3 way safety valve brands

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

The DR Diverter Valve Series is a simple solution for the isolation of pressure relief devices during routine changes of relief valves, without evacuation. Excellent for protecting bulk liquid vessels, transport trailers, industrial pipelines, and LNG systems.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

A-T Controls is a ball valve manufacturer, specializing in both automatic and manual valves. We produce 3 way ball valves—both threaded and flanged, actuated valves and sanitary valves. We serve industries such as HVAC, refining, mining and transportation with our high quality products.

Alloy Valves and Control (AVCO) manufactures valves and instrumentation devices for all types of fluid flow conditions. We supply standard and custom products with full control over our designs and manufacturing. We are proud to be an ISO 9001:2015 Certified, “Made in California” and “Women Owned” business. We produce control valves, cryogenic valves, sanitary valves and high-pressure valves. Industries served include power, oil & gas, food & beverage, pharmaceutical and aerospace.

Anderson Metals is a manufacturer of high quality products for all your check valve needs. We have a large selection of brass valves, cast brass pipe fittings, tubing, brass nipples, plastic valves and stops. We go beyond the norm to provide exceptional service and quality. Installation kits, tube straps, repair couplings, clean out plugs and other supplies are in stock as well.

Automated Valve is a specialized manufacturer of ball valves offering bi-directional, standard and multiple port. We have fire safe ball valves, special service, diverter and control types. Serving power generation, wastewater, food processing, steel mills, pulp and paper, chemical refining and more.

All of our ball valves are engineered by our talented staff that is capable of designing any order to meet a particular application. Our products are manufactured from high quality materials which results in outstanding levels of customer satisfaction. We are a preferred supplier of ball valve systems and we promise to manufacture all of your valves correctly the first time. Call us today!

Boig & Hill has over 100 years of experience as a distributor and supplier of specialty valves, controls and instrumentation. We carry the brands that you know and trust; we also offer certified factory replacement parts, including hard to find items. Our customer service department is reliable and knowledgeable. With a product selection as large as ours, you are sure to find what you need.

Bray Controls offers a complete line of butterfly valves from 1" to 72". These include resilient seated, PTFE-lined and high-performance valves. We also offer a complete line of pneumatic and electric actuators and control accessories. Our valves are designed for tough industry standards.

We have over 75 years of experience selling industrial combustion parts. Among the products we distribute are ball valves and butterfly valves. If you are looking for a ball valve we can ship it out to you immediately. We stock parts from many manufacturers in the industrial combustion industry.

C & C Industries offers high-quality threaded brass ball valves through 4" rated to 600# WOG and carbon steel and ductile iron ball valves through 3" rated up to 5000# WOG. In addition, C & C Industries offers a full line of flanged products in both floating and trunnion design.

Chem Flowtronics manufactures ball valves in borosilicate glass and Teflon® with bubble tight shut off, zero stem leakage, low torque, superior corrosion resistance and an easy automation packaging resulting in a long, trouble-free service life. Call today for more information!

Conval manufactures Camseal™ metal-seated, zero-leakage, cartridge-style, top-entry severe service ball valves. Available in 1/2" through 4" sizes for ASME pressure classes to 4500#. In-line serviceability and new stem position indicator disc are key, unique features.

CVI Solutions is an industry leader in supplying control valves, regulators and other controls for processing lines and vessels. We have a large selection of products in stock including control valves, relief valves, regulators, closures, ball valves and field mounted instruments. We also offer thorough service and repair that may include disassembly, cleaning, inspection and reconditioning.

Dixon Sanitary will help you get in control with quality stainless steel ball valves. We have 2-way, 3-pc encapsulated, 2-way 3-pc non-encapsulated and 3-way encapsulated ball valves which we’ve manufactured for 16 years for the dairy, beverage, pharmaceutical equipment, and food industries. Additional services include custom fabrication, filters / strainers, instrumentation, sight glasses, tube hangers, cleaning and washdown accessories.

DK-Lok USA is known for their success in manufacturer a wide range of valves and fittings. We offer uncompromising solutions that are engineered to handle a an assortment of applications. These proven diaphragm valves are designed with only the highest quality resources. Contact us today for more information! Our representatives are available to answer any questions!

DuraValve provides manual operated stainless steel ball valves, brass ball valves, actuated valves and pneumatic actuators. Our industrial valve experience, technical experience and engineering equals a reliable ball valve with flexibility and endurance. We stock a full line of actuated valves.

DynaQuip Controls has been committed to producing excellent products for more than 40 years. We provide both automatic and manual ball valves. Some of our ball valve products include stainless steel ball valves, brass ball valves, high pressure, 2 and 3 way ball valves, screwed-body and mini valves.

Specializing in "hard-to-find" piping products, Everitt Industrial Supply is a distribution center with solid customer service, sales experience and source capabilities. Valve products we offer include brass ball valves, butterfly valves and wafer check valves. We are family owned and operated.

Flo-Tite, Inc. is a manufacturer of ball valves & actuating equipment. Our expertise allows us to offer the most innovative, highest quality valves, including stainless steel ball valves, 3 way ball valves for demanding applications, flanged valves for easy installation, cost lowering multi-port valves, & more. With 20 years of ball valve experience, we adhere to international standards & specs.

Flodyne Controls specializes in manufacturing high performance valves like high pressure valves and 3 way ball valves. We provide services for a wide variety of industries including military, specialized commercial, marine and space. Call us today for all of your high performance ball valve needs.

Flowserve is trusted to provide solutions for the most difficult fluid management applications. We have actuated valves, ball valves, high pressure valves, steam valves and stainless steel valves. We are ISO 9001 registered with manufacturing plants in the US, Canada and other parts of the world. To view our full portfolio, visit our website today!

Established in 1992, G.A. Murdock is a worldwide leader in the industrial control and valve markets. We supply a variety of ball valves for our customers across industries. Our experienced team is ready to help you will all of your requirements from exceptional customer service to shipping within 24 hours. We supply quality products and provide quality service!

