safety valve plans in stock

Avoid the headache, hassle and costly repair bills caused by a water or sewer emergency on your property, or an in-home plumbing problem. A single call to Safety Valve takes care of it all.

New to Safety Valve? Enter your address below to check eligibility. Already a customer? Log in to manage your account. You must register first if you haven"t done so.

1-800-223-7019. Work must be done by a Safety Valve referred contractor to be covered sodo NOT call a contractor directly or your claim will not be covered.

To start a claim you must call Safety Valve directly at 1-800-713-1613. Work must be done by a Safety Valve referred contractor to be covered so do NOT call a contractor directly or your claim will not be covered.

All leaking internal clean water pipes (hot or cold), fittings and valves from the point the supply enters the house up to and including the shut-off valve before each fixture

The curb box allows access to the curb valve, and the curb valve is the valve located on your property that can be used to shut off the water in the event of an emergency water line leak.

The Water Line Protection Plan covers from where your water service line connects to your main water valve in your basement to the curb valve located on your property. In some instances, you may also own and be responsible for the water line in the street, which runs from your curb valve on your property to the water main in the street. (We suggest you contact your local water utility for clarification.)

No, the main shut-off valve in your home is not covered under the Water Line Protection Plan. It is the point where the water service line coming into your home ends. We consider the main valve as part of your internal plumbing. If you would like coverage for the main shut-off valve, please review our In-Home Plumbing Protection Plan.

All plans take effect 30 days after the enrollment is processed and payment received, regardless of whether you pay by check, bank account or with a credit card. In some cases, we may need to perform an on-site inspection, so we provide customers with a 30-day window to account for this possibility.

