motor driven rotary table supplier

... applications, the BG series of goniometers allows open access to the load. When two BG stage are stacked together, the sample rotates about a common pivot point. These DC motor goniometers ...

... frame design. The "A" frame type turntable has a hollow spindle and uses pre-loaded tapered roller bearings. The bearing housing and main support "A" frame house the motor and gear reducer below the table, ...

This rotational table, manufactured by JAT Gmbh, comes with a 320 x 320 mm clearance and an option for X, Y or Z handling systems. It has been engineered to be ready for connection and has been equipped ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... plate bearing’s layout scheme characterizes the performance data of the rotary table. The structural construction enables a simple and easy-to-maintain system. The Rotary Drive ...

The DTS is a compact cantilevered tilting table consisting of two sets of roller gear cams and a servomotor. It ensures high rigidity by designing compact devices with a smaller stress path and employing dedicated large ...

... axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables feature high acceleration and tilting speeds for maximum ...

The new CNC Rotary Table from UCAM has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine ...

The rotating table mod. TR1200 is placed at the end of the packaging line and its function is to collect the rice cakes packs to be picked up manually by the operator for further finishing (manual twist band application ...

... Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete optimisation of the drive train, the ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

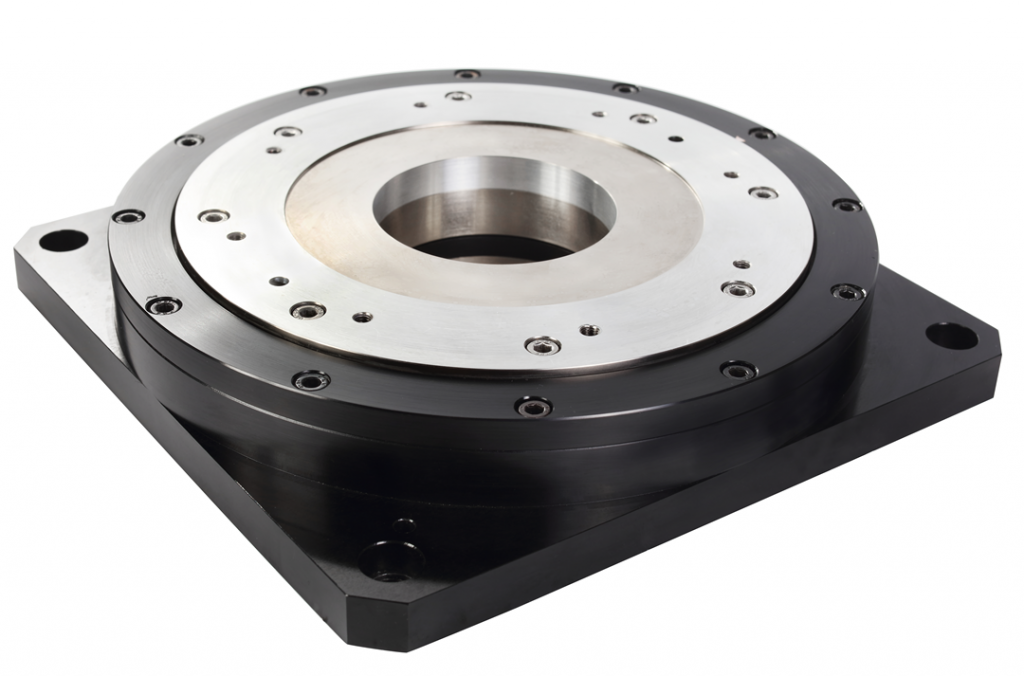

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

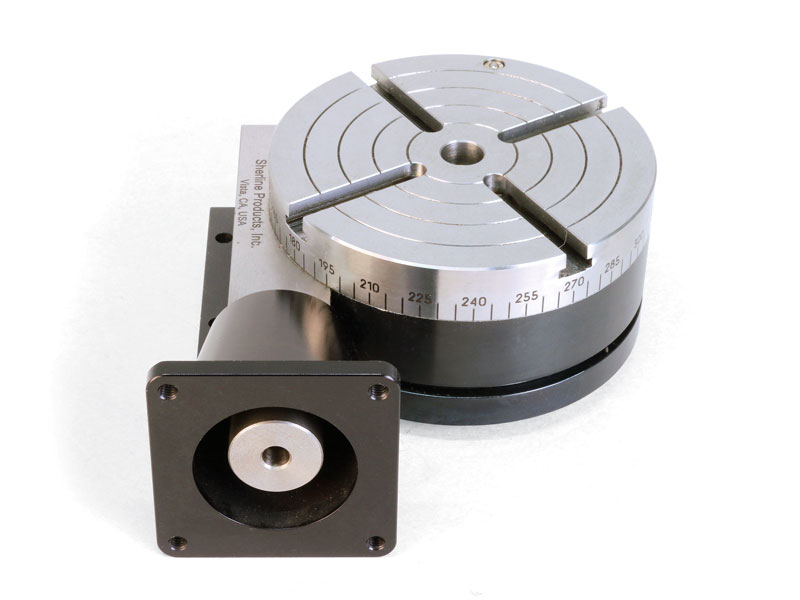

Sherline has taken its manual 4″ rotary table with reverse mount and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

