why is my propane tank leaking from safety valve pricelist

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

If the propane tank on your RV is leaking after a refill, then you have a serious problem on your hands. Of course, leaking propane can be extremely dangerous. So, why is your propane tank leaking after a refill?

The common reasons for a propane tank leaking are due to an open bleeder valve, an open relief valve, or a faulty valve system. We are also going to address the issue of a cracked propane tank. Although very unlikely, they can sometimes suffer serious physical damage.

Yes, absolutely is a leaking propane tank dangerous, and extremely so. Propane is flammable, which is why it is used for heating and cooking. If propane is leaking out of the tank, and it comes in contact with an open flame or spark, it’s going to cause a serious explosion.

It’s going to ignite the gas that is leaking out, and this flame will travel all the way back into the tank, and either just catch fire, or explode. There is also the fact that if it is in an enclosed space, inhaling propane is also very dangerous.

Although propane in itself is technically not toxic, it will displace the oxygen in the air. This means that if you breathe in too much propane, you won’t get enough oxygen, and can effectively suffocate to death.

One of the most common causes of a propane tank leaking after refilling is if the bleeder valve is open. Bleed valves are a special type of manually operated valve designed for bleeding liquids or gases out of a system.

It could also be the case that even if the bleeder valve is not open, the coil that it uses can be clogged with debris. This can then result in your propane tank leaking, specifically if the tank has too much propane in it. A good thing is that this is a very easy problem to solve.

The solution to a bleeder valve being open is simply to close it. All you have to do is to close the bleeder valve. You simply have to rotate the valve clockwise. Generally speaking, you are going to need to use a screwdriver, and you will need to turn the valve in a clockwise direction to close it.

The next reason why your propane tank might leak after a refill is if the relief valve is open. As the name implies, the relief valve is designed to help relieve pressure in the tank if there is too much of it.

Therefore, if it is hot outside, this relief valve may open up to allow pressure to get out of the tank. If the relief valve is slightly open, it will cause propane to leak out of the tank. Moreover, if the whole valve opens up, this can actually be quite dangerous.

the solution to a relief valve being open is actually quite simple, but you don’t actually want to touch the valve. This valve opens up all on its own in order to relieve pressure, and it should close on its own too.

If you tap or touch the valve in any way, or try to manipulate it, you may actually cause it to open up more, which is of course the opposite of what you are looking to achieve.

To solve this problem, you actually want to cool the tank down, which you can do by spraying it with some cool water or submerging it in a cold bath. This will relieve pressure on the tank and will cause the valve to close on its own.

However, if this does not work, then either this is not the issue or the relief valve is damaged to the point where you will just need to replace the propane tank.

The valve stem, or in other words the area where you connect the inlet tube to refill it with propane might be completely damaged or leaking. This is a huge problem because propane leaking out of the main stem can easily catch fire.

The solution to this issue is a little more complex because you will need to replace the entire tank valve stem system to prevent further damage and to prevent explosions from occurring.

Before you try to replace the valve, however, you need to ensure that the propane tank is 100% empty. Once the tank is 100% empty, you want to close the valve by turning the handle clockwise.

You now need to take out the leaking valve. You’re going to use a heat gun to soften up the weld that is holding together the cylinder and the gas valve.

Once this has been done, you want to open the nozzle of the tank to allow the regulator to come down to regular atmospheric pressure. You want to hold the tank very tightly while doing this.

You now need to attach the new valve and make sure that it comes complete with an overfilling prevention device inside of it. You’re going to attach the valve by threading it into the bung of the cylinder, and then tighten it using your pipe wrench.

If the actual propane cylinder itself is cracked or damaged in any way, and this is what’s causing the leak, then your only option is going to be to get a new propane tank.

If you need to replace the valve system on your propane tank, you do need to empty it first. To empty a leaking propane tank, you first want to disconnect it, and then take it to an open area.

The propane that is escaping is causing the hissing sound. Moreover, if the pressure within the propane cylinder gets to the same amount of pressure as the spring that is used to keep the relief valve shut, then the safety relief valve will open.

In other words, if your new propane tank is hissing, it is an issue with the safety relief valve. Refer to the above sections in order to fix a propane tank with an open relief valve.

When there is too much pressure inside a propane tank, the safety relief valve will open up to allow that extra pressure to escape. This is completely normal.

Propane is an extremely flammable gas, and yes, it can explode. If there is any kind of open flame or spark that the leaking propane comes into contact with, the result will be a massive explosion.

As you can see, there are a few reasons why a propane tank might leak after a refill. However, all of these issues are pretty serious, because you obviously don’t want propane leaking out.

