used rotary table shot blasting machine brands

Blasting is the process in which small angular or spherical particles are propelled against a surface under high pressure by compressed air, or mechanical high speed rotating wheels or water pumps. Blasting is used nowadays for various industrial purposes: to clean a surface by removing unwanted rust, scale, paint, etc.; as a surface preparation method for painting, anodizing, welding, or other processes which require a clean surface; to remove burrs, tooling marks, or otherwise finish a crude product; to change metallurgical properties or stress relieve a part by the peening action of multiple impactions; to produce a desired matte or decorative finish; to remove flashing (excess material) from molded plastic or rubber. It is utilized in several types of industries like foundries, shipyards, steel fabrication plants, special purpose job and machine shops, steel mills, breweries, canneries, rubber manufacturers, painting contractors, plastic manufacturers, welders, wood shops and furniture manufacturers, plating and anodizing shops, automotive industries, aircraft manufacturers, electronic manufacturers, petrochemical companies and many others.

Media Delivery Systems:There are three different kinds of media delivery systems by which the blasting media is propelled and delivered at high speed to the part being processed.

Air Blasting (Pneumatic) – Air blast delivery systems can be further sub-divided into two types as: Suction which works on the principle of sucking media from a hopper and Pressure systems which uses a pressurized pot which is energized by compressed air. The pressure blasting systems are much more productive when blasting than suction systems and also the acceleration rates of air/media mix are much higher in pressure blasting than suction blasting.

Mechanical Wheel - Wheel blast system also called as airless blasting utilizes a high speed rotation wheel using centrifugal force to propel the media. Wheel blast systems are a less expensive way to blast because of higher media recyclability and automation than air blasting but they pose restrictions on the type of media that can be selected due to the impact on the media by the hard rotating wheel.

Hydro blasting - This type of blasting system uses a pressurized water stream generated by pumps that are capable of pumping an abrasive charged water supply at high rates of speed. Hydro Systems are best suited for conveying very fine abrasives. They are also used in cleaning gunky, greasy parts, and containing toxic materials.

Media Reclaim Systems: Recoverable medias used in industrial blast systems will run from 5 to 100 times through the blast system. These recoverable medias need to be cleaned, sized and returned to the blast system after being blasted which is accomplished by the media reclaim system. Production rate is consistently maintained by the media reclaim system. Media reclaim systems can be Air Cyclones or Mechanical Systems.

Dust Collection: All Industrial blast systems utilize dust collectors which remove the fine blasting dust keeping the media clean and operators safe through visibility and breathable air. Normally dust collectors remove 99% of 1 micron or larger material. Filters can be added to remove dust particles down to 1/2 micron. Dust collectors are sized to the cabinet size, media type, and amount of blast nozzles or wheels being used.

Portable blast cleaning machines – Portable blast cleaning machines usually require a high volume air supply (in the range of 90 to 100 psi); a container or pressure vessel to contain the abrasive; a metering device to control air-to-abrasive ratio and flow; a flexible hose to deliver the abrasive, and a hand-held nozzle to aim the abrasive onto the work piece. Many portable units also have large hopper-fed storage tanks which enable multiple blasting operations from a single source of supply.

Hand-operated units in blast cleaning rooms – These units are almost similar to the portable machines. The principle benefits afforded by blast cleaning rooms are their ability to provide and use a dust control ventilation system, cost savings from recycling the abrasive and containment of dust and debris so that they do not spread over large areas and expose other workers and machinery to injury and damage.

Hand-operated cabinet type blast cleaning machines – Cabinet type units generally are used for cleaning small parts that can be handheld or positioned on a rotatable mandrel. In such units the job and the abrasive are confined within a metal cabinet. Direction of the abrasive discharge is manually, semi-automatically or automatically controlled.

Automatic blast cleaning machines – These units are larger in dimension and are more heavily constructed than cabinet machines. Most operate on the centrifugal wheel principle and employ timers and automatic shut-off controls to provide the desired amount of abrasive exposure. Work piece can be placed on either a rotating table or an endless revolving belt that tumbles the job to expose all surfaces to the abrasive.

Wet-blast cleaning machines – This method can be applied to portable machines provided that abrasive is thoroughly mixed with water forming slurry. Since rusting of metal parts becomes a problem, rust inhibitors are added to the slurry.