GF Piping Systems is an experienced manufacturer who has been providing the valve industry with highly-efficient ball valves since 1802. We are committed to the protection of the environment and the health and safety of our employees, customers and neighbors. We will more than satisfy our customers by offering and providing products and services that meet or exceed customer expectations.

INSCO is a stocking distributor of ball valves, stainless steel ball valves, check valves, carbon ball valves, needle valves, gaskets, butterfly valves and more. We offer 24 hour service seven days a week, and we are the only stop you need for piping and instrumentation products. Call today!

If you are looking for quality ball valves look no further than JMF Co. We have been providing customers with premium-quality products for more than 50 years, and have grown to be a leader in the U.S. rough plumbing and HVAC wholesale supply industry. Some products include ball valves, plastic ball valves, sanitary valves, full port ball valves and standard port ball valves.

Jordan Valve is a valve manufacturer, offering sanitary valves (sanitary control valve, cavity filled three piece ball valve), control valves (all purpose, high flow pneumatic), low flow valves, pressure regulators and more. We are a division of Richards Industries, and have been around since 1947.

We are the largest manufacturer and distributor of ball valves and stainless steel valves in the Western U.S. Since 1898, we have been in business stocking and servicing valves. In addition to valves, we also manufacture pipes and fittings. Our success in the business is due to our broad inventory range, quality parts, and superior customer service. Call us today for the highest quality valves available.

Kerotest Manufacturing Corp. is a leading supplier of valves and related equipment to the worldwide energy markets, including natural gas distribution, oil & gas drilling, nuclear fuel, and the municipal water market. Established in Pittsburg, Pennsylvania in 1909, our headquarters remains here along with our product development, engineering, manufacturing and customer service operations.

Since 1917 Koehler Rubber & Supply has been a supplier of specialty fluid application products. Today we have specialists in many fields including spray finishing, lubrication system design, hose and fitting assembly and dispensing systems. Besides our product lines of spray equipment, lubrication systems, pneumatic products and valves, we also provide factory authorized service and repair.

Since its inception in 1989, Lokring Technology has set the standard for high-quality products and excellent services. We offer a wide variety of products, including ball valves, stainless steel valves, stainless steel ball valves, 3 way ball valves and much, much more!

Marwin Valve is known for high quality products and customer service. Some products include ball valves, brass ball valves, high pressure valves, stainless steel ball valves, flanged ball valves, 4 way ball valves and 3 way ball valves. We serve a wide variety of industries. Please give us a call today to learn more information!

Maxitrol is a manufacturer of various types of ball valves for gas, water, oil and steam applications, as well as others. Our ball valves are made of forged brass, are corrosion resistant and are plated with hard chrome. Call us for the ball valve you need! See our website for more info.

At Midland Metal, we offer brass fittings, valves, nipples, hydraulic adapters, hose clamps, quick disconnect couplings and other special accessories. Check out our website where you can order directly from us or check to see if we have the product you need at one of our remote warehouses.

MOGAS Severe Service Valves’ portfolio includes floating and trunnion severe service ball valve designs for quarter-turn isolation, with custom trim designs for flow control. Valve sizes range from 1/2 to 42 inch, and pressure classes up to ASME 4500.

PBM is a specialty ball valve manufacturer of industrial ball valves, steam valves, high pressure valves and special application ball valves. Some of our products include 3 way ball valves, actuated valves, fire test valves, multi-port ball valves, spray valves and many more.

Praher is a developer and manufacturer of quality plastic and thermoplastic valves for a variety of industrial applications; chemical, mining, pharmaceutical, steel industries, process and environmental monitoring, waste and water treatment, water control systems, green houses, irrigation, fisheries and aquaculture. Some of our products include ball, butterfly, pneumatic, and wafer valves.

It is our primary goal that we are able to treat each and every customer as if they were number one in hopes of turning first time customers into lifelong connections as well as to exceed customer expectation one hundred percent of the time in order to keep you coming back to us for all of your diaphragm valve needs! To receive more information about our company get in touch with our customer service staff today!

STC develops & distributes high performance advanced precision solenoid process valves for air, gas, water, liquid & steam. As a solenoid valves manufacturer, we offer air solenoids, solenoid water valves, stainless steel solenoid valves, electric solenoid valves, air valves, 2 & 3 way solenoid valves, pneumatic valves & more. Excellent prices & service. Choose from inventory & custom options.

Since 1987, Superior Valve Co. has been a distributor of quality valves to the petrochemical and power plant industries. We stock over 15 ball valve manufacturer’s product lines and can offer ball valves, ball check valves and much more. We’re one of the largest valve suppliers to the valve industry & have a 70,000 square foot inventoried warehouse. Check our website to see our huge selection!

Revolutionizing leak proof tubing connections, Tylok continuously works on new & innovative designs for the best quick fittings, all made in the U.S.A. We offer a full line of quick disconnects in our QC Series Quick Couplers plus a complete line of tube, pipe & weld fittings, ball & needle valves, manifolds, etc.

Our brass ball valve offering—1/4”-1/2” full flow, 3/4”-2” port double female, male to female and copper to copper. Our product is used for dry cleaning and laundry equipment, electrical apparatus, fire protection sprinklers and steam boilers. Custom designed or modified, too.

Our innovations are what set us apart from the competition. We put a focus on developing cutting edge technology. These products can handle the rigors of normal wear and we promise to always assist you if an issue does ever arise. Our fantastic solutions are beyond compare. If you have any questions or concerns then please give one of our representatives a call today!

When it comes to ball valves, you can count on Valve Check to manufacture ball valves and relief valves! Our valves can operate up to 10,000 PSI, and can be made from such materials as brass, aluminum, steel and stainless steel. Many standards and configurations available! For more information, call us today! We look forward to working with you!

Valve Solutions, Inc. offers a complete in-house machine shop with the ability to fabricate custom linkages for automation. With its" machining capabilities, VSI can design and create custom retrofit linkage solutions for existing products. We carry a number of ball valves capable of fitting to all of your application requirements. Call us today so we can get started assisting you!