The reverse rotary table is perfect for using on the tilting angle table. The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

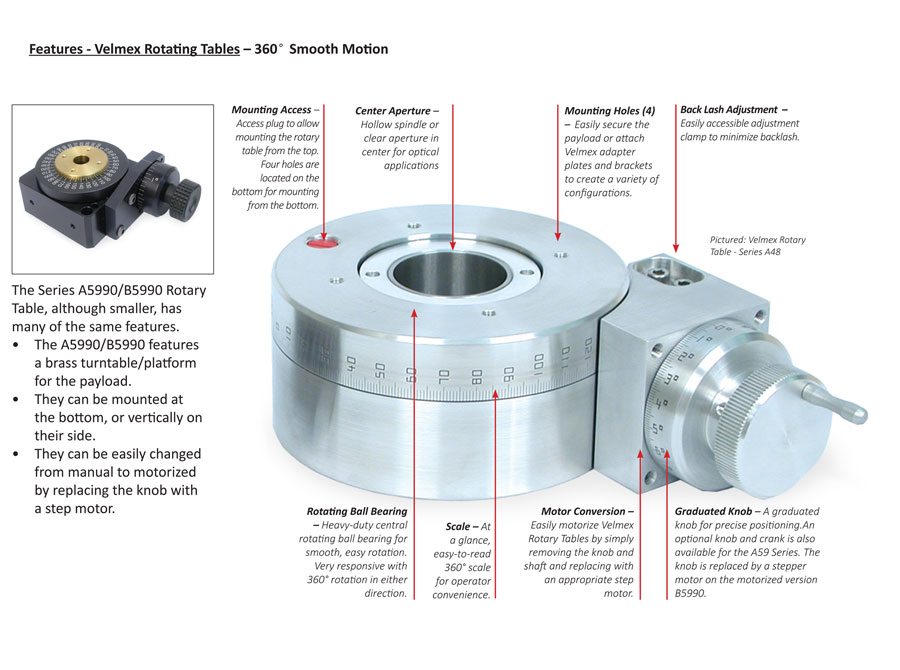

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

... models is available to make the whole range of HMCs complete. The rotary tables dedicated to the Spark line match the 5000 kg max load with excellent dynamics whereas the hydrostatic tables ...

The tilting tables are designed and produced for 5-axis operations on complex work-pieces requiring accessibility to the most unreachable surfaces thus ensuring fast swarf removal at the same time.

Direct Drive (DD) motor or torque motor, will be the trend in mechanical transmission for the future. It has the advantage of high speed, high-accuracy, no backlash, etc. For this reason, in 2008, we have been actively involved in developing the rotary table with a direct drive motor for 4-axis or 5-axis CNC machines. This research and development we could achieve with the able cooperation and support from PMC and could able to showcase the dual-axis NC rotary table at the Taipei International Machine Tool Show 2009 (TIMTOS 2009). This NC rotary table adopted a direct drive motor and encoder procured from Europe and integrated with the Heidenhain controller. By incorporating an appropriate cooling circuit it was possible to extract the max. Torque output from the DD motor torque characteristics.

Recently in the market, NC rotary tables with DD motors are incorporated with existing controllers available for the 4th-axis or 5th-axis on the machine. However, DD servomotors required high precision control system, so it becomes essential to get incorporate higher-level controllers such as HEIDENHAIN, Siemens, Fanuc 31iM, and Mitsubishi M70 for the machine which in turn will increase the overall costs. Due to this reason, SPINTOP developed a model of an external CNC controller that could be interfaced with the original controller or low-level CNC controller to meet the requirement of the DD motor as well as keep the cost reasonably low.

