used rotary table shot blasting machine free sample

The basis of the machines is the production at the Grossenlueder site since 1971. Harth & Seifert-Georg Fischer-Schiffmann and Seidl-Oliver Fritz GmbH & Co. Kg with the long-time known contacts.

We sell a used troughed web shot blasting machine from the manufacturer Rump. The machine is in good used condition. It is also equipped with a placement device and suction.

Casting, forging, pressing, heat treatment, finished product, semi-finished product, steel fabrication etc. It is preferred for surface cleaning, pre-coating preparation or revision works. Its distinct advantages are that it enables versatile sandblasting, and that large and small parts with irregular geometry can be sandblasted. With the help of the digital clock we use in our machines, the sandblasting time can be adjusted according to the part type and desired sand...

Compressor Kaeser M36, year 2019 EZ 2020, 23 operating hours, 10 bar, volume flow 4 m³, pressure adjustable 5-10 bar, check valve sandblasting, compressed air treatment G+ (aftercooler, condensate separation, filter combination, heating, bypass), SUB Jet Inverter 230 Volt socket, Ser.Nr.WKA0F1200K7189450

-Dry ice blasting unit SUB Jet 1, year 2020, 5 operating hours, single hose technology with dosing disc, cyclone separator, stainless steel storage tank 25 liters, automatic vibrator for ice loo...

Injector gravitational tumble belt blasting system for blasting series parts with glass beads, corundum, ceramic balls, etc. Due to the gravitational system, the system has 15-20% more blasting power than a simple injector blasting system. The system has a bucket elevator with wind sifting for cleaning the blasting agent. It is possible to store up to 20 programs for various blasting tasks.

Wet sandblasting unit, Sandblasting unit - Pressure blasting unit SAPIMasch. No. 43207 Year of construction 1989Canister size 140 litre perm. operating overpressure 10 barAir requirement approx. 3000 litres/min.hose length approx. 8 meter- Valve opens and closes via pneumatic operation at the blasting nozzle- Sandblasting protective hood with compressed air connection- Complete system installed on metal pallet with forklift pockets- Accessories such as connection pieces for blasting nozzles at t...

The offered blasting machine is a professional, safe and modern device made by a European manufacturer. The sandblasting machine is equipped with a double, independent chute funnel formed at an acute angle to facilitate the sliding of the material, and an inspection drain for quick emptying of the chute from the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 800 kg in a chamber w...

The FG 1 fine blasting unit is equally suitable for punctual work on large objects as well as for the extremely precise processing of the smallest workpieces. The built-in dosing vibration allows on the one hand the use of a wide range of blasting media and on the other hand a wide control range, which also allows lowest blasting pressures.

The offered blasting machine is a professional, safe and modern device made by a European manufacturer. The sandblasting machine is equipped with a double, independent chute funnel formed at a sharp angle to facilitate the sliding of the material, and an inspection drain allowing for quick emptying of the chute of the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 800 kg in a chamber with working ...

Equipped with self-cleaning filter cartridges and effective abrasive treatment, the injector blast machine type 75 IN MEDICA is extremely reliable in operation and achieves a high degree of reproducibility.

Offered sandblasting machine is a professional, safe and modern device from European manufacturer. The sandblasting machine is equipped with a chute formed at an acute angle to facilitate sliding of the material and with an inspection trigger for quick emptying of the chute from the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 600 kg in a chamber with working dimensions of 1 350 x 1 740 x 690 mm...

The 75 IN injector blasting system can be used very flexibly with its generous working area and the proven "sandmaster" injector blasting system. Whether it is for parts cleaning, deburring or preparation of the adhesive base, the 75 IN sets new standards in the field of manual blasting technology. The system is suitable for smaller to medium-sized workpieces. As an exclusive representative of sandmaster in the Baden-Württemberg area, we as IS Zubehör GmbH offer the 75IN injector blasting machin...

Offered blast machine is a professional, safe and modern device from a European manufacturer. The sandblaster is equipped with a chute formed at an acute angle to facilitate sliding of the material and with a revision trigger allowing for quick emptying of the chute from the abrasive.

An important advantage of using CLEMCO brand valves and carbide nozzles in our equipment, as well as blasting hoses that carry the material, is the ability to dose any type of abrasive - both quartz sand...

The 115 PB pressure blasting system with its efficient pressure blasting system is especially suitable for work where a high removal rate is indispensable. The optionally available turntables allow even heavy workpieces to be processed without any problems. sandmaster offers the pressure blasting machine type 115 PB as an exclusive representative of sandmaster in the Baden-Württemberg area as IS Zubehör GmbH. "sandmaster" pressure blasting system - pressure blasting system with 25 l boiler - hig...