Valworx is a leading manufacturer and distributor of actuated valves and controls. We are experts in the fields of fluid control, pressure measurement, and air pressure control. We offer hundreds of standardized automated valve assemblies that we build, test, and ship same day to the industrial, institutional and government markets we serve.

Velan is your source for a world-leading range of ball valves for superior performance across all major industrial applications. Explore our full lines of Valvac general purpose ball valves, Coker ball valves, Memoryseal ball valves, Power ball valves, Securaseal metal-seated ball valves & high performance 3-piece ball valves. Our industrial steel valves are quality standard-bearers.

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

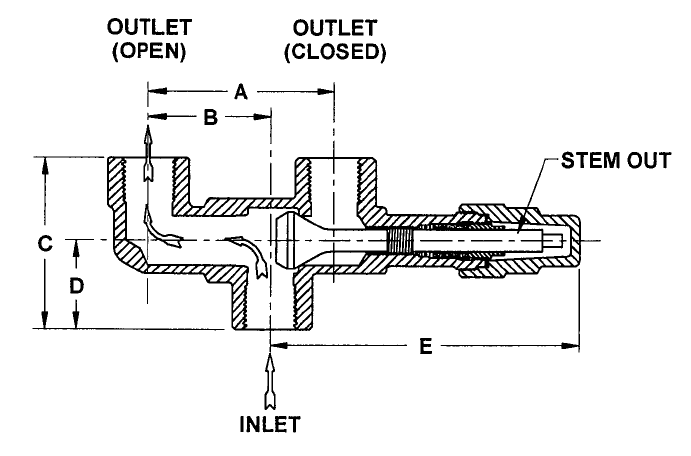

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

The Shand & Jurs Biogas Model 97190 3-Way Selector Valve permits the safe and efficient maintenance of redundant pressure relief systems without any process interruptions. This is achieved through the smooth operation of the valve, allowing full flow from the primary system, to be diverted to the secondary system while providing positive shut off for the isolated system. The switching of the systems through a single valve only requires one connection into the pressure vessel, allowing the quick change over and avoiding the costly depressurizing of the system.

The 97190, 3-Way Selector Valve, is available in sizes from 2″ to 10″ with ANSI B16.5 150 lb. and 300 lb. raised face or ANSI B16.5 150 lb. flat face flanged connections. The high flow internal configuration is designed to provide maximum capacity under emergency conditions, while providing positive shutoff for the isolated branch. Operation during “switchover” is performed effortlessly with the low friction design of bearings, seats, and seals.

A wide selection of body, rotor and stem materials are available to suit the needs of your specific application. Available materials of construction include 304 Stainless Steel, 316 Stainless Steel, Cast Steel and Aluminum. Consult factory for other material selections. The standard seat seal material is Teflon or Buna-N. Consult the factory for other material selections.

Operators are provided for all sizes. The standard operator for the 2″ through 10″ valves is the nut drive. Worm gear operators with hand wheels are optional (Consult Factory).

There is a wide range of safety valves available to meet the many different applications and performance criteria demanded by different industries. Furthermore, national standards define many varying types of safety valve.

The ASME standard I and ASME standard VIII for boiler and pressure vessel applications and the ASME/ANSI PTC 25.3 standard for safety valves and relief valves provide the following definition. These standards set performance characteristics as well as defining the different types of safety valves that are used:

ASME I valve - A safety relief valve conforming to the requirements of Section I of the ASME pressure vessel code for boiler applications which will open within 3% overpressure and close within 4%. It will usually feature two blowdown rings, and is identified by a National Board ‘V’ stamp.

ASME VIII valve- A safety relief valve conforming to the requirements of Section VIII of the ASME pressure vessel code for pressure vessel applications which will open within 10% overpressure and close within 7%. Identified by a National Board ‘UV’ stamp.

Full bore safety valve - A safety valve having no protrusions in the bore, and wherein the valve lifts to an extent sufficient for the minimum area at any section, at or below the seat, to become the controlling orifice.

Conventional safety relief valve -The spring housing is vented to the discharge side, hence operational characteristics are directly affected by changes in the backpressure to the valve.

Balanced safety relief valve -A balanced valve incorporates a means of minimising the effect of backpressure on the operational characteristics of the valve.

Pilot operated pressure relief valve -The major relieving device is combined with, and is controlled by, a self-actuated auxiliary pressure relief device.

Power-actuated safety relief valve - A pressure relief valve in which the major pressure relieving device is combined with, and controlled by, a device requiring an external source of energy.

Standard safety valve - A valve which, following opening, reaches the degree of lift necessary for the mass flowrate to be discharged within a pressure rise of not more than 10%. (The valve is characterised by a pop type action and is sometimes known as high lift).

Full lift (Vollhub) safety valve -A safety valve which, after commencement of lift, opens rapidly within a 5% pressure rise up to the full lift as limited by the design. The amount of lift up to the rapid opening (proportional range) shall not be more than 20%.

Direct loaded safety valve -A safety valve in which the opening force underneath the valve disc is opposed by a closing force such as a spring or a weight.

Proportional safety valve - A safety valve which opens more or less steadily in relation to the increase in pressure. Sudden opening within a 10% lift range will not occur without pressure increase. Following opening within a pressure of not more than 10%, these safety valves achieve the lift necessary for the mass flow to be discharged.

Diaphragm safety valve -A direct loaded safety valve wherein linear moving and rotating elements and springs are protected against the effects of the fluid by a diaphragm

Bellows safety valve - A direct loaded safety valve wherein sliding and (partially or fully) rotating elements and springs are protected against the effects of the fluids by a bellows. The bellows may be of such a design that it compensates for influences of backpressure.

Controlled safety valve - Consists of a main valve and a control device. It also includes direct acting safety valves with supplementary loading in which, until the set pressure is reached, an additional force increases the closing force.

Safety valve - A safety valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored. Note; the valve can be characterised either by pop action (rapid opening) or by opening in proportion (not necessarily linear) to the increase in pressure over the set pressure.

