mazak rotary table pricelist

CNC ROTARY TABLE CARBIDE WORM SYSTEM ■ WORM WHEEL Worldwide Field-proven, NIKKEN CNC Rotary Table NIKKEN Carbide Worm Screw System Ion Nitrided Worm Wheel HV980 NIKKEN produce all worm wheels in their CNC Rotary Tables from custom specified steel. During the production process the material is further hardened and ion-nitrided, giving unbeatable performance in service due to exceptional friction-resistance. The tooth surface and core material hardness is shown below. Depth 0.1mm HV 980 Phosphor Bronze Worm Wheel Inside HRC 36 Hardness of Worm Wheel Backlash Compensation Carbide Worm Screw ■...

VCS-430A CNC ROTARY TABLE OPTIONS CNC202MA CNC202MA Specifications • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

• Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle

VCS-530C CNC ROTARY TABLE OPTIONS CNC202MA • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole 530

CNC260LMA Specifications • Diameter of Table 0mm : 0260 • Max Work Load (kg) : 350(H) 175(V) • Rotation Speed : 16.6(min"), 33.3(min") • Indexing Accuracy (sec) : 20 • Clamping Torque (Nm) : 588 • Net Weight (kg) : 120 • Diameter of Spindle Hole : 08OH7 ■ Diameter of Table 0mm ■ Max Work Load (kg) ■ Rotation Speed ■ Indexing Accuracy (sec) ■ Clamping Torque (Nm) ■ Net Weight (kg) ■ Motor Type ■ Diameter of Spindle Hole

• Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle • Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Tilting Travel Angle

CNC ROTARY TABLE OPTIONS VTC-200C-II & VTC-530C 255 ST (265 ST) • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-200C-II and VTC-530C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-200C-II and...

CNC ROTARY TABLE OPTIONS VTC-300C-II & VTC-760C 380 ST • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-300C-II and VTC-760C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • CNC Rotary Tables for VTC-300C-II and VTC-760C are...

CNC ROTARY TABLE OPTIONS VTC-300C-II & VTC-760C 380 ST • CNC Rotary Tables for VTC-300C-II and VTC-760C are dimensionally identical but not interchangeable due to differences in electrical specification. • Diameter of Table Ømm : Ø200 • Max Work Load (kg) : 60(0 to 30°) 40(30° to 90°) • Rotation Speed : 22.2 min-1 (Rotary) : 16.6 min-1 (Tilting) • Indexing Accuracy (sec) : 20 (Rotary), 60 (Tilting) • Clamping Torque (Nm) : 588 (Rotary), 612 (Tilting) Clamping System 3.5MPa • Net Weight (kg) : 160 • Motor Type : HF-H105T-A48 (Rotary) : HF-H105T-A48 (Tilting) • Diameter of Spindle Hole :...

VTC-800/30SR ROTARY TABLE OPTIONS CNC401MA • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

VTC-800/30SR ROTARY TABLE OPTIONS 800 410 • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole • Diameter of Table Ømm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

CNCB450MA Specifications 1 Diameter of Table 0mm 1Max Work Load (kg) 1Rotation Speed 1 Indexing Accuracy (sec) 1Clamping Torque (Nm) 1 Net Weight (kg) 1Motor Type 1 Diameter of Spindle Hole CNCB630MA 800 CNCB630MA Specifications • Diameter of Table 0mm • Max Work Load (kg) • Rotation Speed • Indexing Accuracy (sec) • Clamping Torque (Nm) • Net Weight (kg) • Motor Type • Diameter of Spindle Hole

Mazak Corporation is an international manufacturer of machining centers with a diverse product line including multi-tasking, 5-axis, turning, vertical machining center and horizontal machining centers as well as an exclusive parts-moving cell system called Palletech, and automation software. Mazak offers multiple software solutions and boasts the ability to connect and secure their CNC of all ages. This makes it possible for you to buy a used Mazak CNC machine and still take advantage of newer, smooth programming, software solutions. For example, the Mazak ismart and Mazak SmartBox, developed in 2015 together with Cisco, provides security, analytics and machine monitoring which is backward compatible with older Mazak machines.

Mazak also provides a number of automation accessories to CNC machining such as bar feeders, gantry loaders and articulating robots. Newer CNC are available with digital solutions including MTConnect, which is a key component of Mazaks iSMART Factory concept since 2015.