The parts to be sandblasted move with the help of roller conveyors located at the entrance and exit of the machine. Turbines are placed in the machine body at appropriate angles so that the part surface can be sandblasted from the bottom and top.

The offered blast machine is a professional, safe and modern unit made by a European manufacturer. The blast machine is equipped with a chute funnel shaped at an acute angle to facilitate the downward movement of the material and an inspection drain for quick removal of the abrasive material form the chute.

The offered blast machine is a professional, safe and modern unit made by a European manufacturer. The blast machine is equipped with a chute funnel shaped at an acute angle to facilitate the downward movement of the material and an inspection drain for quick removal of the abrasive material form the chute.

Land Reko"s RBM Series are compact rotary blast machines designed to blast cylindrical shaped parts. The work piece to be blasted is mounted on an electrically driven rotary work table. The blasting nozzles move parallel to the workpiece axis on one or two sides independently. The design of the machine ensures efficient exposure to the abrasive stream and 100% coverage of the stream during a single cycle, providing a repeatable surface with a homogenous s...

Offered multifunctional Land Reko SBM-230-12 H (B) hydro-jet blast machine is a professional, safe and modern equipment by European manufacturer. The machine is equipped with a pressure tank with a conical bottom for easy sliding of the material and an inspection drain for quick emptying of the abrasive from the tank.

Offered multifunctional Land Reko SBM-130-12 H (B) hydro-jet blast machine is a professional, safe and modern equipment by European manufacturer. The machine is equipped with a pressure tank with a conical bottom for easy sliding of the material and an inspection drain for quick emptying of the abrasive from the tank.

Offered multifunctional Land Reko SBM-76-12 H (B) hydro-jet blast machine is a professional, safe and modern equipment by European manufacturer. The machine is equipped with a pressure tank with a conical bottom for easy sliding of the material and an inspection drain for quick emptying of the abrasive from the tank.

Browse the massive rotary table shot blasting machine range on Alibaba.com. These machines are useful in critical cleaning. rotary table shot blasting machine are highly efficient machines with lower maintenance costs. They enhance anti-fatigue performance and maintain an adequate surface profile in machine parts.

rotary table shot blasting machine on Alibaba.com can be used in conjunction with other equipment or as stand-alone systems. They are useful in several sectors, including, but not limited to, electronics, construction, and manufacturing sectors. They can process a bulk amount of sizeable machine parts in short periods. They employ an array of cleaning processes like steel shot cleaning, grit cleaning, and so on. They also exhibit a clean-in-place feature for straightforward cleaning. These machines exhibit a high degree of automation with premium logic controllers, making them reliable.

Electricity powers rotary table shot blasting machine and they are power-efficient machines. The turbines and other moving parts are constructed of wear-resistant material. A manganese-steel casing houses the devices to provide them with adequate protection. The cleaning mechanism ensures effective cleaning of parts with deep cores and depressions off scale and sand. Equipment are apt for burnishing, descaling, deflashing, and so on. They can also get rid of rust from the working pieces. They are valuable in extending the steel parts" working life and cutting down labor efforts in cleaning. The abrasive materials are cleaned and recirculated for cutting down operating costs.

Grab lucrative rotary table shot blasting machine deals on Alibaba.com at affordable rates. The listed suppliers sell superior quality products and offer after-sales services like installation and providing spare parts. Buy now and enjoy the of benefits of bulk purchase on the platform.

Shot blasting, or abrasive blasting, is an essentialpart of any manufacturing industry seeking tomaintainthe longevity oftheirparts.It is a mechanical method of propelling abrasive using a centrifugal wheel to remove surface contamination, scale,and othersmallimpurities from the surface ofa variety ofsteel applications. For example, this could bestructural steelwhichincludesmassive bridge girders and heavy construction equipment,such aslarge weldments, plate steel, bar and wire steel,and foundry castings.Our shot blasting machines utilize centrifugal force to clean steel utilizing abrasive media. After the steel abrasive hits the surface, the shot blaster recycles the media.Dust and other contaminant particles are removed by an air wash separator within the machine andsentto a dedicated dust collector.This process provides a dust-free operation.In general, blastingbefore moving onto finishing servesa fewprimarypurposes:

.png)

When buying a blasting machine, many factors must be considered, such as the dimension of the piece, what it is made of, the volume of production (how many parts need to be finished in one day or hour) and the type of finishing required (cleaning, paint removal, de-rusting, etc.). Thinking of that, we elaborated a guide to blasting machines.This material serves as an instruction to visualize the blasting machine that can meet your need.

