why is my propane tank leaking from safety valve quotation

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

On hot days when the sun is high overhead and a propane delivery has recently been made, the safety relief valve may open slightly allowing excess pressure to vent. If the relief valve is opened, the protective cap will be removed

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

If you use propane at your Seacoast Region home, you should familiarize yourself with your propane tank and how it works, as well as propane safety information.

One thing that may have you worried is if you hear a hissing sound coming from your propane tank. The understandable first thought is that your propane tank is leaking and that it’s unsafe. That’s why we recommend getting in touch with us immediately if you hear a hissing sound. If there is a leak, we can safely and properly deal with it. The sound may also be from your propane tank’s safety relief valve doing its job, which may indicate problems that we need to fix.

Propane tanks of all sizes, including those used for grilling, are required by law to include pressure relief mechanisms that allow excess pressure to be released from within the tank.

The safety relief valve is kept shut by a sturdy spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. That’s when you’ll hear a hissing sound coming from the tank. That sound is the pressure in the tank being dissipated. The valve will fully open in cases where the tank pressure is significantly greater than the spring pressure. If that happens, you’ll hear a pop.

Once the pressure is down below the pressure of the spring, the valve should close on its own. But that does not mean that the problem is solved. A pressure relief valve opening is a sign that something may be wrong with your tank. Get in touch with us right away if your safety relief valve opens so we can inspect your tank and fix any problems that are found. DO NOT try to replace the safety relief valve or fix it or your propane tank yourself. Any work on a propane tank is not a DIY project and must be done by a trained service technician.

With that kind of expansion, there needs to be room inside your propane tank to accommodate it. Therefore, your propane tank is filled to 80% rather than 100%. The propane in the tank can safely expand thanks to that 20% of empty space within it.

Expansion is also the reason for why propane tanks are painted light colors such as white or beige. These light colors reflect heat away from your tank, minimizing how much the propane in there will expand. Dark colors, on the other hand, retain heat. That much heat can cause the propane inside your tank to expand to dangerous levels.

If the propane tank on your RV is leaking after a refill, then you have a serious problem on your hands. Of course, leaking propane can be extremely dangerous. So, why is your propane tank leaking after a refill?

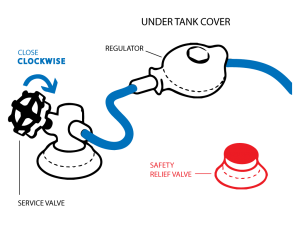

The common reasons for a propane tank leaking are due to an open bleeder valve, an open relief valve, or a faulty valve system. We are also going to address the issue of a cracked propane tank. Although very unlikely, they can sometimes suffer serious physical damage.

Yes, absolutely is a leaking propane tank dangerous, and extremely so. Propane is flammable, which is why it is used for heating and cooking. If propane is leaking out of the tank, and it comes in contact with an open flame or spark, it’s going to cause a serious explosion.

It’s going to ignite the gas that is leaking out, and this flame will travel all the way back into the tank, and either just catch fire, or explode. There is also the fact that if it is in an enclosed space, inhaling propane is also very dangerous.

Although propane in itself is technically not toxic, it will displace the oxygen in the air. This means that if you breathe in too much propane, you won’t get enough oxygen, and can effectively suffocate to death.

One of the most common causes of a propane tank leaking after refilling is if the bleeder valve is open. Bleed valves are a special type of manually operated valve designed for bleeding liquids or gases out of a system.

It could also be the case that even if the bleeder valve is not open, the coil that it uses can be clogged with debris. This can then result in your propane tank leaking, specifically if the tank has too much propane in it. A good thing is that this is a very easy problem to solve.

The solution to a bleeder valve being open is simply to close it. All you have to do is to close the bleeder valve. You simply have to rotate the valve clockwise. Generally speaking, you are going to need to use a screwdriver, and you will need to turn the valve in a clockwise direction to close it.

The next reason why your propane tank might leak after a refill is if the relief valve is open. As the name implies, the relief valve is designed to help relieve pressure in the tank if there is too much of it.

