why is my propane tank leaking from safety valve price

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

If the propane tank on your RV is leaking after a refill, then you have a serious problem on your hands. Of course, leaking propane can be extremely dangerous. So, why is your propane tank leaking after a refill?

The common reasons for a propane tank leaking are due to an open bleeder valve, an open relief valve, or a faulty valve system. We are also going to address the issue of a cracked propane tank. Although very unlikely, they can sometimes suffer serious physical damage.

Yes, absolutely is a leaking propane tank dangerous, and extremely so. Propane is flammable, which is why it is used for heating and cooking. If propane is leaking out of the tank, and it comes in contact with an open flame or spark, it’s going to cause a serious explosion.

It’s going to ignite the gas that is leaking out, and this flame will travel all the way back into the tank, and either just catch fire, or explode. There is also the fact that if it is in an enclosed space, inhaling propane is also very dangerous.

Although propane in itself is technically not toxic, it will displace the oxygen in the air. This means that if you breathe in too much propane, you won’t get enough oxygen, and can effectively suffocate to death.

One of the most common causes of a propane tank leaking after refilling is if the bleeder valve is open. Bleed valves are a special type of manually operated valve designed for bleeding liquids or gases out of a system.

It could also be the case that even if the bleeder valve is not open, the coil that it uses can be clogged with debris. This can then result in your propane tank leaking, specifically if the tank has too much propane in it. A good thing is that this is a very easy problem to solve.

The solution to a bleeder valve being open is simply to close it. All you have to do is to close the bleeder valve. You simply have to rotate the valve clockwise. Generally speaking, you are going to need to use a screwdriver, and you will need to turn the valve in a clockwise direction to close it.

The next reason why your propane tank might leak after a refill is if the relief valve is open. As the name implies, the relief valve is designed to help relieve pressure in the tank if there is too much of it.

Therefore, if it is hot outside, this relief valve may open up to allow pressure to get out of the tank. If the relief valve is slightly open, it will cause propane to leak out of the tank. Moreover, if the whole valve opens up, this can actually be quite dangerous.

the solution to a relief valve being open is actually quite simple, but you don’t actually want to touch the valve. This valve opens up all on its own in order to relieve pressure, and it should close on its own too.

If you tap or touch the valve in any way, or try to manipulate it, you may actually cause it to open up more, which is of course the opposite of what you are looking to achieve.

To solve this problem, you actually want to cool the tank down, which you can do by spraying it with some cool water or submerging it in a cold bath. This will relieve pressure on the tank and will cause the valve to close on its own.

However, if this does not work, then either this is not the issue or the relief valve is damaged to the point where you will just need to replace the propane tank.

The valve stem, or in other words the area where you connect the inlet tube to refill it with propane might be completely damaged or leaking. This is a huge problem because propane leaking out of the main stem can easily catch fire.

The solution to this issue is a little more complex because you will need to replace the entire tank valve stem system to prevent further damage and to prevent explosions from occurring.

Before you try to replace the valve, however, you need to ensure that the propane tank is 100% empty. Once the tank is 100% empty, you want to close the valve by turning the handle clockwise.

You now need to take out the leaking valve. You’re going to use a heat gun to soften up the weld that is holding together the cylinder and the gas valve.

Once this has been done, you want to open the nozzle of the tank to allow the regulator to come down to regular atmospheric pressure. You want to hold the tank very tightly while doing this.

You now need to attach the new valve and make sure that it comes complete with an overfilling prevention device inside of it. You’re going to attach the valve by threading it into the bung of the cylinder, and then tighten it using your pipe wrench.

If the actual propane cylinder itself is cracked or damaged in any way, and this is what’s causing the leak, then your only option is going to be to get a new propane tank.

If you need to replace the valve system on your propane tank, you do need to empty it first. To empty a leaking propane tank, you first want to disconnect it, and then take it to an open area.

The propane that is escaping is causing the hissing sound. Moreover, if the pressure within the propane cylinder gets to the same amount of pressure as the spring that is used to keep the relief valve shut, then the safety relief valve will open.

In other words, if your new propane tank is hissing, it is an issue with the safety relief valve. Refer to the above sections in order to fix a propane tank with an open relief valve.

When there is too much pressure inside a propane tank, the safety relief valve will open up to allow that extra pressure to escape. This is completely normal.

Propane is an extremely flammable gas, and yes, it can explode. If there is any kind of open flame or spark that the leaking propane comes into contact with, the result will be a massive explosion.

As you can see, there are a few reasons why a propane tank might leak after a refill. However, all of these issues are pretty serious, because you obviously don’t want propane leaking out.

Therefore, you want to take all of the necessary steps to remedy the issue as quickly as possible. If the propane tank cannot be fixed, you have to get a new one. Propane is just way too dangerous to take any chances with.

My name is Madeline Cooper, and I have now been living and traveling across the states in my RV for the past 8 years. It has been such an amazing experience, and I have learned so much along the way.

Through this blog, I want to share all of my hints and tips, along with reviews of the best RVing accessories. I hope this blog will help others with their RV trips, and make traveling easier for you.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

One thing you should pay attention to is the propane tank’s safety relief valve. All propane tanks, including the cylinders you use for your BBQ grill, are required by law to have pressure relief devices to allow for the release of excess pressure in the tank.

A spring keeps the safety relief valve closed as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear pop if that occurs.

