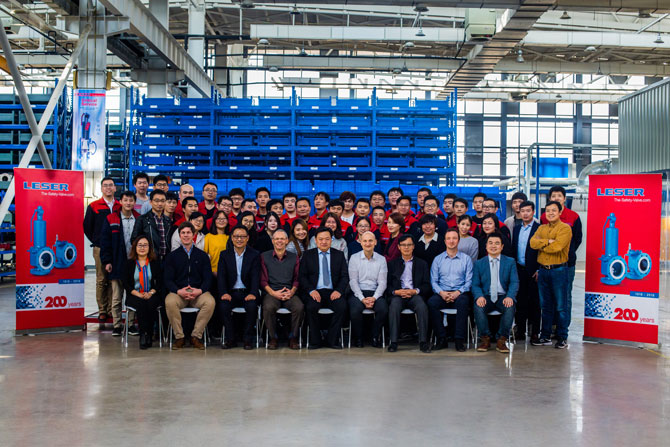

leser safety valve made in china

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

LESER China offers technical advice and customer support for safety valves in China directly from the manufacturer. The wholly-owned subsidiary covers all areas of a safety valve manufacturer with production (machining, assembly, storage and inspection), order processing, logistics, safety valve consulting, project management, after-sales service and marketing.

LESER sales offices in Tianjin, Beijing and Shanghai as well as sales service in Shenzhen, Xi"an and Wuhan ensure regional customer proximity. LESER partner Sinobright Pesch serves major customers and the province of Xinjiang.

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

With 11.000 kilometers from north to south and 18 countries, the Spanish speaking Latin America is one of the biggest economical regions of the world. Since 2004, LESER build-up a sales and service partner network in this extensive region. Today, LESER is represented in all industries 20 sales and service partners supported by four nativespeaking Sales Market Developers and around. With this network LESER provides local support with technical consulting and short delivery times to the market.

LESER safety valves are produced at the Hohenwestedt plant, which is, with a capacity of 130,000 valves per year, the largest production site for safety valves in Europe. In addition, LESER manufactures in Paithan/India and Tianjin/China for the respective local markets.

Prefabrication and assembly are largely carried out on automated production lines. Through this process, LESER ensures the consistently high quality standard of the products, regardless of whether it is a series component or an individual production of your choice.

LESER China in Tianjin produces locally for the Chinese market with the same quality as in Germany. The localised safety valves cover 90% of China"s industrial demand. LESER sales offices and partner network ensure regional customer proximity throughout China.

With almost 200 years of history, LESER has manufactured its safety valves to reflect state-of-the-art design and developed a product range to provide solutions for all sectors of industry. Customer satisfaction is the impetus behind LESER’s progress. LESER defines its products based on 7 pillars of achievement; rapid availability, product range, global network, quality, reliability, price and sustainability.

W&O, a global supplier to the marine and upstream oil and gas markets for pipe, valves and fittings, valve automation, and engineered solutions, has partnered with LESER in an exclusive distribution agreement to bring its safety relief valves to the United States maritime industry. This marks W&O’s first exclusive distribution agreement with a direct original equipment manufacturer of safety relief valves in the company’s 40-year history.

“W&O is excited to announce this partnership with LESER, and to do so at one of the industry’s marquee events, the International WorkBoat Show”, said Michael Hume, president and CEO of W&O. “The LESER safety relief valves are German-engineered and manufactured, and will be an excellent addition to the tank venting solutions we currently bring to our customers. This partnership is a natural fit for W&O, as LESER is equally committed to meeting customer needs, providing the highest quality product and engineering solutions to fit specific applications.”

The W&O and LESER partnership will prove very beneficial to customers for numerous reasons, including: short delivery times due to high stock of raw material and finished goods at the Charlotte, North Carolina, LESER facility, a variety of solutions from eight product groups and 40 safety relief valve types, and customer support offered by both companies.