The primary operating system for Mazak CNC is called Mazatrol, which was first introduced in 1981 and has since been developed into an advanced connected digital platform. In 2014 Mazak introduced the CNC Mazatrol SmoothX controller. That same year they released the Mazatrol SmoothG and Mazatrol SmoothC CNC systems. Any used Mazak for sale online should provide you with information on the control and connectivity options. You may want to find out from Mazak what upgrade options are available for a particular machine before you buy.

Mazak is leading manufacturer of CNC machines worldwide, and as such, they have hundreds of models under a wide range of series names that have changed throughout the years.

Mazak Quick Turn Nexus CNC Lathe QTN 100, QTN 100MS, QTN 100MSY, QTN 150, QTN 150M, QTN 150MS, QTN 150MSY, QTN 200M, QTN 200MS, QTN 200MSY, QTN 250, QTN 250M, QTN 250MS, QTN 250MSY, QTN 350M, QTN 350MS, QTN 350MSY, QTN 400, QTN 400M, QTN 400MS, QTN 400MSY, QTN 450, QTN 450M, QTN 450MS

Mazak Quick Turn Smart CNC Lathe Mazak QTU-200, QTU-200M, QTU-200MSY, QTU-250, QTU-250M, QTU-250MS, QTU-250MSY, QTU-350, QTU-350M, QTU-250MS, QTU-250MSY, QTU-350, QTU-350M, QTU-350MS, QTU-350MSY

Mazak Mega Turn VTL Mega Turn 400, Mega Turn 500, Mega Turn 500M, Mega Turn 600, Mega Turn 600M, Mega Turn 900, Mega Turn 900M, Mega Turn 1600, Mega Turn 1600M

Mazak currently offers the following over 40 different machines under the Mazak INTEGREX model name including multiple CNC machines in each of these categories 2018, e-H, e-Ramtec, e-V, I, i AM, i-V and i. Many used Mazak machines available today are from the earlier Integrex e-Series.

Mazak Integrex i Integrex i-100, Integrex i-100ST, Integrex i-150, Integrex i-200, Integrex J-200, Integrex i-200ST, Integrex i-300, Integrex i-300ST, Integrex i-400, Integrex i-400ST, Integrex i-500, Integrex i-500, Integrex i-500V/5, Integrex i-630V/6, Integrex i-800V/8 Mazak Integrex e Integrex e-420H, Integrex e-420HS, Integrex e-500H, Integrex e-500HS, Integrex e-650HS, Integrex e-670HS, Integrex e-800H, Integrex e-1060V, Integrex e-1250V/8, Integrex e-1600V/10, Integrex e-1850v/12, Integrex e-Ramtec V/8, Integrex e-Ramtec V/10, Integrex e-Ramtec V/12,

There are many reasons that machine shop owners and manufacturers across the country rely on Mazak for all their machining needs. Mazak has been building machines and innovating for over 100 years and has a reputation for designing and supplying high-quality, innovative and customer-friendly machines. No matter what your machining needs, theres a good chance that theres a used Mazak that will be a good fit for your application.You can see a breakdown of more of thier machines by see our used Mazak mill and used Mazak lathe Inventory.

CNC Indexing has both pneumatic and hydraulic tables in stock for immediate delivery! Looking for a TJR rotary table price? We have a range of cost-effective options to suit your needs!

For TJR’s pneumatic series of rotary tables, prices start at $5,685. The AR Series is offered in both right hand and left hand motor mount options, with face plate diameter ranges of 125mm – 255mm.

Both the pneumatic and hydraulic brake series TJR rotary table price includes standard features such as an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. For new TJR tables, a standard 3-year parts warranty is included.

