mazak rotary table quotation

For unmatched high-precision small parts production, the simple but innovative HC-5000 machining center delivers durability, reliability and long-term accuracy with an unbeatable price-performance ratio.

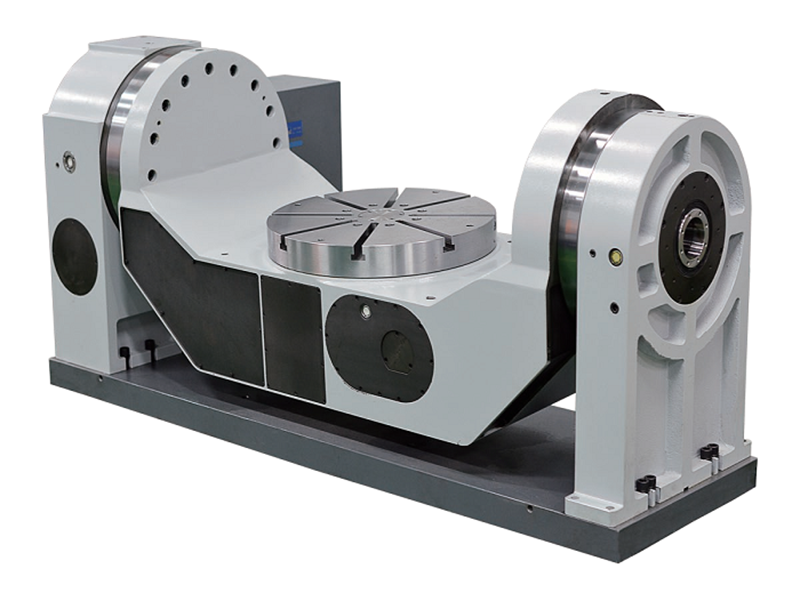

A rigid tilting/rotary table enables the machine to perform turning operations at maximum speeds of 500 rpm. A trunnion unit supports the table on both ends, a design that does not interfere with the milling operations. Roller gear cams on the swiveling A-axis and a direct-drive motor powering the rotary C-axis ensure high-speed, high-accuracy machining performance.

It is one of the few machines with a trunnion-style tilting table to feature a 50-taper spindle and Multi-Tasking operations. As such, users can reduce the inaccuracies that occur when moving parts across multiple workstations, eliminate work-in-process inventory and boost overall throughput.

The HCR-5000S 5-axis, single-table (S) Horizontal Machining Center performs efficient, high-speed machining of small- and mid-sized aluminum components such as those commonly found in the aerospace and semi-conductor/high-tech industries.

For extremely accurate performance, the machine features a solid base X-axis construction, high-rigidity bed and a tilt/rotary table where both the A and C axes use a roller gear cam system for positioning to increments of 0.0001-degrees. The HCR-5000S efficiently evacuates large amounts of machined chips to ensure excellent surface finishes and prevent downtime.

The machine is equipped with high-output integral spindle motor with two gear ranges for a wide scope of heavy-duty machining. A drop-worm system that performs with the same positioning accuracy as a machining center rotary table drives the machine"s C-axis (0.0001-degree increments).

The Kentucky-built VC-Ez 16X Vertical Machining Center has a trunnion-style rotary/tilt table that allows for accurate and cost-effective processing of small complex parts via 3+2 or full 5-axis machining. With two spindle and auto tool changer options available, plus a wide array of chip/coolant management options, the highly configurable machine meets many production demands. Enhanced operator ergonomics, along with a generous work area, improves the loading and unloading of workpieces and tools, while an extremely fast traverse rate of 1,654 ipm in the X, Y and Z axes enables higher throughput.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Pre-owned MAZAK V515 1998 Vertical Machining Center. This Vertical Machining Center has average cutting time and is equipped with a Mazatrol M-Plus control. This CNC Machine is currently located in Kansas. This MAZAK Vertical Machining Center is available for a limited time. Get a quote today on this