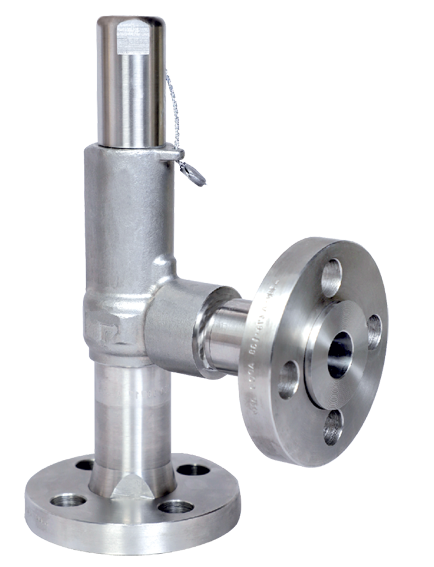

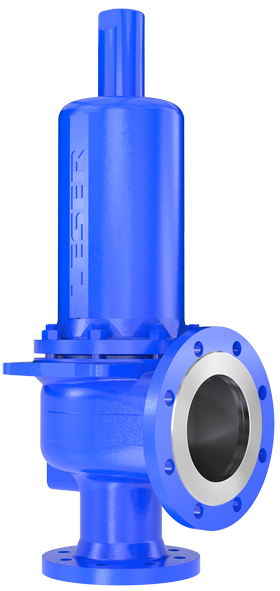

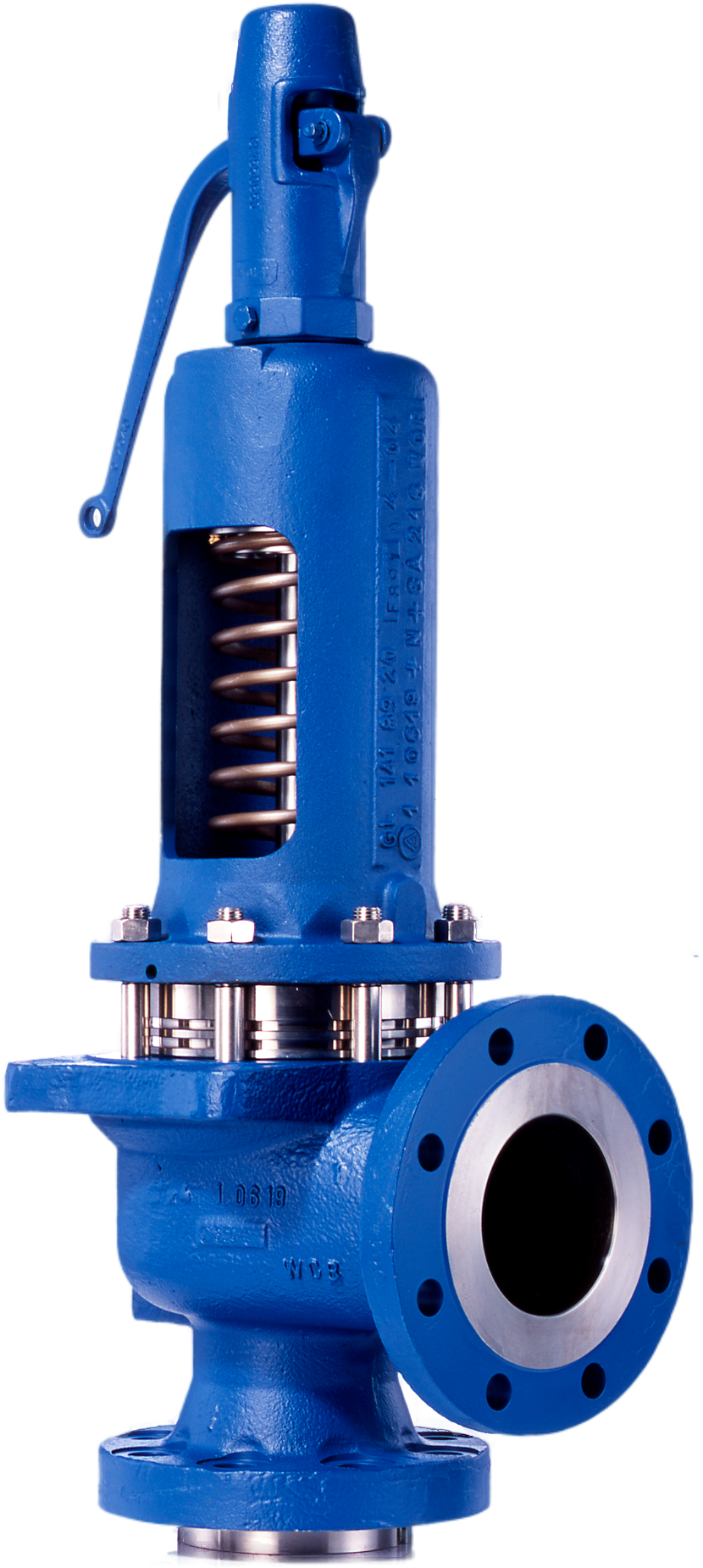

The Leser Flanged Safety Relied Valve Series in accordance to API 526 are designed to meet all applications which require API. These valves open rapidly with an overpressure of max. 10% to full design lift and have a maximum blowdown of 7% for steam/gas service and 20% for liquid service. Service for protection of processes and equipment.

LESER uses modern technologies to manufacture safety valves precisely and in high quality. Their safety valves are produced at the Hohenwestedt plant, which is, with a capacity of 130,000 valves per year, the largest production site for safety valves in Europe. In addition, LESER manufactures in Paithan/India and Tianjin/China for the respective local markets.

Prefabrication and assembly are largely carried out on automated production lines. Through this process, LESER ensures the consistently high quality standard of the products, regardless of whether it is a series component or an individual production of your choice.

In September, LESER – the largest manufacturer of safety valves in Europe, hosted the Experience Days at the LESER-Kontor in Hamburg as part of its 200th year of existence. With more than 300 participants from 55 nations, the conference was very international and well attended.

The global isolation and safety valve market is expected to grow at a significant pace by 2023. One of the important factors contributing to market growth is the tremendous rise in the oil & gas sector especially in Asia-Pacific countries such as India and China.

Rising trend for the use of customized isolation and safety valves in the market on account of as a lack of product differentiation has been leading to increasing competition among vendors. Thus, local as well as international vendors have been trying to differentiate every product through customized valves which are offered at reasonable prices to the customers. This trend will influence the growth of the industry significantly over the next years.

The focus the Experience Days was on a conference with lectures on current topics of overpressure protection. Under the headlines ‘Plant Safety & Digitalization’, ‘From Market to Product’ and ‘Safety Valve Technology’, topics were presented in three parallel lectures so that each participant could make the appropriate choice.

“This event is the meeting place for the world of overpressure protection,” says Christian Joachim Schult, Head of Marketing at LESER, when asked what the Experience Days are all about.