It is worth mentioning that this is estimative and, in addition, CMV® blast machines can be customized to best meet your company"s needs. We provide free technical consulting to our customers. We talk and analyze which blasting machine best meets their needs, aiming at the bestcost-benefiton the market.

See the recommended blasting machine by clicking on the item you are interested in below. If you prefer, you can solve your question by talking directly to our sales team by filling out a form.

This is the industry that proportionally uses the most shot peening machines. There is a multitude of aircraft components that are treated with shot peening, including several components of the blast wheels, structural parts and the landing gear.

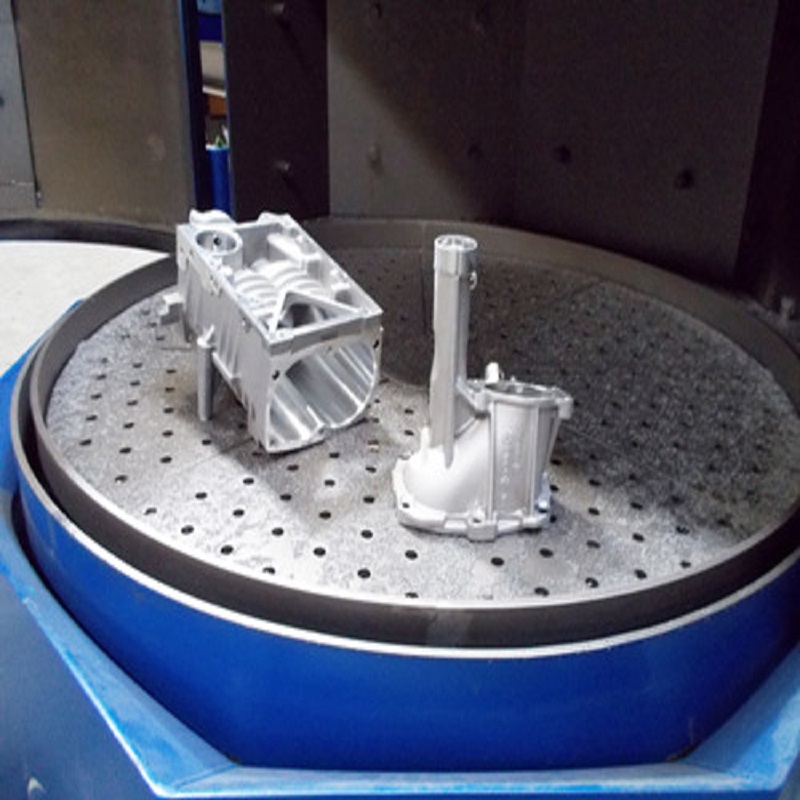

It is becoming more and more necessary for the industry to prepare the surfaces of castings and aluminum parts. We are prepared for this demand, meeting the needs of our customers and aiming for the best cost-benefit in the market. We have several blasting machines specially developed for surface treatment and deburring of aluminum parts. See some examples:

We have developed a machine specifically designed to blast aluminum rims and wheels. Its capacity is impressive, as the process takes only 6 minutes to complete.

To meet the demand of one of the largest weapons manufacturers in the world, we developed a blasting machine with an indexed table and replaceable planetariums for the various components to be blasted with two B-306 blast wheels with 5 HP each. The blasting time for each part averages 10 seconds.

The equipment used will depend a lot on the parts finishing process. We have many solutions specially developed for the automotive industry. We listed below some examples of parts and blasting machines suitable for the operation:

We have already developed different types of blasting machines with a specific focus on chassis. It is necessary to evaluate each case, but see the example below:

See in the video below the blasting equipment that was developed for the blasting of valves for fuel injection and that performs the production of 70 pieces per minute. The cabinet was without the final finish, as it was in the testing phase in our headquarters.

The stabilizer bar is located on most vehicles on the front suspension and on some models on the rear. It is a fundamental piece of equipment for the stability of the vehicle and, therefore, a shot peening machine with a high precision finish is necessary.

The machine in question has an extremely efficient abrasive recycling system, which makes it possible to obtain a very narrow range of roughness. The new table indexing system ensures extremely accurate positioning of the parts in front of the blast nozzle, providing a uniform finish.

In the case of truck stringers, we recommend using an overhead monorail shot blasting machine. See an example: This blasting machine has 4 blast wheels of 40 CV (30Kw), each with a passing speed of 3 m/min.