Therefore, if it is hot outside, this relief valve may open up to allow pressure to get out of the tank. If the relief valve is slightly open, it will cause propane to leak out of the tank. Moreover, if the whole valve opens up, this can actually be quite dangerous.

the solution to a relief valve being open is actually quite simple, but you don’t actually want to touch the valve. This valve opens up all on its own in order to relieve pressure, and it should close on its own too.

If you tap or touch the valve in any way, or try to manipulate it, you may actually cause it to open up more, which is of course the opposite of what you are looking to achieve.

To solve this problem, you actually want to cool the tank down, which you can do by spraying it with some cool water or submerging it in a cold bath. This will relieve pressure on the tank and will cause the valve to close on its own.

However, if this does not work, then either this is not the issue or the relief valve is damaged to the point where you will just need to replace the propane tank.

The valve stem, or in other words the area where you connect the inlet tube to refill it with propane might be completely damaged or leaking. This is a huge problem because propane leaking out of the main stem can easily catch fire.

The solution to this issue is a little more complex because you will need to replace the entire tank valve stem system to prevent further damage and to prevent explosions from occurring.

Before you try to replace the valve, however, you need to ensure that the propane tank is 100% empty. Once the tank is 100% empty, you want to close the valve by turning the handle clockwise.

You now need to take out the leaking valve. You’re going to use a heat gun to soften up the weld that is holding together the cylinder and the gas valve.

Once this has been done, you want to open the nozzle of the tank to allow the regulator to come down to regular atmospheric pressure. You want to hold the tank very tightly while doing this.

You now need to attach the new valve and make sure that it comes complete with an overfilling prevention device inside of it. You’re going to attach the valve by threading it into the bung of the cylinder, and then tighten it using your pipe wrench.

If the actual propane cylinder itself is cracked or damaged in any way, and this is what’s causing the leak, then your only option is going to be to get a new propane tank.

If you need to replace the valve system on your propane tank, you do need to empty it first. To empty a leaking propane tank, you first want to disconnect it, and then take it to an open area.

The propane that is escaping is causing the hissing sound. Moreover, if the pressure within the propane cylinder gets to the same amount of pressure as the spring that is used to keep the relief valve shut, then the safety relief valve will open.

In other words, if your new propane tank is hissing, it is an issue with the safety relief valve. Refer to the above sections in order to fix a propane tank with an open relief valve.

When there is too much pressure inside a propane tank, the safety relief valve will open up to allow that extra pressure to escape. This is completely normal.

Propane is an extremely flammable gas, and yes, it can explode. If there is any kind of open flame or spark that the leaking propane comes into contact with, the result will be a massive explosion.

As you can see, there are a few reasons why a propane tank might leak after a refill. However, all of these issues are pretty serious, because you obviously don’t want propane leaking out.

Therefore, you want to take all of the necessary steps to remedy the issue as quickly as possible. If the propane tank cannot be fixed, you have to get a new one. Propane is just way too dangerous to take any chances with.

My name is Madeline Cooper, and I have now been living and traveling across the states in my RV for the past 8 years. It has been such an amazing experience, and I have learned so much along the way.

Through this blog, I want to share all of my hints and tips, along with reviews of the best RVing accessories. I hope this blog will help others with their RV trips, and make traveling easier for you.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pressure relief valves ensure efficiency and safety in many chemical, oil, and gas plants, but they’re susceptible to leaks. If a pressure relief valve is leaking, systems can become overpressurized and even fail, especially if the valve isn’t addressed or repaired quickly.

When you shut down the system, carefully examine the pipelines and the valve itself to determine the cause of the leak. This will help you figure out exactly what you need to do to repair it.

Pressure relief valve leaks usually occur when the valve isn’t properly seated or when the seal is broken or damaged. Leaks can also happen when the pressure relief valve is operating too closely to the set point.

If the valve isn’t completely repaired after your first attempt, you have up to 15 days to perform any additional repairs according to the EPA. If the valve still isn’t fixed, then you can either replace the pressure relief valve or wait until the next shutdown cycle to do more repairs.

