the safety valve reduces pressure at pricelist

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale pressure relief valve price list on Alibaba.com. When you search for pressure relief valve price list and related items, you will be able to find many types of pressure relief valve price list varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of pressure relief valve price list that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale safety valve price list on Alibaba.com. When you search for safety valve price list and related items, you will be able to find many types of safety valve price list varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of safety valve price list that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Finding a quality driving school in can be a difficult and time consuming task. driving-schools.com comprehensive database of driving schools helps you pick one that’s right for you.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pressure valves regulatethe flow of gas through a pipeline by opening or closing in response to changes in the pressure of the gas, air, water, or steam flowing through the pipe. Pressure valves are commonly used on natural gas systems, propane systems, and other types of gas systems.

A pressure valve regulates the flow of gas through pipelines by opening or closing in accordance with changes in the pressure of gas flowing through the pipe, thereby maintaining a constant pressure within the pipeline.

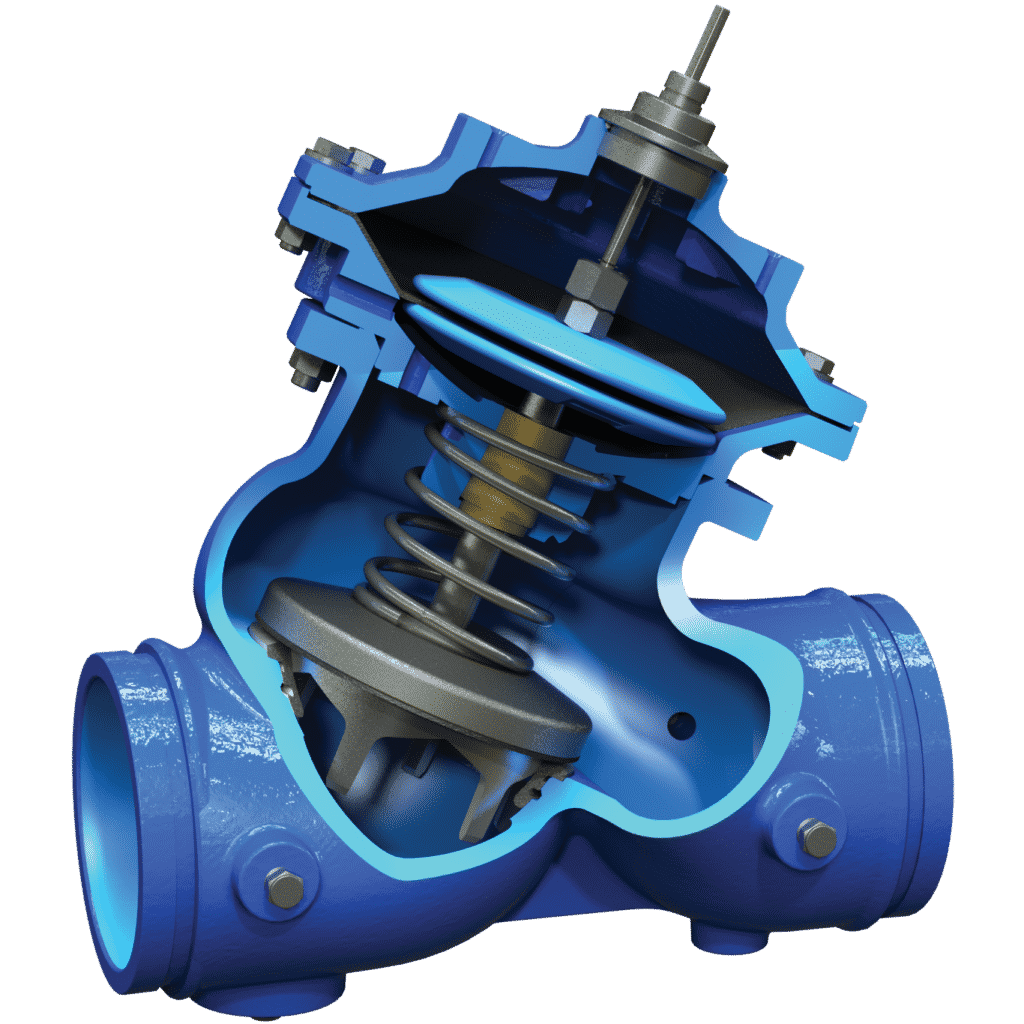

Pressure valves work by using a spring-loaded diaphragm or electrical actuator to open or close the valve in the pipeline. As the pressure inside the pipeline rises, the diaphragm moves away from the valve seat, allowing more gas to pass through. Conversely, as the pressure falls, the diaphragms move toward the valve seat, restricting the flow of gas.

