leser safety valve free sample

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

The primary purpose of a pressure relief valve is to protect life, property and the environment. Pressure relief valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of pressure relief valves differs depending on the main type or loading principle of the valve. The main types of pressure relief valves are spring-loaded, weight-loaded and controlled pressure relief valves.

Regardless of the type or load, pressure relief valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Certificates indicate the quality of the material used and the tests a safety valve has undergone during the production process at LESER. You can download the safety valve certificates that you have ordered from LESER for your valve at any time. This gives you full access to your documentation regardless of where your safety valve is installed.

Enter the combination of your customer number and the order number (LESER job number) and you will receive all the certificates from a complete order.

Safety valves from the API product group meet all the requirements of API 526 such as standardized capacity, nominal diameter, and center to face dimensions which offers 100% compatibility. Because of their robust construction, they are especially suitable for being constructed from special materials such as Duplex, Monel, and Hastelloy.

API 526 is a purchase specification in which the nominal diameters, flange pressure ratings, center to face dimensions, flow areas, body and spring materials and their service limits are stipulated for "API safety valves" API safety valves are used worldwide in the petrochemical industry, both on- and off-shore. These applications are characterised by standardised plants, blow-down systems and long pipework sections. The LESER type 526 combines the requirements of the API standards and the ASME Code with the tried and tested service reliability of the LESER range.

Safety valves from the Clean Service product group were specially developed for the food, beverage, and pharmaceutical industries and meet all the relevant standards and regulations such as DIN 11866 or ASME BPE. With a low deadspace inlet area, the unique LESER HyTight assembly, and the optional pneumatic lifting device you have very good cleanability (CIP, SIP). With a large selection of aseptic connections (threaded, flanged, or clamped) the valve can be optimally fitted to different requirements.

The safety valves of the 48x series can be fitted with manually lockable lifting devices H4 to hold open at a small lift, and with pneumatic lifting devices H8 for automated systems (CIP process).