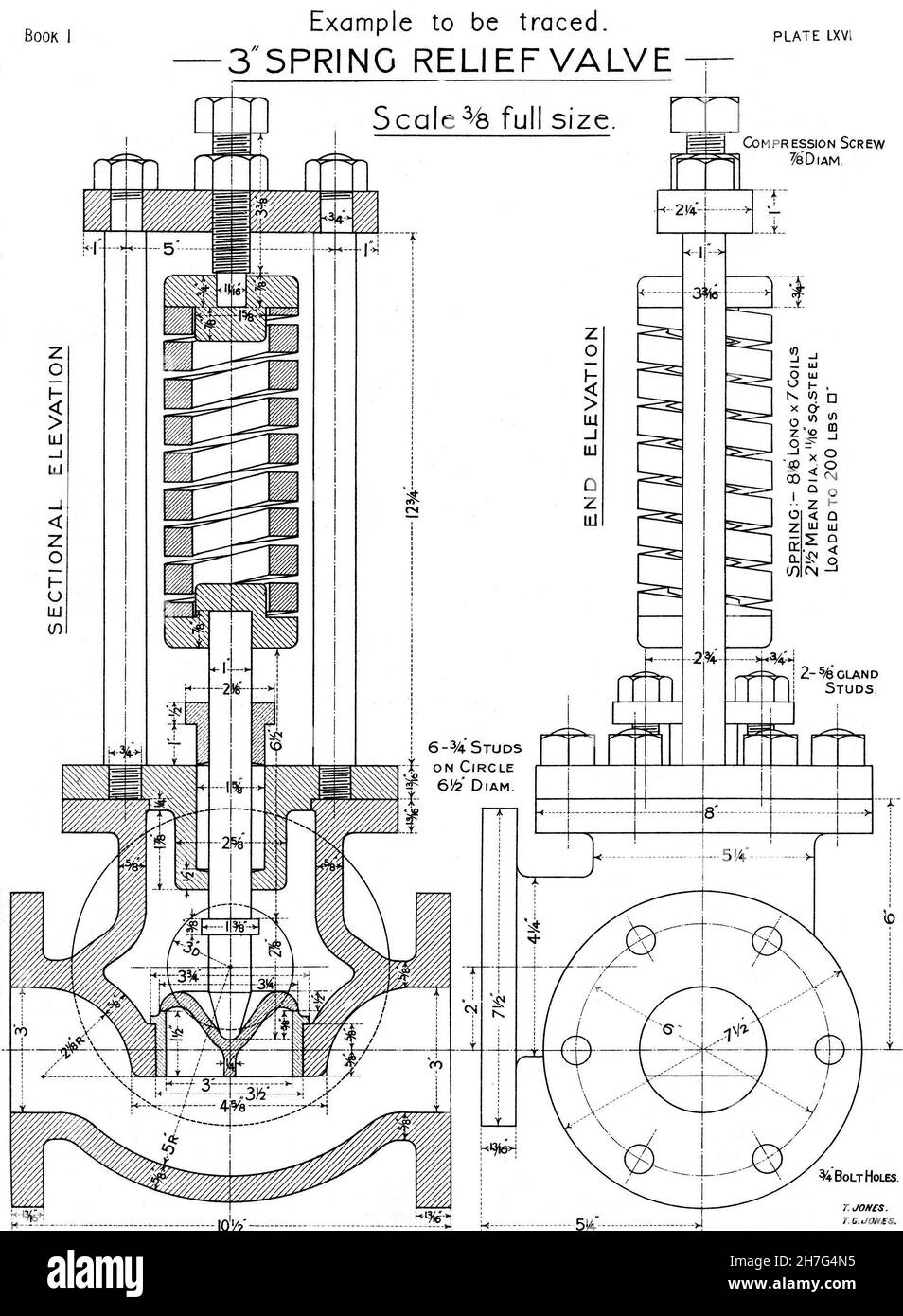

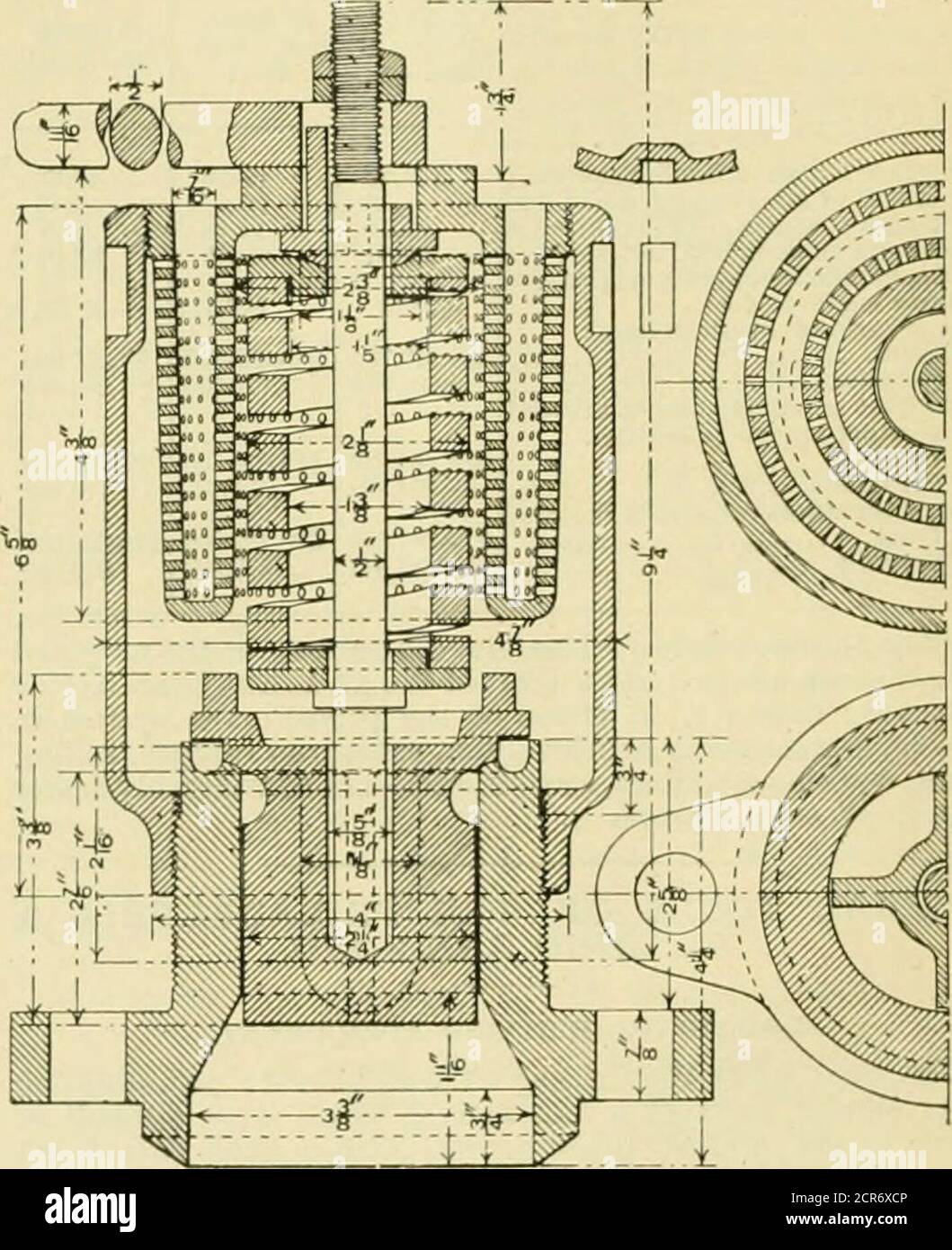

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

With our partner specifications archives, six on-site lathes, technical know-how and 35,000 in-stock valves, we’ve got your valve repairs covered. Valves are quickly repaired and set following exact specifications, and if they’re irreparable, chances are we’ve got a replacement in stock.