Your propane tank needs to have room for the propane inside it to expand. That is why your propane tank is filled to 80% of its capacity. The 20% of the tank that is empty space allows the propane to safely expand.

That expansion is why propane tanks are white or beige. Light colors reflect heat to minimize expansion. Dark colors retain heat and can cause the propane inside your tank to expand to dangerous levels. So, even if your propane tank doesn’t go with the color of your siding, leave it alone.

If you use propane at your Seacoast Region home, you should familiarize yourself with your propane tank and how it works, as well as propane safety information.

One thing that may have you worried is if you hear a hissing sound coming from your propane tank. The understandable first thought is that your propane tank is leaking and that it’s unsafe. That’s why we recommend getting in touch with us immediately if you hear a hissing sound. If there is a leak, we can safely and properly deal with it. The sound may also be from your propane tank’s safety relief valve doing its job, which may indicate problems that we need to fix.

Propane tanks of all sizes, including those used for grilling, are required by law to include pressure relief mechanisms that allow excess pressure to be released from within the tank.

The safety relief valve is kept shut by a sturdy spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. That’s when you’ll hear a hissing sound coming from the tank. That sound is the pressure in the tank being dissipated. The valve will fully open in cases where the tank pressure is significantly greater than the spring pressure. If that happens, you’ll hear a pop.

Once the pressure is down below the pressure of the spring, the valve should close on its own. But that does not mean that the problem is solved. A pressure relief valve opening is a sign that something may be wrong with your tank. Get in touch with us right away if your safety relief valve opens so we can inspect your tank and fix any problems that are found. DO NOT try to replace the safety relief valve or fix it or your propane tank yourself. Any work on a propane tank is not a DIY project and must be done by a trained service technician.

With that kind of expansion, there needs to be room inside your propane tank to accommodate it. Therefore, your propane tank is filled to 80% rather than 100%. The propane in the tank can safely expand thanks to that 20% of empty space within it.

Expansion is also the reason for why propane tanks are painted light colors such as white or beige. These light colors reflect heat away from your tank, minimizing how much the propane in there will expand. Dark colors, on the other hand, retain heat. That much heat can cause the propane inside your tank to expand to dangerous levels.

On hot days when the sun is high overhead and a propane delivery has recently been made, the safety relief valve may open slightly allowing excess pressure to vent. If the relief valve is opened, the protective cap will be removed

The following list is a starting point, but you will need to consider everything around you:Open flames: Make sure that there are no open flames, and do not flick any cigarette lighters.

Stir a cup of dishwashing liquid into a cup of warm water and pour into a spray bottle. Then simply spray around the gauges and valves of the propane tank.

After this, slowly open the cylinder valve so that a little gas comes out. If you have sprayed it with soap solution, you will see bubbles at the site of the leak.

After about 15 minutes, spray the solution again on the areas that were leaking before. Slowly turn the cylinder valve to check if there is still a leak.

If your tank is still leaking you are in danger, and need to evacuate the area. It’s important to wait until you are clear of the area and the leak before using a cellphone.

I highly recommend that you get the pressure relief valve on your motorhome"s propane tank replaced. This is a very important part of the safety systems on your RV. When you get your RV filled up with liquid propane, it is never filled up to a 100%. The tank is actually filled up to 80% capacity. The reason is that liquid propane expands with heat. Filling the tank up to only 80% capacity allows for expansion of the liquid propane.

Let"s say you got your propane tank filled up on a very cold day and then a couple of days later you decide to take a trip to a hotter climate. Being in a hotter climate causes the propane to expand. In some cases the propane expands so much that it could exceed the pressure rating of your RV"s propane tank. Before the pressure gets above the tanks pressure rating the relief valve automatically opens up and vents the excess propane.

If the pressure relief valve is not working; the pressure in the tank could get high enough to exceed the tanks rating and rupture the tank releasing all of the propane at one time. If the propane gets close to an open flame the gasses will explode with great force. That is why a propane dealer will not fill up a propane tank with defective relief valve.

Yes, you could use a portable BBQ propane canister, but that would require a modification to the propane lines leading to your RV"s propane regulator. This modification if not done properly can cause a serious fire hazard and possibly cost more than getting your pressure relief valve replaced.

I cannot tell you how much getting the pressure relief valve replaced will cost. But, I can tell you that it will cost you a lot less money than having to replace your RV because it caught fire due to a bad pressure relief valve on your propane tank.

None of this is meant to scare you I am just trying to emphasize the fact that you need to take your RV to an RV repair shop and have the propane tank fixed by a certified RV Technician. You may be surprised that it will not cost as much as you think it might but, it must be done and it must be done right.

A new very young attendant did not release pressure prior to filling our 1988 Winnebago Itaska fixed propane tank. My husband asked him to right at the beginning.

3 hours later and fire chief in attendance, they poured hot water over the frozen valve, to allow release, after calling for the 2nd time to the propane supplier in another city on a Saturday.

Now we"ve ordered a new tank and are having to have a major RV sales / car and truck service dealer (not Camping World) put the 31 foot rig up, and remove the tank for us. Not sure what that will cost, but we cannot find any 5 ton jacks to borrow to do it ourselves.

Bottle jack would not lift this 11k pound Itaska high enough to get under there to undo the bolts. And we cannot find anyone will 5 ton jacks we could use. Suggestions welcome.

A common sight in a hydronic boiler room is water dripping from the discharge pipe of the boiler relief valve. While it may appear to be inconsequential, it could cause extensive damage to the heating system.