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

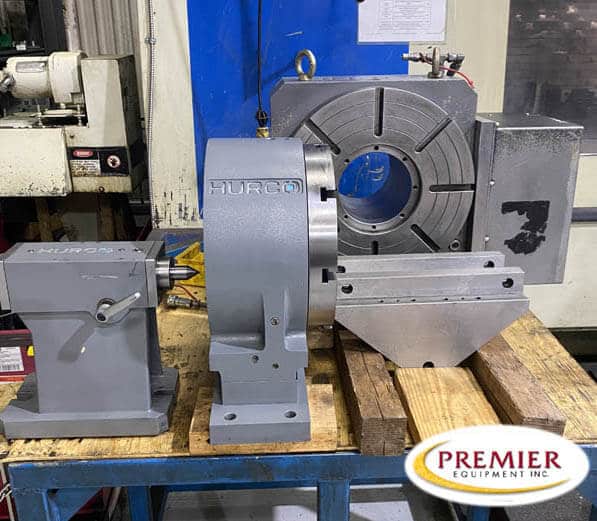

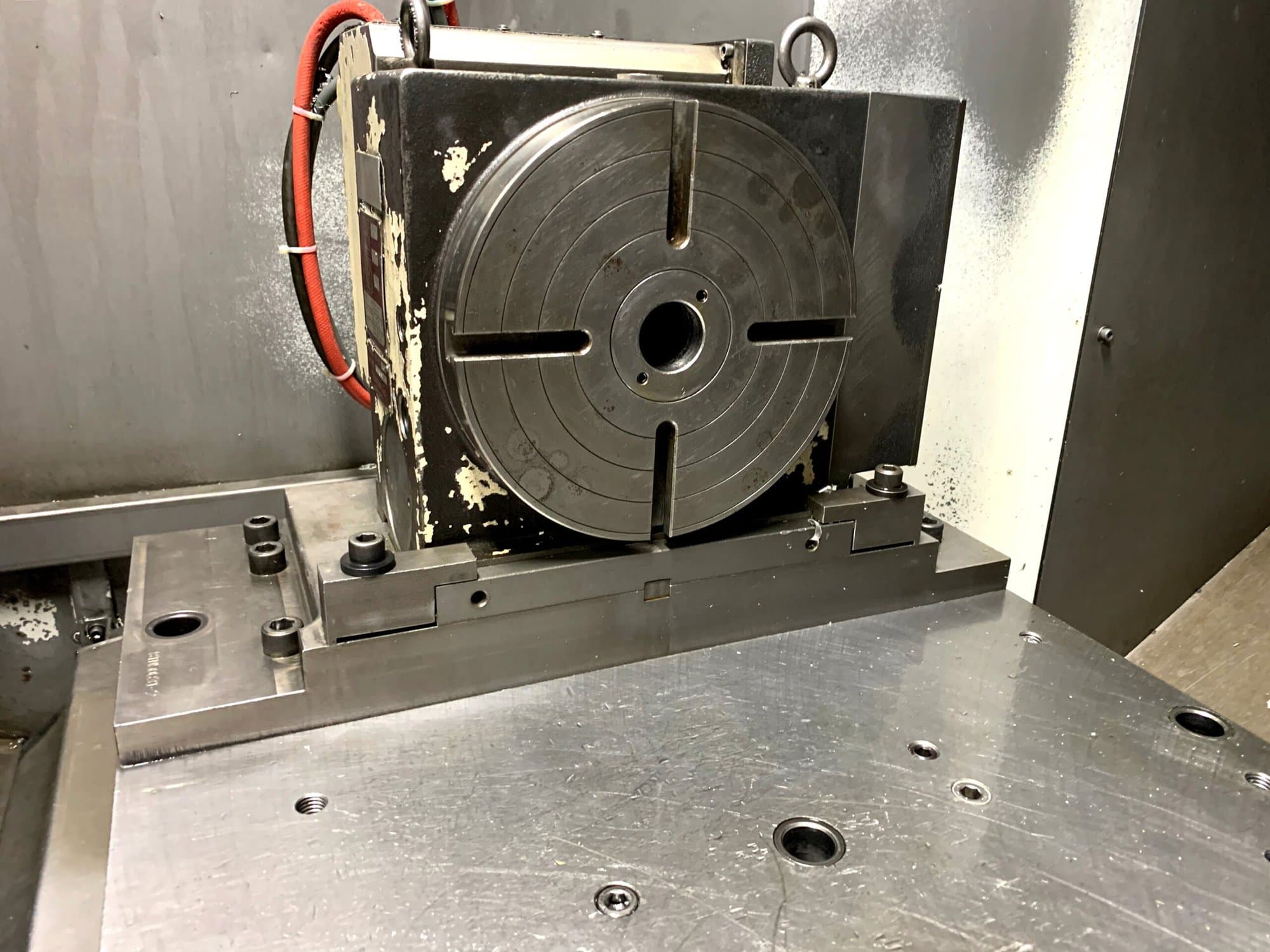

Mazak SmoothG CNC Control, 4th Axis Programmable with Mazak MR-250RAM01 Rotary Table with 250mm Faceplate and Tailstock, Renishaw Wireless RTS Tool Probe and OMP 600 Parts Probe System, Grundfos 213 PSI Through Spindle Coolant, 48 Station Expanded Tool Changer, Remote Jog Handle with LCD Screen, Synchronized Tapping, Cylindrical Interpolation, Ethernet Port, 8MB Expanded Program Storage, Tool Life Management and Breakage Detection, Jorgensen Chip Conveyor, Coolant System with Tank and Pumps, Full