A pressure safety valve actuated by inlet static pressure and characterized by rapid opening or rapid popping action. This safety valve is tight shut-off and is for safety only. Meets ASME SEC. VIII (Not a Fulflo valve)

A spring loaded pressure relief valve, actuated by the static pressure upstream of the valve. The valve opens normally in proportion to the increase in pressure over the set pressure. (Fulflo)

A pressure relief valve characterized by rapid opening or pop-action in direct proportion to the pressure increase, depending on the application. (Fulflo)

The pressure existing at the outlet of a pressure relief valve, due to the pressure in the discharge system. The pressure can be constant or variable. It is the sum of the superimposed and build-up pressure.

Fulflo was established in 1912 and is celebrating its 100th anniversary. Located in Blanchester, OH, Fulflo was incorporated in 1933 under its present name and trademark. Patents for the original guided piston, direct acting relief valve were obtained in 1935, coinciding with the onset of fluid power systems. The need for providing large flows without excessive bulk was met by the pilot-valve-control relief valve which was patented in 1943.

Fulflo parts and valves are used in oil and gas refineries, are essential to the military, including ships and aircraft carriers, and amusement roller coaster rides.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

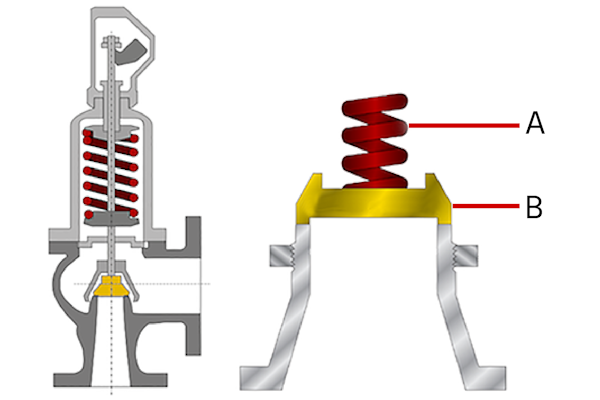

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Dante Valve is a full-service manufacturer, distributor and VR™ certified repair facility of valves and related products for the industrial and military markets.

We manufacture military specification Danco pressure relief valves; we distribute Kunkle relief valves and TRAC regulating, reducing, and temperature regulating valves, fittings and flanges; we also provide CNC machining services.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

Industrial valves comprise many products that manage the flow of gases and fluids in industrial applications. Among these, pressure safety valves are designed for process control, process safety, original equipment manufacturer (OEM) applications, and others across several end-user industries.Report OverviewDue to the COVID-19 pandemic and Russia-Ukraine War Influence, the global market for Pressure Safety Valve estimated at USD 42 million in the year 2022, is projected to reach a revised size of USD 53 million by 2028, growing at a CAGR of 4.1% during the forecast period 2022-2028.These valves prevent the over-pressurization of pressure-based equipment and machineries by sensing and subsequently guiding the additional surge in pressure towards alternate passages or into atmosphere. As a result, they are used in steam boilers, heating boilers, pressure-based vessels and systems, OEM applications, industrial machineries, and other applications. The valve design and construction are varied to have a manual or automatically-operated opening and closing of valves at working settings during the system operation.Report ScopeThis latest report researches the industry structure, capacity, production, sales (consumption), revenue, price and gross margin. Major producers" production locations, market shares, industry ranking and profiles are presented. The primary and secondary research is done in order to access up-to-date government regulations, market information and industry data. Data were collected from the Pressure Safety Valve manufacturers, distributors, end users, industry associations, governments" industry bureaus, industry publications, industry experts, third party database, and our in-house databases.This report also includes a discussion of the major players across each regional Pressure Safety Valve market. Further, it explains the major drivers and regional dynamics of the global Pressure Safety Valve market and current trends within the industry.

As well as providing an overview of successful marketing strategies, market contributions, and recent developments of leading companies, the report also offers a dashboard overview of leading companies" past and present performance. Several methodologies and analyses are used in the research report to provide in-depth and accurate information about the Pressure Safety Valve Market.