Some boiler rooms have a bucket under the relief valve discharge pipe to mask the problem. The following are some suggestions if you would like to resolve the problem.

Leaking water from a sealed hydronic system can reduce the life of the system by introducing untreated makeup water containing oxygen and solids to the system. The oxygen can attack and pit the boiler and piping, causing corrosion and leaks.

The solids can affect the efficiency and safety of the system. Solids form scale on the hottest surfaces in the boiler lowering the heat transfer ability and efficiency of the system. A leaking relief valve can allow solids to form on the seat of the relief valve increasing the rate of the leak.

A worse situation occurs when the solids form on the spring side of the relief valve as it could alter the opening pressure. A relief valve was a contributing factor in a fatal boiler accident as scale formed on the relief valve, prohibiting it from opening properly.

The relief valve, rated for 30 psig, was tested after the accident and did not open until the pressure reached 1,500 psig. Diagnosing the cause of the leaking relief valve is time-consuming and sometimes frustrating. I like to explain this to the customer to prepare them when the diagnosis and repair may take more than one visit.

The first thing I check is the system pressure. Most hydronic boilers have a gauge called a tridicator, or PTA (pressure, temperature, altitude) gauge. How much pressure do we need for the system? Each pound of system pressure will raise water 2.3 feet. The way to calculate how much pressure you need is to determine the height of the tallest radiator and divide the height by 2.3.

For example, we have a radiator on the sixth floor, and the elevation is 60 feet high. When you divide the height (60 feet) by 2.3, we get 26.09 pounds. We should add 3 to 4 pounds to that number to allow for better air removal and to limit the chance of the hot water flashing to steam. This takes our normal system pressure to 29-30 psig.

The next step is to verify the pressure rating of the relief valve. The pressure rating of the relief valve should be at least 10 psig higher than the operating pressure of the system but less than the maximum allowable working pressure (MAWP) of the boiler. Many hydronic boilers are shipped with a 30 psig relief valve from the factory. In this example, the relief valve should be at 40 psig or higher. If the system pressure is 30 psig and the relief valve, rated for 40 psig, is leaking, the relief valve is most likely defective.

Another troubleshooting task I perform is watching the tridicator (or PTA gauge) while the boiler is firing and heating the water. When water is heated from 65° F to 180°, the water volume expands by 3%. If the pressure gauge starts creeping up as the water heats, I would suspect a flooded compression tank or plugged piping to the compression tank.

In some instances, it may take several days for the pressure to build and open the relief valve and these are the most difficult to troubleshoot. The first place I would look is the compression tank. If the tank is flooded, there are a couple of reasons.

The most common causes are leaking gauge glass fittings above the water line of the tank, excessive system pressure, undersized tank, or the tank has a leak above the water line. If the system has been operating correctly for years, I would be hesitant to believe the tank is undersized.

A pinhole leak on top of the tank may be impossible to find and one of the ways to test the integrity of the tank is to valve off the water feeder to the system and check the tank in a few days to see if it flooded. If the tank is flooded, you might have to replace the tank.

If the compression tank has an enclosed bladder, check the pressure on the bladder side of the tank. To do this, you have to reduce the system pressure to 0 psig and check the bladder pressure using a tire pressure gauge. The internal pressure should be that same as the system pressure. From above, we know the system pressure is 30 psig.

Another culprit that can cause the pressure to rise and open the relief valve is if the boiler has an indirect water which uses the boiler water to heat the domestic water using a water to water heat exchanger. A leaking heat exchanger could allow the higher city water pressure to enter the space heating side and increase the system pressure. To test this idea, shut the valves from the domestic water side and see if the pressure still rises.

The last item to check is the pressure-reducing valve (PRV). This is a brass valve with an adjustment screw. Some models have a quick-fill feature, which allows you to pull a lever and quickly fill the system. A stethoscope is sometimes used to trouble shoot the PRV to detect if water is leaking through the valve.

Another way to test for leaking is to feel the downstream pipe and see if it is cold. In many instances, the water is fed slowly and difficult to detect. Another way to test to see if the PRV is leaking through is to shut off the valves on the feed water pipe and see if the pressure still rises. If it does, I will suspect the piping to the compression tank is restricted or the tank is flooded. If the pressure does not rise, it could be the pressure reducing valve.

If you hear a hissing sound coming from your propane tank, don’t immediately presume you have a propane leak (unless you smell a leak’s telltale rotten egg odor – in which case follow propane safety procedures immediately).

That fact is, that hissing sound may not be a propane leak at all. As our friends at propane101.com explain, several other culprits could be to blame, including:

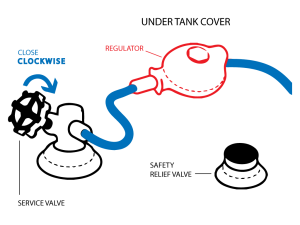

An open bleeder valve – The bleeder valve – also called a liquid level gauge – is a small device that enables your delivery technician to accurately monitor how much propane is in the tank during a refill. To deliver your propane, your driver must open the bleeder valve; occasionally, it doesn’t close properly. If this is the case, simply turn the bleeder valve clockwise to stop the flow of gas.

An open relief valve – A pressure relief valve is a required feature on all propane tanks and cylinders, because propane expands when it’s heated. On a hot, sunny day, you may find that the relief valve is open (and hissing); that is because it is doing what it is designed to do on hot days – slowly release pressure built up by the propane, which expands when subjected to heat. Never try to close, look into, or tap an open relief valve! Instead, you can relieve some pressure in your tank by spraying cool water from a garden hose on the tank’s surface.

