leser safety valve brands

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

LESER China offers technical advice and customer support for safety valves in China directly from the manufacturer. The wholly-owned subsidiary covers all areas of a safety valve manufacturer with production (machining, assembly, storage and inspection), order processing, logistics, safety valve consulting, project management, after-sales service and marketing.

LESER sales offices in Tianjin, Beijing and Shanghai as well as sales service in Shenzhen, Xi"an and Wuhan ensure regional customer proximity. LESER partner Sinobright Pesch serves major customers and the province of Xinjiang.

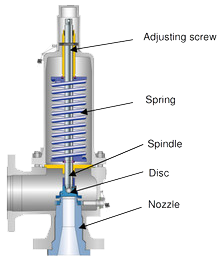

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

With 11.000 kilometers from north to south and 18 countries, the Spanish speaking Latin America is one of the biggest economical regions of the world. Since 2004, LESER build-up a sales and service partner network in this extensive region. Today, LESER is represented in all industries 20 sales and service partners supported by four nativespeaking Sales Market Developers and around. With this network LESER provides local support with technical consulting and short delivery times to the market.

In addition to the small installation space of the above-mentioned compressors, they should be completely covered by an acoustic enclosure to reduce noise emissions. In order to reduce the size of the very cost-intensive sound enclosure, AERZEN requires special valves that are adapted to the available small installation space. Compressors are discontinuous machines for pressure generation.

In order to ensure that occurring pulsations do not impair the function of the safety valve, the set pressure of the valve is adjusted accordingly and an appropriate distance to the pressure line is ensured by design.

The LESER solutionAs a renowned manufacturer of safety valves, it is advantageous to be able to react flexibly to the above-mentioned concerns, primarily to the small installation space, with its portfolio. Being able to change the installation position of safety valves is a clear advantage for the compressor designer. They are much more variable in their design and construction options and can also respond more flexibly to special customer specifications. If the progressive modularization of compressors requires more compact designs, safety valves in different mounting positions, for example, can be an answer to the problem, unlike the classic upright position. In addition, the spindle guide plays a special role here. The friction at the guiding points must be reduced as much as possible so that the spindle runs smoothly. Otherwise, a safety valve can only be installed vertically.

Why LESER safety valves?For a global acting OEM like AERZEN, a specialist like LESER, who has not only the knowledge but also the necessary approvals, is an important component for success. LESER offers a global approval concept that allows safety valves to be used regardless of location. When ordering safety valves, only the applicable regulations must be specified in order to ensure appropriate labeling and material selection. In addition, LESER has tested and approved further installation positions in addition to the conventional installation situation, standing on the inlet pipeline. For example, some types of valves may be installed with a horizontal stem or even upside down, e.g. Types 526 and 441. For horizontal installation, care must be taken to align the outlet. Liquids, e.g. in the form of condensate, should be able to drain off downwards to avoid back pressures and even corrosion. When installed upside down, the inverted weight forces are corrected by correction factors. LESER offers not only safety valves with basic documentation and accessories but also other special documentation and options. From the “Fugitive Emission Test” with helium up to 3.2 ship class castings and from back pressures up to more than 200 bar-g to high pressure heating jackets for up to 30 bar-g, LESER sales engineers develop solutions for customer specific applications as described above for AERZEN.

LESER safety valves are used by leading petrochemical, industrial gas, machine building, oil and gas production, chemical, food and pharmaceutical companies. LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements. The LESER product range offers the right product for almost every application.

LESER safety valves are developed and manufactured in Germany. The LESER product range offers the right product for almost every application. Multiple options and special materials complete the range as a well as client-specific solutions.

Attractive Pricing - As the largest safety relief valve manufacturer in Europe (and #3 worldwide), LESER has the ability to produce high-quality products in a cost-efficient manner through large batch sizes and full automation of production; this allows LESER to pass on cost savings to the customer.

LESER Authorized Repair Centre (LARC) Network - More than 30 LARCs in North America provide the end-user with access to authorized, reliable, and convenient local support for the repair of their installed base.

With almost 200 years of history, LESER has manufactured its safety valves to reflect state-of-the-art design and developed a product range to provide solutions for all sectors of industry. Customer satisfaction is the impetus behind LESER’s progress. LESER defines its products based on 7 pillars of achievement; rapid availability, product range, global network, quality, reliability, price and sustainability.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

LESER uses modern technologies to manufacture safety valves precisely and in high quality. Their safety valves are produced at the Hohenwestedt plant, which is, with a capacity of 130,000 valves per year, the largest production site for safety valves in Europe. In addition, LESER manufactures in Paithan/India and Tianjin/China for the respective local markets.

Prefabrication and assembly are largely carried out on automated production lines. Through this process, LESER ensures the consistently high quality standard of the products, regardless of whether it is a series component or an individual production of your choice.

Project: Gas mixing panel Gas: Oxygen Pressure Safety Valve Size: G3/8” or ½” + Material: Brass or Equivalent suitable oxygen service + Set pressure: 170 bar + Working pressure: 150 bar + Q’ty: 1 Pc - Document request: + Detail drawing with a material component + Certification oxygen cleaned + Certificate type approval for Oxygen

W&O, a global supplier to the marine and upstream oil and gas markets for pipe, valves and fittings, valve automation, and engineered solutions, has partnered with LESER in an exclusive distribution agreement to bring its safety relief valves to the United States maritime industry. This marks W&O’s first exclusive distribution agreement with a direct original equipment manufacturer of safety relief valves in the company’s 40-year history.

“W&O is excited to announce this partnership with LESER, and to do so at one of the industry’s marquee events, the International WorkBoat Show”, said Michael Hume, president and CEO of W&O. “The LESER safety relief valves are German-engineered and manufactured, and will be an excellent addition to the tank venting solutions we currently bring to our customers. This partnership is a natural fit for W&O, as LESER is equally committed to meeting customer needs, providing the highest quality product and engineering solutions to fit specific applications.”

The W&O and LESER partnership will prove very beneficial to customers for numerous reasons, including: short delivery times due to high stock of raw material and finished goods at the Charlotte, North Carolina, LESER facility, a variety of solutions from eight product groups and 40 safety relief valve types, and customer support offered by both companies.

The Leser Flanged Safety Relied Valve Series in accordance to API 526 are designed to meet all applications which require API. These valves open rapidly with an overpressure of max. 10% to full design lift and have a maximum blowdown of 7% for steam/gas service and 20% for liquid service. Service for protection of processes and equipment.

8613371530291

8613371530291