Blast media, type, shape, size and hardness affect the process and materials they are capable of blasting. Higher blast pressures increase production but reduce media life. Blasting harder work pieces also reduces media life. Recoverable blasting medias which are used in industrial blasting have two basic shapes; Round (spherical) and Angular. Spherical medias are used for peening and produce smoother surface finishes. Angular medias chip at a parts surface thereby they are capable of removing paint, rust and scale quicker, with better results than round medias. Angular medias produce a rougher surface finish and produce superior anchor patterns for paint and coating adhesions.

Trademachines is the only online marketplace to find various types of blasting machines aggregated from various sellers and auction houses in order to make your blasting equipment selection easier and cheaper. Wheelabrator, OMSG, RÖSLER, Turbotechnica, TOSCA, AGTOS, NORDBLAST, ASCO and BUSE are some of the popular brands involved in the manufacturing of various kinds of blasting systems.

Once inside, the build is automatically raised in stages, allowing the twin, robot mounted blast guns to do their work. Blasting with the removed powder ensures that your components and powder remain undamaged and uncontaminated. ...

... most effective blasting process for removing sand, scale and burrs from heavy or sharp-edged mass production parts that require the robust steel mill design found in our Model MR tumble blast machines. ...

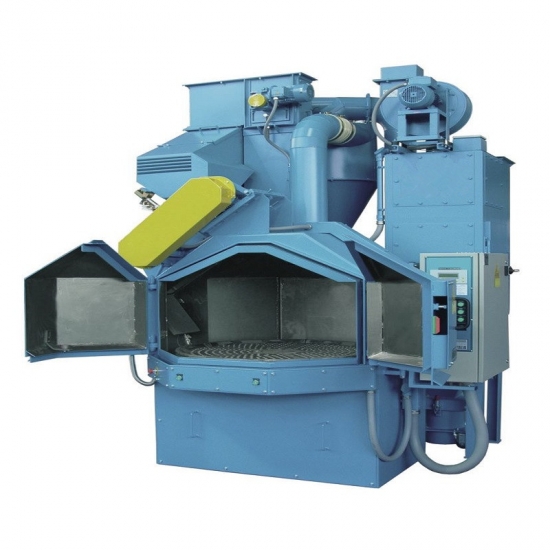

Conventional rotary table blast machines are usually loaded manually. The machines are most frequently used to batch clean cast or die-cast work pieces and to roughen ...

It’s about highly modern machines according to a well-tried principle. Because of many new technical details the new AGTOS drum blast-machines are convincing. This unit type is very capable for treating ...

The LS Industries DB25 Drum Blaster is a quick and efficient machine for cleaning burnt steel drums and barrels. The DB25 can blast the outside and inside of open-end drums in under 2 minutes. The blaster ...

... LSTB8460 Indexing Table Blaster has dual satellite tables to rotate parts into the blast cabinet section. The open front allows for loading / unloading while the other ...

... in position, nozzles moves to first stored position and starts blasting according to the recipe. After blasting is done workpiece is unclamped, unloaded and ready for next one.

Even though machine is designed for manual work, all other features to control the process have been included in solution. That means all components meet shot ...

A 3 – axis automatic machine with full working process control (media flow, shape and size classification, controlled manipulation of parts and peening delivery. Used ...

... manufactures single table and multi table shot blasting machines for processing sensitive components that only need to be blasted on one side, as well as complex, heavy ...

... additional structural work required, the ALFA rotary table blast machines represent the simplest, most versatile and cost-effective solution to your surface treatment issues.

QLX3320A continuous crawler shot blasting machine removes the molding sand on the surface of the workpiece,and eliminates the stress of the workpiece, improves the fatigue strength of the workpiece, and ...

Our rotary drum shot blasting machine enables workpieces to be uniformly cleaned by means of the rotation of a barrel. It is basically used for the shot blasting of small ...

It is designed to work with steel shot (carbon or stainless steel) for cleaning, deoxidation, descaling, deburring, surface finishing for painting and shot peening.

System for automatic processing of rotationally symmetric serial parts of various dimensions. The turntable is completely loaded in the blast chamber; the processing ...

