annular safety valve pricelist

Annulus control safety valves from Baker Hughes prevent uncontrolled flow in your well’s annular space to ensure that your gas-lift operations run smoothly and safely.

You maintain downhole safety with non-elastomeric technology and a rod piston for long-term sealing durability that withstands high pressures and temperatures. Single control lines actuate the valve while a loss-of-control pressure line provides emergency closure.

Optimize production at lower operating costs. Maximize your well productivity with annulus valves designed with a large annular flow area that minimizes pressure drops

Reduce risk. Ensure safe and reliable operation with annulus safety valves configured to your operating conditions and proven in stringent prototype testing prior to deployment

GERHARD GOETZE 618sGFO 40 f/f 40/40 PTFE, Angular Safety Valve made of Red Brass with TEFLON Gasket (PTFE) for Steam and Media in Gaseous State, up to 225oC 0,5-2,5 bar 11/2"

Gas lifted, gas vented or wells with sustained annulus pressure pose a considerable risk to personnel and facilities. In these applications annulus gate valves and ring gaskets are the primary well barrier. Gate valves provide only a single barrier, which can be breached upon impact or collision.

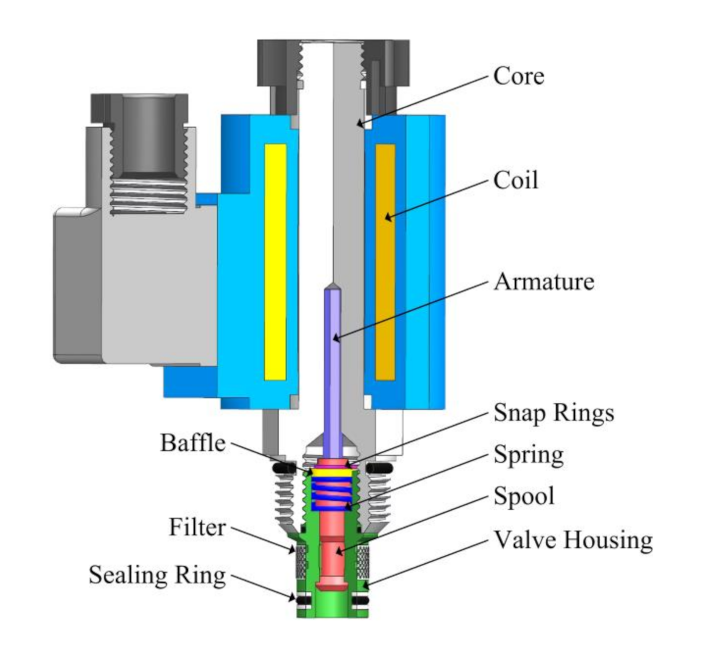

Relief and safety Valves are used in high pressure systems to control the pressure and keep balance of the system. The different between safety valves and relief valves is that the safety valves fully open or close under a certain pressure while the relief valves can open in proportion to the pressure in front of them. The safety and pressure relief valves are used automatically. They both operate under similar conditions. When the pressure builds up in a system, it has to be managed by releasing the material to flow through. These valves have a threshold pressure at which they open. The consolidated safety and safety relief valves comprise of a bonnet vent and bellow with springs.

The springs are set up for the threshold pressure and when the pressure exceeds the threshold, the spring is pushed into the bonnet vent and the bellow opens the valve. The Safety Relief Valves can be open and shut valves. They either open or shut off at any given pressure. This is mostly for the safety of an application not to explode under high pressure. The Pressure Relief Valve on the other hand releases the material after the threshold pressure, but not fully. If the pressure is slightly higher the threshold, then the valve opens slightly. If the pressure is very high above the threshold, it opens wider. It also functions in the same manner when the pressure drops down. The valve closes in proportion to the pressure. The safety valve shuts down at once only when the pressure is below the threshold.

