mazak 4th axis rotary table supplier

The Mazak VCN-510C is an exclusive part of our Vertical Machining Centers inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

Mazak SmoothG CNC Control, 4th Axis Programmable with Mazak MR-250RAM01 Rotary Table with 250mm Faceplate and Tailstock, Renishaw Wireless RTS Tool Probe and OMP 600 Parts Probe System, Grundfos 213 PSI Through Spindle Coolant, 48 Station Expanded Tool Changer, Remote Jog Handle with LCD Screen, Synchronized Tapping, Cylindrical Interpolation, Ethernet Port, 8MB Expanded Program Storage, Tool Life Management and Breakage Detection, Jorgensen Chip Conveyor, Coolant System with Tank and Pumps, Full Top Enclosure Option, Machine Manuals. Mazak Dealer Demo sold in August 2020. Note: Vises, Tool Holders, Chick Fixture plate, Mist Collector - NOT INCLUDED WITH QUOTED PRICE.

Benefiting from TJR’s proven knowledge and experience, TJR provides diverse transmission mechanisms such as 1. Driven by Worm & Worm Gear, 2. Driven by Roller Gear Cam, 3. Driven by Direct Drive Motor to meet various needs. If you are looking for the 4th axis rotary tables cooperation partner, please feel free to check out 4 axis rotary table here and get in touch with TJR.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

CNC ROTARY TABLE CARBIDE WORM SYSTEM ■ WORM WHEEL Worldwide Field-proven, NIKKEN CNC Rotary Table NIKKEN Carbide Worm Screw System Ion Nitrided Worm Wheel HV980 NIKKEN produce all worm wheels in their CNC Rotary Tables from custom specified steel. During the production process the material is further hardened and ion-nitrided, giving unbeatable performance in service due to exceptional friction-resistance. The tooth surface and core material hardness is shown below. Depth 0.1mm HV 980 Phosphor Bronze Worm Wheel Inside HRC 36 Hardness of Worm Wheel Backlash Compensation Carbide Worm Screw ■...

VCS-430A CNC ROTARY TABLE OPTIONS CNC202MA CNC202MA Specifications • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

• Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle

VCS-530C CNC ROTARY TABLE OPTIONS CNC202MA • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole 530

CNC260LMA Specifications • Diameter of Table 0mm : 0260 • Max Work Load (kg) : 350(H) 175(V) • Rotation Speed : 16.6(min"), 33.3(min") • Indexing Accuracy (sec) : 20 • Clamping Torque (Nm) : 588 • Net Weight (kg) : 120 • Diameter of Spindle Hole : 08OH7 ■ Diameter of Table 0mm ■ Max Work Load (kg) ■ Rotation Speed ■ Indexing Accuracy (sec) ■ Clamping Torque (Nm) ■ Net Weight (kg) ■ Motor Type ■ Diameter of Spindle Hole

• Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle • Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle

CNC ROTARY TABLE OPTIONS VTC-200C-II & VTC-530C 255 ST (265 ST) • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-200C-II and VTC-530C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-200C-II and...

CNC ROTARY TABLE OPTIONS VTC-300C-II & VTC-760C 380 ST • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-300C-II and VTC-760C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-300C-II and VTC-760C are...

CNC ROTARY TABLE OPTIONS VTC-300C-II & VTC-760C 380 ST • CNC Rotary Tables for VTC-300C-II and VTC-760C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm : Ø200 • Max Work Load (kg) : 60(0 to 30°) 40(30° to 90°) • Rotation Speed : 22.2 min-1 (Rotary) : 16.6 min-1 (Tilting) • Indexing Accuracy (sec) : 20 (Rotary), 60 (Tilting) • Clamping Torque (Nm) : 588 (Rotary), 612 (Tilting) Clamping System 3.5MPa • Net Weight (kg) : 160 • Motor Type : HF-H105T-A48 (Rotary) : HF-H105T-A48 (Tilting) • Diameter of Spindle Hole :...

VTC-800/30SR ROTARY TABLE OPTIONS CNC401MA • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

VTC-800/30SR ROTARY TABLE OPTIONS 800 410 • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

CNCB450MA Specifications 1 Diameter of Table 0mm 1Max Work Load (kg) 1Rotation Speed 1 Indexing Accuracy (sec) 1Clamping Torque (Nm) 1 Net Weight (kg) 1Motor Type 1 Diameter of Spindle Hole CNCB630MA 800 CNCB630MA Specifications • Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