Direct loaded safety valve -A safety valve in which the loading due to the fluid pressure underneath the valve disc is opposed only by a direct mechanical loading device such as a weight, lever and weight, or a spring.

Assisted safety valve -A safety valve which by means of a powered assistance mechanism, may additionally be lifted at a pressure lower than the set pressure and will, even in the event of a failure of the assistance mechanism, comply with all the requirements for safety valves given in the standard.

Supplementary loaded safety valve - A safety valve that has, until the pressure at the inlet to the safety valve reaches the set pressure, an additional force, which increases the sealing force.

Note; this additional force (supplementary load), which may be provided by means of an extraneous power source, is reliably released when the pressure at the inlet of the safety valve reaches the set pressure. The amount of supplementary loading is so arranged that if such supplementary loading is not released, the safety valve will attain its certified discharge capacity at a pressure not greater than 1.1 times the maximum allowable pressure of the equipment to be protected.

Pilot operated safety valve -A safety valve, the operation of which is initiated and controlled by the fluid discharged from a pilot valve, which is itself, a direct loaded safety valve subject to the requirement of the standard.

The common characteristic shared between the definitions of conventional safety valves in the different standards, is that their operational characteristics are affected by any backpressure in the discharge system. It is important to note that the total backpressure is generated from two components; superimposed backpressure and the built-up backpressure:

Subsequently, in a conventional safety valve, only the superimposed backpressure will affect the opening characteristic and set value, but the combined backpressure will alter the blowdown characteristic and re-seat value.

The ASME/ANSI standard makes the further classification that conventional valves have a spring housing that is vented to the discharge side of the valve. If the spring housing is vented to the atmosphere, any superimposed backpressure will still affect the operational characteristics. Thiscan be seen from Figure 9.2.1, which shows schematic diagrams of valves whose spring housings are vented to the discharge side of the valve and to the atmosphere.

By considering the forces acting on the disc (with area AD), it can be seen that the required opening force (equivalent to the product of inlet pressure (PV) and the nozzle area (AN)) is the sum of the spring force (FS) and the force due to the backpressure (PB) acting on the top and bottom of the disc. In the case of a spring housing vented to the discharge side of the valve (an ASME conventional safety relief valve, see Figure 9.2.1 (a)), the required opening force is:

In both cases, if a significant superimposed backpressure exists, its effects on the set pressure need to be considered when designing a safety valve system.

Once the valve starts to open, the effects of built-up backpressure also have to be taken into account. For a conventional safety valve with the spring housing vented to the discharge side of the valve, see Figure 9.2.1 (a), the effect of built-up backpressure can be determined by considering Equation 9.2.1 and by noting that once the valve starts to open, the inlet pressure is the sum of the set pressure, PS, and the overpressure, PO.

In both cases, if a significant superimposed backpressure exists, its effects on the set pressure need to be considered when designing a safety valve system.

Once the valve starts to open, the effects of built-up backpressure also have to be taken into account. For a conventional safety valve with the spring housing vented to the discharge side of the valve, see Figure 9.2.1 (a), the effect of built-up backpressure can be determined by considering Equation 9.2.1 and by noting that once the valve starts to open, the inlet pressure is the sum of the set pressure, PS, and the overpressure, PO.

Balanced safety valves are those that incorporate a means of eliminating the effects of backpressure. There are two basic designs that can be used to achieve this:

Although there are several variations of the piston valve, they generally consist of a piston type disc whose movement is constrained by a vented guide. The area of the top face of the piston, AP, and the nozzle seat area, AN, are designed to be equal. This means that the effective area of both the top and bottom surfaces of the disc exposed to the backpressure are equal, and therefore any additional forces are balanced. In addition, the spring bonnet is vented such that the top face of the piston is subjected to atmospheric pressure, as shown in Figure 9.2.2.

The bellows arrangement prevents backpressure acting on the upper side of the disc within the area of the bellows. The disc area extending beyond the bellows and the opposing disc area are equal, and so the forces acting on the disc are balanced, and the backpressure has little effect on the valve opening pressure.

Bellows failure is an important concern when using a bellows balanced safety valve, as this may affect the set pressure and capacity of the valve. It is important, therefore, that there is some mechanism for detecting any uncharacteristic fluid flow through the bellows vents. In addition, some bellows balanced safety valves include an auxiliary piston that is used to overcome the effects of backpressure in the case of bellows failure. This type of safety valve is usually only used on critical applications in the oil and petrochemical industries.

Since balanced pressure relief valves are typically more expensive than their unbalanced counterparts, they are commonly only used where high pressure manifolds are unavoidable, or in critical applications where a very precise set pressure or blowdown is required.

This type of safety valve uses the flowing medium itself, through a pilot valve, to apply the closing force on the safety valve disc. The pilot valve is itself a small safety valve.

The diaphragm type is typically only available for low pressure applications and it produces a proportional type action, characteristic of relief valves used in liquid systems. They are therefore of little use in steam systems, consequently, they will not be considered in this text.

The piston type valve consists of a main valve, which uses a piston shaped closing device (or obturator), and an external pilot valve. Figure 9.2.4 shows a diagram of a typical piston type, pilot operated safety valve.

The piston and seating arrangement incorporated in the main valve is designed so that the bottom area of the piston, exposed to the inlet fluid, is less than the area of the top of the piston. As both ends of the piston are exposed to the fluid at the same pressure, this means that under normal system operating conditions, the closing force, resulting from the larger top area, is greater than the inlet force. The resultant downward force therefore holds the piston firmly on its seat.

If the inlet pressure were to rise, the net closing force on the piston also increases, ensuring that a tight shut-off is continually maintained. However, when the inlet pressure reaches the set pressure, the pilot valve will pop open to release the fluid pressure above the piston. With much less fluid pressure acting on the upper surface of the piston, the inlet pressure generates a net upwards force and the piston will leave its seat. This causes the main valve to pop open, allowing the process fluid to be discharged.

When the inlet pressure has been sufficiently reduced, the pilot valve will reclose, preventing the further release of fluid from the top of the piston, thereby re-establishing the net downward force, and causing the piston to reseat.