Therefore, you want to take all of the necessary steps to remedy the issue as quickly as possible. If the propane tank cannot be fixed, you have to get a new one. Propane is just way too dangerous to take any chances with.

My name is Madeline Cooper, and I have now been living and traveling across the states in my RV for the past 8 years. It has been such an amazing experience, and I have learned so much along the way.

Through this blog, I want to share all of my hints and tips, along with reviews of the best RVing accessories. I hope this blog will help others with their RV trips, and make traveling easier for you.

If you use propane at your Seacoast Region home, you should familiarize yourself with your propane tank and how it works, as well as propane safety information.

One thing that may have you worried is if you hear a hissing sound coming from your propane tank. The understandable first thought is that your propane tank is leaking and that it’s unsafe. That’s why we recommend getting in touch with us immediately if you hear a hissing sound. If there is a leak, we can safely and properly deal with it. The sound may also be from your propane tank’s safety relief valve doing its job, which may indicate problems that we need to fix.

Propane tanks of all sizes, including those used for grilling, are required by law to include pressure relief mechanisms that allow excess pressure to be released from within the tank.

The safety relief valve is kept shut by a sturdy spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. That’s when you’ll hear a hissing sound coming from the tank. That sound is the pressure in the tank being dissipated. The valve will fully open in cases where the tank pressure is significantly greater than the spring pressure. If that happens, you’ll hear a pop.

Once the pressure is down below the pressure of the spring, the valve should close on its own. But that does not mean that the problem is solved. A pressure relief valve opening is a sign that something may be wrong with your tank. Get in touch with us right away if your safety relief valve opens so we can inspect your tank and fix any problems that are found. DO NOT try to replace the safety relief valve or fix it or your propane tank yourself. Any work on a propane tank is not a DIY project and must be done by a trained service technician.

With that kind of expansion, there needs to be room inside your propane tank to accommodate it. Therefore, your propane tank is filled to 80% rather than 100%. The propane in the tank can safely expand thanks to that 20% of empty space within it.

Expansion is also the reason for why propane tanks are painted light colors such as white or beige. These light colors reflect heat away from your tank, minimizing how much the propane in there will expand. Dark colors, on the other hand, retain heat. That much heat can cause the propane inside your tank to expand to dangerous levels.

On hot days when the sun is high overhead and a propane delivery has recently been made, the safety relief valve may open slightly allowing excess pressure to vent. If the relief valve is opened, the protective cap will be removed

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

If you hear a hissing sound coming from your propane tank, don’t immediately presume you have a propane leak (unless you smell a leak’s telltale rotten egg odor – in which case follow propane safety procedures immediately).

That fact is, that hissing sound may not be a propane leak at all. As our friends at propane101.com explain, several other culprits could be to blame, including:

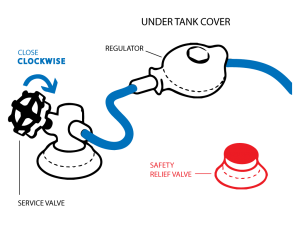

An open bleeder valve – The bleeder valve – also called a liquid level gauge – is a small device that enables your delivery technician to accurately monitor how much propane is in the tank during a refill. To deliver your propane, your driver must open the bleeder valve; occasionally, it doesn’t close properly. If this is the case, simply turn the bleeder valve clockwise to stop the flow of gas.

An open relief valve – A pressure relief valve is a required feature on all propane tanks and cylinders, because propane expands when it’s heated. On a hot, sunny day, you may find that the relief valve is open (and hissing); that is because it is doing what it is designed to do on hot days – slowly release pressure built up by the propane, which expands when subjected to heat. Never try to close, look into, or tap an open relief valve! Instead, you can relieve some pressure in your tank by spraying cool water from a garden hose on the tank’s surface.

Keep your family safe in your propane-powered home by using your eyes, nose and ears! Learn more about propane safety here – or contact us with questions any time.

But how much do you know about your home’s propane system, specifically, your propane tank? You should learn about your propane tank, as well as propane safety.

All propane tanks, including the cylinders you use for your BBQ grill or firepit, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

A strong spring keeps the safety relief valve closed as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may be replaced. However, this is a job for a professional. DO NOT try to fix or replace it on your own. Contact us for assistance.

There needs to be room inside your propane tank to accommodate such a large amount of expansion. That is the reason your propane tank is filled to 80% of its capacity and not to 100%. For example, a 500-gallon propane tank is filled to 400 gallons. The 20% of the tank that is empty space allows the propane to safely expand.

Expansion is why propane tanks are painted white or beige. Light colors reflect heat away from your tank, minimizing how much the propane in there will expand. Dark colors, on the other hand, retain heat. That much retained heat can cause the propane inside your tank to expand to dangerous levels.

8613371530291

8613371530291