Hodge Clemco purpose-designed and manufactured an internal cyclinder cleaning machine for the leading manufacturer of aluminium gas bottles in the UK. The machine was designed to be both simple to operate ...

... satellite automatic machine for large components. The machine consists of 3 work stations which can load and unload in a masked time. The machine comes with a cyclone used for sorting ...

The basis of the machines is the production at the Grossenlueder site since 1971. Harth & Seifert-Georg Fischer-Schiffmann and Seidl-Oliver Fritz GmbH & Co. Kg with the long-time known contacts.

We sell a used troughed web shot blasting machine from the manufacturer Rump. The machine is in good used condition. It is also equipped with a placement device and suction.

Casting, forging, pressing, heat treatment, finished product, semi-finished product, steel fabrication etc. It is preferred for surface cleaning, pre-coating preparation or revision works. Its distinct advantages are that it enables versatile sandblasting, and that large and small parts with irregular geometry can be sandblasted. With the help of the digital clock we use in our machines, the sandblasting time can be adjusted according to the part type and desired sand...

Compressor Kaeser M36, year 2019 EZ 2020, 23 operating hours, 10 bar, volume flow 4 m³, pressure adjustable 5-10 bar, check valve sandblasting, compressed air treatment G+ (aftercooler, condensate separation, filter combination, heating, bypass), SUB Jet Inverter 230 Volt socket, Ser.Nr.WKA0F1200K7189450

-Dry ice blasting unit SUB Jet 1, year 2020, 5 operating hours, single hose technology with dosing disc, cyclone separator, stainless steel storage tank 25 liters, automatic vibrator for ice loo...

Injector gravitational tumble belt blasting system for blasting series parts with glass beads, corundum, ceramic balls, etc. Due to the gravitational system, the system has 15-20% more blasting power than a simple injector blasting system. The system has a bucket elevator with wind sifting for cleaning the blasting agent. It is possible to store up to 20 programs for various blasting tasks.

Wet sandblasting unit, Sandblasting unit - Pressure blasting unit SAPIMasch. No. 43207 Year of construction 1989Canister size 140 litre perm. operating overpressure 10 barAir requirement approx. 3000 litres/min.hose length approx. 8 meter- Valve opens and closes via pneumatic operation at the blasting nozzle- Sandblasting protective hood with compressed air connection- Complete system installed on metal pallet with forklift pockets- Accessories such as connection pieces for blasting nozzles at t...

The offered blasting machine is a professional, safe and modern device made by a European manufacturer. The sandblasting machine is equipped with a double, independent chute funnel formed at an acute angle to facilitate the sliding of the material, and an inspection drain for quick emptying of the chute from the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 800 kg in a chamber w...

The FG 1 fine blasting unit is equally suitable for punctual work on large objects as well as for the extremely precise processing of the smallest workpieces. The built-in dosing vibration allows on the one hand the use of a wide range of blasting media and on the other hand a wide control range, which also allows lowest blasting pressures.

The offered blasting machine is a professional, safe and modern device made by a European manufacturer. The sandblasting machine is equipped with a double, independent chute funnel formed at a sharp angle to facilitate the sliding of the material, and an inspection drain allowing for quick emptying of the chute of the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 800 kg in a chamber with working ...

Equipped with self-cleaning filter cartridges and effective abrasive treatment, the injector blast machine type 75 IN MEDICA is extremely reliable in operation and achieves a high degree of reproducibility.

Offered sandblasting machine is a professional, safe and modern device from European manufacturer. The sandblasting machine is equipped with a chute formed at an acute angle to facilitate sliding of the material and with an inspection trigger for quick emptying of the chute from the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 600 kg in a chamber with working dimensions of 1 350 x 1 740 x 690 mm...

The 75 IN injector blasting system can be used very flexibly with its generous working area and the proven "sandmaster" injector blasting system. Whether it is for parts cleaning, deburring or preparation of the adhesive base, the 75 IN sets new standards in the field of manual blasting technology. The system is suitable for smaller to medium-sized workpieces. As an exclusive representative of sandmaster in the Baden-Württemberg area, we as IS Zubehör GmbH offer the 75IN injector blasting machin...