Keep your family safe in your propane-powered home by using your eyes, nose and ears! Learn more about propane safety here – or contact us with questions any time.

Has your propane tank valve gotten stuck yet again? This can put a serious damper if you’ve planned a BBQ, or literally anything that requires your propane tank. But here’s some good news: this article will tell you exactly how to unstick a propane tank valve.

Before we move onto the meat of the matter, you need to understand how your propane tank works. This applies to anything that runs on propane: fireplaces, water heaters, stoves, gas grills, and even RVs. Knowing how your tank operates will make it easier to troubleshoot minor issues.

A basic tank is filled with propane liquid and uses a special machine that forces the propane gas into the tank under pressure, turning it into its liquid form. It remains pressurized in the tank until the valve is released. When the valve is turned, the pressure decreases and the gas converts to vapor and escapes through the opening.

The propane gas is allowed to escape the canister under a certain pressure determined by the size of the valve. Large commercial propane tanks have multiple valves and gauges.

The main valves are the fill valves to refill the tank, a service valve to release the propane, and a relief valve. The relief valve prevents too much pressure from building up in the tank and exploding.

Tanks also have gauges that measure the level of liquid in the tanks called a float gauge, as well as a vapor recovery valve that can be used to release excess vapor in the tanks when getting it serviced.

The tanks are often closed very tightly to prevent leaks. If your propane tank won’t open after you bring it home the first time, try using a wrench or a pair of pliers. You can also unhook the tank from your stove and apply a bit of oil to the valve, before trying to yank it open with pliers.

Before you try to fix a propane safety valve (or any other tank valve), you need to identify the cause of the blockage. This will determine what you need to do to correct the issue.

The most important thing to bear in mind is that propane is highly combustible. When correcting a faulty tank valve, make sure you don’t puncture the tank and cause more damage. Safety is always a priority, so work in a ventilated area and do not light matches or lighters near your tank.

Set the propane tank on a steady, level surface. Make sure you are in a dry and cool area. Carefully check the tank for any signs of obvious damage and try to find the source of any possible leaks.

Wrap the rubber band around the outer edges of the valve to get a better grip on the blocked valve. Once you get a firm grip, twist firmly to loosen and dislodge the valve with your hand.

If this doesn’t work, spray a bit of oil or lubricant on the valve. Shake the valve back and forth to loosen it up, and then try to twist it open once again.

If the valve is still stuck, use a pair of pliers or a wrench to force it open. Grasp the edge of the valve with your pliers firmly and twist counterclockwise to open the valve. Try not to use too much pressure or as this can break the valve instead.

If your valves have rust or water damage, assess the situation. If it is still in the early stages, you can use baking soda and vinegar to get rid of the rust. However, if it is too far gone, you will need to replace the valve.

To avoid the fuss of a propane tank valve that needs to be dislodged, you can follow a few simple steps to prevent it from happening in the first place.

Don’t twist the valve closed too tightly. This might sound obvious, but people tend to close the valve really tightly, especially after a refill. Shut it tight, but don’t overdo it.

After buying a new tank or refilling your old one, smack the bottom of the tank on the ground once or twice. This will loosen the valve so you can open it more easily.

Don’t open the valve of a new cylinder rapidly as this can make it get jammed the next time. Instead, test the water and work it slowly and carefully.

If your propane tank leaks when connected, you most likely need a new valve. Check for the site of the leak by spraying soapy water at the valve, connection point, and pipes. If you see bubbles at the valve or connection, the gasket is broken and the valve requires replacing.

Soak the hose for a few minutes in warm soapy water to clean it. Use grease-cutting dish soap or something similar to break down accumulated oil and debris. Rinse the hose thoroughly under running water and allow it to dry.

The propane tank shut-off valve is your best bet during leaks if the hose or valve isn’t the one behind the leaks. The service or shut-off valve is the metallic spigot-like dial located under the tank cover and hooked to the top of the tank.

You need to use this valve to turn the gas off at the tank in the event of an emergency or leak. Always turn this valve to the right (clockwise), completely to shut off the gas.

This kind of valve is required on all large 4-to-40-pound commercial cylinders in vapor service. The OPD valve is a protective device and is exactly what it sounds like. It prevents the tank from overfilling.

Place the open jaws of the crescent wrench over the large bolt of the tank’s gas regulator. This is located at the meeting point of the propane tank and the gas regulator. Use the thumbscrew to grip the jaws around the large nut.

Then, loosen the nut with the wrench. Continue to remove the nut by hand until you can pull the neck of the regulator from the propane tank connection. You may catch a small whiff of gas as the regulator’s neck is pulled from the propane tank, but this is nothing to be worried about.

Remove the tank from the grill’s cart. In some models, you might have to loosen a safety strap. Store the empty tank in a safe and dry location, outdoors and well away from any flames.

It is perfectly normal to smell a little propane as tiny amounts can leak when the tank is in use. You can also smell the gas when the tank is nearly empty.

It is common for a propane tank to hiss. Hearing this sound is an indication that your tank is leaking so shut off all the valves and check for the location of the leak.

It is always a little scary when dealing with gas tanks, as we are well aware of the risks. However, knowing how to handle any kind of malfunctioning will make it much easier to deal with.