CMV® has state-of-the-art technology to treat bars and tubes, regardless of their shape. It is possible to treat different types of bars and profiles in one single blasting machine, due to a vertical support roller that can be installed on the equipment"s table, causing different shapes of bars to advance in a helical way.

This machine has an extremely high production efficiency and can be easily incorporated into automatic or semi-automatic production lines. It meets the central safety and health standards, and it’s available in two models pre-fabrication and post-fabrication.

We are prepared to meet the most diverse demands of the energy industry. Both gas protection and cleaning protection ducts, construction preparation and final coating. CMV® meets all these demands with tube blasting machines. We also have a blast and paint and pipe coating line.

This tumble blasting machine is suitable for blasting and shot peening of forged, stamped, injected and cast parts. This high-efficiency equipment is capable of uniformly blasting several parts at the same time.

There are metal castings that require special attention as they may be subject to impact damage. In this case, the blasting machine with the tumble belt (mentioned above) is not recommended, as the tumble could cause damage. And yes, an overhead blasting machine or even a wire mash blast machine. In both equipments, all the faces of the part are blasted at once, but without the risk of any damage.

No matter what your demand is, we have a shot blasting machine that can meet it. We manufacture both, standard equipment and customized machines. Whatever is necessary to better meet the needs of our customers. From small to large productions, we develop shot blasting machines with the best performance on the market.

Discover our products.If you prefer, talk to our sales team. We provide free technical advice so that we can understand which machine is best for your company.

We are a reference when it comes to the construction of blast rooms for shipyards, having in our experience the manufacture of the largest blasting and painting room in Latin America. A few years later, we developed a paint booth with the largest free-standing door, also in Latin America.

We have blasting machines that work with metal sheets and profiles. It’s possible to purchase only a part of the equipment or the complete line, including conveyor, blowing, drying, blasting, cleaning (sweeping and blowing), painting and drying the paint with gas or electric oven. It also treats the volatiles eventually generated in the process.

With extensive experience in the forge and foundry industries, Rosler Metal Finishing understands that no two shot blasting processes and work pieces are alike. With that in mind, we continue our Forge & Foundry Blog Series with an overview of our machines offering excellent finishing for sand castings.

If you demand precise, repeatable results when shot blasting sand castings, consider the following machines. As always, the experts at Rosler are also available to develop a customized machine to accommodate your unique work pieces and challenges.

Work pieces pass through the shot blast area on a wire mesh belt, never touching each other during the shot blast process. The heavy-duty foundry version of the RDGE includes an extra 5/8-in-thick wear lining, special eight-bladed turbines, and a vibratory screen conveyor in place of a media auger.

The RMT’s specially shaped rotary drum optimizes work piece mixing. For foundry applications, a vibratory screen conveyor replaces the standard media auger and a magnetic separator and extra wear lining are added.

The heart of the RMBC batch machine is an endless belt made from rubber or steel slats forming a trough. Work pieces tumble intensively within the trough.

Ideal Work Pieces — Mid-sized to large, heavy components including the cleaning of prototypes, large casters, pulleys; frequently used for cleaning of casting, forging, and other molds

The center of the RROB is a robot, which does the loading/unloading as well as the handling of the work pieces in the blast machine. The robot picks up one, single raw work piece from the staging system (e.g. a conveyor), holds the work piece into the blast chamber while constantly rotating it, and deposits it back on the conveyor.

The RMBS is a specialized machine equipped with a gripper system that rotates and oscillates work pieces weighing up to 11,000 lbs in the blast chamber. Twin robots transfer the work pieces to and from the gripper system.

The experts at Rosler are available to collaborate with you to find the right machine and process for your sand castings. Contact us today to learn how we can help improve your finishing processes and schedule a free sample processing in our test center.

Guyson Corporation now manufactures its Model GWB-702L rotary table wheel-blast system with two direct drive blast turbines positioned to enable thorough coverage of three-dimensional components.