Testing a pressure valve should be done before installing it into a system. If there are leaks in the pipe, the valve will not work properly. To test a pressure valve, use a leak detector to check for leaks in the pipe. Then, turn off the main supply line and connect a gauge to the valve. Turn the valve on slowly until the pressure reaches the desired level. Once the pressure has reached the desired level, turn the valve off and wait for the pressure to drop back down to normal levels.

Pressure valve control is used in many applications, but they’re mainly found in all pneumatic and hydraulic systems. Pressure valve control has a wide range of functions that can be used to maintain a set pressure level in a part of a control loop or to keep system pressures below a desired limit.

There are many different types of pressure valve control in the industry, such as pressure relief valves, pressure reducing valves, pressure safety valves, counterbalance valves, unloading valves, and sequencing valves. Most of these pressure valves are typically closed valves, but pressure reducing valves are commonly open valves. It’s important for most of these valves to have restrictions so that the required pressure control can be achieved.

The flow must be consistent at all times in certain applications. Injuries or deaths can be caused by variations in the flow of gases. That’s why pressure control valves are so important in the processing loop.

Pressure relief valves are used to keep the pneumatic and hydraulic systems under the desired pressure value. Based on the different installation positions, pressure relief valves have different functions as below. The downstream pressure should be reduced to a constant level whenever it goes over a threshold.

A pressure relief valve is usually made of three parts: a ball/diaphragm, a spring-loaded mechanism, and a valve nozzle. A spring-loaded mechanism is placed in the valve’s housing, which is used to close the orifice. The pressure relief valve’s spring-loaded mechanism can be adjusted to change the pressure on the spring mechanism. If you want to increase the set pressure limit, just simply increase the pressure on the valve spring-load mechanism directly. If you want to decrease the set pressure limit, only decrease the pressure on the spring-load mechanism directly. A relief valve set-pressure can be specified by the manufacturer if there is no adjustability. When the set pressure is reached, the pressure overcomes the spring pressure and pushes the ball or diaphragm back opening the orifice and releasing the excess pressure. Depending on the media, it is either released into the atmosphere or discharged into it. It is possible to return to a tank or pumping circuit with compressed air.

There are two types of PRVs used in industry, one is the direct-acting pressure reducing valves, and the other type is pilot operated pressure reducing valves. The pressure reducing valves use globe type or angle type valve bodies. Most of the time, the main type of valve used in water systems is the direct acting valve, which consists of a globe-type body with a spring-loaded, heat-resistant diaphragm connected to the outlet of the valve that acts upon a spring. This spring holds a pre-set tension on the PRVs seat that’s installed with a pressure equalizing mechanism for precise water pressure control.

Pressure reducing valves are widely used in water conditions, such as in buildings, industrial plants, water treatment plants, homes, and so on. It will automatically reduce the water pressure from the main supply, in case to lower the water pressure to the destination and more sensible pressure for equipment.

Sequence valves are widely used in hydraulic systems, and are a type of pressure valve. Sequence valves are similar to pressure relief valves, but are used to control a set of pressure-related operating sequences. The main function of a sequence valve is to divert the flow in a predetermined sequence, and its construction is very similar to a pressure relief valve, which is a pressure actuated valve, usually a closed valve.

The sequence valve works on the principle that the valve plug will be moved when the main system pressure exceeds the spring setting. As a result, the outlet of the sequence valve will remain closed until the upstream pressure rises to a predetermined value, and then the valve will open, allowing air to transfer from the inlet to the outlet. Sequence valves are primarily used to force two actuators to operate in sequence. One nice feature of the sequence valve is that the valve has a separate drain connection to the spring chamber, under normal operating conditions, high pressures may occur at the output port. When the pressure rises above its limit, the pressure sequence valve will allow flow to occur in another part of the system. The pressure sequence valve is installed in a pneumatic control and its switching operation requires a specific pressure.