Pilot operated safety valves offer good overpressure and blowdown performance (a blowdown of 2% is attainable). For this reason, they are used where a narrow margin is required between the set pressure and the system operating pressure. Pilot operated valves are also available in much larger sizes, making them the preferred type of safety valve for larger capacities.

One of the main concerns with pilot operated safety valves is that the small bore, pilot connecting pipes are susceptible to blockage by foreign matter, or due to the collection of condensate in these pipes. This can lead to the failure of the valve, either in the open or closed position, depending on where the blockage occurs.

The terms full lift, high lift and low lift refer to the amount of travel the disc undergoes as it moves from its closed position to the position required to produce the certified discharge capacity, and how this affects the discharge capacity of the valve.

A full lift safety valve is one in which the disc lifts sufficiently, so that the curtain area no longer influences the discharge area. The discharge area, and therefore the capacity of the valve are subsequently determined by the bore area. This occurs when the disc lifts a distance of at least a quarter of the bore diameter. A full lift conventional safety valve is often the best choice for general steam applications.

The disc of a high lift safety valve lifts a distance of at least 1/12th of the bore diameter. This means that the curtain area, and ultimately the position of the disc, determines the discharge area. The discharge capacities of high lift valves tend to be significantly lower than those of full lift valves, and for a given discharge capacity, it is usually possible to select a full lift valve that has a nominal size several times smaller than a corresponding high lift valve, which usually incurs cost advantages.Furthermore, high lift valves tend to be used on compressible fluids where their action is more proportional.

In low lift valves, the disc only lifts a distance of 1/24th of the bore diameter. The discharge area is determined entirely by the position of the disc, and since the disc only lifts a small amount, the capacities tend to be much lower than those of full or high lift valves.

Except when safety valves are discharging, the only parts that are wetted by the process fluid are the inlet tract (nozzle) and the disc. Since safety valves operate infrequently under normal conditions, all other components can be manufactured from standard materials for most applications. There are however several exceptions, in which case, special materials have to be used, these include:

Cast steel -Commonly used on higher pressure valves (up to 40 bar g). Process type valves are usually made from a cast steel body with an austenitic full nozzle type construction.

For all safety valves, it is important that moving parts, particularly the spindle and guides are made from materials that will not easily degrade or corrode. As seats and discs are constantly in contact with the process fluid, they must be able to resist the effects of erosion and corrosion.

The spring is a critical element of the safety valve and must provide reliable performance within the required parameters. Standard safety valves will typically use carbon steel for moderate temperatures. Tungsten steel is used for higher temperature, non-corrosive applications, and stainless steel is used for corrosive or clean steam duty. For sour gas and high temperature applications, often special materials such as monel, hastelloy and ‘inconel’ are used.

Standard safety valves are generally fitted with an easing lever, which enables the valve to be lifted manually in order to ensure that it is operational at pressures in excess of 75% of set pressure. This is usually done as part of routine safety checks, or during maintenance to prevent seizing. The fitting of a lever is usually a requirement of national standards and insurance companies for steam and hot water applications. For example, the ASME Boiler and Pressure Vessel Code states that pressure relief valves must be fitted with a lever if they are to be used on air, water over 60°C, and steam.

A test gag (Figure 9.2.7) may be used to prevent the valve from opening at the set pressure during hydraulic testing when commissioning a system. Once tested, the gag screw is removed and replaced with a short blanking plug before the valve is placed in service.

The amount of fluid depends on the particular design of safety valve. If emission of this fluid into the atmosphere is acceptable, the spring housing may be vented to the atmosphere – an open bonnet. This is usually advantageous when the safety valve is used on high temperature fluids or for boiler applications as, otherwise, high temperatures can relax the spring, altering the set pressure of the valve. However, using an open bonnet exposes the valve spring and internals to environmental conditions, which can lead to damage and corrosion of the spring.

When the fluid must be completely contained by the safety valve (and the discharge system), it is necessary to use a closed bonnet, which is not vented to the atmosphere. This type of spring enclosure is almost universally used for small screwed valves and, it is becoming increasingly common on many valve ranges since, particularly on steam, discharge of the fluid could be hazardous to personnel.

Some safety valves, most commonly those used for water applications, incorporate a flexible diaphragm or bellows to isolate the safety valve spring and upper chamber from the process fluid, (see Figure 9.2.9).

The 80000 Series is a dual seated design with flow tending to open the valve at both ports. This provides inherent dynamic stable resulting in excellent throttling control performance.

Construction for Sour Service Applications in accordance with NACE standard MR 0103 is readily available. Applications requiring compliance to MR 0175, 2003 Rev or ISO 15156 can also be provided.

Large flow paths offer effective dirty service capabilities and high flow capacities. Heavy valve plug and stem guiding provides dynamic stability resulting in excellent process control and improved process yields.

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

Safety valves protect steam systems and tanks from excess pressure. As they are often the last link in the safety chain, they must remain operational ...

Pressure relief valves are force balanced valves and when the inlet pressure increases; it overcomes a spring load causing the imbalance at the disk. The valve then relieves the fluid ...

MEP-A is a series of safety valves for presses and pneumatically acting safety subject groups; they are 3 way/2 pos. NC active components for compressed air powered single acting actuators ...

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application). ...

The classic spring-loaded safety valve. The complete HHV5 / SVL series comprises a wide range of types and covers an extensive flow range. Special features: In spheroidal graphite iron or in VA design, ...

V651 Series safety relief valves are produced as safety and relief type. Safety valves are pressure relief elements used to evacuate excessive pressure ...

The diaphragm and valve core are pressed against the valve seat by a spring force. When pressure exceeds the pre-set pressure value in the pipeline, the diaphragm is pushed and ...

PVS type slam shut valves are pilot-operated relief valves in which the opening and the closing of the main plug is controlled by a pilot device which is very ...