Offered blast machine is a professional, safe and modern device from a European manufacturer. The sandblaster is equipped with a chute formed at an acute angle to facilitate sliding of the material and with a revision trigger allowing for quick emptying of the chute from the abrasive.

An important advantage of using CLEMCO brand valves and carbide nozzles in our equipment, as well as blasting hoses that carry the material, is the ability to dose any type of abrasive - both quartz sand...

The 115 PB pressure blasting system with its efficient pressure blasting system is especially suitable for work where a high removal rate is indispensable. The optionally available turntables allow even heavy workpieces to be processed without any problems. sandmaster offers the pressure blasting machine type 115 PB as an exclusive representative of sandmaster in the Baden-Württemberg area as IS Zubehör GmbH. "sandmaster" pressure blasting system - pressure blasting system with 25 l boiler - hig...

The parts to be sandblasted move with the help of roller conveyors located at the entrance and exit of the machine. Turbines are placed in the machine body at appropriate angles so that the part surface can be sandblasted from the bottom and top.

The offered blast machine is a professional, safe and modern unit made by a European manufacturer. The blast machine is equipped with a chute funnel shaped at an acute angle to facilitate the downward movement of the material and an inspection drain for quick removal of the abrasive material form the chute.

The offered blast machine is a professional, safe and modern unit made by a European manufacturer. The blast machine is equipped with a chute funnel shaped at an acute angle to facilitate the downward movement of the material and an inspection drain for quick removal of the abrasive material form the chute.

Land Reko"s RBM Series are compact rotary blast machines designed to blast cylindrical shaped parts. The work piece to be blasted is mounted on an electrically driven rotary work table. The blasting nozzles move parallel to the workpiece axis on one or two sides independently. The design of the machine ensures efficient exposure to the abrasive stream and 100% coverage of the stream during a single cycle, providing a repeatable surface with a homogenous s...

Offered multifunctional Land Reko SBM-230-12 H (B) hydro-jet blast machine is a professional, safe and modern equipment by European manufacturer. The machine is equipped with a pressure tank with a conical bottom for easy sliding of the material and an inspection drain for quick emptying of the abrasive from the tank.

Offered multifunctional Land Reko SBM-130-12 H (B) hydro-jet blast machine is a professional, safe and modern equipment by European manufacturer. The machine is equipped with a pressure tank with a conical bottom for easy sliding of the material and an inspection drain for quick emptying of the abrasive from the tank.

Offered multifunctional Land Reko SBM-76-12 H (B) hydro-jet blast machine is a professional, safe and modern equipment by European manufacturer. The machine is equipped with a pressure tank with a conical bottom for easy sliding of the material and an inspection drain for quick emptying of the abrasive from the tank.

Browse the massive rotary table shot blasting machine range on Alibaba.com. These machines are useful in critical cleaning. rotary table shot blasting machine are highly efficient machines with lower maintenance costs. They enhance anti-fatigue performance and maintain an adequate surface profile in machine parts.

rotary table shot blasting machine on Alibaba.com can be used in conjunction with other equipment or as stand-alone systems. They are useful in several sectors, including, but not limited to, electronics, construction, and manufacturing sectors. They can process a bulk amount of sizeable machine parts in short periods. They employ an array of cleaning processes like steel shot cleaning, grit cleaning, and so on. They also exhibit a clean-in-place feature for straightforward cleaning. These machines exhibit a high degree of automation with premium logic controllers, making them reliable.

Electricity powers rotary table shot blasting machine and they are power-efficient machines. The turbines and other moving parts are constructed of wear-resistant material. A manganese-steel casing houses the devices to provide them with adequate protection. The cleaning mechanism ensures effective cleaning of parts with deep cores and depressions off scale and sand. Equipment are apt for burnishing, descaling, deflashing, and so on. They can also get rid of rust from the working pieces. They are valuable in extending the steel parts" working life and cutting down labor efforts in cleaning. The abrasive materials are cleaned and recirculated for cutting down operating costs.

Grab lucrative rotary table shot blasting machine deals on Alibaba.com at affordable rates. The listed suppliers sell superior quality products and offer after-sales services like installation and providing spare parts. Buy now and enjoy the of benefits of bulk purchase on the platform.

