alfa laval safety valve quotation

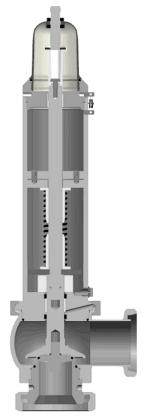

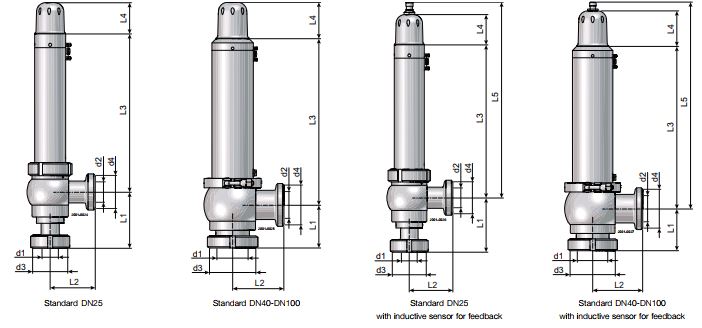

It is used to prevent inadmissible overpressures of fluids in tanks, containers, and plant sections. From the factory, the valve is configured with a set pressure upon request that is created than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure. Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontally the set pressure will be a bit lower than specified due to the missing weight of the piston.

The metal stem plug of the relief valve is held in the closed position by manually adjusted spring tension. As the pipe line pressure increases beyond the spring"s relief set point, the stem plug is forced open, allowing pressure to be relieved through the discharge port. As the pressure lowers below the spring set point, the plug will return to the closed position.

The compression valve is operated by means of a "tee" handle turning mechanism. This allows the valve to gradually open and close.OPTIONSPressure range springs (relief spring chart above)

Alfa Laval relief valves prevent vacuum or pressure build up inside tanks or vessels used in the brewery, food and beverage, personal care and biopharm industries.

To protect against overpressure and vacuum conditions while filling or emptying the tank of liquid, Alfa Laval two-way relief valves are mounted on top of an atmospheric tank in hygienic process lines.

The Alfa Laval range of relief valves (RV) consists of two models made of either polyethylene or AISI 304/316 stainless steel. The polyethylene model is designed for product flows up to 800 hl/h and is available in four different standard sizes: RV130, RV400, RV400A and RV800. The stainless steel model is designed for more stringent hygienic requirements. It handles product flows up to 1000 hl/h and is available in two different standard sizes: RV600 and RV1000.

Alfa Laval’s innovative valves enables gentle and sustainable production of a wide range of food and beverage products. Their innovative and robust solutions allow customers to achieve a never before seen level of hygiene and safety in their industrial processes and at the same time improve taste, nutritional value, texture and appearance of the food and beverage products. No matter how complex your process line or plant are, their specialists work closely with the customers to tailor the right solution. They are committed to ensuring maximum uptime and continuous optimization of your processes.

A compact safety valve that minimizes the risk of implosion of tanks when a vacuum condition arises. These conditions occur while filling or emptying the vessel of liquid, cool rinsing after hot-cleaning or caustic cleaning in a CO2 atmosphere. Designed for use in the brewery, dairy, food and beverage industries, it helps optimize the safety, reliability and performance of critical processes and maximize uptime.

To prevent damage to the tank and help ensure safe operations, the Alfa Laval SB Pressure Relief Valve protects a pressurized tank during an overpressure event. It is designed for hygienic processes in the brewery, dairy, food and beverage industries. The valve can be integrated with a SCANDI BREW® tank top system.

This pressure relief valve removes excess liquid that creates overpressure in the tank due to overfilling. When pressure in the tank exceeds a preset value, the pressure relief valve opens to vent fluid in the event of liquid overfilling, and closes when the tank pressure has returned to a safe level.

Few moving parts and smooth, crevice-free stainless steel surfaces make this valve easy to clean. When the valve is in closed position, it is cleaned as part of the routine Cleaning-in-Place (CIP) cycle. For thorough cleaning of the valve seat, an optional pneumatic force opener and a splash guard is available.

The Alfa Laval SB Membrane Sampling Valve is a compact, cost-effective way to take bulk or aseptic samples from tanks and pipework in breweries (and other hygienic processes such as food and dairy) under sterile conditions. This aseptic sampling valve is suitable for highly viscous products, such as harvest yeast, and ensures minimal risk of contamination, high accuracy, exceptional repeatability and excellent reliability.

The Alfa Laval Unique mixproof CP-3 valve is a highly efficient light-weight, reduced vent valve designed to be configurable and protect product in all processing occasions. Engineered with the latest efficiency and sustainability principles in mind, they maximize floor space while greatly minimizing CIP consumption and downtime.

Alfa Laval Unique Mixproof CP-3 features two independent plugs designed to be PMO compliant and meet the strict guides of 3A Sanitary Standard 85-03 ensuring the pressure in the leakage chamber is atmospheric or less during any working condition. Therefore, a single Unique Mixproof CP-3 valve can often replace two or more valves of other types.

Unique mixproof CP-3 valves feature a top-loaded design, making maintenance fast and easy. It also features no adjustable components, a maintenance-friendly actuator and built-in leakage detection on all seals. Unique mixproof valves meet most hygienic standards and can be supplied with the optional SpiralClean cleaning system.

You get the full benefit of using Unique mixproof valves by combining them with Alfa Laval ThinkTop and ThinkTop Basic valve sensing and control units.

Alfa Laval valve clusters can be supplied pre-assembled and pre-tested as well as fully wired and with all the necessary pneumatic tubing, junction boxes and control panels pre-connected.

They combine the innovation of Alfa Laval with the time-proven reliability of Tri-Clover brand valves, providing the options required to meet your processing needs.