When the pressure relief valve has been fixed or replaced, it’s important to take the necessary steps to avoid leaks in the future. To do that, consider implementing a leak detection and repair (LDAR) program for your company.

An LDAR program will help to train workers on everything they need to know about detecting and repairing a leak before system damage can occur. It will also help you monitor valves more efficiently so you can spot leaks faster and spend less money on overall valve repair and maintenance costs.

Propane gas is stored in either portable or stationary tanks. You may have one connected to your outdoor grill, or you’ve noticed them outside of homes in rural areas. While these tanks are ideal for storing liquid propane gas, from time to time, propane tank repair is required. While propane gas is a safe way to cook and heat, a leaking tank is not safe.

Propane gas is a petroleum gas in liquefied form, LPG, that is compressed and stored in tanks. It is then delivered in a liquid form by trucks that fill the tanks at homes and businesses.

With proper use and storage, this colorless, non-toxic, virtually odorless gas is a safe method of energy. At home it can be used on the outdoor grill, for a gas fireplace, and even to heat your home, water, and food. It is essentially a clean and safe energy source.

However, because the liquid form is compressed and stored in tanks, it is under high pressure. This leads to people unfamiliar with LPG tanks having concerns about them exploding. Each propane tank, whether it is portable or stationary, is equipped with a PRV (Pressure Relief Valve), located within another valve for safety and then incorporated with the propane tank’s main valve.

If the tank’s pressure increases, gas is automatically released by the PRV to ease that pressure. Until a tank has reached up to 1,000 PSGI (poundsper square gauge), a well-maintained propane tank will not explode. It is for this reason that if you smell any gascoming from a propane tank, immediate propane tank repair is a must.

Having a complete and thorough understanding of propane gas tanks is always important. Getting immediate propane tank repair when necessary can prevent numerous accidents. Remembering this, you can heat your home, cook your meals, and heat up water with peace of mind.

The vapor from propane gas is an asphyxiating gas, but not toxic. Propane will displace any oxygen in the lungs, making breathing difficult or even impossible if inhaled for an extended time in a high concentration. This is why as soon as there is any suspicion of a leak, propane tank repair should be sought immediately.

Breathing will become difficult if you find yourself breathing in propane fumes, and physical activity can make the situation worse. Symptoms of propane gas exposure will depend on how the exposure to the gas happened. Symptoms that may be experienced with low exposure are:

When liquid propane escapes from a tank, it is extremely cold and contact with the propane at that point can irritate the skin and cause frostbite. Frostbite can lead to skin blistering, tissue death, and infections. When any chill is felt from a propane tank, it should be taken to the dealer, or the LPG company should be called for emergency propane tank repair.

A damaged propane tank cannot be repaired and reused. There are many laws regarding the regulation of propane tanks for sale, rent, or repair. There are also significant rules surrounding propane and propane tanks that must be thoroughly understood, and extensive training is required of any propane suppliers. It is their responsibility to advise the homeowners that rent the tanks for their grills or other home uses on best practices regarding propane tanks.

Never should a homeowner attempt propane tank repairs or make any modifications to a propane system or tank. This should only be done by a licensed individual or a propane supplier. If a supplier sees that a propane tank repair or modification has been made by someone who is not authorized, they can refuse to service the customer. It is federal law that any damaged propane tank that cannot be repaired should be destroyed.

If you discover that the propane tank you’re using is leaking, it is imperative that you deal with the matter immediately. While propane tank repairs should only be done by authorized and licensed dealers or supplier, there are a few steps you can take that may stop the leak.

Usually, there is a hissing sound coming from a leaking propane tank. You may notice a smell like rotten eggs or skunk. This is not the odor of the propane gas itself, but is still a sign of leakage. This is because while propane gas is odorless, suppliers add a chemical that creates this odor.

If you have noticed a hissing sound or an odor, turn off everything electrical or gas nearby to avoid possible sparks that can cause an explosion, and then follow these steps:

After turning off the propane tank valve, there will typically be enough gas left to help you determine where it is leaking. As quickly as possible, mix one cup of dishwashing liquid with one cup warm water in a spray bottle. Spray until the surface is covered.

