment manufacturers) of pL LEHMANN. Any other use is subject to copyright terms. In case of doubt, please don’t hesitate to contact us.

Usually, the data is updated on a weekly basis. Possible amendments are agreed with the customer in the case of running orders, provided that these orders are affected by such amendment. pL LEHMANN shall not be liable for any data used prior to placing of orders or after delivery.

pL LEHMANN has developed a rotary table program optimized for measurement technology – the MQ series. The Swiss manufacturer offers two distinctly different models, the "Q-Line" and the "M-Line". While the "Q-Line" can be retrofitted to almost any measuring device at any time and automated if required, the "M-Line" is available from the measuring machine manufacturer (OEM) as a fully integrated model.

The Q-Line is ideal for stand-alone use. It is suitable for both new and retrofit equipment of coordinate measuring machines (CMM), for example, from all established manufacturers and also of other measuring devices (for roundness, contour, surface...), which it transforms into versatile measuring stations.

As an entry-level model – suitable for simple applications on the shop floor or in measurement laboratory – pL LEHMANN offers the manual, super-flexible rotary table MA-508.m Q. It can be combined with height, contour, and surface measuring devices and is recommended for run-out test equipment and coordinate measuring machines. Users can set different ratios to fast or slow in just a few steps. A smooth-running, sensitive handwheel makes it possible to approach any position very precisely and unerringly. A fold-out digital display shows the angular position with a resolution of 0.001°.

pL Q-Line rotary tables are optionally available in a housing made of aluminum (e.g. for transmitted light systems) or of spheroidal graphite iron (e.g. for CMMs). In addition, each unit is equipped with an emergency stop switch to meet the high safety requirements.

The clamping means serves as the starting point on the Lehman CNC rotary table and can be be set up easily for your workpieces through use of a wide variety of clamping

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

In its production facility, complex parts are machined to high accuracy on a Mazak VCN 530C vertical machining centre and through the addition of a 2-axis CNC rotary table from Switzerland-based Peter Lehmann AG, the company can machine parts on five sides using five axes.

The company has enjoyed a close business relationship with Mazak since 1979 so not surprisingly Loesch"s ground floor houses six Mazak CNC machines – the latest being a 3-axis VCN 530C VMC. Following the purchase, a CNC rotary table combination from Peter Lehmann was added to the set-up to enable 5-axis machining.

However, a true 5-axis machine wasn’t an option for Michael Loesch: “Rocker-mounted rotary tables are usually pretty small – but the alternative was to spend a lot more money on a larger machining centre,” he reveals.

A 3+2-axis approach is less expensive while offering a greater flexibility: “For us the Mazak VCN extended by the Lehmann rotary/tilting table is the perfect solution,” Mr Loesch enthuses. “It even leaves enough room to accommodate two more vices on the machine table, thus providing further clamping options for simpler workpieces.”

To the Loesch team, the 1,300 x 550mm table was of particular importance as it can accommodate the Lehmann CNC rotary table and still provide enough space for two (125mm) vices.

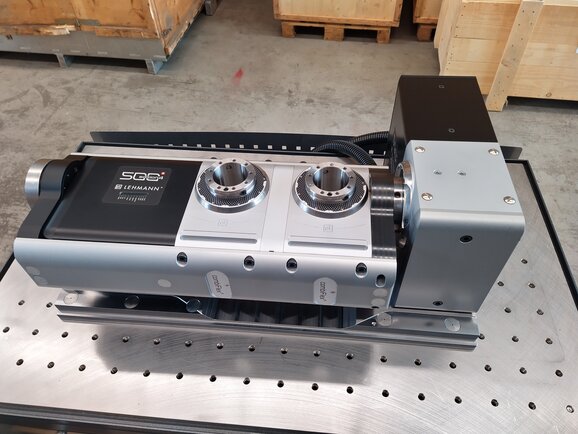

Supported by the Swiss rotary table specialist and German sales and service partner IVO Oesterle, the team selected the T1-510520.RR TOP2 2-axis model. “The Swiss quality won us over from the start,” Mr Loesch recalls. “With regard to performance and suitability for digitalisation and Industry 4.0, we simply didn’t need to consider any alternatives.”

3D CAD data of the CNC rotary table was submitted to the team beforehand, so a matching workspace concept could be established via the in-house CAD system.

The 2-axis Lehmann T1-510520.RR TOP2 rotary table is 711mm long, 301mm wide and 250mm high. It clamps workpieces of up to 340mm in diameter which is more than enough for Loesch which mainly processes small to medium-sized workpieces up to cube edge dimensions of around 150mm.

Precision is also of paramount importance to Loesch. Also, precision is a core value at LOESCH. The indexing accuracy (Pa) specified by Lehmann of ±17 arc/seconds and ±21 arc/seconds (fourth and fifth axis) as well as the average repeat accuracy (Ps) of ±2 arc/seconds respectively were verified Loesch onsite using a calibration cube. The results actually exceeded the specification.

In practice the high positioning speed of the rotary/tilting table is another significant benefit: “If possible we use one single tool, e.g. a chamfer milling cutter, to execute all operations in sequence, turning and tilting the workpiece than repeatedly changing the tool.”

“This required up-front collaboration between Lehmann and the Mazak control system developers but the result was well worth the effort. I can now program our VCN 530C with its 2-axis rotary table just like a 5-axis Mazak Variaxis which reduces programming to a fraction of the time. The productivity gains are significant – particularly for single and small-series parts. Typical batch sizes for us about between 20 and 200 pieces.”

Michael Loesch is very satisfied with his investment: “Thanks to the Mazak VCN 530C, the Lehmann rotary table and the other options we specified, we have made considerable time savings and reduced the effort required for re-clamping, thereby freeing up our machine operators to take care of other tasks,” he states.

Next on the agenda is an automated system to feed the VCN, but the Lehmann rotary table is already ahead of the game because it offers media channels to facilitate the remote control of automatic clamping systems.

“The force clamp on the rotary table is already pneumatically controlled and the two vices on the machine table will then be converted from manual to hydro-pneumatic operation,” Mr Loesch concludes. “This will allow us to fully machine all six sides without any manual intervention. This is definitely the way forward for us.”

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

8613371530291

8613371530291