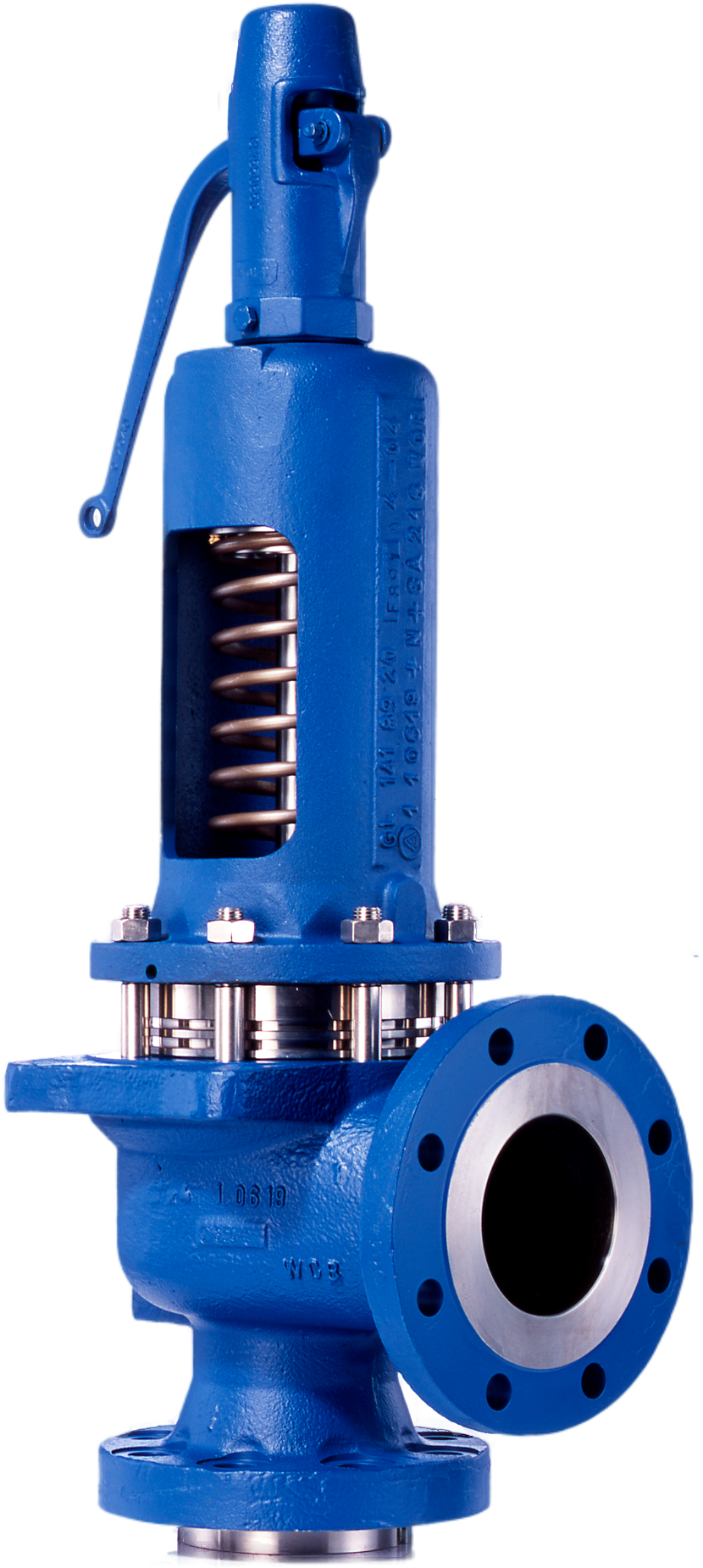

Safety valves from the High Performance product group offer especially high capacity for their size. With a large quantity of nominal diameters (DN), pressure ranges and product options, they have proven themselves as a universal safety valve for many applications.

Full Flanged Safety Valves with Flanged Connections open rapidly to the full design lift.They are used in particular for vapours and gases, in applications where the maximum mass flow has to be discharged rapidly. LESER type 441 is suitable for almost any industrial application, and are worldwide one of the best selling spring-loaded flange type safety valves.

Type 441 ANSI: Cast steel construction with ANSI flanges. Two body materials: stainless steel and cast steel. Center to face length in accordance with API 526, greater discharge capacity than standard API valves.

PTFE-lined safety valves from the Critical Service product group are utilized for highly corrosive media such as chlorine, acids, and lyes. With their highly resistant lining they offer a safe solution for corrosive media.

The product group Compact Performance includes threaded and flanged safety valves with compact dimensions for economical protection of small and midsized capacites. Due to its many orifice diameters, seals, and connections this product group offers a very wide area of application.

Type 437:Safety relief valve spring loaded for small mass flows (e.g. thermal expansion and overflow). Body material: stainless steel, 430 chrome steel.

Type 459/462Full lift safety valve spring loaded for the medium mass flow range (e.g. small scale or pilot plant). Two body materials: stainless steel or steel.

Change-over valves from the Best Availability product group increase plant availability.Change-over Valves are used when a plant shutdown is impossible or undesirable for process engineering or commercial reasons. With change-over valves, it is possible to switch over between parallel safety valves without interrupting operation, so as, for example, to perform maintenance work. The design of the change-over valves ensures: low pressure losses on discharge flow (3% criterion) adequate open passage in any position during the change-over process stable operation of the downstream safety valves The combination of LESER change-over and safety valves has been comprehensively tested on full flow test labs.

Safety valves from the Modulate Action product group feature a standard or proportional opening characteristic. They minimize medium loss when opening and are used for protection from pressure peaks, thermal relief, and liquids.

Relief and Safety Relief Valves with Flanged Connections are ideal relief valves for medium mass flows. Their large proportional range leads to consistent functioning and relief of pressure peaks, particularly with liquids. Both proportional and safety relief valves are characterized by particularly stable operation.

LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide, backed by more than 200 years of tradition. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the API, PED and ASME VIII. Major companies in the oil and gas, petrochemical, chemical, energy, technical gases, LNG/LPG etc use LESER safety valves. LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME VIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

During the forecast period, the global safety valve market size is estimated to reach USD 13.2 Billion by 2030 and is expected to exhibit a significant growth rate of 9.20% CAGR.

Safety Valves are precautionary valves that automatically actuate when the preset safety valve pressure and temperature are exceeded. These safety valves can be used to protect the critical equipment from damage by controlling excess pressure without any electrical support. For protecting equipment from unsafe pressure these mainly operate at a predetermined pressure. Additionally, these valves protect the employees around the plants and the environment around them. Safety valves are used in various applications like pharmaceutical, construction, oil & gas industries which foster the growth of the market.