Next, open the valve slowly. If bubbles start forming in the solution, that’s where the leak is located. Small bubbles indicate a small leak. Large bubbles indicate a large leak. Mark each area that has bubbles.

Let the tank sit for ten minutes and spray the soap/water mixture on the areas you marked earlier. Turn the cylinder valve back on slowly and see if bubbles are still forming.

If you still see bubbles, propane tank repair isn’t possible. Turn the tank in to the supplier and request a new one. If the propane leak is inside your home, evacuate and call 911 immediately. After that, call a propane dealer or supplier. They will have the equipment and knowledge of how to repair the propane tank valve if that’s the problem.

The bleeder valve or fixed level gauge is typically opened when a propane tank is filled. If it isn’t closed all the way after the fill is done, propane will begin leaking.

If the leak is at the valve but it isn’t open, it may be from a clogged coil, which happens when a propane tank has been leaking. It is an easy propane tank repair, starting with turning the bleeder valve off.

A propane tank will have a relief valve that relieves pressure in the tank when there is too much. When the propane tank is in heated areas, the PRV opens a bit to relieve any pressure building up. Sometimes, propane gas will leak from the opened PRV.

For this propane tank repair, don’t turn the valve. Simply tap on it gently with a screwdriver to encourage the PRV to close on its own. You can run cool water over the tank with a hose to cool the tank down; this will prompt the valve to close as designed.

Now there is a possibility that the tank valve may be damaged and causing it to leak, which can be harmful and dangerous. In this situation, do not attempt to do your own propane tank repair. Return the tank to the dealer or supplier.

Absolutely! Fortunately, a certified and licensed propane supplier knows to leave enough empty space in a propane tank for expansion. When a propane tank has been overfilled, it is putting the tank, and you, at risk of leaks or explosion.

There are different sizes and types of propane tanks. They can be installed in the ground or set up above ground. Of course, there are also propane tanks for outdoor grills. Both in-ground and above ground propane tanks cost $1,500 and up to $3,800. Portable tanks for outdoor grills can cost $40 to $60 depending on the retailer.

There are a few more things to remember if you’re planning to get a propane tank for your home. Propane tanks have an expiration date on them to remind you when to replace a propane tank. Generally, a portable propane bottle will have up to 12 years before expiration. When being refilled and recertified, this can range between 5 years and 12 years.

It could be the fixed liquid level gauge (bleeder valve), which is opened by the delivery person every time the tank is filled with propane. On occasion, the bleeder valve is not closed completely, whether due to driver error or debris blockage. If this is the case, simply turning the bleeder valve clockwise will close the valve and stop the flow of gas. This is not unheard of and is easily remedied by simply closing the bleeder valve. The hissing noise could also be coming from the safety relief valve. On hot days when the sun is high overhead and a propane delivery has recently been made, the safety relief valve may open slightly allowing excess pressure to vent. If the relief valve is opened, the protective cap will be removed from the top of the valve from the pressure buildup. Do not look into the relief valve or tap it with anything. Doing so may cause the relief valve to open all the way. One way to remedy the situation is to cool the tank down by spraying water from a garden hose on the surface of the tank. This will generally cause the relief valve to close. Lastly, it could be the regulator humming and the pressure needs to be readjusted. Just call our office and a technician will be happy to stop by and readjust it for you.

The design of the OPD valve is such that turning the cylinder service valve hand wheel will not produce any effect if the cylinder is not hooked up to an appliance. In other words, a connection must be made between the appliance hose end and the cylinders service valve. The inside of the OPD valve is engineered to only allow propane in or out if the internal valve is actuated by being depressed. This OPD valve feature adds additional safety in case the hand wheel is turned, opening the valve. For this reason, OPD equipped cylinders will not allow gas out of the cylinder when opened. The same is true for industrial forklift cylinders. Also, the hose end connection on either a fill hose or appliance supply line is designed to work only with OPD equipped cylinders. For the OPD valve to operate with the hand wheel open, the hose end connection must be securely attached. The hose end connection has an elevated brass fitting which is surrounded by acme threads. When attached to a cylinder valve and tightened, the brass fitting will push the internal valve open and allow gas to flow out of the cylinder to the appliance, if the hand wheel is in the open position. This fitting must be in place for gas to flow out of the cylinder. Otherwise, turning the hand wheel will not produce the intended result.

