torque motor rotary table pricelist

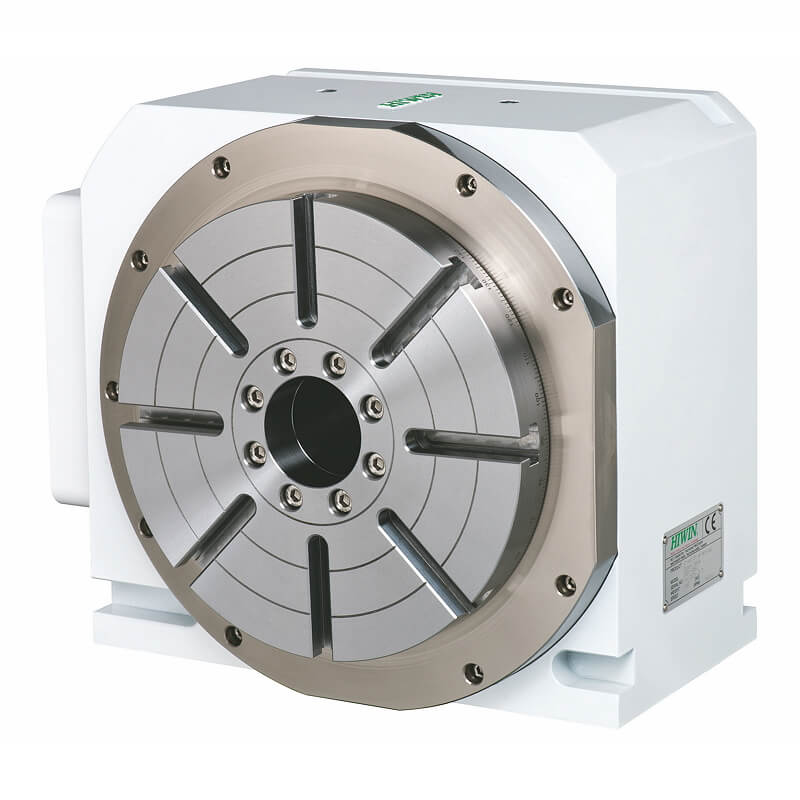

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

The MOR-200-55 motorized rotation stage uses the precision ground and hardened worm gear with self-compensating preload and precision crossed roller bearings. The precision ground worm gear produces consistent driving torque to the rotating carriage. The crossed roller bearings with high rotation accuracy are capable of bearing loads in every direction.

This motorized rotation stage is equipped with a hardware origin and allows for continuous rotation of 360°. The central aperture is 55mm. A hall effect sensor (as the zero position) is built in the rotation stage, so the top plate can"t move in a negative direction to pass over the zero position.

02 series motion controller can be used to control motorized stage with NEMA23 stepper motor. We have 220V and 110V power supply options for each motion controller. The USB line can be used to connect the motion controller to laptop. Please click following links to get more information.

Kitagawa"s new GT200 rotary table is a through hole unit capable of withstanding high cutting loads. It features a 200mm diameter table and provides ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis ...

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages ...

... , photonic component alignment, high-accuracy laser machining and precision wafer inspection. These rotary stages can also be configured as multi-axis gimbals.

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small vertical ...

... secured. High positioning accuracy ensures precise results for 5-axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary Table is the perfect answer for the ideal application. This complete series is provided with or without its perfectly coupling amplifier. Motor Power Company proposes not just components but complete motion solutions, combining direct drive motors with a series of drives with high flexibility and exceptional capabilities in a wide range of applications.

Our best seller, the VH-8 has a 8.25" (210mm) diameter spindle with a 2.0" through hole. With 225 ft. lbs. of brake torque, the VH-8 maintains a rigid design with dual tapered roller bearings supporting the front and back of the spindle. The centerline is 6.75". The worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There is an optional 8" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The standard configuration places the motor at the side or we also offer the option to wrap the motor around the back to save space, reduce overall length and eliminate possible machine interferences. The wrap around motor option does restrict the length on through hole capability.

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Designed for machine tool OEM’s and retrofitters, the TMRT series enables three-axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even five-axis capability. High speed, high-torque, built-in high-rigidity high-precision bearings, absolute encoders and a powerful brake system promote acceleration capabilities and high-precision when machining complex part geometries.

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

※ The scale ring on the periphery of the table top is a laser scribing scale, which can rotate relative to the table top to facilitate initial positioning and reading

The company presented new products for this modular system at EMO 2017 – rotary table bearings with increased performance and smooth running torque motors.

Three standard torque motor series from Schaeffler’s subsidiary INA Drives & Mechatronics (IDAM) and three series of rotary table and rotary axis bearings from Schaeffler can be combined as desired, enabling the user to apply exactly the right solution for every machining process – whether it’s combined soft turning and milling, plane milling, gear grinding, grinding and hard turning, spindle applications, positioning tables, or swivel-type axes for ultra-precise machining. This optimum combination of components is adjusted by Schaeffler’s engineers to match each individual customer’s cutting process to deliver the required precision and dynamics.

Torque motors in the RIB series are suitable for extremely dynamic movements and precise positioning. Ideal applications for these motors include rotary tables, axes for rotary vibration tables, and milling heads for highly dynamic and powerful milling, positioning, clocking and swiveling.

The RKI-series of motors, which differ from the standard RI series mainly due to their innovative rotor design, produce significantly greater power outputs with 30% more force, increased torque and higher speeds. These motors offer a very favourable combination of a high power yield, very good uniform running characteristics, and low power loss. Ideal applications include rotary tables with optional turning operation and rotary tables for combined milling, turning, hard turning, or grinding.

The new SRV series of torque motors stand out due to their extremely smooth running characteristics and allow high quality surfaces with outstanding form and dimensional accuracy to be achieved without optical defects. SRV motors are therefore ideal for use in ultra-precise milling, grinding, and gear cutting machines, particularly as drives for rotary tables and rotary axes with very high speeds and tool or workpiece spindles (up to 14,000 rpm).

Schaeffler has an extraordinarily large range of rotary table bearings for each application’s preferred machining process, axis type, size, cutting force, and speed range. The two YRTC series of axial-radial cylindrical roller bearings – which are now available in X-life quality and a YRTS (S = Speed) version – and the ZKLDF series of axial angular contact ball bearings, represent the broadest range of products for rotary tables and rotary axes on the market. Furthermore, these bearings are also geometrically interchangeable, which can be a major advantage during the development phase.

Another major advantage is the integrated measuring system, which can be selected as an option for all rotary table bearings. The new YRC bearings are particularly suitable for use in plane milling machines and in positioning and swivel-type axes that are subjected to high loads. YRTS axial-radial bearings are the perfect solution for ultra-precise milling, grinding, and gear grinding machines, particularly as drives for rotary tables and rotary axes with very high speeds. The application of choice for ZKLDF axial angular contact ball bearings are bearing supports that have a long operating duration in rotary tables with a main spindle function (e.g. for combined milling and turning operations), bearing supports in milling, grinding, and honing heads, and in measuring and testing equipment.

8613371530291

8613371530291