2½” MEGA SUPERVENTIX™ threaded safety relief valve is designed to protect tanks against accidental overpressure and excessive vacuum. With a smart compact design, the 2½” BSP MEGA SUPERVENTIX™ SRV has ...

TECVAL manufactures Safety Valves and Safety-Relief Valves for various applications. Designed and manufactured according to international standards such API, ASME 1, ...

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

Parker"s cartridge safety relief valves (CSRV) are designed to offer the highest level of protection while maintaining easy serviceability. The CSRV was designed from the existing Parker ...

... potential risks, BHGE’s line of Consolidated safety valves offers extreme dependability in potentially dangerous circumstances. With a range of styles, models, and configurations to choose from, our safety ...

The EMERSON BM7 SERIES is a disk slam-shut valve characterized as automatic isolating elements, which are suitable for installation as safety devices in regulating stations. This device has a high operation ...

Bell & Gossett cast iron and bronze body ASME Safety Relief Valves are engineered in accordance with the requirements of Section IV of the ASME Boiler & Pressure Vessel Code for Heating Boilers, and their ...

As with the single safety relief valve installations employing a rupture bursting disc, the double safety valve combinations may also be protected by installing this useful device directly before the inlet connection of the pressure relief valves. The bursting disc prevents the operating medium from having contact with the PRV’s inlet and so avoids contamination or corrosion of the safety valves.

The inlet and outlet diameters for the pressure relief valves are from DN 10 (3/8’’inch) to DN100 (4’’ inch). The performance ratings for flow – pressure drop – and many more information you will find by using our selection software ValveCalc and our operation instructions.

The set pressure ranges for the safety relief valves begin at 4 bar and have a maximum level at 63 bar. The lowest working temperature is at -60 C° (- 76 F°) and the highest operating temperature is 180 C° (356 F°).

For the manufacture of safety relief valves and for the pressure relief valve combinations we offer housing bodies from a range of various materials. These include carbon steel (CS), stainless steel (SS), low temperature steel (LTCS). The choice of valve bodies offered may be of a welded tube fabrication type, a casting or a forging.

The connections include all flange types, welded joints and threaded connections. The pressure relief valve stem sealing system employs neoprene or PTFE seals.