Once you know how to unstick a propane tank valve, you can loosen the valve or spigot without any trouble. And this will make the process of grilling much easier. Happy cooking!

Water heaters come equipped with a temperature and pressure relief valve, also known as a TPRV. This valve allows water or steam to escape from the water heater if the temperature or pressure gets too high. This prevents a water heater from exploding or turning into a missile.

When a TPRV at a water heater leaks, it’s usually a simple fix; just replace the valve. These valves cost less than $15 and replacing the valve is a basic job. There are plenty of videos on YouTube showing how to do this, and the whole project probably won’t take more than fifteen minutes.

If you replace a TPRV and it starts leaking again, it probably means the valve is doing its job; it’s relieving excess pressure. When this happens, the fix gets a little bit more involved, and some troubleshooting is in order.

The TPRV on a water heater is set to discharge at 150 PSI or 210° Fahrenheit. These numbers will be printed right on the valve, or on a tag attached to the valve. See below.

If a pressure relief valve for a boiler is accidentally installed on a water heater, it will leak like crazy from the start. These valves may look identical, but they’re set to go off at 30 psi, not 150 psi.

The easiest way to do this is to get a gauge with a garden hose thread, connect it to an outside garden hose faucet, and open up the faucet. If that’s not an option, you can also use the hot or cold spigot for a washing machine. You should expect the pressure to be somewhere in the 40 – 80 PSI range with no other water running. If the pressure is over 80 PSI, it should be corrected. That’s too high for your system. The solution is to have a pressure regulator installed. Get a plumber to do that, as they’ll need to install an expansion tank at the same time. I’ll come back to those in a minute.

If the pressure is within the acceptable range, you probably have an intermittent problem with excessive pressure that can be easily re-created. Go run a bunch of hot water at your plumbing fixtures until you’ve exhausted the hot water supply on your water heater, and keep running the water for another few minutes. If you have several fixtures open, this should only take about ten to fifteen minutes. Now stop running water at all of your fixtures and wait.

You’ve just replaced the hot water in your water heater with cold water, which will cause your water heater to run for a while. This will cause the water to expand significantly until the water heater thermostat is satisfied. That might take about an hour or two. In most situations, this water will expand back out through the cold water inlet, all the way back to the water supply coming into the house. The municipal water supply for the house acts as a gigantic expansion tank… and nobody notices. This is illustrated in the diagram below.

Your pressure gauge shouldn’t change a bit while this happens. If the pressure increases with this test, however, you’ve made an important discovery. You have a closed system!

A closed system exists when water can’t leave your house. One way for this to happen is to have a check valve installed on the water supply coming into the home. I don’t see a lot of these in Minnesota, but I do see them periodically.

The other way to create a closed system is to have a pressure regulator installed that contains a built-in check valve. With either of these installed, water can’t leave the house. When water expands and can’t go anywhere, pressure in the system increases. Watch your pressure gauge to verify this. Once the pressure gets to 150 PSI, the TPRV should do its job and leak.

When a closed system exists on the water distribution piping in a home, an expansion tank needs to be installed somewhere on the plumbing system. This is a simple and straightforward fix; an expansion tank will give the water somewhere to go when it expands, and the TPRV on the water heater will stop causing problems.

Expansion tanks are required when a closed system exists, both by water heater manufacturers and by plumbing codes. The Minnesota State Plumbing Code requires an expansion tank when a pressure regulator is installed (608.2):

An approved expansion tank shall be installed in the cold water distribution piping downstream of each such regulator to prevent excessive pressure from developing due to thermal expansion and to maintain the pressure setting of the regulator.

A water system provided with a check valve, backflow preventer, or other normally closed device that prevents dissipation of building pressure back into the water main shall be provided with an approved, listed, and adequately sized expansion tank or other approved device having a similar function to control thermal expansion.

If an expansion tank is already installed and there is still a problem with excessive pressure, you have a problem with the expansion tank. I’ll talk about expansion tanks in next week’s blog post.

In the manufacturing industry, we’re taught to look at the big picture when it comes to troubleshooting. If a pressure relief valve experiences failure, is releasing pressure before a system reaches maximum pressure, or is constantly leaking or chattering, it’s always best to assume that there’s something wrong with the system.

When maintained properly, a pressure relief valve can stay in service for up to 30 years, and if you’ve been having your valves tested regularly, it’s likely that there’s something else in your system that’s to blame. That said, pressure relief valves can and do fail, and it’s important to be able to recognize the signs in order to quickly solve the problem, and keep your facility safe. Here are 3 signs of pressure relief valve failure to watch out for when you’re troubleshooting your facility’s system:

If your system isn’t reaching pressure, this could be a sign of pressure relief valve failure. In some cases, this could be fixable. If the valve was calibrated to the wrong set pressure, it could simply be releasing early. This happens occasionally when changes are made to your facility’s plant design, and technicians forget to recalibrate pressure relief valves for the system’s new normal operating pressure. Your valve technicians can go in and adjust the valve’s set pressure to address this issue.

If that doesn’t solve the problem, and all other aspects of your system seem to be functioning properly, then it’s possible that your pressure relief valve needs to be changed. After years of service, the valve could have become damaged or eroded by dirt and debris in the environment, blocking the valve from fully closing. This often causes chattering, where the valve isn’t fully open, but is opening and closing rapidly, preventing it from properly doing its job.

