mazak 4th axis rotary table in stock

All CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

The Mazak VCN-510C is an exclusive part of our Vertical Machining Centers inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

Mazak SmoothG CNC Control, 4th Axis Programmable with Mazak MR-250RAM01 Rotary Table with 250mm Faceplate and Tailstock, Renishaw Wireless RTS Tool Probe and OMP 600 Parts Probe System, Grundfos 213 PSI Through Spindle Coolant, 48 Station Expanded Tool Changer, Remote Jog Handle with LCD Screen, Synchronized Tapping, Cylindrical Interpolation, Ethernet Port, 8MB Expanded Program Storage, Tool Life Management and Breakage Detection, Jorgensen Chip Conveyor, Coolant System with Tank and Pumps, Full Top Enclosure Option, Machine Manuals. Mazak Dealer Demo sold in August 2020. Note: Vises, Tool Holders, Chick Fixture plate, Mist Collector - NOT INCLUDED WITH QUOTED PRICE.

This 4th axis rotary table system can be added to any of our machines, even if you already have your machine. Just send us the electronics panel and we can add the electronics for you. Includes all necessary electronics installed inside the machine with a plug on the front console. Wired, installed, and completely ready to run.

4th axis programming can be done with a 3 axis CAD program by converting the Y axis to A axis in the post processor. Just make the Y dimension of your drawing the same dimension as the cylindrical circumference of your work piece.

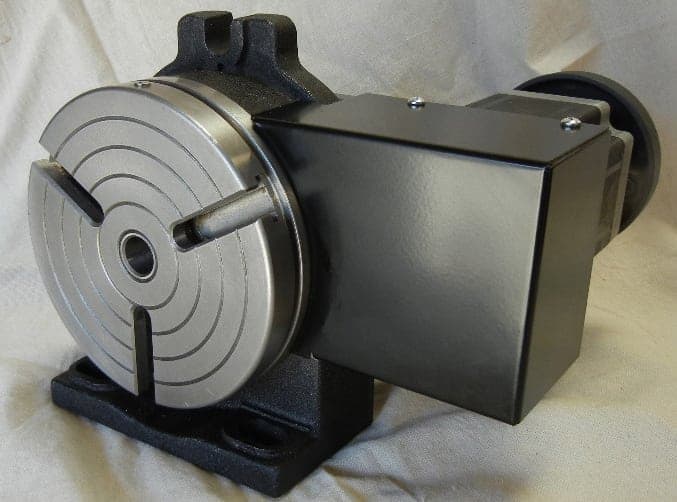

4th Axis rotary table for use with the Pulsar milling machine. Bipolar 200 step drive motor with adjustable worm gear (90:1 ratio) engagement for zero backlash. Includes tail stock.

For unmatched high-precision small parts production, the simple but innovative HC-5000 machining center delivers durability, reliability and long-term accuracy with an unbeatable price-performance ratio.

Add a 4th axis to your CNC Shark! The CNC Shark 4th axis gives you the ability to create precision-turned spindles or columns that include intricate carvings and designs that will astonish your clients. With virtually a plug-and-play design, the CNC Shark 4th axis easily bolts to your existing shark bed. The kit comes complete with a nova precision midi 4 jaw chuck and features a standard 1"x 8 TPI driveshaft to allow you to use just about any of your lathe accessories. Machined from solid aluminum stock the CNC Shark 4th axis is built to last.

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

NIKKEN’s world-renowned CNC Rotary Table range provides proven performance, reliability and accuracy benefits for any application or requirement that others simply cannot hope to emulate.

With an extensive range of rotary table sizes, configurations and options available, all fully supported by our extensive global network, you can be sure to find the perfect product to meet any requirement or machine tool.

Single Axis, Twin Axis, Multi-Spindle, Standard Drive, High-Speed Drive, and Direct Drive capabilities are all available from stock. These can be configured and supplied for control directly by the CNC Machine or by integrating our exclusive Alpha 21 and EZ controllers to provide precise positioning and also full Macro B control (Macro B function – Alpha 21 only).

NIKKEN can also provide a complete and expansive range of accessories precisely engineered and customised to suit both the machine tool and the component. These options include a wide variety of chucking solutions, vices, bespoke trunnions & workpiece fixturing along with a wide range of NIKKEN manufactured rotary work supports and tailstocks to cater for all production expectations.

8613371530291

8613371530291