Counterbalance valves are used to handle loads that are over-limited and to safely suspend loads, these valves commonly work with hydraulic cylinders. This type of valve can also be used with hydraulic motors and is then commonly referred to as a brake valve. Both counterbalance valves and pilot-operated check valves can be used to lock the fluid in the cylinder to prevent drift. However, pilot-operated check valves cannot control over-running loads. A counterbalance valve should be used when uncontrolled motion may occur with an overrunning load.

The pressure safety valve is one of the most critical automatic safety devices in a pressure system, and in many cases is the last line of defense for safety. The important function of a pressure safety valve is overpressure protection, so ensure that the pressure safety valve can operate properly in any situation. Pressure safety valves are mainly used in pressurized vessels or equipment to protect the environment, property safety, and life safety in the event of an overpressure event. A pressure safety valve opens and releases excess pressure in a vessel or equipment, and closes again when normal conditions are restored and prevents the further release of fluid.

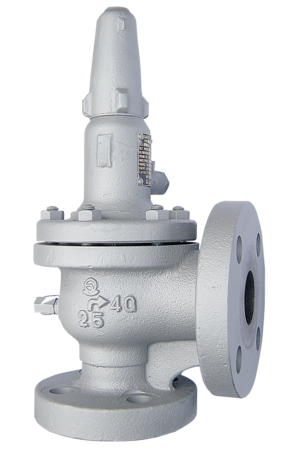

In order to protect the systems that are designed according to different fluids and a certain pressure against all the adversities, the valves that provide controlled discharge of the fluid (steam, liquid, gas) when the design pressure rises above a certain value are called safety valve.

It releases a certain amount of steam, gas or liquid if the system pressure rises above the valve"s set pressure. In this way, it protects the desired pressure system against unauthorized pressure increases.The safety valve reaches its full discharge capacity with a maximum pressure increase of 10% of the set pressure. Shut-off pressure of the safety valve: It is maximum 10% for compressible materials and less than 20% for incompressible substances.

Park on level ground, chock the wheels, release the parking brake when you have enough air pressure, shut the engine off, and repeatedly press and release the brake pedal.

When performing a final check of your air brake, make sure your vehicle has low air pressure by shutting off the engine, chocking the wheels, and releasing the air pressure by pulling on and off the brakes. Continue doing so until the spring brakes come on automatically, which should be between 20 and 45 psi once you"ve confirmed the low-pressure warning is valid.

Being a client oriented organization, we are occupied in presenting an extensive range of Water Blast Pressure Hoses. Provided products are precisely fabricated under the guidance of our experienced professionals using optimum quality raw materials and upgraded technology. In order to ensure their efficiency and quality, theseread more...

DOMBIVALI, Thane Vivek Arun Patil B-2,306 Amber Enclave 90 Feet Road Near Laxmi Park Thakurli East, DOMBIVALI, Thane - 421201, Dist. Thane, Maharashtra

Use these valves for emergency relief where pressures must be relieved quickly to reduce damage that could result from overpressure in a system. Where the overpressure needs to be controlled more gradually ,such as in back pressure or pump bypass applications use our

Although the valve is typically installed in the position illustrated, it can operate in any position or orientation, vertical horizontal, etc as long as it can be easily accessed for making adjustments.

These valves do not carry the Canadian CRN or ASME approval stamp and should not be applied where this requirement must be met. However, the valves generally meet or exceed ASME design criteria with wall thicknesses that are much heavier than the minimums required. For an additional charge, valves can be ordered with material certs and with a certified hydro-test certificate and other tests to meet special documentation and acceptance requirements.

Avoid locating the valve where freezing can occur, and if unavoidable, take precautions to insulate or heat wrap valve and piping to keep from freezing.

As you know, the main prerequisite for doing any work is to have accurate information about that subject. In the discussion of selection, checking the prices, buying, and getting to know more about the types of pressure relief valves and safety valves, the following contents are included for you, dear visitors of the specialized website of Demataheheez (an official member of the heating and air conditioning equipment sellers" union), with the help of With these tips, you can choose and buy a pressure relief valve and a safety valve suitable for your living or work environment with enough information.