Freezing and frosting of propane regulators is quite common and usually nothing to be concerned about, provided everything is in working order and operating as it should. Frost can form on regulators connected to both propane cylinders and bulk (stationary) LP gas tanks. If in doubt about the safety of your regulator, turn off the tank service valve and contact your propane company. Further reading will help propane users understand the reasoning and causes of a “freezing” regulator. During normal operation propane regulators can become covered in frost, which may alarm some users. While this “freezing” of the regulator may be a symptom of a more severe problem, it’s usually is a sign that outside humidity is at a level capable of producing condensation. The only difference is, the condensation forming on a regulator is frozen. As described, propane regulators act as a barrier between high tank pressures and delivery pressure as required by downstream appliances and/or equipment. Once a propane appliance is actively in use, the liquid propane in a tank or cylinder begins to boil. The propane vapor, as boiled off the top of the liquid begins its journey downstream to the point at which it is used. Before making its way to the LP gas system piping, it passes through the regulator where its pressure is reduced to a usable level. Keep in mind that the regulator will only deliver a constant pressure on the outlet side while inlet pressures can significantly vary. As the propane passes through the regulator, it expands (resulting in sub-zero temperatures) and causes the regulator to gradually reach the extremely cold temperature of the propane vapor passing through it. Depending on the temperature and humidity of the surrounding air, the regulator will produce condensation, much like that of a frozen mug or glass taken out of a freezer. This is why, under normal operation in hot and humid climates, the external surface of a regulator will freeze and appear to be frozen or frosted. The rate at which propane is being withdrawn from the tank or cylinder will also cause the container to display a visible frost line, which indicates the liquid level of the propane within the tank. Although regulators can freeze under normal and “proper” operating conditions, there are times when regulators are freezing because of actual problems. One of the problematic issues causing a regulator to freeze is due to liquid propane entering and passing through the regulator. Liquid propane can produce an effect of extreme freezing when introduced abruptly into a regulator. There are two ways that liquid can be delivered through the tank (or cylinder) service valve: 1) If the container is overfilled or, 2) If the tank, usually a bottle, is not upright with the service valve communicating with the vapor space of the container. Both of these scenarios are possible and while avoidable, are not very common.

The only way to lock in a price is through our price protection program. Our customers who choose a variable “market” price plan cannot lock their price. These customers are charged a price based on the market price for propane on the day of delivery. That means a customer’s price on the day of delivery may be higher or lower than when they called to request the delivery. During the last heating season, propane prices started to rise, so on some days the price may be higher than when the customer called. In falling markets, our variable priced customers can potentially benefit from a lower price on the day of delivery.

Unless you are on a budget plan or have pre-paid in advance, you have 30 days from the date of delivery to make a payment. Just like any business, we also have to pay our suppliers and employees, so we appreciate payment on time. If we haven’t received payment in 30 days, we’ll send you a friendly reminder. We know that sometimes life happens – a delivery slip may be lost, or could be put in the bill drawer. If at any time you are having trouble making a payment, please call or email us and we can arrange for a payment plan. After 30 days, 1.5% interest is charged per month.

Charges resulting from interest, fuel surcharges, tax, service calls, labor, etc. are billed to the same account as your residential propane deliveries so they deduct from any credit on your account. However, your fuel credit will be replenished when payment is made for these charges.

