motor driven rotary table factory

... applications, the BG series of goniometers allows open access to the load. When two BG stage are stacked together, the sample rotates about a common pivot point. These DC motor goniometers ...

... frame design. The "A" frame type turntable has a hollow spindle and uses pre-loaded tapered roller bearings. The bearing housing and main support "A" frame house the motor and gear reducer below the table, ...

This rotational table, manufactured by JAT Gmbh, comes with a 320 x 320 mm clearance and an option for X, Y or Z handling systems. It has been engineered to be ready for connection and has been equipped ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... plate bearing’s layout scheme characterizes the performance data of the rotary table. The structural construction enables a simple and easy-to-maintain system. The Rotary Drive ...

The DTS is a compact cantilevered tilting table consisting of two sets of roller gear cams and a servomotor. It ensures high rigidity by designing compact devices with a smaller stress path and employing dedicated large ...

... axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables feature high acceleration and tilting speeds for maximum ...

The new CNC Rotary Table from UCAM has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine ...

The rotating table mod. TR1200 is placed at the end of the packaging line and its function is to collect the rice cakes packs to be picked up manually by the operator for further finishing (manual twist band application ...

... Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete optimisation of the drive train, the ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... a heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HT Ring Table Series are designed to propose new solutions for fixed or flexible positioning of heavy loads, thanks to the high performance of the cross-roller bearing.

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ...

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product ...

Direct drive: Electronically commutated 3-phase-synchronous motor with permanent magnetically excited rotor. The motor develops a high torque up to revolutions zero. ...

... with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute ...

The rotary indexer RT is often used in the assembly technology, the testing technology, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

Numerous advantages are offered by indexing tables. No matter whatever is the transfer velocity or the load is, the motion is very smooth and progressive. Robust and accurate MCPI cam shaft movement design ...

This turnkey, four-station rotary indexing assembly station from ISUMATIC is meant for driving multiple fasteners simultaneously. They have horizontal and vertical heads, X-Y robots, rotary ...

The TS Series is manufactured by SOPAP Automation. It is a rotary indexing table, that is constructed mainly for plates of a large diameter. Features of the TS includes continuous or ...

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or water; SAT rotary ...

... distributed on the turntable (or total weight)(*) – the maximum total load refers to the forces on the turntable. This does not mean that the indexing table will be able to rotate this ...

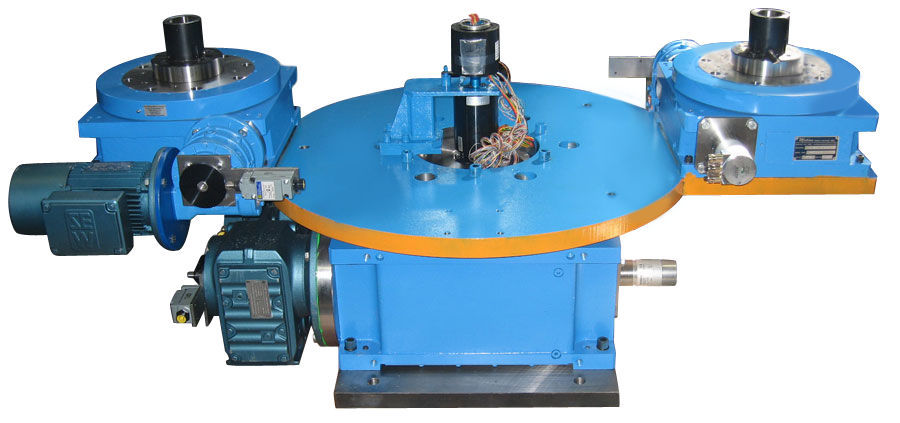

Motion’s Multi-dex Indexer solution provides one large base rotary index table with smaller satellite indexers. This allows the tooling or part to be rotated on one end of the work cell ...

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

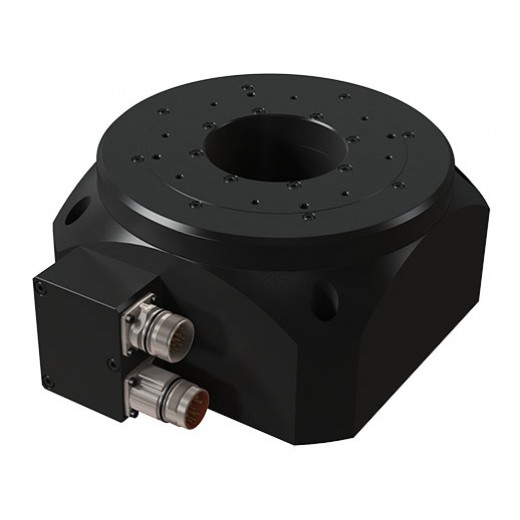

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

HIWIN Corp. will feature families of precision motion control components this year at IMTS, with their torque motor rotary tables as a highlight of their booth.

The TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates gear reducers, resulting in dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The series is compatible with most major CNC brands and uses HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer.

can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

Sherline�s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table.

The 200RT Series Rotary Tables are designed for precise motor-driven rotary positioning and indexing. These tables are designed to function independently or in conjunction with linear tables used for precision automation applications. Their low profile design minimizes stack height in multi-axis configurations and enables them to fit in many places where other motorized rotary devices cannot. Models are available in 5, 6, 8, 10, or 12 inch diameters and are offered with four gear ratios making it convenient to match size, speed, and load requirements. They can be selected in either English or metric mounting. They are found in virtually all industries where intermittent part indexing, part scanning, skew adjustment, or precise angular alignment is required. At the heart of these tables is a rugged main support bearing which is comprised of two preloaded angular contact bearing races. It is designed for high load capacity and smooth, flat rotary motion. The drive is a precision worm gear assembly which is preloaded to remove backlash. The top and base are constructed of high quality aluminum with an attractive black anodized finish. The top and bottom mounting surfaces are precision ground to assure flatness.

Programmable Rotary Tables have a multitude of applications in a wide variety of industries. They are used to position components that need to be rotated in specific, very accurate degrees of rotation so that manufacturing operations can be performed. Programmable rotary tables can be used to position parts for welding, machining, assembly, inspection or any number of operations requiring components to be presented at precise angles.

Traditional rotary index tables are positioned using mechanical components called ‘cams indexers’ in order to repeatedly rotate the table into a precise position. The cam indexers provide precise positioning to position a load using a mathematical motion curve that is machined into the cam. The mechanics provide a smooth and highly repeatable motion.

These tables are ideal for consistently delivering components to a fixed and repeatable angular position. They work well for applications that require high precision positioning at a lower cost. A traditional rotary index table may have very limited control functionality, perhaps using a sensor to determine where the indexer is along its rotational cycle. The sensor might be used to stop and start the cam motion in order to increase or decrease the ‘dwell’ period that occurs between rotary motions. This is a relatively inexpensive form of ‘programming’ a rotary index table.

An alternative to the traditional rotary index table is a programmable rotary table. A fully programmable rotary table uses a servo motor as the drive motor. A servo drive motor and programmable control system offer up nearly infinite indexing possibilities.

A simple application for a programmable rotary table is when an operation may require different or extended dwell times. A programmable rotary table enables a feedback system that allows the table to progress when an operation is satisfactorily completed.

A more advanced application for programmable rotary tables is when multiple products are run across the same production line. Having the ability to program the rotary motion of the table enables any number of product profiles to be run on the same machine, saving significant capital costs vs having to purchase multiple rotary index tables.

It’s important when selecting a rotary table to work with a company that has extensive applications engineering expertise. Matching the cam type, the drive and control system and the mechanics of the table to ensure that the system will perform with the moment of inertia of the component being handled, the cycle times and long-term durability of the table is vital.

Automated Expert rotary tables & index drives help expedite line production with products for more constant motor rotation in fabrication or assembly processes. EXPERT® (formerly EXPERT-TÜNKERS) is recognised as a world leader in production efficiency with highly dynamic drives for rotating, lifting and traversing operations.

A long trusted Romheld Automation provider of line production essentials, EXPERT is an excellent supply partner for index drives, rotary tables, trunnion drives, conveyors, lifting axes, shuttle systems and complete transport solutions. If you’re looking for Expert-Tunkers products, we can get them.

As a rule, the rotary tables are driven by a factory installed shaft-mounted gear motor. The indexing time is defined by the gear ratio. The rotary table can be delivered without drive and directly integrated into machinery drive chains.

EXPERT globoidal rotary tablesare used for packaging machines, assembling machines, textile machinery, automated handling systems, conveying systems, welding machines, machinery for glass-making and fabrication processes in which extremely short cycle times are required due to high output.

Oriental Motor offers Network products under the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuringI/O, RS-485 / Modbus (RTU) or Factory Automation. Networked products enable operating data and parameters for each motor to be set at a Master Controller and sent to each driver. In addition, operation commands can be input send set using various communication methods to meet the need of a wide range of available Network Solutions.

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor"s own RS-485 communication protocol. Connection to FLEX-compatible products is completed with one RS-485 communication cable.

They are characterized by a whole new machine concept and design approach, allowing flexible use. All components are freely programmable and represent sound solutions for re-engineering. It could be added planetary gearbox to increase the gear ratio, available for matching with any brand servo motor and stepper motor based on our flexible flange system, thus make it easy for automation production line building and robot designing.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

8613371530291

8613371530291