Browse the massive used shot blasting machine range on Alibaba.com. These machines are useful in critical cleaning. used shot blasting machine are highly efficient machines with lower maintenance costs. They enhance anti-fatigue performance and maintain an adequate surface profile in machine parts.

used shot blasting machine on Alibaba.com can be used in conjunction with other equipment or as stand-alone systems. They are useful in several sectors, including, but not limited to, electronics, construction, and manufacturing sectors. They can process a bulk amount of sizeable machine parts in short periods. They employ an array of cleaning processes like steel shot cleaning, grit cleaning, and so on. They also exhibit a clean-in-place feature for straightforward cleaning. These machines exhibit a high degree of automation with premium logic controllers, making them reliable.

Electricity powers used shot blasting machine and they are power-efficient machines. The turbines and other moving parts are constructed of wear-resistant material. A manganese-steel casing houses the devices to provide them with adequate protection. The cleaning mechanism ensures effective cleaning of parts with deep cores and depressions off scale and sand. Equipment are apt for burnishing, descaling, deflashing, and so on. They can also get rid of rust from the working pieces. They are valuable in extending the steel parts" working life and cutting down labor efforts in cleaning. The abrasive materials are cleaned and recirculated for cutting down operating costs.

Grab lucrative used shot blasting machine deals on Alibaba.com at affordable rates. The listed suppliers sell superior quality products and offer after-sales services like installation and providing spare parts. Buy now and enjoy the of benefits of bulk purchase on the platform.

Goff"s Table Blast shot blast machines are the ideal choice for blast-cleaning automotive parts and engine components, petroleum valves and compressors, castings, fabrications and weldments, and numerous other items that are not suitable for tumbling due to size and shape. Parts to be cleaned are rotated on the table, exposing the parts or castings to the abrasive blast media. Table diameters range from 36" to 96" with workload capacities from 300 to 8,000 pounds. All tables are covered with abrasive resistant liners for superior wear. Goff Table Blast shot blast machines are offered in various configurations with blast wheels mounted on the side, hip and top of the machine. Some shot blast models offer oscillating blast wheels to allow more thorough blast pattern coverage.

Available in single table, single and double-door swing, satellite multi-table and plain table models. Goff"s Table Blast shot blast machines offer the user unparalleled performance and versatility in blast cleaning for industrial and manufacturing needs. Download specs & details on Goff Table Blast shot blast machines.

Rotary table disc rotates with work pieces on it . Blasting wheels on top blast steel shots and grits on work pieces. Table disc is resistant casting alloy with holes to let used steel shots and grits down to bottom screw conveyor for recycling.

We"re professional rotary table shot blasting machine manufacturers and suppliers in China, specialized in providing high quality machines with competitive price. We warmly welcome you to buy durable rotary table shot blasting machine for sale here from our factory.We constantly innovate in the Hook Shot Blasting Machine For Large Valve, Industry Bag Filter Dust System, Drum Type Shot Blasting Machine field, continuing to exceed customer expectations, and make unremitting efforts to achieve sustainable development.

Benjamin Tilghman was a general in the army and saw the effect of wind-blown sand on windows in the desert. The might be the basis of his shot blasting machine invention.

Shot blasting is a technique in which a selected class of abrasive particles is used to do surface preparation, that is, remove material from a surface at a high speed (65-110m/s) corrosion rate. It is the operation of forcing the abrasive stream to the surface under high pressure to smooth the rough surface, roughen the smooth surface, and shape or remove surface contaminants. A pressurized fluid (usually compressed air), or a centrifugal wheel is used to propel the blast material (commonly referred to as the medium).

Table type shot blasting machine comprises of one/ two rotary table for loading of the constituent. This table straddling on the door swings inside the cabinet, thus it is also called Swing Table Blasting Machine, and the blast wheel on the uppermost cleans the section. The table rotates in a circular and anticlockwise direction to guarantee the blasting surface"s thorough cleaning by the blast wheel.

The table shot blasting machine is commonly known as Swing Table Shot Blasting Machine, which comprises rotary tables for the component loading. This shot blasting table soars on the door swings inner surface the cabin and the blast wheel on the top clean the component.