A pressure relief valve is a valve that reduces the inlet fluid pressure and also controls the fluid pressure at the outlet of the valve so that the outlet pressure is lower than the inlet pressure. Pressure relief valves are usually used to control high water pressure in high towers, wide fluid transmission networks, large industrial tanks, etc. They are not used for domestic water piping systems. Join us in introducing and checking the performance of different types of pressure relief valves and safety valves in the rest of this article.

Most of the time, and by mistake, pressure relief and safety valves are considered one product. If these two valves have two different functions, each one has a different application. Below we mention one of these differences.

When the tank pressure rises above a specific limit, the safety valve opens entirely and releases the pressure at once without the help of the controller.

But when the pressure in the pressure relief valve increases, the controller or actuator operates. When the pressure relief valve disk opens, the excess pressure in the tank is gradually discharged.

The force of the water pressure, which is indicated by the green arrow in the picture below, pushes the spring upwards, and the force of the spring, which is indicated by the red arrow, constantly pushes the spring down; as a result of this function, both forces neutralize each other, and the pressure is stable. We will have at the output.

This valve has a pilot that directly operates the valve and reduces the pressure, and is used to control high pressures. It has two types of piston and diaphragm.

This valve has a large diaphragm that is responsible for operating the valve and can minimize pressure drop fluctuations during flow control. This valve can control high flows and can reduce a lot of pressure. This valve is used in industry, large construction projects, wide and high-pressure fluid transmission and distribution networks, air conditioning equipment, irrigation, etc.

This valve has a piston for the operation of the valve and is widely used in steam lines, and has high control ability to reduce pressure with fluctuations of up to 0.05 MPa. This valve is also used in various industries, large construction projects, wide and high-pressure fluid transmission and distribution networks, air conditioning equipment, irrigation, etc., just like diaphragm pilot valves.

This valve regulates the fluid flow in the hydraulic system, which is connected to the valve as a manual lever and is used in industries such as automobile manufacturing, cement, steel, etc.

The pressure in this valve is sensed by the sensor and sent to the controller. This milk is used in agriculture, textile, automotive, food, wood, etc.

Safety valves have a protective function by performing pressure adjustment; that is, when the pressure of the fluid entering them rises above a specific value, they operate automatically, and their valve opens, and by draining the fluid, it brings the pressure to the standard level and avoids risks such as an explosion. They are prevented in closed tanks, and finally, when the pressure reaches a level lower than the maximum pressure of the safety valve used, the valve closes again. The pressure measurement unit is in Bar or PSI, and the safety valves have two ASME or API526 standards.

Among the safety valve applications, we can mention the use in hot water tanks with coils, double-walled engine room sources, fuel storage tanks, boilers, piping systems, pressure tanks, etc.

Spring-loaded safety valve: In this type of design, the spring is designed to push the disk against the incoming flow, and when the pressure exceeds a certain level, the spring opens, the disk is released, and the fluid flows into the valve.

Net weight safety valve: in this type, no spring is used, and with increasing pressure, the disk rises, excess pressure is discharged, and it is used for low-pressure tanks.

Safety valve with the pilot: This valve consists of two parts: the main and pilot valves. In this model, the pressure is adjusted by the pilot valve, and it is used in high-pressure tanks and large valves, where a higher reliability factor is required.

In the group of pressure relief valves and safety valves of the Damatajhiz reference site, information and prices of all types of pressure relief valves, safety valves, venting valves, etc., from brands such as CS Case, Hysk, Honeywell, etc., with original warranty for review and purchase. It is presented to you, dear users and employers.

In addition to a valid business license from the heating and air-conditioning trade union, Damatajhiz has an electronic trust symbol. It started operating its store site in 2013 in Tehran"s head office.