When your system cannot reach pressure, you’ll likely experience production slowdown, if not total downtime. It’s good to know that checking your pressure relief valves can help you determine the problem.

Pressure relief valves and safety relief valves are what keep your facility safe. In the event that your system builds up above the maximum pressure for safe functionality, safety relief valves open up to let off additional pressure, keeping your facility, your employees, and your equipment safe.

If your system is above pressure and your pressure relief valves have not released, this is likely a functional pressure relief valve failure. Again, you’ll need to make sure that the valves are set to the correct set pressure, and you’ll want to take a look at the big picture of your system to understand why it’s functioning overpressure in the first place. Outside of those two concerns, if your pressure relief valves haven’t released, it’s likely that they’ve failed.

Contaminants, like dirt, lint, rust, sludge, or even the misalignment of the valve can cause the pressure relief valve to stick. At this point, you might see that your system is above pressure, or you’ll notice other pressure relief valves in the system releasing to make up for this valve’s malfunction.

While the other two signs are pretty obvious, this last sign is more noticeable when you’re directly inspecting your pressure relief valves. Leaking valves are a problem, and can contribute to slower, less efficient production, but they can be more difficult to notice as their effect on the entire system can be much smaller. This is part of the reason that preventative valve testing and maintenance is so important.

If your pressure relief valve has no pressure, it’s likely that the balance hole has become plugged, the spring is broken, or the valve simply has a loose fit. In the case of a loose fit or broken spring, replacement is a must. The valve isn’t able to function properly within your system, which means it’s not protecting your facility, your employees, or your equipment in the event that there is a larger problem.

Pressure valve leakage is a little more complicated to troubleshoot, as there are a variety of potential causes. It could be the valve itself, it could be that misalignment is causing a failure to reseat after a correct opening, or it could be that there is greater pressure in your system than the valve’s set pressure. A quality inline safety relief valve testing system can help you here. Systems like AccuTEST offer a leak check capability that allows you to test specifically for pressure leaks.

The greatest takeaway from this article should be that a malfunctioning pressure relief valve is most often a symptom of a greater problem, rather than a problem itself. As we mentioned earlier, pressure relief valves that are properly maintained can last for up to 30 years. In most cases, it’s important to look at the “why” behind pressure relief valve failure, rather than just replacing the valve in question.

This article from the Journal of Emerging Technology and Advanced Engineering provides a helpful flowchart outlining the troubleshooting procedure to take in the event that you experience any sort of pressure relief valve failure.

If your facility is having trouble diagnosing a pressure relief valve failure, inline testing can help. Instead of removing the valve and either replacing it or sending it out for testing, use inline testing equipment like the AccuTEST system to quickly and efficiently test your pressure relief valve and safety valve’s functionality. You’ll get accurate, real-time results helping your facility get back on track quickly, and safely. For more information about AccuTEST, give us a call at 616-394-1401 or request a live demo today!

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

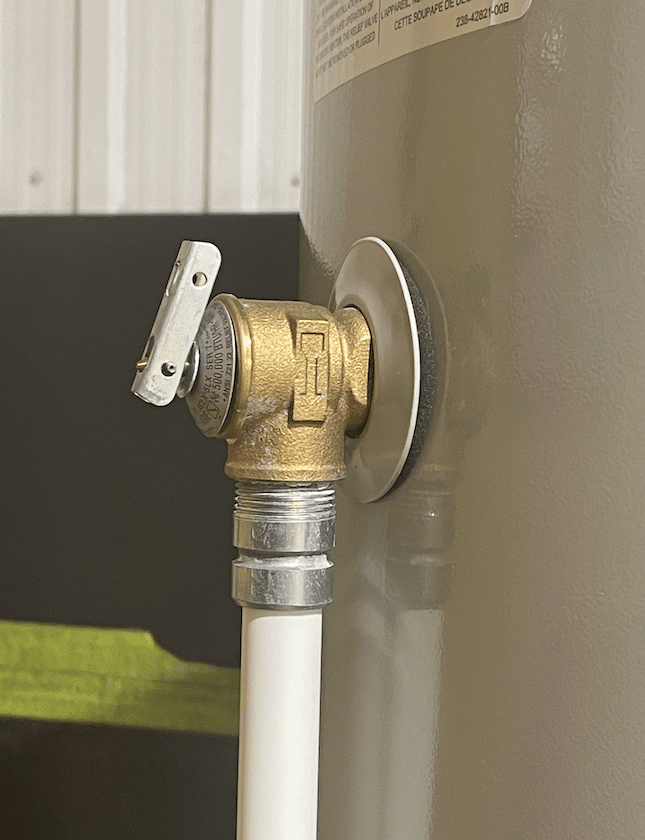

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

Check for leaks— buy a small spray bottle and keep a mixture of a small amount of dish soap and water in the bottle. When you connect your tank to your grill and open the valve, spray the soap water on your tank connection and look for bubbling that indicates a leak. If you see bubbles increasing in size or quantity, you have a leak. Close the valve and check your connections. Don’t light your grill until your connection is leak-free.

Know your grill— when it comes to getting great results and staying safe around your gas grill, there is no substitute for reading your owners manual. Study your owners manual for proper safety guidelines. If you can’t find your manual, search for the manufacturer on the Internet and download the manual. Make safety your first priority!

Have a fire extinguisher nearby— if your grill flares up and you have to shut off your gas, you may still have to put out a fire. Have a handy extinguisher in the event your fire gets the best of your food. Keep in mind that the first step to eliminate the fire is to deny the oxygen (close the grill top) and the second is to deny the fuel (shut off the gas).

