alfa laval safety valve for sale

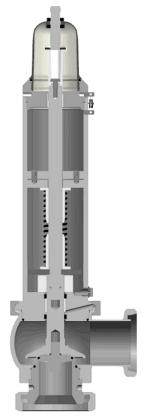

It is used to prevent inadmissible overpressures of fluids in tanks, containers, and plant sections. From the factory, the valve is configured with a set pressure upon request that is created than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure. Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontally the set pressure will be a bit lower than specified due to the missing weight of the piston.

The Alfa Laval SB Anti Vacuum House minimizes the risk of implosion in closed process tanks that are subject to vacuum conditions, such as while filling or emptying the tank, cool rinsing after hot-cleaning, or caustic cleaning in a CO2 atmosphere. Capable of being integrated into a SCANDI BREW® tank top system, the valve is designed for hygienic processes in the brewery, dairy, food and beverage industries.

The Anti Vacuum House is used for minimizing the risk of implosion of tanks exposed to vacuum e.g. during emptying, cool-rinsing after hot-cleaning or caustic cleaning in a CO2 atmosphere. The Anti Vacuum House can be combined with safety valves or pressure regulators mounted the top.

The Anti Vacuum House operates as standard at 50 mmH2O / 5 mbar for all valve sizes. Safety valves protect the vessel and ensures discharge if pressure in the tank exceeds the preset opening value.

When the tank is cleaned a small volume of cleaning fluid will pass the valve body and clean the seat. To ensure thorough flushing of valve seat, force opening of the valve is necessary – this must be done when the tank is pressureless. The use of a drain collector is recommended to prevent CIP fluid spilling on to the tank.

The Alfa Laval Unique mixproof CP-3 valve is a highly efficient light-weight, reduced vent valve designed to be configurable and protect product in all processing occasions. Engineered with the latest efficiency and sustainability principles in mind, they maximize floor space while greatly minimizing CIP consumption and downtime.

Alfa Laval Unique Mixproof CP-3 features two independent plugs designed to be PMO compliant and meet the strict guides of 3A Sanitary Standard 85-03 ensuring the pressure in the leakage chamber is atmospheric or less during any working condition. Therefore, a single Unique Mixproof CP-3 valve can often replace two or more valves of other types.

Unique mixproof CP-3 valves feature a top-loaded design, making maintenance fast and easy. It also features no adjustable components, a maintenance-friendly actuator and built-in leakage detection on all seals. Unique mixproof valves meet most hygienic standards and can be supplied with the optional SpiralClean cleaning system.

You get the full benefit of using Unique mixproof valves by combining them with Alfa Laval ThinkTop and ThinkTop Basic valve sensing and control units.

Alfa Laval valve clusters can be supplied pre-assembled and pre-tested as well as fully wired and with all the necessary pneumatic tubing, junction boxes and control panels pre-connected.

Pressure can build inside vessels or systems due to blocked discharge, thermal expansion, chemical reactions, or a combination of these events. The Alfa Laval Safety Valve is designed to flexibly relieve excess pressure from vessels or equipment at all times and under any circumstances. As the last and vital component in accident prevention, a high-quality, hygienic safety valve is an essential part of your operations.

Depending on the causes of excess pressure, a different mass or volume flow may need to be discharged. With this type of variable flow, a perfectly fitted safety valve is essential. The Alfa Laval Safety Valve comes in sizes from DN25 to DN100 with a spring-loaded set pressure range between 0.2 and 12.0 bar depending on the size of the valve.

In a potentially dangerous situation, the Alfa Laval Safety Valve is designed to open at a predetermined set pressure. The compressed spring force, which keeps the valve closed below the set pressure, is forced open when pressure builds up at the inlet of the safety valve. As these forces balance out, the valve will discharge and decrease pressure, ultimately reclosing as the system returns to normal.

They combine the innovation of Alfa Laval with the time-proven reliability of Tri-Clover brand valves, providing the options required to meet your processing needs.

From compression and relief valves to sampling and CPM valves, Alfa Laval has the products and technology to provide you with sanitary, efficient and economical valve solutions to suit your unique application.

January 19, 2016 - Alfa Laval announces Safety Valves that protect against overpressure in tanks and pipelines caused by overfilling or fermentation processes.

In a potentially dangerous situation it will open at a predetermined set pressure. The compressed spring force, keeping the valve closed, is forced open when pressure builds up at the inlet of the safety valve. As these forces balance out, the valve will discharge and decrease pressure, ultimately reclosing as the system returns to normal.

These safety valves protect also protect against implosion due to vacuum caused by cold rinsing after hot cleaning or blocking of gas supply during emptying.

The Alfa Laval safety valve can be combined with the Alfa Laval SB anti vacuum house into a combined safety valve, protecting against both vacuum and overpressure in one hygienic valve solution with a single tank connection.

The Alfa Laval LKC-2 non-return valve consists of an upper valve body, lower valve body, valve plug, seal ring, and guide disc. The valve body is assembled by means of a clamp and hygienically sealed with a special seal ring. A guide disc and four legs guide the spring-loaded valve plug with an O-ring seal. LKC-2 has welding ends for ISO or DIN connections.

The spring acts on the valve plug, keeping the valve closed until the force from the pressure in the inlet exceeds the force of the spring. If a reverse flow should occur, the spring force and the pressure from the outlet will keep the valve closed.

Alfa Laval’s ThinkTop pulse seat clean, is being launched by the company as a water and time saving product. Drain valves comprise up to 20% of all valves in a typical processing plant, says the company, but cleaning them is difficult. Alfa Laval offers what its says to be a solution in the ThinkTop pulse seat clean. It quickly cleans drain valves while saving up to 95% in Cleaning-in-Place (CIP) liquid.

The Alfa Laval ThinkTop V50 and V70 generates savings through its standard automated valve-position feature triggered by a rising programmable logic controller (PLC) signal and controlled by the sensing and control units.

“The ThinkTop pulse seat clean brings unheard-of savings in CIP liquid to process plant owners and operators compared to conventional PLC timer-controlled seat cleaning,” said René Stietz, product portfolio manager, valves and automation, Alfa Laval. “Alfa Laval is the first and only valve automation solutions provider to deliver significant savings in CIP liquid for drain valves.”

Short bursts, or pulses, drive the valve cleaning process, activating the valve when shear forces peak. Each position-based pulse takes less than a second, preventing pressure shocks in the system. The pulse creates high turbulent flow as the liquid passes through the narrow gap between the valve house and valve seat, effectively removing all residuals for spotless drain valves.

The pulse seat clean makes control and validation of valve cleaning cycles easy. The valve position is not controlled by the PLC timer but by the Alfa Laval ThinkTop. Besides reducing the volume of CIP liquid used, programming the sensor to open and close the seat quickly ensures faster, more rigorous cleaning and hygiene than timer-controlled cleaning. The ThinkTop also verifies that valve cleaning has been completed.

Intended for use with single-seat valves or butterfly valves used as drain valves, pulse seat clean is a standard feature of ThinkTop V50 and V70 sensing and control units with one solenoid valve. Regardless of actuator mode, the drain valve may be configured as a normally open or normally closed shutoff or changeover valve. The pulse seat clean simplifies valve commissioning, prevents pressure shocks, and reduces CIP liquid and time.

8613371530291

8613371530291