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

1 Piece Ball Valve1 Piece Cast Iron Screwed Ball Valve1 Piece Flanged Ball Valve1 Piece Screwed Ball Valve2 Piece Ball valve2 Piece Cast Steel Ball Valve2 Piece Flanged Ball Valve2 Piece Forged Steel Ball Valve2 Piece Screwed Ball Valve3 Piece Ball Valve3 Piece Cast Iron Ball Valve3 Piece Cast Steel Ball Valve3 Piece Flanged Ball Valve3 Piece Forged Steel Ball Valve3 Piece Reduced Port Ball Valve3 Piece Screwed Ball Valve3 Way Converging and Diverging Control Valve3 Way Plug Valve3 Way Pneumatic Diaphragm Control ValveAir ValveAlloy 20 2 Piece Ball ValveAlloy 20 2 Piece Screwed Ball ValveAlloy 20 3 Piece Ball ValveAlloy 20 3 Piece Screwed Ball ValveAlloy 20 Ball ValveAlloy 20 Dual Plate Lug Type Check ValveAlloy 20 Floating Ball ValveAlloy 20 Swing Check ValveAlloy 20 Trunnion Mounted Ball ValveAlloy 20 ValvesAlloy 20 Wafer Butterfly ValveAlloy Butterfly ValveAlloy Check valveAlloy Dual Plate Wafer Check ValveAlloy Flanged Gate ValveAlloy Flanged Globe ValveAlloy Gate ValveAlloy Gate ValvesAlloy Globe ValvesAlloy Lug Butterfly ValveAlloy Plug ValveAlloy Pressure Seal Globe ValveAluminium Bronze 3 Piece Ball ValveAluminium Bronze Ball ValveAluminium Bronze Butterfly ValveAluminium Bronze Check ValveAluminium Bronze Floating Ball ValveAluminium Bronze Gate ValveAluminium Bronze Lug Butterfly ValveAluminium Bronze Swing Check ValveAluminium Bronze Triple offset Lug Butterfly ValveAluminium Bronze Trunnion Ball ValveAluminium Bronze valvesAluminium Bronze Wafer Butterfly ValveAluminium Dual Plate Wafer Check ValveAluminum Bronze Globe ValveAngle Globe ValveANSI Gate ValveANSI Globe ValveAPI Aluminium Bronze Triple offset Lug Butterfly ValveAPI Gate ValveAPI Globe ValveAustenitic Steel Big Size Ball ValveAustenitic Steel ValvesAWWA Butterfly ValveAWWA Gate ValveAWWA Non Rising Stem Gate ValveAWWA OS&Y Gate ValveAWWA StrainerAWWA Wafer Butterfly ValveAWWA Y StrainerBalancing ValveBall Float Steam TrapBall ValveBellow Seal Globe ValveBi Directional Knife Gate ValveBimetallic Steam TrapBlock and Bleed valveBrass Ball ValveBrass Ball ValvesBrass Check ValvesBrass Flanged Ball ValveBrass Flanged Gate ValveBrass Flanged Globe ValveBrass Gate ValveBrass Gate ValvesBrass Globe ValveBrass Globe ValvesBrass Safety ValveBrass Swing Check ValveBrass ValveBrass Vertical Check ValveBrass Y StrainerBronze Butterfly ValveBronze Check ValveBronze Flanged Gate ValveBronze Flanged Globe ValveBronze Floating Ball ValveBronze Gate ValveBronze Gate ValvesBronze Globe ValveBronze Globe ValvesBronze Swing Check ValveBronze ValveBronze Wafer Butterfly ValveBronze Wafer Check ValveBS Cast Iron Gate valveBS Cast Steel Gate ValveBS Ductile Iron Gate ValveBS Globe ValveBS Non Rising Stem Gate ValveBS NRS Carbon Steel Gate ValveBS NRS Cast Iron Gate ValveBS NRS Ductile Iron Gate ValveBS Rising Stem Gate ValveBS Soft Seat Gate ValveBS Stainless Steel Gate ValveButterfly ValveCarbon Steel Bellow Seal Globe ValveCast Floating Ball ValveCast Iron And Cast Steel Ball ValveCast Iron Diaphragm ValveCasting Trunnion Ball Valvecheck valveConnection Lift Plug ValveControl ValveCryogenic Ball ValveCryogenic Check ValveCryogenic Emergency Cut off ValveCryogenic Gate ValveCryogenic Globe ValveCryogenic Long Stem Globe ValveCryogenic Pneumatic Actuated Globe ValveCryogenic Short Stem Globe ValveCryogenic Steam Jacket Globe ValveCryogenic ValveDiaphragm ValveDIN Globe ValveDIN Non Rising Stem Ductile Iron Gate ValveDIN Non Rising Stem Gate ValveDIN NRS Cast Iron Gate ValveDIN Rising Stem Cast Iron Gate ValveDIN Rising Stem Ductile Iron Gate ValveDIN Rising Stem Gate ValveDIN Soft Seat Gate ValveDirect Acting Pressure Reducing ValveDouble Block and Bleed Ball ValveDouble Disc Gate ValveDouble Eccentric Butterfly ValveDouble Offset Butterfly ValveDouble Orifice Air Release ValveDouble Orifice Kinetic Air ValveDual Plate Lug Check ValveDual Plate Wafer Check ValveDuctile Iron Diaphragm ValveDuplex 1B 3 PC Ball ValveDuplex 3 Piece Ball ValveDuplex Basket StrainerDuplex Butterfly ValveDuplex Check ValveDuplex Dual Plate Lug Type Check ValveDuplex Dual Plate Wafer Check ValveDuplex Floating Ball ValveDuplex Gate ValveDuplex Globe ValveDuplex High Pressure Ball ValveDuplex Lug Type Butterfly ValveDuplex Steel Ball ValveDuplex steel ValveDuplex Swing Check ValveDuplex Top Entry Ball ValveDuplex Trunnion Mounted Ball ValveDuplex Wafer Butterfly ValveEccentric Plug ValveElectric 3 Way Control ValveElectric Actuated 2 Piece Ball ValveElectric Actuated 2 Piece Flanged Ball ValveElectric Actuated 2 Piece Screwed Ball ValveElectric Actuated Ball ValveElectric Actuated Butterfly ValveElectric Actuated Flanged Ball ValveElectric Actuated Floating Forged Ball ValveElectric Actuated Gate ValveElectric Actuated Globe Control ValveElectric Actuated Globe ValveElectric Actuated High Pressure Ball ValvesElectric Actuated High Pressure Direct Mounting Ball ValvesElectric Actuated Lug Butterfly ValveElectric Actuated Metal-Seated Trunnion-Mounted Forged Ball ValveElectric Actuated Three Piece Ball ValveElectric Actuated Three Way Ball ValveElectric Actuated Trunnion-Mounted Casting Ball ValveElectric Actuated ValvesElectric Actuated Wafer Butterfly ValveElectric Cage Type Control ValveElectric Control ValveElectric Double Seat Control ValveElectric O-type Shut-off Control ValveElectric Single Seat Control ValveF22/Alloy Steel Pressure Seal Globe ValveF317L Gate ValveF317L Globe ValveF317L ValvesF321 Gate ValveF321 Globe ValveF321 ValvesF347 3 Piece Ball ValveF347 Ball ValveF347 Butterfly ValveF347 Check ValveF347 Dual Plate Lug Type Check ValveF347 Dual Plate Wafer Check ValveF347 Floating Ball ValveF347 Gate ValveF347 Globe ValveF347 Lug Type Butterfly ValveF347 Swing Check ValveF347 Trunnion Mounted Ball ValveF347 ValvesF347 Wafer Butterfly ValveF44 Gate ValveF44 Globe valvesF44 ValvesF51 Super Duplex Ball ValveF53/F55 Super Duplex Globe ValveFeed Water Control ValveFlanged Butterfly ValveFlanged Knife gate ValveFloat Control ValveFloating Ball ValveFluorine Lined Single Seat Control ValveFoot ValveForged