The current market dossier provides market growth potential, opportunities, drivers, industry-specific challenges and risks market share along with the growth rate of the global Pressure Safety Valve market. The report also covers monetary and exchange fluctuations, import-export trade, and global market

For centuries, safety relief valves have served as a vital line of protection against excessive overpressure that – left unaddressed – can cause considerable damage to industrial processes including equipment failure and process upset, along with secondary hazards arising from an uncontrolled release of pressurized fluid.

These essential safety devices are designed to automatically open when the force exerted by the pressure reaches a setpoint to rapidly discharge the fluids. Once the overpressurization has dissipated, the valve recloses, conserving the remaining fluid.

In developing codes and standards, the industry has largely standardized around the 90-degree flow path design outlined by the American Petroleum Institute (API). This standardized approach requires a drop in pressure inside the valve before it discharges fluid from the exit nozzle.

To ensure proper performance, the orifice diameter at the inlet side is smaller than the nominal valve size, with an outlet diameter that is larger than both. A two by three-inch traditional API configuration safety relief valve will be designed with either a 0.785” diameter H orifice or a 1.287” diameter J orifice at its inlet and a three-inch outlet, for example.

While it may be convenient for the purposes of standardization, other approaches to safety relief valve design are possible while meeting industry codes and standards such as those published by The American Society Of Mechanical Engineers (ASME), said Geof Brazier, Managing Director, BS&B Safety Systems, Custom Engineered Products Division.

So, BS&B had a novel idea: what if the safety relief valve was an inline device, with outlet and inlet connections that were the same size and an inlet orifice diameter to match the inlet connection?

“With an inline design, the flow moves in a straight line and doesn’t have to change direction,” said Brazier. “The design allows for a certain amount of flow expansion, but we don’t have nearly the same level of turbulence inside the valve, which increases the capacity of the device,” said Brazier.

By having the inlet diameter match the nominal size of the valve, there is more flow [capacity]. The valve can also be more compact, lighter in weight and requires smaller size and therefore less expensive piping. The result is simplified installation and a lower total cost of investment.

To address the need for increased flow, BS&B has introduced the IDV Safety Valve, a self-reclosing safety pressure relief valve that functions the same as a traditional safety relief valve but with an inline configuration rather than the traditional angle body configuration.

The inline configuration allows for up to 3 times the capacity of a conventional valve. The smaller the nominal size, the greater the capacity benefit from the IDV Safety Valve.

This new technology enables customers to achieve the same overall outcome as a traditional valve. The increased capacity allows engineers and operators to optimize their pressure safety systems and, in many applications, reduce the piping configuration (line size) by one or more nominal sizes.

The IDV Safety Valve is compact and lightweight and can be installed using ANSI/ASME B 16.5 and international flange connections. Mounting can be either horizontal or vertical, adding to the flexibility of application for this design.

The valve can be combined with an optional integrated rupture disk at the inlet and/or outlet. The combination of a rupture disk device with a safety relief valve has many benefits arising from valve isolation to the normal process conditions including optimal leak tightness, increased operating pressure, extended valve life and reduced valve maintenance.

The IDV has already been installed in over 10,000 processes worldwide, making it an established alternative to the safety relief valve that meets the same codes and standards.

Building Quality Mixing Valves is what we do at Leonard. At the same time we offer the industries best Service. It starts with the Best Engineers, followed by the most technically knowledgeable Regional Sales Managers, topped off with the industries best Specification Reps. Our team of experts are easily accessible and have decades of market experience and knowledge on Mixing Valves and Mixing Valve Systems. Learn More

Every building is different and all manufacturers of mixing valves pipe recirculation uniquely. We have a video to help explain the basic design of a tempered recirculation system with a Master Mixer. This video will help the plumbing professional select the proper piping method for the job. Learn More

American Society of Sanitary Engineers publishes product standards of safety for plumbing systems.There are 5 major standards for mixing hot and cold water. Four of these standards are mentioned specifically in both the IPC and UPC Plumbing codes as well as the four states that use their own codes (California, Illinois, Wisconsin, and New Jersey).Commercial building require ASSE certified valves. Click below to understand how and when to use these valves. As always, you may contact a Leonard Sales/Engineering Specialist for assistance. Learn More

Our expert team of sales engineers can help you with all stages of your project — valve design & selection, plumbing & building code and specification assistance. Some of our professional installs are shown here. View Installs

8613371530291

8613371530291