Keep your cylinder valve closed when not in use – it is a very simple step in preventing accidents to shut off the gas supply on your grill or burner AND on your cylinder supply valve. Keep your tank plugged or capped when it is not connected to your grill. Remember that quick connect cylinder valves have two check valves so they do not require a plug but capping a quick connect cylinder will protect it from dust and moisture.

Always use your cylinder in an upright position— your gas grill is designed to burn propane vapor, not liquid propane. If your propane tank is laying on it’s side liquid propane can escape from the cylinder valve. Liquid propane cannot escape from the valve of an upright propane tank.

Never use a gas grill indoors— your gas grill is consuming oxygen and propane as it burns. The use of a propane gas grill, propane gas camp stove or propane gas burner indoors can result in carbon monoxide poisoning, asphyxiation and death. Carbon monoxide is colorless, odorless and lethal. Do not use a propane gas grill indoors.

Keep your gas grill away from your house— in the event that your grill suffers from a flare-up or a propane leak. You can’t imagine how quickly a small flare-up can lead to a big disaster when your grill is too close to a carport, home or shed.

Keep your spare tank away from the grill – you may have a storage area underneath or beside your grill. Use if for cooking tools or whatever else suits you but never store an extra propane cylinder under or beside your grill.

Safety check and clean your grill regularly — look at the entire grill from the ground up. Check for rust that could lead to a structural failure. Look at the condition of the hoses, burner assemblies and ignition system. Clean it out and replace the grills if necessary. Your grill can easily last twice as long if you spend two hours a year keeping it in top condition.

Buy a quality cover for your grill— the corrosive impact of weather is as bad for your grill as the intense heat of your hottest fire. The low cost of a good cover will pay for itself many times over—especially if you invested in a quality gas grill!

A leak from your water heater’s pressure relief valve is a major concern, especially if it’s the first time dealing with this problem. While some people tend to panic and get help immediately, others may just shrug their shoulders and assume that the leak is a common occurrence. However, there are many causes of leaks in water pressure relief valves. And all these must be addressed immediately given the high risks of property damage and hazards that can occur if the issue is ignored.

The pressure relief valve gives steam and water a chance to escape when either the pressure or temperature in the water tank gets too high. A malfunctioning valve can cause the water heater to explode and is the major cause of water heater explosions. In water heater pressure relief valves, the valve is set to open when the pressure exceeds 150 psi.

A leaking valve is not always a broken valve. In some cases, a water heater’s pressure relief valve may leak because it is functioning as intended. As excess pressure is relieved out of your water heater system, some water may leak. This necessitates the need to test the pressure in your water heater.

The process is not complicated. However, if you are not comfortable checking the water pressure, you can always contact your technician. To test the pressure, use a pressure gauge and attach it to either the cold-water pipe or the hot water pipe. However, one of the easiest places to connect the pressure gauge is the outdoor hose faucets. For this, ensure you purchase a pressure gauge that is designed for garden hoses.

Turn off all water outlets and faucets. The pressure reading should be between 40 psi- 80 psi. If the gauge shows a psi reading of 150 and above, then the cause of the leak could be high pressure. If the water pressure is normal and the leak is persistent, then high water pressure is not the cause of the leak.

If you get a high-pressure reading, then you could be dealing with a closed plumbing system issue. This means that when the water is heated, the pressure increases as it should. But with nowhere to go, the valves open to relieve the pressure. Luckily, this can be solved by installing an expansion tank that gives the pressure an outlet other than a pressure relief valve.

Although rare, your water heater’s pressure relief valve could be leaking as a result of excessively high temperatures. However, the water has to be near the boiling point. To check the water temperature, ensure you turn on the hot water faucet. Run the water for one minute and use a meat thermometer to take the temperature reading. The temperature should be around 120 degrees. If more than this, then you need to have the water heater checked. The water temperature would need to be close to 212 degrees to set off the relief valve.

While this is an uncommon occurrence, it is not far-fetched. Your technician could have used a pressure valve for another appliance since they have the same function. However, these other pressure relief valves are set to go off at a lower psi. For instance, boiler pressure valves go off at 30 psi. If installed in a water heater, you are likely to get leaks immediately after installation. As such, if you have had your water heater for years and only experienced the leaks after a long period, then this is an unlikely cause of the leak.

A slight leak may occur if your water heater’s pressure relief valve has not been opened for a while, say a few years. While this leak is normal and may not be an indicator of a problem with the water heater system, you may need to replace the valve if the leak becomes more serious. It is cheaper to replace the entire valve than to repair it and have to deal with the same problem later on.

A leak in your water heater’s pressure relief valve could also be caused by a faulty pressure relief valve. While pressure relief valves barely break down, excessive wear and improper installation can cause extensive damage. Unfortunately, a faulty pressure valve can not be repaired and must be replaced. However, the cost of pressure valves is affordable and ranges around $30.

Know your water heater and how it functions– Water heaters can be intimidating, especially for people with less technical know-how. Understand what every part of the system plays in heating water such as the water shutoff valve, drain valve, thermostat, and pressure relief valve. This eases the maintenance routine and ensures you have a fair understanding of any malfunctions.

Carry out regular maintenance– Inspect your water heater monthly, ensuring that all valves and pipes are in good shape. This also helps you catch corrosion and leaks early enough before they turn out to be bigger problems. And every year, carry out a water heater flush. Given that you cannot pinpoint all problems, have a qualified technician inspect the system annually.