If the tank is leased by Garrow Propane, then no. Our Garrow tanks come painted a sliver/gray color with a tan hood. If your Garrow tank is starting to rust or the paint is chipping please contact our office and we will put you on the paint list. Every summer we repaint the tanks on the list for that year. If you own the tank, you can paint it if you’d like, but not any color you choose. All too often propane customers take it upon themselves to paint their tank a color that complements the colors of their home or landscaping. This presents a safety problem as well as a serviceability problem if the tank color is dark or non-reflective. Dark colors absorb heat while lighter colors reflect it. Have you ever worn a dark colored shirt on a sunny day? A dark shirt on a sunny day will make you much warmer than a white shirt. The principle is the same with LP gas tanks, and the last thing a propane tank needs is to absorb heat. Perhaps a better example is walking barefoot on the concrete sidewalk and stepping onto an asphalt street on a hot sunny day. Concrete sidewalks are fairly light in color (heat reflective) while asphalt streets and roads are dark in color (heat absorbent). The sidewalk is much more bearable to walk on while the asphalt road can be quite painful. Propane tanks need to reflect heat, not absorb it. The entire reasoning behind propane tank color involves pressure and some simple laws of chemistry that apply to fluids and gases when they are heated. The law “as temperature increases, volume increases” applies. Because propane exists as both a liquid and a gas within the tank, the absorption of heat due to a non-reflective color creates the possibility of a high-pressure situation that may cause the safety relief valve to open. The bottom line is this: Dark (Non Reflective) Propane Tank = Absorbed Heat = Propane Expansion = Relief Valve May Open.

In its natural state, propane is an odorless gas. As a safety precaution, a chemical called Ethyl Mercaptan is added so that any presence of propane may be easily detected. The concentration level of ethyl mercaptan that is added to propane is not harmful.

No, propane is an approved, clean fuel listed in the 1990 Clean Air Act and the Energy Policy Act of 1992. Propane is one of the cleanest burning of all fossil fuels. Tests conducted by the U.S. Environmental Protection Agency show that propane-fueled vehicles produce 30-90% less carbon monoxide and about 50% fewer toxins and other smog-producing emissions than gasoline engines. Propane also is nontoxic, so it’s not harmful to soil or water. In the event of a leak, propane will dissipate into a vapor, leaving no lasting effect on the surrounding environment

Propane tanks are most commonly referred to by their water capacity volume, and propane tanks are normally filled to 80% of its water capacity. For example, a 120 gallon tank will hold approximately 100 gallons of propane when completely full. Since propane is stored in a liquid state under pressure, it needs room to expand into a vapor. This extra “room” that is in the tank allows for that expansion. Depending on the ambient temperature outside, propane may expand more or less.

Safety is a part of everything we do. We charge a hazmat fee to help us cover the costs of ensuring the safety of our customer and employees. These measures include policies, procedures, gas check training, cylinder requalification, to our own facility and vehicle operations.

When you rent a tank, Garrow Propane assumes responsibility for equipment upkeep and maintenance of your propane system, including painting the tank and replacement of first-stage regulators. You are invoiced the tank rent only if you are a low volume user as your lease agreement states. In this case your usage does NOT cover the cost of equipment Garrow Propane has provided you. Those that use the minimum amount of fuel required annually, are not invoiced a tank rent.

When you run out of propane, you will begin to smell gas. This is the mercaptan that is sitting on the bottom of the tank that is added to make propane have an odor. There is no harm in this. If you are a will-call customer, there is a pressure check charge associated with the run out. The system needs to be pressure tested and we have to ensure you ran out of fuel for lack of looking at the gauge vs. you have a gas leak.

As a company that supplies propane to thousands of Americans, safety is a top priority. Always has been and always will be. Each and every day our dedicated and prepared employees strive to be entirely aware of the wellbeing and safety to all. In our books, you, our customers, and our employee’s own safety is No. 1. Plain and simple.

That’s precisely why we want to inform you on any safety risks regarding the use of propane. One safety concern that may come about is an overfilled propane tank. Although the chances of your propane tank being overfilled are rare, it is a possibility. It’s doesn’t happen often due to the National Fire Protection Association in 1998 requiring DOT cylinders, grill tanks included, to have an overfilled protection device (OPD). If you’re wondering what an OPD looks like, you’ve likely seen and used it many times. It’s the triangular handle that you use to turn the gas on and off.