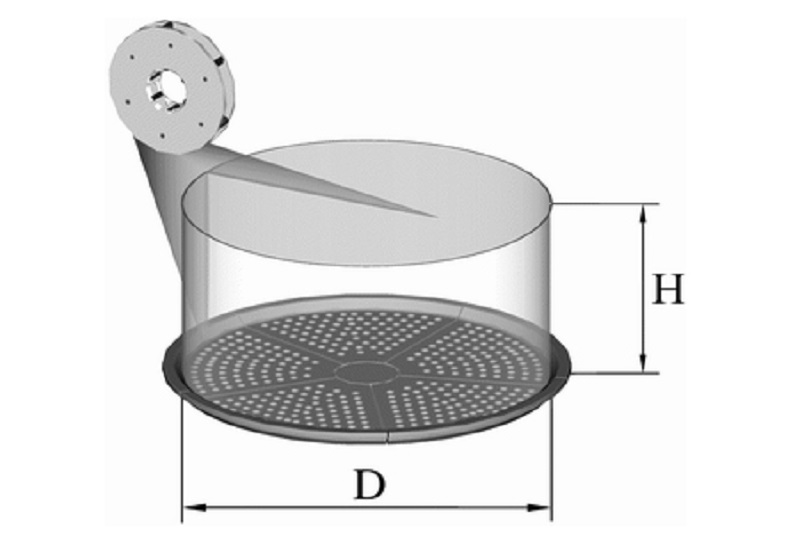

The 70-inch (1.8 m) diameter turntable of the GWB-702L is heavily armored with replaceable plates cast in abrasion-resistant alloy, as are all areas of the interior of the machine that are directly exposed to media blast. The weight capacity of the gear driven rotary table is 4,000 lbs. (1,800 kg).

Located on the upper left side of the blast chamber, the two 10 HP blast wheels rotate in opposite directions, so that their blast patterns overlap to completely cover components on the machine’s slowly revolving table. This wheel configuration is particularly effective for rapid cleaning or finishing of vertical surfaces and the sides of components, as well as the top aspect of the parts.

A wheeled transfer cart is optionally available to simplify loading and handling of bulky items. The rigidly welded cart features a roll-in table fabricated in manganese steel and a catch tray to collect media that might be carried out when blast cleaned components are unloaded.

The twin blast wheels deliver approximately 440 lbs. (200 kg) of media per minute. Media reclamation in the standard Model GWB-702L is accomplished by a high performance three-stage system that includes a rotary sieve to screen out coarse contaminants, a cascade air wash separator to remove dust and fines, plus a tunable cyclone separator to recycle reusable media. This specially enhanced reclaim is essential when exceptionally fine bead media are used for nondestructive cleaning of molds and dies, or when microscopic shot is used to produce a distinctive cosmetic finish.

Guyson Corporation has expanded its line-up of automated blasting systems with small-footprint models designed to meet the special requirements of cell-based production. The RSSA-6 rotary blast machine is adaptable for various purposes, such as deburring, cosmetic finishing and technical surface preparation.

The single spindle or table of the Model RSSA-6 is fitted with a component-holding fixture that is easily changeable for processing of different parts. As the component rotates at controlled and adjustable speed, it is exposed to the timed blast from up to four suction-feed blast guns affixed to telescoping brackets that allow each nozzle to be positioned at the correct angle and offset for coverage of target surfaces.

Engineered-to-order, the finishing system is supplied with a suitably sized media reclaimer and cyclone separator, as well as a cartridge-type, reverse pulse dust collector with an extraction capacity of 1000 cubic feet of air per minute. The media delivery system can be enhanced by an electronic sensor-activated replenisher that automatically adds shot or grit when a low media level is detected. Guyson also offers a comprehensive package of abrasion resistance features, such as rubber cabinet lining and cast urethane ducting, when aggressive blast media are to be used in the blast system.

Prospective users of automated blasting equipment are encouraged to submit sample components for freelaboratory testingand application engineering evaluation at Guyson’s design and manufacturing center in northeastern New York State.

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

The choice of the appropriate machine concept depends on your work pieces, the required level of performance and last but not least on your specific needs regarding an optimized production process.

When processing work pieces in batch mode, the rotary table stops, the doors open and several work pieces are then placed on the rotary table. The door closes and the work pieces are rotated into the blasting zone and then cleaned.

In continuously operating rotary table blasting units, the work pieces are continuously blasted in the rear area of the rotating table. Loading and unloading take place in the front of the machine. Special vestibules seal the loading and unloading areas of the rotary table and prevent the escape of stray abrasive.

Other rotary table machines operate in so-called duplex mode. While one batch is blasted, another is loaded or unloaded. In duplex machines, two batches are located in the machine at the same time.

In satellite rotary table blasting machines, work pieces are blasted on rotating platforms arranged in a radial pattern. Machines such as these are usually operated in indexing mode.

In all of these different machine types, the blasting abrasive is continuously cleaned, recirculated and reused. An abrasive metering device feeds the cleaned abrasive from the abrasive storage bunker to the high-performance turbines.

A fan unit creates the partial vacuum necessary to maintain dust-free operation of the blasting unit. Extracted air is cleaned in a special filter unit.

Conventional rotary table blast machines are usually loaded manually. The machines are most frequently used to batch clean cast or die-cast work pieces and to roughen the surfaces of work pieces prior to coating.