Safety valves or pressure relief valves are pressure regulating devices that are responsible for expelling excess pressure from the system when the maximum pressure levels for which they have been designed are exceeded, usually due to a

Safety valves perform their function when the pressure of the system where the fluid is contained, becomes higher than the maximum set pressure of the valve previously adjusted. When the system pressure is higher than the valve’s set

pressure, this opens, releasing the excess pressure to the atmosphere or to containment tanks, depending on the toxicity of the fluid. After releasing the excess, the valve closes again and the system pressure returns to normal.

To ensure total safety of personnel and installation, make sure that the valves have passed all safety tests and meet the requirements of the system where they are to be installed. All our valves are supplied with certificates of materials, cas-

What is the difference between the instantaneous full opening safety valve AIT (PSV) and the normal opening relief valve AN or progressive opening relief valve AP (PRV)?

The Pressure Safety Valve (PSV) opens instantaneously and fully upon reaching the set pressure for which it is designed, expelling the excess pressure from the system immediately. They are optimised for use with steam or gases.

In contrast, the normally or progressively opening Pressure Relief Valve (PRV) opens gradually as the system pressure rises above the set pressure of the valve above its setting. They are optimised to work with liquids.

At VYC Industrial we are specialists in the design and manufacture of all types of safety valves. We have a wide range of safety valves to cover all the needs of the sector.

The Mod. 496 EN safety valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The Mod. 495 EN pressure relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

Fabrication program Catalogues by product Operating principles AP CP EP ES Assembly and disassembly instructions AP CP EP ESComplementary technical instructions

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

They are used in places such as power, chemical and petrochemical plants to discharge safety valves, control valves, etc. in pressure lines and equipment that convey compressible substances such as steam, air, carbon dioxide, helium, methane, nitrogen, oxygen and other gases.

Test bench for regular inspections and setting and resetting safety valves. Ideal for distributors, maintenance companies or with in-house maintenance. It allows safety valves to be adjusted, tested and/or checked to the test pressure (setting) Pe wile cold (simulating service conditions), matching the opening pressure Ps and the closing pressure Pc, in accordance with the standard regulations.

Controlled safety pressure relief system CSPRS valves are mainly used where conventional direct-loaded spring action valves cannot guarantee the opening and closing margins that certain specifi c conditions of service demand.

The objective is to help the closure by means of pressure so that the valve remains completely watertight until reaching the set pressure and/or to activate the opening with pressure.

Once evacuated and in keeping with a previous adjustment, to assist with closing pressure, to once again achieve closure with the desired watertightness.

Increase the operating pressure of the system up to 99.9% of the set pressure.The control safety pressure relief system CSPRS device can be used with any safety valve available in the market and in particular, with models VYC Mod. 485, 486, 494, 495 and 496.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pressure reducing valve installed in the system and used to regulate the pressure in the system. The pressure relief valve series is used to reduce the outlet pressure of the fluid.

Unlike a safety valve, which relieves pressure by releasing pressure directly to the outside, a pressure reducing valve is thanks to the operation of a pressure reducing valve disc located in the valve body.

Taiwan flanged pressure reducing valve is a basic line of pressure reducing valve designed with flange connection type, valve is designed with flange to connect to pipeline with flange connection type.

Taiwan flanged pressure reducing valve is used to reduce the pressure in the system when the pressure rises above a pre-set level, called rated pressure.

Taiwan flanged pressure relief valve is made in Taiwan, with solid design and structure, Taiwan flanged pressure reducing valve has good quality, reasonable price.

Taiwan threaded pressure reducing valve is a series of pressure reducing valve using threaded connection type. This series of threaded pressure relief valves allows for quicker installation than flanged pressure relief valves.

China"s flanged pressure reducing valve line is the same, it has a very cheap price, compared to valves originating from Taiwan or Korea, the price of Chinese pressure reducing valves is much cheaper.

Pressure relief valve is used with the main purpose of reducing the pressure of the flow in the system flowing through the valve, thereby helping to reduce the pressure of the whole system.

The pressure relief valve helps to protect the safety of the system, avoiding the system cracking when the pressure is too high, thereby prolonging the life of the system.

Cla-Val is a world-leading designer and manufacturer of automatic control valves. From reducing and relief valves to deluge, air valves and more, Cla-Val manufactures and provides a wide variety of solutions for use in some of the world’s most demanding applications.

8613371530291

8613371530291