asme safety valve testing requirements pricelist

Is on a fixed pricing model based on a predefined Class structure. The Class type, six in total, is determined by the number of employees at the location covered under the QPS Quality Program. Depending on the complexity of the program and organizational structure, an Additional Resource fee may be applied. The Additional Resource fee, when applied, is discussed with the applicant when an application has been submitted. The fixed price is established when the application has been accepted by ASME. The fixed price includes the price of the Certificate, Auditor Activities and Expenses to initiate and complete a Survey (Stage I and Stage II), and, when applied, the Additional Resource.

Is on a fixed pricing model based on a predefined Class structure for companies that have obtained a QPS Certificate and are seeking to maintain the certification status of its QPS quality program as an active ASME recognized program. The Class type, six in total, is determined by the number of employees at the location covered under the QPS Quality Program. Depending on the complexity of the program, organizational structure, results of past assessments, an Additional Resource fee may be applied. The fixed price is established 5 months in advance of the annual audit. The fixed price is an all-inclusive price which includes the activities to initiate and complete the audit, the expenses of the auditor, and when applied, the Additional Resource.

1. Includes price of the certificate and all conformity assessment activities and services provided by ASME and its auditors to initiate and complete a survey. Price will differ when an Additional Resource is added or a re-survey is required.

2. Includes price of all conformity assessment activities and services provided by ASME and its auditors to initiate and complete an audit. Price will differ when an Additional Resource is added or a re-audit is required.

Possibly the most important single safety device on a boiler or pressure vessel, the pressure relief device (PRD) is all that stands between overpressure conditions and catastrophic explosions. This comprehensive review of the design, construction, installation, operation, inspection and maintenance of pressure relieving devices currently in use on boilers and pressure vessels details how to protect pressurized equipment from exceeding the maximum allowable working pressure.

This course is designed for engineers of all levels from early career engineers to experienced engineers. It is an essential resource for mechanical engineers, and design engineers; process engineers, and chemical engineers; reliability engineers, and maintenance engineers; inspectors, and testing engineers; as well as plant supervisors, and managers.

ThisASME Virtual Classroom course is held live with an instructor on our online learning platform. Certificate of completion will be issued to registrants who successfully attend and complete the course.

Kingston Valves perform reliably under even the harshest conditions. For over 100 years, Kingston Relief Valves and Kingston Check Valves have provided proven solutions for critical process control applications. Trust Kingston Valves.NOTE: There is a $150 minimum order requirement for Kingston Valve products. All Kingston Valves may be mixed and matched to achieve the minimum requirement.

Riggio Valve Services technology enables safe and economical in-place safety relief valve testing during normal operations with no operational interruption. Yearly re-certification may be achieved without the need for valve removal provided specific prerequisites and qualifications meet code requirements. Test procedures, measurements and analysis facilitate:

Riggio is authorized by the National Board of Boiler and Pressure Vessel Inspectors. The procedure is recognized by ASME and can be found in Interpretations I-83-31 and VIII –1-83-350. It is also covered in ASME Section I PG-72.2

ASME section VIII “UV” stamp | PED “CE” mark | DOT, API | Marine IGC, ABS, BV, DNV-GL, LR | ISO 9001:2015 | Canadian CRN Approval (all provinces/territories)

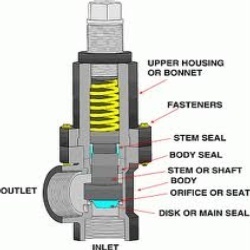

Safety valves or pressure relief valves are pressure regulating devices that are responsible for expelling excess pressure from the system when the maximum pressure levels for which they have been designed are exceeded, usually due to a

Safety valves perform their function when the pressure of the system where the fluid is contained, becomes higher than the maximum set pressure of the valve previously adjusted. When the system pressure is higher than the valve’s set

pressure, this opens, releasing the excess pressure to the atmosphere or to containment tanks, depending on the toxicity of the fluid. After releasing the excess, the valve closes again and the system pressure returns to normal.

To ensure total safety of personnel and installation, make sure that the valves have passed all safety tests and meet the requirements of the system where they are to be installed. All our valves are supplied with certificates of materials, cas-

What is the difference between the instantaneous full opening safety valve AIT (PSV) and the normal opening relief valve AN or progressive opening relief valve AP (PRV)?

The Pressure Safety Valve (PSV) opens instantaneously and fully upon reaching the set pressure for which it is designed, expelling the excess pressure from the system immediately. They are optimised for use with steam or gases.

In contrast, the normally or progressively opening Pressure Relief Valve (PRV) opens gradually as the system pressure rises above the set pressure of the valve above its setting. They are optimised to work with liquids.

At VYC Industrial we are specialists in the design and manufacture of all types of safety valves. We have a wide range of safety valves to cover all the needs of the sector.

The Mod. 496 EN safety valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The Mod. 495 EN pressure relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

They are used in places such as power, chemical and petrochemical plants to discharge safety valves, control valves, etc. in pressure lines and equipment that convey compressible substances such as steam, air, carbon dioxide, helium, methane, nitrogen, oxygen and other gases.