From understanding whydos and don’ts of grilling, Ferrellgas and Blue Rhino are committed to providing peace of mind for all customers. That includes the importance of knowing what to do when safety precautions are necessary when dealing with propane. Our employees undergo rigorous training on how to fill tanks, and, per federal guidelines, they’re instructed to only fill tanks to 80% capacity to allow propane to expand when external temperatures rise. The hotter it is outside; the more propane expands to fill the extra 20%.

In rare instances, yes. The first sign that a propane tank is overfilled comes in the form of smell. An overwhelming smell of propane gas, or mercaptan, which is added to the odorless propane, means that propane could be escaping the tank. If true, a vapor stream of liquid propane will come out of the tank, and, if not handled properly, it can be a safety and fire hazard.

When a propane tank is filled properly, propane releases a quick spurt when the connection is released. Sometimes, too, no spurt will be heard. So, yes, a propane tank can be overfilled, which makes it important to know the risks and how to handle the situation.

The ultimate risk, and downright worst-case scenario, is an explosion. It can certainly happen, which is why it’s important to be aware of how to act. An explosion is usually the result of improper handling of propane. Also, a note: It is not advisable to drain an overfilled propane tank.

If this happens to you, you’ll first want to clear the area and make sure there are no ignition sources nearby, which could result in explosion or open fire.

Next, callyour propane specialists and we’ll help you with next steps. Your local propane pros are trained to swiftly diffuse these situations. Quite simply, it’s our job to protect you.

When you let Ferrellgas help fuel what matters most to you, you’re working with the very best and most trustworthy propane professionals in the industry. There’s eight decades of history to back that up. And when it comes to safety, we"ll always have your back.

Check that the hose attachment is properly connected to the propane tank, and double-check that the screw-on valve is tightened. Some propane tanks have safety features that won’t allow gas to escape from the canister unless the hose connection is tightly secured with the gas release mechanism.

Take a look at your connector. If it’s less than an inch long, it won’t be long enough to depress the check valve inside the valve. In this case, you’ll need a new connector that’s over an inch long.

If your valve is turned all the way on, the tank may not release propane. This is a safety feature. Start over, turning the valve only once, then igniting the grill.

If none of these actions work, it’s possible that you have a faulty regulator, which stops the flow of propane. In this case, it’s best to get a new hose with a regulator, and try again.

Re-lighting your pilot light on your own can be dangerous. Please carefully follow all of the manufacturer"s instructions and warnings concerning the appliance, and read the following list of precautions. You can contact our customer service team or appliance professional for further guidance.

Exert force or use tools on the pilot light or its controls. This could cause damage and lead to gas leakage. Use only your hands to operate knobs, switches, or buttons.

If you"re leaving your home for an extended period of time, consider closing all your propane supply valves—including the main supply valve on your propane tank and the gas supply valves on each appliance.

When you come back, you MUST call AmeriGas to conduct a leak check before your propane supply is turned back on. After we confirm there are no leaks, we can also re-light your pilot lights if you need help.

In extreme heat, which often accompanies drought conditions, make sure the 10 foot radius around your propane tank and your propane grill is clear of flammable materials. Remove any debris that is combustible or easily ignited, including leaves, brush, any vegetation, and rags.

Floods can move, shift, or damage gas lines and tanks. A large propane tank can become dislodged from its service line and float away, striking trees, vehicles, or other heavy objects along its path. Water and debris can find their way inside regulators and controls, causing potential safety issues. Fallen trees and power lines can create extra safety concerns. If you have any doubts about your safety, leave the area immediately, alert AmeriGas or your utility company, and have your property inspected by a qualified building inspector or structural engineer before re-entering.

High winds and hail—often accompanying hurricanes, tornadoes, and winter storms—can move, shift, or damage gas lines and tanks. If your propane tank becomes dislodged from its service line, it’s likely to be leaking gas out into the surrounding area. A spark from a fallen power line or other ignition source could pose a danger to anyone nearby. Debris and water can find their way inside regulators and controls, causing potential safety issues. If you have any doubts about your safety, leave the area immediately, alert AmeriGas or your utility company, and have your property inspected by a qualified building inspector or structural engineer before re-entering.