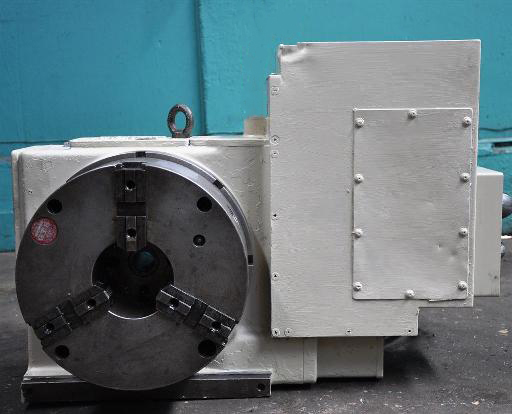

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Made in Kentucky, the VC-500A/5X Vertical Machining Center has a trunnion-style rotary/tilt table that allows for the accurate, cost-effective processing of small complex parts via full 5-axis machining. The machine also features the MAZATROL SmoothX CNC that allows for easier programming and faster part cycle times, in either EIA or MAZATROL conversational.

Axis travels for the VC-500A/5X measure 19.88" in X, 19.88" in Y and 20.07" in Z, allowing it to accommodate a part sizes up to 19.68" in diameter and 12" high. Rapid traverse speeds for these three linear axes are now 1,181 ipm.

To minimize thermal displacement, Mazak incorporates an oil chiller that cools the VC-500A/5X’s head and table. The machine’s trunnion-style rotary/tilt table is constructed with durable high-speed roller gear cam drive technology for high torsional rigidity and positioning accuracy. The table tilts +110 degrees / -110 degrees in the B axis and rotates 360 degrees in the C axis and can accommodate workpiece weights up to 440 lbs.

Mazak’s MAZATROL SmoothX CNC on the VC-500A/5X makes it easy to generate programs for highly complex parts production. It has several advanced functions that allow it to ensure the shortest possible machining cycle times, especially in fine increment programs for simultaneous 5-axis operations and free-form die-mold machining. These functions include High Gain Feed Forward Control, Fast Rotary Axis Speeds, Variable Acceleration Control and Intelligent Pocket Milling.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

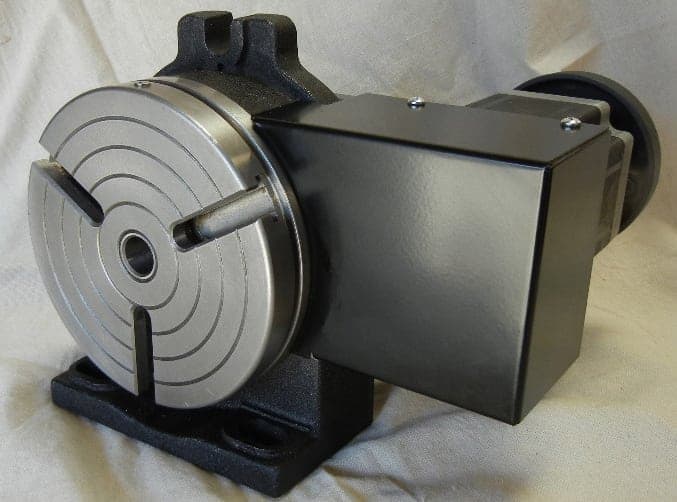

Whether your CNC control has AC or DC drives, uses Fanuc, Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build your rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we also supply the parts you need; such as amplifiers, drives, cables and connectors. If your application does not require simultaneous 4th axis cutting, we offer an easy-to-program, single-axis control box that can be M-function interfaced to your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

Direct Drive (DD) motor or torque motor, will be the trend in mechanical transmission for the future. It has the advantage of high speed, high-accuracy, no backlash, etc. For this reason, in 2008, we have been actively involved in developing the rotary table with a direct drive motor for 4-axis or 5-axis CNC machines. This research and development we could achieve with the able cooperation and support from PMC and could able to showcase the dual-axis NC rotary table at the Taipei International Machine Tool Show 2009 (TIMTOS 2009). This NC rotary table adopted a direct drive motor and encoder procured from Europe and integrated with the Heidenhain controller. By incorporating an appropriate cooling circuit it was possible to extract the max. Torque output from the DD motor torque characteristics.

Recently in the market, NC rotary tables with DD motors are incorporated with existing controllers available for the 4th-axis or 5th-axis on the machine. However, DD servomotors required high precision control system, so it becomes essential to get incorporate higher-level controllers such as HEIDENHAIN, Siemens, Fanuc 31iM, and Mitsubishi M70 for the machine which in turn will increase the overall costs. Due to this reason, SPINTOP developed a model of an external CNC controller that could be interfaced with the original controller or low-level CNC controller to meet the requirement of the DD motor as well as keep the cost reasonably low.

Due to this, the DD motor has characteristics of high speed, zero backlash and the ability to adapt to a normal encoder we can offer an NC Rotary Table of stable performance with reduced fault or error. It is easy to interface and integrate DD motor NC Rotary table within the existing machine with the help of the spare Mcode available.

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

8613371530291

8613371530291