In automated lines, primarily in the automotive industries, satellite rotary table blasting machines often include integrated robotic handling devices. Such a configuration is used to harden the surfaces of transmission components, for example.

Our Spinner Hanger Blast Machines have been designed to shot blast components of all sizes, complex shapes and fragile parts. These systems can process large components which cannot be tumbled together during the shot blasting process, due to the risk of impingement.

The TG Tumble Rubber Belt Blast Machine is ideal to shot blast batches of small or medium parts and fragile components. Any type of material can be processed in these machines, from forged and heat-treated components, to steel, aluminium and brass parts and fragile plastic components.

A shot blasting technology ideal to process batches of medium to large and heavy parts. The TA series is recommended for finishing steel and brass press-forged parts, cast iron, aluminium, steel or brass castings & heat-treated components.

STL/A Wire Mesh Belt Shot Blasting Machines are built for a continuous shot blasting process of aluminum and steel parts. These machines are also perfect for processing components slots and wholes which are difficult to reach, such as gears, die-castings, castings, gearboxes or forged parts.

GSA Continuous Feed Overhead Rail Blasting Machine is built for treatment of components hanged on a hook which run on a O-ring motorised overhead rail. This shot blasting equipment is widely used by steel, cast iron and aluminium foundries for the surface cleaning of metallic products.

The Roller Conveyor Shot blasting machines are designed to process metal sheets or plates, profiles and metallic structures and any other long or/ and flat component, in a continuous feed process.

The GRT blast cleaning technology is designed to be a continuous feed shot blasting machine for pipes, bottles, cylindrical parts, round bars, torsion bars, gas cylinders and drill rods.

The Rotary Table Shot Blasting Machine is suitable for shot blasting small and medium size parts. This installation is provided with a variable speed drive controlled turbine and a turntable, which has a diameter of 2500 mm.

At ActOn Finishing we offer the STL Tunnel Concrete Shot Blast machine, designed for surface treatment of marble, granite, natural stone, concrete and aggregate blocks to obtain a bush-hammered, flame treated, antique appearance finishing.

BlastKing Provide turnkey installation for the shot blaster. But DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing. Furthermore, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. Thus BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. At the same time, BlastKing has developed a complete program of maintenance training seminars. Above all, these are just scheduled not only for new users but also for existing users. In short, This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of shot blasting machine will be one to five years. Most importantly, technical support will be during the whole blasting machine life. In addition, consumable spare parts will be supplied periodically.

General emergency stop button is on all the BlastKing’s control panel. And sub emergency stop buttons are on conveyor systems. Moreover, detectors on the blast wheel covers, blasting chamber windows, elevators, separators will protect safety of the operators. Further, dust collection unit of shot blast machine dust emisssions is under 3mg/m3 which also bring dust free working environment.

Shot Blasting Machine market report provides a detailed study of global market scope, regional and country-level market size, segmentation, growth, share, competitive Landscape, sales analysis, impact of domestic and global market players, value chain optimization, trade regulations, recent developments, opportunities analysis, strategic market growth analysis, product launches, area marketplace expanding and technological innovations.

A shot blasting machine is an enclosed machine which is used for abrasive blasting for preparing and cleaning stone, metals, and other surfaces. The machine is used for short peening and cleaning metal parts such as steel surfaces, casting parts, rusted metal parts, heavy metal structures, and others. The machine also has a dirt collection system for preventing minute particles, dust particles, contaminant, and others.

Market segmentationShot Blasting Machine market is divided by Type and Application. For the period 2022-2030, the growth among segments provides accurate calculations and forecasts for revenue by Type and Application. This analysis can help you expand your business by targeting qualified place market

The choice of the appropriate machine concept depends on your work pieces, the required level of performance and last but not least on your specific needs regarding an optimized production process.

When processing work pieces in batch mode, the rotary table stops, the doors open and several work pieces are then placed on the rotary table. The door closes and the work pieces are rotated into the blasting zone and then cleaned.

In continuously operating rotary table blasting units, the work pieces are continuously blasted in the rear area of the rotating table. Loading and unloading take place in the front of the machine. Special vestibules seal the loading and unloading areas of the rotary table and prevent the escape of stray abrasive.

Other rotary table machines operate in so-called duplex mode. While one batch is blasted, another is loaded or unloaded. In duplex machines, two batches are located in the machine at the same time.

In satellite rotary table blasting machines, work pieces are blasted on rotating platforms arranged in a radial pattern. Machines such as these are usually operated in indexing mode.