If you smell gas or are experiencing signs of a gas leak immediately exit the premises and contact 800-805-0659 or 9-1-1 for immediate assistance. All gas leaks potentially pose a serious threat.

The best way to reduce the risk of carbon monoxide poisoning is to have a qualified service technician check your appliances and venting systems regularly.

If you smell gas or are experiencing signs of a gas leak immediately exit the premises and contact 800-805-0659 or 9-1-1 for immediate assistance. All gas leaks potentially pose a serious threat.

You"ll need to get your propane grill tank re-certified periodically, depending on the tank. This is essential in order to keep your propane tank in safe operating condition. When you get a new grill tank from AmeriGas, it"s already been certified. If you"re concerned about an old tank, you can exchange it for a new one to be sure it"s certified, or Contact AmeriGas for additional support.

If you smell gas or are experiencing signs of a gas leak immediately exit the premises and contact 800-805-0659 or 9-1-1 for immediate assistance. All gas leaks potentially pose a serious threat.

If the suspected leak is coming from a portable propane tank or grill tank, and it is safe to do so, turn off the cylinder valve, turning it to the right (clockwise). If you are unable to turn off the valve, immediately leave the area and dial 911 or call your local fire department. Before you use the grill again, have a qualified service technician inspect your grill and cylinder. It"s best to move away from the source of the leak, and to ensure pets and people are not at close range.

Propane is a combustible material created from natural gas processing and oil refining over long periods. The naturally occurring gas includes eight hydrogen atoms and three carbon atoms. The combustibility of propane makes it a very versatile product. It can be used for many different reasons, such as central heating, barbecue grills, engine fuels, and torches.

Unfortunately, propane’s combustibility is also the reason why it can be dangerous and cause an explosion. Accidents related to propane explosions can be divided into two groups. The first category actually has very little to do with the propane tank itself. Instead, the propane gas explosion results from the propane leaking because a tank was left open, and the gas supply is ignited from exposure to flames or high temperatures. This is usually the cause of gas grill tank explosions.

On rare occasions, propane tank explosions can occur from the pressure of the propane tank reaching higher than the pressure that the tank can safely vent, causing the tank to burst open. This kind of explosion is called a Boiling Liquid Expanding Vapor Explosion (BLEVE).

Built-in Relief Valves – Most propane tanks come with a relief valve which acts as the primary method of defense for any explosions. If the tank’s pressure reaches higher than a specific point, the relief valve will open automatically. This lets the gas vent and reduces the pressure. That is why direct exposure to pressure or extremely high temperatures are needed to even cause a BLEVE. Still, it is important to practice safe handling and storage techniques from your end to prevent any explosions.

Yes, they can. On a warm summer day, temperatures can rise quickly. As the propane tank gets hotter, the pressure inside the tank will increase. Although portable propane tanks are equipped with safety relief valves designed to release pressure build-up, the smartest place to store a tank is out of direct sunlight. The safest place to store a propane tank is outdoors, in the shade, and in cool temperatures.

The best way to prevent a BLEVE is by always making sure that the propane tank is closed when you are not using it. You will also want to check the connections and hoses for any leaks routinely.

Do not store a propane tank right next to a tank that is being used – If other tanks are stored nearby, high temperatures can cause bleeder valves to open, which can expand a fire, causing a chain reaction.

Follow OSHA requirements – The Occupational Safety and Health Administration (OSHA) guidelines require a chemical to be mixed with propane (propane has no odor) so that users will smell a scent that resembles a “rotten egg” if a leak happens.Make sure you familiarize yourself with the smell just in case of an emergency.

Although propane-based explosions are rare, it is nothing to take lightly. An explosion can cause serious injury or even death to those who come in contact with it.

If you smell gas coming from your propane tank, you should take the following steps.If there are no sparks or flames, you can pull out all the smoking material and any other open flames.

If you need new propane for your home, we are here to help.Great Valley Propaneoffers high-quality propane tanks in durable containers with built-in safety features. Our team of experts is extremely knowledgeable and will take the utmost safety precautions in any services we provide for you and your family.

8613371530291

8613371530291