During the lockdown, the global safety valve market is negatively impacted. Not only the safety valve market but the whole world was also affected drastically by this pandemic. To control the prevalence of the coronavirus, the government has imposed stringent regulations like lockdowns, maintaining social distance, covering the face with masks, manufacturing industries shut down, and transportation bans.

Even though at the primary stage of the pandemic, the safety valve market has fallen. Developing the innovations in the safety valve system and growing awareness regarding the benefits of the safety valve market by the key players are increasing the growth of this market.

Growing demand for safety valves in the oil & gas industry, the rise in nuclear energy generation, the growing importance of safety valves in industrial processes are the major driving factors of this market. The continuous need for safety valve replacement and the use of 3D printers in manufacturing lines are boosting the growth of the market. The safety valve market is highly dependent on investments in manufacturing facilities.

Some of the numerous factors that drive the safety valve market are rising demand for water & power, pollution control regulations, and rapid growth of process industries are supposed to escalate the growth of the safety valve industry during the assessment period. Growth in the construction of nuclear power plants is fueling the growth of the market. The increase of accidental incidences and soaring demand for safety valves in several industrial sectors are increasing the growth of the global market.

The constant growth of oil & gas exploration in few parts across the globe is restraining the market. The fabrication of safety valves are very expensive which is hindering the market growth

To increase the growth of the safety valve market industry integration of safety valves into the Internet of Things (IoT) environment is creating the opportunity. The innovations in the safety valve systems are anticipated to increase the strong growth of the market.

To provide a strategic profile of the prominent key players in the market, analyze their core competencies, forecast statistics, and draw a global safety valve market growth landscape.

The global safety valve market based on material is sub-segmented into steel, alloy, cast iron, cryogenic, and others. As the steel safety valves are durable and don’t leak in hot or cold temperatures, the steel segment is expected to dominate the global market.

It is segmented into less than 1”, 1” to 10”, and 11” to 20”, and 20” & above. Among these, during the review period, the 1” to 10” segment is projected to grow at the significant CAGR for the safety valves market for the benefits behind this size range like controlling the flow and pressure of liquids, gases, and slurries within different end-use industries.

The global safety valve market industry is divided into oil & gas, energy & power, food & beverage, chemicals, water & wastewater treatment, and others. In the global safety market, the oil & gas segment is expected to hold the largest share, because the oil & gas industries are the most significant revenue-generating industries which need almost all types of valves like gate, globe, ball, check and butterfly. Some of the products include a safety valve air compressor, safety valve boiler, and safety valve heater.

Asia-Pacific, Europe, North America, the Middle East & Africa, and South America are the main geographies included in this market. Due to the rapid urbanization and growing industrialization Asia-Pacific holds the largest safety valve market share.

The global safety valve market region-wise is divided into Asia-Pacific, Europe, North America, and the Middle East & Africa. Out of these regions, Asia-Pacific holds the largest market share for its growing infrastructural developments, rise of investments in various industries like oil & gas, construction industry, and drastic urbanization. Growing demand from mining, chemical, and municipal industries is expected to propel market growth in this region.

Safety valves are used in the application of the construction industry to control liquid flow in firefighting systems, water supply systems, and piping systems. The rising construction industry propels the market growth in this region. North America is accounting as the second-largest market for its growing investments in the construction industry.

Naples, Italy, Baker Hughes launched a new steam test facility in November 2018, ASME Section I safety valves that serve better to the European aftermarket with a rapid response for steam applications. The future development of the current aftermarket is launched as the new aftermarket plant which is expanded by the product scope and capacity of the plant. To fulfill the range of Masoneilan control valves and consolidated safety valves ranging up to 2000 psi test pressure.

In October 2018, Emerson Electric Co. to help the LNG marine transportation consumers developed low-pressure pilot operated pressure relief valves (POPRVs) by reducing their size which helps to reduce the investments by 25% and protects the end-users from overpressure by offering them extra profit margin.

In May 2019, the Mexican government announced that it is going to construct a new refinery set in the Tobasco coast, Mexico in June 2019. Hence safety valves are used in refineries to control the pressure of liquids and gases in plants.

This global safety valve market research includes the Market Overview, COVID-19 analysis, Market Dynamics, Study Objectives, Segment Overview, Regional Analysis, Competitive Landscape, Recent developments, Segmentation Table, and FAQs. The market scenario includes the safety valve market drivers, restraints, challenges, and opportunities. The safety valve forecast segments are material, size, end-use, and region.

8613371530291

8613371530291