From compression and relief valves to sampling and CPM valves, Alfa Laval has the products and technology to provide you with sanitary, efficient and economical valve solutions to suit your unique application.

Our ball valves are constructed with a full-flow body design, enabling the product to pass through the valve with no restrictions and with a minimal pressure drop. The basic design allows cleaning and product recovery using pigging systems, and they are ideal for use with viscous liquids and liquids containing solid or semi-solid particles. Alfa Laval ball valves for hygienic use bear the Alfa Laval SBV and Alfa Laval Tri-Clover® designations.

During the forecast period, the global safety valve market size is estimated to reach USD 13.2 Billion by 2030 and is expected to exhibit a significant growth rate of 9.20% CAGR.

Safety Valves are precautionary valves that automatically actuate when the preset safety valve pressure and temperature are exceeded. These safety valves can be used to protect the critical equipment from damage by controlling excess pressure without any electrical support. For protecting equipment from unsafe pressure these mainly operate at a predetermined pressure. Additionally, these valves protect the employees around the plants and the environment around them. Safety valves are used in various applications like pharmaceutical, construction, oil & gas industries which foster the growth of the market.

During the lockdown, the global safety valve market is negatively impacted. Not only the safety valve market but the whole world was also affected drastically by this pandemic. To control the prevalence of the coronavirus, the government has imposed stringent regulations like lockdowns, maintaining social distance, covering the face with masks, manufacturing industries shut down, and transportation bans.

Even though at the primary stage of the pandemic, the safety valve market has fallen. Developing the innovations in the safety valve system and growing awareness regarding the benefits of the safety valve market by the key players are increasing the growth of this market.

Growing demand for safety valves in the oil & gas industry, the rise in nuclear energy generation, the growing importance of safety valves in industrial processes are the major driving factors of this market. The continuous need for safety valve replacement and the use of 3D printers in manufacturing lines are boosting the growth of the market. The safety valve market is highly dependent on investments in manufacturing facilities.

Some of the numerous factors that drive the safety valve market are rising demand for water & power, pollution control regulations, and rapid growth of process industries are supposed to escalate the growth of the safety valve industry during the assessment period. Growth in the construction of nuclear power plants is fueling the growth of the market. The increase of accidental incidences and soaring demand for safety valves in several industrial sectors are increasing the growth of the global market.

The constant growth of oil & gas exploration in few parts across the globe is restraining the market. The fabrication of safety valves are very expensive which is hindering the market growth

To increase the growth of the safety valve market industry integration of safety valves into the Internet of Things (IoT) environment is creating the opportunity. The innovations in the safety valve systems are anticipated to increase the strong growth of the market.

To provide a strategic profile of the prominent key players in the market, analyze their core competencies, forecast statistics, and draw a global safety valve market growth landscape.

The global safety valve market based on material is sub-segmented into steel, alloy, cast iron, cryogenic, and others. As the steel safety valves are durable and don’t leak in hot or cold temperatures, the steel segment is expected to dominate the global market.

It is segmented into less than 1”, 1” to 10”, and 11” to 20”, and 20” & above. Among these, during the review period, the 1” to 10” segment is projected to grow at the significant CAGR for the safety valves market for the benefits behind this size range like controlling the flow and pressure of liquids, gases, and slurries within different end-use industries.

The global safety valve market industry is divided into oil & gas, energy & power, food & beverage, chemicals, water & wastewater treatment, and others. In the global safety market, the oil & gas segment is expected to hold the largest share, because the oil & gas industries are the most significant revenue-generating industries which need almost all types of valves like gate, globe, ball, check and butterfly. Some of the products include a safety valve air compressor, safety valve boiler, and safety valve heater.

Asia-Pacific, Europe, North America, the Middle East & Africa, and South America are the main geographies included in this market. Due to the rapid urbanization and growing industrialization Asia-Pacific holds the largest safety valve market share.

The global safety valve market region-wise is divided into Asia-Pacific, Europe, North America, and the Middle East & Africa. Out of these regions, Asia-Pacific holds the largest market share for its growing infrastructural developments, rise of investments in various industries like oil & gas, construction industry, and drastic urbanization. Growing demand from mining, chemical, and municipal industries is expected to propel market growth in this region.

Safety valves are used in the application of the construction industry to control liquid flow in firefighting systems, water supply systems, and piping systems. The rising construction industry propels the market growth in this region. North America is accounting as the second-largest market for its growing investments in the construction industry.

Naples, Italy, Baker Hughes launched a new steam test facility in November 2018, ASME Section I safety valves that serve better to the European aftermarket with a rapid response for steam applications. The future development of the current aftermarket is launched as the new aftermarket plant which is expanded by the product scope and capacity of the plant. To fulfill the range of Masoneilan control valves and consolidated safety valves ranging up to 2000 psi test pressure.

In October 2018, Emerson Electric Co. to help the LNG marine transportation consumers developed low-pressure pilot operated pressure relief valves (POPRVs) by reducing their size which helps to reduce the investments by 25% and protects the end-users from overpressure by offering them extra profit margin.

In May 2019, the Mexican government announced that it is going to construct a new refinery set in the Tobasco coast, Mexico in June 2019. Hence safety valves are used in refineries to control the pressure of liquids and gases in plants.

This global safety valve market research includes the Market Overview, COVID-19 analysis, Market Dynamics, Study Objectives, Segment Overview, Regional Analysis, Competitive Landscape, Recent developments, Segmentation Table, and FAQs. The market scenario includes the safety valve market drivers, restraints, challenges, and opportunities. The safety valve forecast segments are material, size, end-use, and region.

8613371530291

8613371530291