Regardless of the possible cause of a leak in your water heater’s pressure relief valve, please contact a qualified plumber as soon as possible. And if you think it’s a problem that you can solve without getting help, ensure you have a qualified plumber confirm that the system is performing optimally after. Water heater issues should not be taken lightly as they can cause more issues, even explosions.

If you’ve been having issues with your water heater recently, you might find that you’re paying high energy bills, not getting access to hot water when you want it, or your water pressure is low.

Fortunately, by understanding how relief valves work, you can solve whatever problem you’re having with the one on your water heater. In this article, we’ll review everything you should know about this valve.

A water heater pressure relief valve, also referred to as a T&P valve, pressure relief valve, or water heater temperature valve is a safety feature that you can find on any water heater. The reason it’s there is to keep you safe in case the water pressure is too high.

Without this safety feature, your water heater could end up breaking. You could potentially end up with burns if the high water pressure is dangerously high.

This valve also ensures that there aren’t any leaks in your water heater, which would lead to low water pressure when you want to use it to wash the dishes or take a shower.

The water heater pressure relief valve is in place so that it can relieve excess pressure and temperature in a water heater if either of these is too high. Because this everyday appliance is a closed system, thermal expansion occurs in water heaters.

Here’s how it works. Whether your water heater is heated by electric elements or a gas burner, both the metal tank and the water inside expand when the hot water temperature is somewhere between 120 and 140 degrees.

It’s totally normal for the water and water heater to expand to a certain extend. After all, this is what naturally happens when the temperature rises.

However, when the temperature is 210 degrees—or the pressure is 150 pounds per inch (psi)—this is far too much pressure and heat in the water heater. If it’s the case, you should change your hot water heater temperature.

If your water heater pressure relief valve is working, this is when it will open. This releases steam and hot water from the discharge tube, making your water heater operate safely again.

On the micro-level, the functioning of this valve works like this. The relief valve itself has been set up by a professional or pre-designed to open when the temperature or pressure reaches a dangerous level.

When functioning properly, it will open as it’s designed to when the levels of heat or pressure are high. The liquid comes out through this auxiliary route, relieving the heat and pressure within the water tank.

This specific state that the water heater is in is called the “blowdown.” Usually, the “blowdown” is defined by professionals (and is used in the design or set up of the valve) as a specific pressure percentage.

The “blowdown” is usually somewhere between 2 and 20%. Once the pressure has reached the “blowdown” amount, the pressure relief valve will close again so that you can use the water heater as intended.

If you’ve been noticing any issues with your water heater pressure relief valve, then you need to know where it is on your water heater. Usually, you can find it on the top or side of this appliance. It’s a valve that’s connected to a plastic or metal discharge tube that points up.

The water heater pressure is already installed when you receive your water heater (or buy a home that has one already). It’s actually welded onto the tank; you’ll see a threaded inlet where it is.

This is for safety reasons. Everything has been done according to standards that have been mandated by plumbing codes. So if you’re having any issues with the valve, you’ll have to call a professional to have it fixed.

This said, if you’re only having issues with the discharge tube, this is easy to replace. You won’t have to drain or power down your water heater, and you can deal with it yourself.

This said, considering that there might be other issues causing discharge tube problems—issues connected to high water pressure or temperature—it’s safest to have a professional deal with this too.

If you suspect there’s a problem with your water heater pressure relief valve, you can do a test. This is actually good idea if you don’t have any problems at all, as this type of maintenance will protect your water heater—and yourself.

To get started, identify where the relief valve shut off is. Usually, you can find it upon the cold water feed, which is on top of the water tank, on the right side where the inlet is.

Once you’ve done this, take a look at the discharge tube to make sure that it’s attached firmly. Then, take a bucket and put it under the discharge tube.

Finally, release the level so that it quickly snaps into the original position. If it doesn’t snap quickly into this original position, then your water heater valve isn’t working and needs to be replaced.

When your water heater pressure relief valve isn’t functioning properly, it’s usually for one of to two reasons. It either sticks so that it doesn’t properly open or close, or it has a leak, which means that it’s continually dripping, lowering your water pressure.

If your valve is sticky, then it becomes stuck in a closed (downward) or open (extended position). If it’s closed, then the valve won’t be able to relieve the heat or pressure that builds up in the closed water heater system. There could be a rupture as a result.

Sometimes, you can easily fix this problem by opening and closing the valve lever a few times. However, if it continues to stick, then you’ll need to replace it.

Your water heater is leaking? Make sure that it doesn’t come from the valve before replacing it. If your pressure relief valve is leaking, then this maybe because it isn’t seated properly in the tank’s threaded opening. This is quite a common issue if you’ve recently replaced your old valve with a new one. To fix this issue with this cause, you have to take several steps.

If the lever snaps into its original position and it’s still leaking, you need to turn off the gas valve by turning it to the off position. Then, shut the water off so you can replace the valve safely.

If a water pressure issue is what is causing the water heater pressure relief valve to not work, then it might be dangerous for you to change the valve yourself. Generally speaking, it’s a good idea to hire a professional to protect yourself.

Now that we’ve reviewed everything you should know about a water heater pressure relief valve you might have realized that you need to replace your water heater valve. However, to be as safe as possible, you want to hire a professional.

8613371530291

8613371530291