In all of these different machine types, the blasting abrasive is continuously cleaned, recirculated and reused. An abrasive metering device feeds the cleaned abrasive from the abrasive storage bunker to the high-performance turbines.

A fan unit creates the partial vacuum necessary to maintain dust-free operation of the blasting unit. Extracted air is cleaned in a special filter unit.

Conventional rotary table blast machines are usually loaded manually. The machines are most frequently used to batch clean cast or die-cast work pieces and to roughen the surfaces of work pieces prior to coating.

In automated lines, primarily in the automotive industries, satellite rotary table blasting machines often include integrated robotic handling devices. Such a configuration is used to harden the surfaces of transmission components, for example.

The utility model discloses a device used for the surface nanocrystallization of an automobile tire mould. The device is formed by integrating a common pneumatic shot blasting machine, a boosting tank, an oscillating screen, a spray-gun swing mechanism and a rotary tray mechanism, and comprises an electric-control cabinet, a step ladder, a shot, a spray gun, a 36 bag dust, a dust-collecting pipe, and a lifted speed reductor, wherein the spray gun is connected with a spray-gun swing reductor, the 36 bag dust collector is connected with a high-pressure blower, one end of the dust-collecting pipe is connected with a wind-separation mechanism and the other end thereof is connected with a container below a rotary-tray rotating and reducing member, the lifted speed reductor connected with a lifter, the rotary-tray rotating and reducing member is connected on the rotary tray mechanism, the spray gun is connected with one end of the boosting tank, the other end of the boosting tank is connected with a sand-control valve, the spray gun is positioned above the rotary tray mechanism, and the oscillating screen mechanism is positioned below the wind-separation mechanism and is connected with the wind-separation mechanism. By the shot-blast treatment adopting the device, a nanocrystal layer with a thickness ranging from 20 Mum to 30 Mum is formed on the surface of the die cavity of the Al/Mg alloy tyre mould, thereby improving the service performance of the tire mould and prolonging the service life of the tire mould.

Ultrasonic shot peening equipment is because there is the deficiency of two aspects in its mechanical feature.The first, the specimen thickness of processing can not be too big, and is also restricted to other sizes of test specimen.The second, can not handle test specimen with complicated shape, can only handle the thin plate test specimen about 100mm * 100mm.

On the general shot-blasting machine that industry is used always, pass through the frequency of Frequency Converter Control motor, and then the speed of control bullet ejection, adopt big bullet, increase the shot-peening time, improved the shot-peening coverage rate, prepare certain thickness nanometer layer at industrially pure titanium, surface of low-carbon steel.On general shot-blasting machine, to obtain the required energy of material surface nanometer, just must raising speed.Like this, killing and wounding of sample surfaces deepened, surface damage and come off comparatively serious.

A kind of device that is used for the automobile tire mould making Nano surface of the present invention then is by common pneumatic type shot blasting equipment, and booster jar, vibratory sieve, spray gun swing mechanism, rotating disk mechanism is integrated forms.

A kind of device that is used for the automobile tire mould making Nano surface, comprise electric cabinet 1, step 10, bullet, spray gun 2 connects spray gun and waves reductor 9,36 bag-type dust casees 3 connect high pressure positive blower 4, one end of sweep-up pipe 5 connects pneumatic separator 6, container under the other end connection rotating disk rotation deceleration 11 of sweep-up pipe 5 promotes reductor 7 and connects elevators 8, and rotating disk rotates the 11 connection rotating disk mechanisms 12 that slow down, above-mentioned spray gun 2 connects an end 14 of pressurized canister, pressurized canister 14 other ends connect transfers sand valve 15, and spray gun 2 is positioned at rotating disk mechanism 12 tops, and vibratory sieve mechanism 13 is positioned at the below of pneumatic separator 6 and interconnects.

1. passing through on common pneumatic shot blasting equipment increases booster jar, and the pressure of gas extends to 0.7Mpa from 0.10Mpa when making shot-peening

3. on common pneumatic shot blasting equipment, increase spray gun pendulous device and sample platform tumbler, wherein spray gun ± 45 ° swing, sample platform per minute 10~20 is walked around moving.Thereby guarantee that the mold cavity surface can obtain the nanometer crystal layer of 20~30um after bead.

2. according to the cooperating of the required nanocrystalline layer thickness of mould and surface roughness, select the bullet diameter.Used bullet diameter is selected 0.50,0.70,1.0, between the stainless steel ball of 1.5mm.