This table type shot blasting machine comprises a round table over which the ingredients or material to be blasted are kept. The swing table rotates vertically, hence exposing the components to the blast stream by the blast wheel. This blasting machine has an additional table hinged to them to reduce the cycle time. The second part of the table is on another side of the opening that rides and loaded when the blasting is in technique on the first one. Table Shot Blasting Machines are available at a very reasonable price.

It also consist a round table over which, the ingredients to be blasted are placed and the table rotates vertically therefore exposing the components to the blast stream. These machines also have another table hinged to them in order to reduce the cycle time. The second part of the table is on other side of opening which is offloaded and loaded when the blasting is in process on the first one. Our table type shot blasting machines are available at very competitive price.

Quality Space Centre is the premiere table type shot blasting machine Manufacturers are entirely ground-breaking in all the aspects. It has been extensively designed with airless, automatic, and simple handled machines for more applications. At quality space centre, the leading Shot Blasting Machine Manufacturer in Faridabad, India, brings you the finest rotary table machine based on the unique source with the single and double door based on the production rate well the desired output. It is most suitable for the immense to small foundry industries in a more state-of-art way.

Rotary shot blasting machine or table type shot blasting machine is suitable for various shapes and dimensions, casts, forged parts, pressed parts, steel, and non-ferrous metal parts and parts made from fragile materials, cleaning surface, removing casting sand and filings, consolidating the surface (micro handling), roughing the surface before colouring, etc.

Rotary shot blasting machines are split into single rotary table shot blasting machine and swing table shot blasting machine. swing table shot blasting machine efficiency is much higher than the single rotary table shot blasting machine.

Treated objects are loaded on a perforated rotating table. A big door, provide simple and fast loading. The machine can have the table fitted to the machine"s door, which enables loading with a hoist or fork-lift truck to the entire surface of the table. The machine also can be equipped with two tables, enabling simultaneous shot blasting of treated objects inside the machine and loading or turning treated objects in front of the machine.

The machine"s housing is robust and protected by wear-resistant materials. High efficiency of the machine is enabled by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials. Standard equipment of larger machines includes PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc. For shot blasting cast containing larger quantities of casting sand, a magnetic sand cleaner may be installed.

QINGGONG MACHINERY is a professional shot blasting machine manufacturers. We provide Roller Conveyor Shot Blasting Machine, sand blasting machine parts, blastpro shot blaster, rotary table shot blasting machine for sale, rotary shot blast machine, table blast machine, rotary table blast machine, used rotary table shot blasting machine and so on. Want to know about shot blasting machine specifications and rotary blast table? Please contact us.

Wheel blasting or peening equipment, directly converts electric motor energy into kinetic abrasive energy by rotating a turbine wheel. With these large amounts of accelerated abrasive, wheel blast machines are used where big parts or large areas of parts have to be de-rusted, descaled, de-burred, de-sanded or cleaned in some form prior to coating.

Often the method of transporting the component parts to the blast machine will define the type of unit to be installed. Simple table machines allow for easy manual hand loading of small components. Integrated automatic roller machines may require pullies and other lifting equipment to position components. While on the largest end of the scale there are complete crane roller conveyors and track systems.

The key difference between using the methods of surface preparation is the process used during the blasting. Shot blasting is the process of using a throwing wheel to propel the abrasive media at the surface of the object to be prepared. While the abrasive air blasting process incorporates the use of compressed air to create a stream of abrasive that is directed towards the objects surface.

During shot blasting, abrasive gets acceleration through the throwing wheel, which is rapidly turning in a special steel housing, with one side oriented opening. Shot blasting is used for blasting metal, different profiles and welded constructions. The process is controlled within the production machine and require far less manual labor during the blasting process.

DescriptionUsed Rosler RMT 15 Multi-Tumbler Shot Blast Machine with skip loader, vibratory unload conveyor, automatic media replenishing, maintenance platform, and new electrical control cabinet (480V/60Hz/3ph) | Machine is operational and available for testing, immediate delivery, or rental, very low operating hours (< 500hrs) | max. batch capacity: 2250 lbs., max. work piece size (diagonal): 18 inches (450 mm), max. work piece weight 150 lbs./ea. | Blast Turbine: 1x Rosler JWL-610 @ 30hp (22 kW)

8613371530291

8613371530291