CNC Indexing & Feeding Technologies is proud to carry TJR Precision Technology rotary tables. All of TJR’s rotary tables incorporate a range of features that give them an edge over competitors, and the dual lead worm gear is at the top of the list. How Does A Dual Lead Worm Gear Work? With the dual […]

CNC Indexing & Feeding Technologies is proud to offer the best the industry has to offer in our complete line of Ganro Industrial Corp. rotary tables. While parts of a rotary table may seem the same no matter what brand you choose, the true test of quality lies in the equipment design. Ganro has been developing […]

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Our best seller, the VH-8 has a 8.25" (210mm) diameter spindle with a 2.0" through hole. With 225 ft. lbs. of brake torque, the VH-8 maintains a rigid design with dual tapered roller bearings supporting the front and back of the spindle. The centerline is 6.75". The worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There is an optional 8" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

One thing that is sorta misleading about the CNC tables unless you"re seen one first hand is just how big they are. I"ve got a Tsudakoma THNC-301, which is a 320mm (12"+) table thats rotary powered and manually tiltable from horizontal to a bit past vertical. It weighs somewhere between 400 and 450 lbs, and I guess the new cost now is somewhere north of $16,000. They have positioning accuracy within a few arc seconds, and are capable of holding accuracies like this with a part that weighs a couple hundred pounds and cutting forces that can generate several hundred ft-lbs of torque.

Pricewise, assuming my 16K current estimate is accurate, that would work out to a bit less than $40/lb, because it definitely weighs over 400#. For comparison, a 10" Kitagawa power chuck for a lathe retails now for about $4000, and although I"ve never weighed one, I guess they weigh less than a hundred lbs from picking one up a "few" times. So that puts the chuck at over $40/lb. If you ever have cause to take one of these chucks apart, they are surprisingly simple. They"re accurate and repeatable, and everything is hardened and ground, but they"re still simple, especially when compared to a rotary table. A good sized collet chuck from Royal to fit an A-8 spindle nose on a lathe weighs barely over 40 lbs and costs close to $2500. Once again, its all hardened and ground, but this is the price of a pullback type chuck which is just one single piece of steel with no moving parts whatsoever, yet it sells for over $60/lb. When you compare the rotary tables and their size and complexity to other machine tool parts of similar complexity and quality, the price begins to look not so far out of line, even though its still not cheap by a long shot.

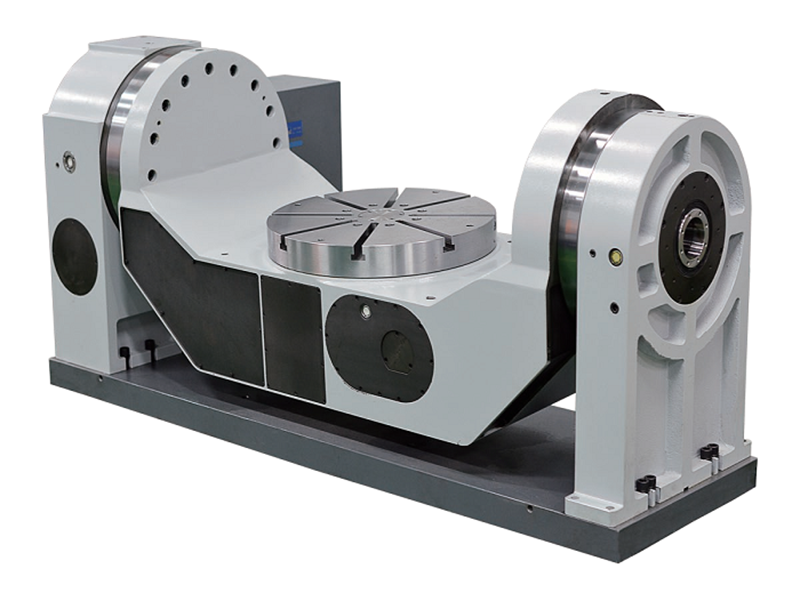

The tilting/rotary table is rigidly supported on both ends by the trunnion unit. High-speed, high-accuracy machining is ensured thanks to dual roller gear cam on the A-axis and the direct drive motor on the C-axis

pL LEHMANN has been developing and producing CNC rotary tables for over 40 years. – genuine SWISS QUALITY. The experience gained is incorporated into our products and services. With innovative CNC rotary axes, organized in a standard modular system, we want to meet the international needs for economical production of very small to medium-sized workpieces in the machining industry by satisfying individual requirements with appropriate combinations.

The 12/48 Stallion Trunnion Table allows for even larger parts than the 9/35 or 10/30. At this size, we recommend adding our hydraulic clamping outboard braking system to decrease the possibility of tool forces moving the rotary table by overpowering the rotary table brake system. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Trunnion Table minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary.

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

8613371530291

8613371530291