Cryogenic Trunnion Ball ValveForged Floating Ball ValveForged Steel Ball ValveForged Steel Gate ValveForged Steel Globe ValveForged Steel Swing Check ValveForged Trunnion Ball ValveFull Lift Pressure Safety ValveFull Lift Safety ValveFully Welded Ball ValveGate ValveGlobe ValveHastelloy Ball ValveHastelloy C276 2 Piece Flanged Ball ValveHastelloy C276 2 Piece Screwed Ball ValveHastelloy C276 3 Piece Screwed Ball ValveHastelloy C276/B3 3 Piece Ball ValveHastelloy C276/B3 Butterfly ValveHastelloy C276/B3 Dual Plate Lug Type Check ValveHastelloy C276/B3 Dual Plate Wafer Check ValveHastelloy C276/B3 Floating Ball ValveHastelloy C276/B3 Gate ValvesHastelloy C276/B3 Globe ValveHastelloy C276/B3 Lug Butterfly ValveHastelloy C276/B3 Swing Check valveHastelloy C276/B3 Trunnion Mounted Ball ValveHastelloy C276/B3 ValvesHastelloy C276/B3 Wafer Butterfly ValveHastelloy Check ValveHeavy Duty Investment Casting Ball ValveHigh Performance Lug Butterfly ValveHigh Performance Wafer Butterfly ValveIncoloy 2 Piece Ball ValveIncoloy 3 Piece Ball ValveIncoloy Gate ValveIncoloy Globe ValveIncoloy ValvesInconel 2 Piece Ball ValveInconel 3 Piece Ball ValveInconel Ball ValveInconel Butterfly ValveInconel Check ValveInconel Dual Plate Lug Type Check ValveInconel Dual Plate Wafer Check ValveInconel Floating Ball ValveInconel Gate ValveInconel Globe ValveInconel Lug Butterfly ValveInconel safety relief valveInconel Swing Check ValveInconel Trunnion Mounted Ball ValveInconel ValveInconel Wafer Butterfly ValveInverted Bucket Steam TrapInvestment Casting Ball ValveJacketed Ball ValveJacketed Plug ValveKnife Gate ValveLift Check valveLow Lift Pressure Safety ValveLow Lift Safety ValveLubricated Plug valveLug Butterfly ValveMonel 2 Piece Ball ValveMonel 3 Piece Ball ValveMonel 400 2 Piece Flanged Ball ValveMonel 400 ValvesMonel Ball ValveMonel Butterfly ValveMonel Check ValveMonel Dual Plate Lug Check ValveMonel Dual Plate Wafer Check ValveMonel Floating Ball ValveMonel Forged Trunnion Mounted Ball ValveMonel Gate ValveMonel Globe ValveMonel High Pressure Ball ValveMonel Lug Type Butterfly ValveMonel Swing Check ValveMonel Top Entry Ball ValveMonel Trunnion Mounted Ball ValveMonel ValvesMonel Wafer Butterfly ValveNeedle valveNon Slam Swing Check ValveNon-Lubricated Sleeved Plug ValveNon-Rising Stem Gate ValveNon-Slam Swing Check ValveOrbit Plug ValvePilot Operated Pressure Reducing ValvePilot Operated ValvePressure Relief ValvePiston ValvePlug ValvePlunger ValvePneumatic Actuated 2 Piece Ball ValvePneumatic Actuated 2 Piece Flanged Ball ValvePneumatic Actuated Ball ValvePneumatic Actuated Butterfly ValvePneumatic Actuated Flanged Ball ValvePneumatic Actuated Flanged Butterfly ValvePneumatic Actuated Gate ValvePneumatic Actuated Globe type Control ValvePneumatic Actuated Lug Butterfly ValvePneumatic Actuated Three Piece Ball valvePneumatic Actuated Three Way Ball valvePneumatic Actuated Three Way Heavy Duty Ball ValvePneumatic Actuated Two Piece Ball ValvePneumatic Actuated ValvesPneumatic Actuated Wafer Butterfly ValvePneumatic Angle Control ValvePneumatic Angle Seat Control ValvePneumatic Angle Type High Pressure Regulating Control ValvePneumatic Bi Directional Knife Gate valvePneumatic Cage Control ValvePneumatic Control ValvePneumatic Double Seat Control ValvePneumatic Flow Control ValvePneumatic Knife Gate ValvePneumatic Metal Seat Flanged Ball ValvePneumatic Single Seat Globe Control ValvePneumatic Sleeve Type Control ValvePneumatic Three piece Ball ValvePneumatic Three Piece Flanged Ball ValvePneumatic Three Way Ball ValvePneumatic Three Way Flanged Ball ValvePneumatic Trunnion Casting Ball ValvePneumatic Trunnion Forged Ball ValvePneumatic Trunnion Forged Metal Seat Ball ValvePneumatic Unidirectional Knife Gate ValvePressure Reducing ValvePressure Safety ValvePressure Seal Gate ValvePressure Seal Globe ValvePressure Seal Swing Check ValveRotary Airlock ValveSafety ValveSimplex Basket StrainersSingle Orifice Air ValveSingle Plate Wafer Check ValveSlab Gate ValveSlurry Knife Gate ValveSoft Seal Gate ValveSpeciality ValveSS304 Bellow Seal Globe ValveSS316 Bellow Seal Globe ValveSS316L Gate ValveSS316L Lug Butterfly ValveSS316L Wafer Butterfly ValveSteam Pressure Reducing ValveSteam Safety ValveSteam TrapStrainersSuction DiffuserSuper Duplex 2 Piece Ball ValveSuper Duplex 3 Piece Ball ValveSuper Duplex 5A Flanged Gate ValveSuper Duplex 5A Globe ValveSuper Duplex 5A Swing Check ValveSuper Duplex Ball ValveSuper Duplex Butterfly ValveSuper Duplex Check ValveSuper Duplex Dual Plate Lug Type Check ValveSuper Duplex Dual Plate Wafer Check ValveSuper Duplex Floating Ball ValveSuper Duplex Gate ValveSuper Duplex Gate ValvesSuper Duplex Globe ValveSuper Duplex High Pressure Ball ValveSuper Duplex Knife Gate ValveSuper Duplex Lug Butterfly ValveSuper Duplex Pressure Reducing ValveSuper Duplex Top Entry Ball ValveSuper Duplex Trunnion Mounted Ball ValveSuper Duplex ValvesSuper Duplex Wafer Butterfly ValveSurge Anticipator ValveSwing Check ValveThermal Safety ValveThermodynamic Steam TrapThermostatic Steam TrapThree Piece Flanged Ball ValveThree Way Ball ValveThrough Conduit Knife Gate ValveTilting Disc Check ValveTitanium 3 Piece Ball ValveTitanium Ball ValveTitanium Butterfly ValveTitanium Check ValveTitanium Dual Plate Lug Type Check ValveTitanium Dual Plate Wafer Check ValveTitanium Floating Ball ValveTitanium Forged Trunnion Mounted Ball ValveTitanium Gate ValveTitanium Globe ValveTitanium Gr.2 2pc Flanged Ball ValveTitanium Gr.2 3pc Ball ValveTitanium Gr.5 2pc Flanged Ball ValveTitanium Gr.5 3pc Ball ValveTitanium Lug Butterfly ValveTitanium Swing Check ValveTitanium Trunnion Mounted Ball ValveTitanium valvesTitanium Wafer Butterfly ValveTop Entry Ball ValveTriple Duty ValveTriple Eccentric Butterfly ValveTriple Offset Butterfly ValveTrunnion Ball ValveTwin Seal Plug ValveUL/FM Approved ValvesUnidirectional Knife Gate ValveWafer Butterfly ValveWater Pressure Reducing ValveY StrainerY Type Globe ValveZirconium Floating Ball ValveZirconium Gate ValveZirconium Globe ValveZirconium Valves

8613371530291

8613371530291