This type of controller can control the DD motor to rotate at any angle with mi. increment of 0.001° with the help of a midrange encoder. According to the requirement of accuracy from a customer such as ±5 sec, ±15 sec and ±30 sec we choose to use multi-angle or multi-surface processing.

Due to this, the DD motor has characteristics of high speed, zero backlash and the ability to adapt to a normal encoder we can offer an NC Rotary Table of stable performance with reduced fault or error. It is easy to interface and integrate DD motor NC Rotary table within the existing machine with the help of the spare Mcode available.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer.

can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

Sherline�s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table.

The 200RT Series Rotary Tables are designed for precise motor-driven rotary positioning and indexing. These tables are designed to function independently or in conjunction with linear tables used for precision automation applications. Their low profile design minimizes stack height in multi-axis configurations and enables them to fit in many places where other motorized rotary devices cannot. Models are available in 5, 6, 8, 10, or 12 inch diameters and are offered with four gear ratios making it convenient to match size, speed, and load requirements. They can be selected in either English or metric mounting. They are found in virtually all industries where intermittent part indexing, part scanning, skew adjustment, or precise angular alignment is required. At the heart of these tables is a rugged main support bearing which is comprised of two preloaded angular contact bearing races. It is designed for high load capacity and smooth, flat rotary motion. The drive is a precision worm gear assembly which is preloaded to remove backlash. The top and base are constructed of high quality aluminum with an attractive black anodized finish. The top and bottom mounting surfaces are precision ground to assure flatness.

There is no mechanical reduction mechanism such as a worm system in a rotary table with a DD motor. DD (Direct Drive) motor is built in the rotary table to drive directly. The compact two-axis direct drive rotary table enables rapid acceleration/deceleration and high-speed rotation. Its biggest advantage is the super high speed up to 2000 rpm. Thus, it can work as a mill/turn component. As a result of the lack of a mechanical reduction mechanism, the driving torque of the rotary table is not strong. It is necessary to choose an application for the rotary table with a DD motor.

A high torque motor drives the direct drive rotary table directly. There is no backlash or abrasion generated during rotation because it is not driven by worms and gears. Typically, these rotary tables are used in applications requiring high accelerations and decelerations, such as blade machining. For high-speed drilling centers with very important indexing times, a two-axis direct drive rotary table is an excellent choice.

Benefiting from TJR’s proven knowledge and experience, TJR provides diverse transmission mechanisms such as 1. Driven by Worm & Worm Gear, 2. Driven by Roller Gear Cam, 3. Driven by Direct Drive Motor to meet various needs. If you are looking for the 4th axis rotary tables cooperation partner, please feel free to check out 4 axis rotary table here and get in touch with TJR.

Ensure that your servo drive can handle the Nominal- and Peakcurrent of the Motor. An adjustment of the Speed and DC Bus Voltage can be done after consultation. The nominal data in this datasheet are based on an ambient/coolant temperature of 20°C.

Because the exact duty type depends also on the thermal connection of the motor, the embedded thermal monitoring system has to be analysed and attented. However, attention has to be payed that the temperature sensors do not show the exact temperature of the winding and this could be up to 20 K higher due to thermal capacities. Despite an electrical insulation towards the winding, you are only allowed to connect the sensors to your controller by using a galvanic separation in between.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Motorized Rotary Table,motor driven rotary table is driven by motor to realize the automation of angle adjustment. Finish machining worm gear or gear transmission, angle adjustment without limit. Precision shafting design ensures high precision and large bearing capacity; The stepper motor and transmission parts are connected through imported high-quality elastic coupling to eliminate space and machining form and position errors. The scale of the outer ring of the rotating table is intuitive; Standard interface to facilitate signal transmission; Manual handwheel configuration, electric and manual. Optional servo motor or stepping motor.

Right angle type: the motor shaft is perpendicular to the central axis of the rotary table, which is a side shaft rotary platform.It is equipped with a closed-loop control platform to realize the real-time operation of the hollow stepping motor with a closed-loop feedback system.

Open loop stepping type: the combination of hollow rotating platform and special stepping motor with open-loop control system, which retains the practicability of stepping motor and improves the positioning accuracy of hollow rotating platform.

CNC indexing device, manipulator joint, the fourth machining axis of machine tool, military radar, automatic production line, laser marking, rotary chuck in engraving machine, rotary axis in precision alignment mechanism

8613371530291

8613371530291