torque motor rotary table factory

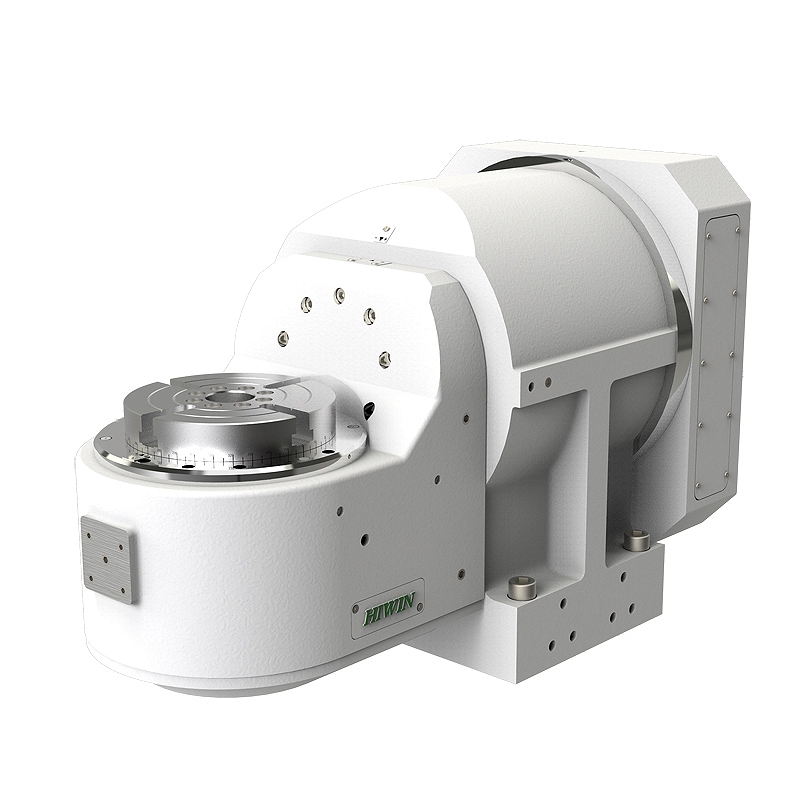

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

HIWIN Corporation torque motor and rotary tables ensure excellent acceleration capabilities and high precision uniform movements. Hiwin torque motor and rotary tables are backlash free, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

HIWIN Corp. will feature families of precision motion control components this year at IMTS, with their torque motor rotary tables as a highlight of their booth.

Designed for machine tool original equipment manufacturers (OEM) and retrofitters, the TMRT series enables 3-axis machine tools to be upgraded to 3+1, 3+2, 4+1 or even 5-axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders, and a brake system ensure acceleration capabilities and high precision when machining complex part geometries.

The TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates gear reducers, resulting in dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The series is compatible with most major CNC brands and uses HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Designed for machine tool OEM’s and retrofitters, the TMRT series enables three-axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even five-axis capability. High speed, high-torque, built-in high-rigidity high-precision bearings, absolute encoders and a powerful brake system promote acceleration capabilities and high-precision when machining complex part geometries.

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

TJR provides torque motor rotary tables with excellent acceleration and deceleration capabilities. Our torque motor rotary tables are zero-backlash, extremely rigid, wear-free durability, have high dynamic accuracy, are suitable for a wide range of automated production machining.

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Generally speaking, the torque motor can be used in any application in which the customer requires dynamics, precision and a high duty cycle. Constant changes in speed, acceleration, torque and/or position are perfect applications for a torque motor (rotary table).

In packaging applications, torque motors (rotary tables) successfully replace indexing tables and intermittently rotating chucks. The high torque and high loading capacity of a torque motor make it possible to increase dynamics and precision, reduce the amount of space necessary and, above all, offer 360º freedom of positioning.

In semi-conductor applications, torque motors (rotary tables) offer high positioning accuracy (very low-end jump and eccentricity) and an extremely compact size. The “flat” series offers customers motor heights starting at 30 mm.

Complex cutting machines with 4 or 5 axes of freedom require highly precise and highly dynamic rotating heads. Torque motors (rotary tables) offer all these features and more. In addition, the through bore offers the possibility of threading cables and supplies through the central hole of the motor.

HIWIN Corporation, a provider in motion control and system technology, will feature families of precision motion control components this year at IMTS, with their Torque Motor Rotary Tables, (TMRT), as a highlight of their booth. IMTS will be held September 12-17, 2022, in Chicago.

Designed for machine tool OEMs and retrofitters, the TMRT series enables 3-axis machine tools to be readily upgraded to 3+1, 3+2, 4+1, or even 5-axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders, and a powerful brake system ensure excellent acceleration capabilities and high precision when machining complex part geometries.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlashes enable tighter part tolerance. Direct drives provide smooth motion, resulting in an improved part surface finish.

HIWIN Torque Motor Rotary Tables utilize HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Oriental Motor offers Network products under the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuringI/O, RS-485 / Modbus (RTU) or Factory Automation. Networked products enable operating data and parameters for each motor to be set at a Master Controller and sent to each driver. In addition, operation commands can be input send set using various communication methods to meet the need of a wide range of available Network Solutions.

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor"s own RS-485 communication protocol. Connection to FLEX-compatible products is completed with one RS-485 communication cable.

Hiwin (Booth 134514) will feature families of precision motion control components this year at IMTS, with the company"s Torque Motor Rotary Tables (TMRTs) as a highlight.

Designed for machine tool OEMs and retrofitters, the TMRT series enables 3-axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even 5 axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders and a powerful brake system ensure excellent acceleration capabilities and high precision when machining complex part geometries.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

8613371530291

8613371530291