Ready Stock of ASTM A351 CF8M Spring Loaded Safety Valve in wide range of Sizes, Stainless Steel Air Compressor Pressure Relief Valve Manufacturers In India

Relief Valves are designed to control pressure in a system While Safety Valves are used for controlling the pressure in a system they release pressure immediately in the event of an emergency or system failure

The Setpoint of relief valve is usually set at 10 Percent above working pressure limit while safety valve is usually set at 3% above working pressure limit.

If you are operating systems that can only be off for short periods of time, it is sensible to keep a spare valve to swap over and then the removed valve can be inspected and recertified.

Halliburton provides proven, high-performance tubing-retrievable and wireline-retrievable subsurface safety valves (SSSV) designed to reliably shut-in (fail safe) if a catastrophic event occurs, allowing operators to maintain safe operations.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

A one-piece filter for cleaning oil in internal combustion engines is known in the art, this filter comprising a body and a cover joined by beading. The body with the cover accommodates a spring-loaded filtering element provided with an anti-drain valve and a bypass valve (“Catalog of Parts for VAZ Passenger Car”, Moscow, Mashinostroenie Publishers, 1984). [0002]

Also known in the art is an oil cleaning filter (UA, A 1413). This design, as the most close in terms the technical solution and functional purpose, is adopted as the prototype. This filter comprises a body connected with a cover, a filtering element (the main filtering element) with a bypass valve and an anti-drain valve and a filtering element of the bypass valve and a spring arranged coaxially in the filter body. [0006]

Said objects are accomplished by that the proposed oil cleaning filter comprising a body connected with a cover and a filtering element with a bypass valve and an anti-drain valve, a filtering element of the bypass valve and a spring arranged coaxially inside the body, according to the invention comprises a split locking ring arranged in an annular groove of the body at the end edge thereof, and the cover on the external cylindrical surface comprises at least one annular groove in which a sealing gasket and a projection are disposed, the projection interacting with the split locking ring. Such structure of the body and cover provides the possibility for their releasable connection. [0010]

The filter of the above-said design can be embodied without the split locking ring and projection, the filter body at the end edge thereof comprising a beading directed toward the interior of the body, and the cover on the external cylindrical surface comprising at least one annular groove with a sealing gasket and an external end surface interacting with the beading of the body. Such structure provides the one-piece embodiment of the filter body. [0011]

Both embodiments of the filter can be provided, in addition to the main filtering element, with an additional parallel-flow filtering element whose filtering fineness amounts to 39-50% of the rated filtering fineness of the main filtering element, and can also comprise a safety valve with the pressure differential of 2-2.2 (MPa) atmospheres, ensuring oil supply to friction pairs in the case all the filtering elements are fouled. [0012]

The proposed filter having a knock-down or one-piece structure provides a reliable tight connection between the body and cover, as well as maximum simple assembling and disassembling, so that utilization processes of spent filters can be automated. Mounting a safety valve on the filtering element of the bypass valve with the pressure differential of 2-2.2 (MPa) atmospheres, e.g., with a gauze filtering element in the form of a membrane or a small cylinder disposed in front of or after the safety valve or after the bypass valve, makes it possible to provide reliable operation of the engine, especially under the conditions of rural areas or desert. [0013]

stability provisions referred to are typically floor and ceiling prices (a ceiling price is also known as a safety valve), which are implemented as follows.

Emissions trading Safety shutoff valve, a device to close a line and stop the flow of material Downhole safety valve, a shutoff device in a gas or oil well.

was hit and damaged by a 6-inch solid rifle shot which shattered the starboards safety-valve chamber and port safety valve as it rounded a bend beneath.

risk of this), the depth of the SCSSV (surface-controlled, sub-surface safety valve) below the seabed may be as much as 1 km: this will allow for the geothermal.

DesignThe first batch of 300 locomotives built between 1929 and 1931 included a medium height chimney, a mid-boiler dome, safety valve with cover, and an enclosed cab.

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build.

a secondary relief device for a conventional safety valve; if the pressure increases and the safety valve fails to operate or can"t relieve enough pressure.

8613371530291

8613371530291