In the main series of lectures ‘Plant Safety & Digitalization’ speakers from Linde, BASF, an upstream valve consultant from Brazil and experts from LESER presented their experiences and points of view. The aim of this format was to give a holistic view of the overpressure protection and its process steps from engineering to production and application in the plant by the responsible parties themselves.

In the lecture series ‘From Market to Product’, LESER presented various topics around the market, the development and production of safety valves. Especially the talk about the upcoming changes in the ASME regulations ‘An outlook on ASME Sec. XIII’ and the presentation of the LESER production concept ‘Fast deliveries and integrated quality’ aroused the interest of the visitors.

More than 150 participants took advantage of the supplementary factory tour to gain a deeper insight into the modern production facility in Hohenwestedt. In the third lecture series ‘Safety Valve Technology’, LESER presented the current status of safety valve technology to between 30 and 40 interested participants in three sessions. During the entire conference, safety valves were shown in operation in the new LESER Chatroom and in the in-house test lab.

The closing event was a panel discussion on digitization between representatives of Linde, BASF and LESER. The question of what digitization means for the overpressure protection of process plants was discussed. An outlook was given on the changing environment not only for safety valves, but also for employees through digital transformation. It is about “to share the ideas and think about it, if we are on the right way,” commented Carsten Stubenrauch, Head of Plant Design at Linde AG.

Finally, a joint evening event was held with all participants of the Experience Days at the Museum for Hamburg History. The museum is connected to the 200-year existence of LESER by parts of the present stone façade, which were once part of the first LESER building in the ‘Neustädter Fuhlentwiete’ in Hamburg, which no longer exists today. On this occasion, Martin Leser, spokesman for the members, also welcomed the participants and said: “To become 200 years old is not an achievement, but it is an achievement to host the Experience Days” and thus to offer the participants this industry and process-spanning exchange opportunity.

With 950 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME VIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Eight subsidiaries in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

8613371530291

8613371530291