Test bench for regular inspections and setting and resetting safety valves. Ideal for distributors, maintenance companies or with in-house maintenance. It allows safety valves to be adjusted, tested and/or checked to the test pressure (setting) Pe wile cold (simulating service conditions), matching the opening pressure Ps and the closing pressure Pc, in accordance with the standard regulations.

Controlled safety pressure relief system CSPRS valves are mainly used where conventional direct-loaded spring action valves cannot guarantee the opening and closing margins that certain specifi c conditions of service demand.

The objective is to help the closure by means of pressure so that the valve remains completely watertight until reaching the set pressure and/or to activate the opening with pressure.

Increase the operating pressure of the system up to 99.9% of the set pressure.The control safety pressure relief system CSPRS device can be used with any safety valve available in the market and in particular, with models VYC Mod. 485, 486, 494, 495 and 496.

Relief valves are designed to open at a preset pressure (or temperature) level and relieve the system when it has exceeded the desired level. The valve"s relief of elevated liquid, gas, or steam pressures prevents damage to the system. We offer a wide selection of relief valves for any application.

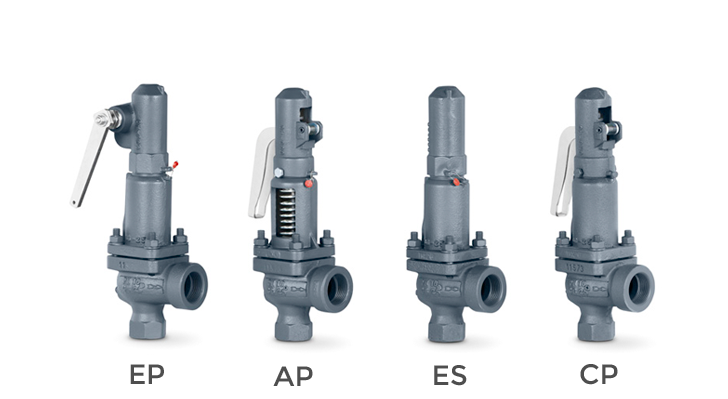

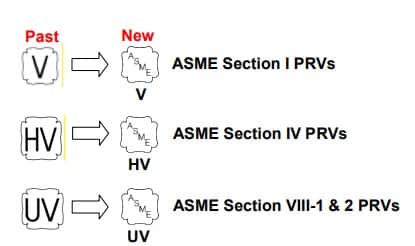

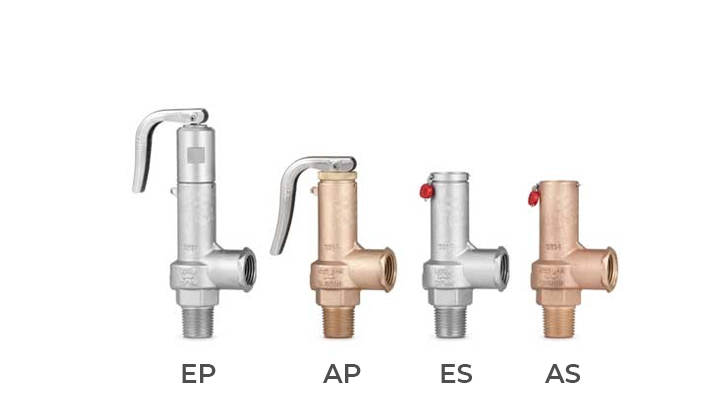

ASME safety valves are used across several applications including low-pressure and high-pressure boilers, process equipment, and air, gas, and vapor equipment. We have multiple products in a range of configurations and material construction that meet ASME Class I, IV, and VIII.

The National Board’s goal is to maintain the integrity of the National Board marks and symbols (NB,VR, andT/O) and the ASME Certification mark with V ,UV, UD, HV, and NV designators. By doing so, we make it possible for National Board members to rely on the presence of these marks in their efforts to protect the general public.

The National Board offers the Certificate of Authorization and VR Stamp for the repair of pressure relief valves. Requirements are included in the current mandatory edition of the National Board Inspection Code(NBIC), Part 4, and NB-514, Accreditation of VR Repair Organizations.

The National Board offers the Certificate of Authorization for use of the T/O mark which indicates accreditation as a pressure relief valve Testing Organization. The program includes provisions for minor adjustments to restore valve performance. Requirements are based upon the current mandatory edition of the National Board Inspection Code(NBIC), Part 2, Part 4, and NB-528, Accreditation of T/O Test Only Organizations.

Representatives from the National Board are assigned to visit company sites to select production sample valves for testing at National Board- and ASME- accepted labs.

Leader Valves Limited is a leading valve manufacturing company of India. We are a totally integrated valves manufacturing unit. The company was set- up seven decades ago when India was on the threshold of industrial

revolution and there were no good valve manufacturers in the country. It has over the years built up an excellent track record by following the policy of customer satisfaction through continual improvement in Designs,

8613371530291

8613371530291