1. device that is used for the automobile tire mould making Nano surface, comprise electric cabinet (1), step (10), bullet, spray gun (2) connects spray gun and waves reductor (9), 36 bag-type dust casees (3) connect high pressure positive blower (4), one end of sweep-up pipe (5) connects pneumatic separator (6), the other end of sweep-up pipe (5) connects the container under the rotating disk rotation deceleration (11), promote reductor (7) and connect elevator (8), rotating disk rotation deceleration (11) connects rotating disk mechanism (12), it is characterized in that: above-mentioned spray gun (2) connects an end (14) of pressurized canister, pressurized canister (14) other end connects transfers sand valve (15), spray gun (2) to be positioned at rotating disk mechanism (12) top, and vibratory sieve mechanism (13) is positioned at the below of pneumatic separator (6) and interconnects.

2. the automobile tire mould making Nano surface device that is used for according to claim 1 is characterized in that: above-mentioned spray gun (2) ± 45 ° swing.

3. the automobile tire mould making Nano surface device that is used for according to claim 1 is characterized in that: used bullet is that diameter is the stainless steel ball of 0.5mm~1.5mm.

With the help of abrasive media like copper slag, aluminium oxide, glass dabs, quartz sand, and so on, a Sand Blasting Machine may remove rust, corrosion, and debasement from the surface of a metal object. Silica sand, used as a grating in the sandblasting process, is typically used by the manufacturers of sandblasting machines. The metal’s outside is also designed and cleaned with a sandblasting machine.

You can abrade, clean, or change the surface of a part with the help of sandblasting equipment, which consists of systems or machinery and components for projecting blast media against the surface. Blast media, including sand, abrasive, metal shot, and others, are propelled or driven by pressure, compressed air, or a blast wheel.

When preparing a surface with a sandblaster, a great deal of dust is produced. Contractors that specialise in the industrial painting may be subjected to various air contaminants because of the nature of the blasting media employed, the types of coatings being removed, and the materials being abraded from the blasted surfaces.

Barium, tributyltin, cadmium, copper, zinc, chromium, iron, nickel, aluminium, crystalline silica, cobalt, beryllium, amorphous silica, lead, manganese, and arsenic are only some examples. The dust produced during sandblasting can impair sight and cause the floors to become slick, creating unsafe working conditions and being harmful to health when PPE is inadequately applied.

The sandblasting procedure poses a significant health risk in regions without proper ventilation due to the dust produced. When operating with sandblasting equipment, operators may need to shut it down to clear the region of dense clouds of dust that tend to gather nearby and impede the view. Therefore, properly built and maintained ventilation systems are crucial for worker health and productivity.

Working in poorly ventilated spaces increases the risk of eye damage from Sand Blasting Machine. Before beginning work, sandblasting tests should be performed to establish the degree of eyesight impairment from dust generation and address potential reasons.

Sandblasting is an extremely noisy process regardless of the machinery employed. Noise levels should be assessed and compared with the hearing damage criterion to get an accurate idea of the volume to which the operators will be subjected. Workers are entitled to receive hearing protection appropriate for their noise exposure.

The wet Sand Blasting Machine is a self-contained device that cleans, descales, and degreases surfaces with a slurry of Abrasive Media and water. The slurry is pumped through a high-pressure pump that propels the abrasive material to a cannon by controlled air pressure. The system is closed-loop and dust-free. For extra protection of sensitive parts, water can be added as a buffer catalyst between the metal and the medium.

The suction sand blasting machine is the most popular type of blasting equipment in use today. This sand blasting machine has two hoses linked to its cabinet; one delivers compressed air, and the other vacuums abrasive into the section gun. On the other hand, pressure-blast nozzles feature a single, giant hose for providing a composite media particle mix during sandblasting.

This air-operated pressure sandblasting equipment is a member of the surface pressure blaster family and is best used in moderate-output settings. High-velocity air current drives the abrasive stream, which erodes the parts. The parts need to be positioned so that they are directly under the blasting Stream. More significant parts can be stored on the blast cabinet’s floor or rotated using a rotary table. Air operation necessitates that this machine is operated by hand. The component of this apparatus is installed inside the housing unit.

The toughest sandblasting media currently on the market is silicon carbide. Since it’s so challenging, you’ll save time compared to other methods. When polishing tough rocks like granite, the range of sizes available for silicon carbide, from coarse grit to fine powder, is ideal.

We offer the best machine to solve the problem of organising a comprehensive surface cleaning. At Surface International, we have Shot Blasting machineandSand Blasting Machinethat is both powerful and simple to use. Request a free quote, as we are leading Sand Blasting Machine Manufacturers and Suppliers in India.

8613371530291

8613371530291