Top Enclosure Option, Machine Manuals. Mazak Dealer Demo sold in August 2020. Note: Vises, Tool Holders, Chick Fixture plate, Mist Collector - NOT INCLUDED WITH QUOTED PRICE.

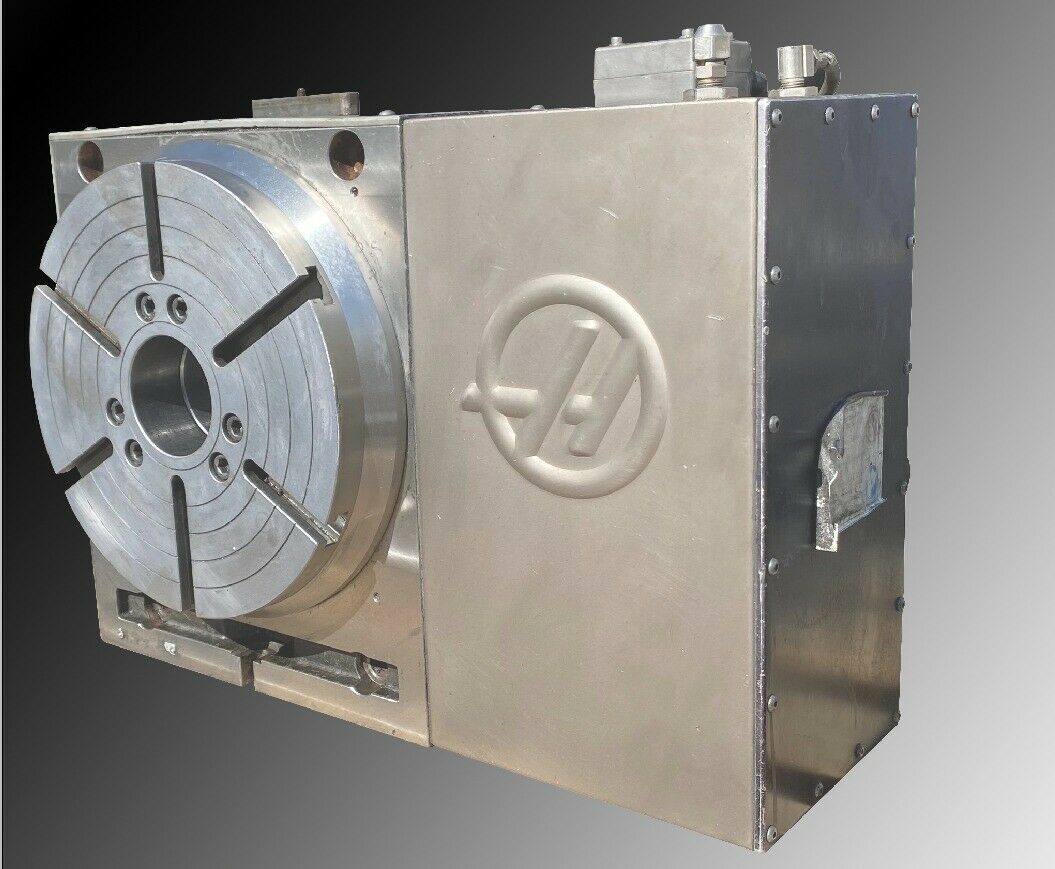

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

KME CNC Rigid Cast Iron Trunnion Tables are one of the leaders in the industry for accuracy, surface finishes and repeatability. Allowing you to speed up your cycle times, these tables are ideal for high volume production applications. Powerful and compact trunnion design ensures smooth operation over the entire travel range.

8613371530291

8613371530291