alfa laval safety valve pricelist

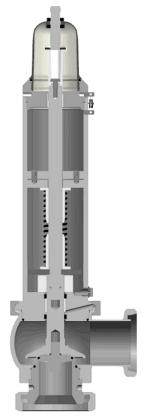

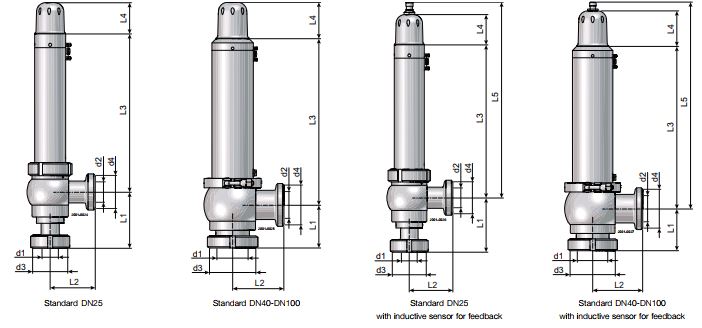

It is used to prevent inadmissible overpressures of fluids in tanks, containers, and plant sections. From the factory, the valve is configured with a set pressure upon request that is created than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure. Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontally the set pressure will be a bit lower than specified due to the missing weight of the piston.

The Alfa Laval SCANDI BREW® Pressure Relief Valve is a hygienic safety valve. This Flange Mounted Valve is designed with a counterweight, which is set and locked at the desired pre-set pressure value for tanks and vessels used in hygienic process lines in the brewery, dairy, food, beverage and many other industries. The valve can also be integrated onto a tank top system.

Alfa Laval valve indication units provide basic information about the position of valves used in hygienic applications. Based on proven technology, this range of valve position indicators offers safe, reliable and economical operation.

Alfa Laval indication units are cost-effective digital devices with up to two feedback signals that are mounted directly on the valve yoke, which provide feedback on the valve’s open/closed position. These valve position indicators (Side indicator and brackets) may be used on any Alfa Laval valve, but are especially competitive solutions for Alfa Laval SSV Single seat valves,and mixproof valves (brackets), and butterfly valves.

Based on principles of electromagnetic conductivity and metallic detection, this non-contact electronic sensor is inherently resistant to dust, humidity and oil in industrial environments. This increases operational safety and reliability.

Based on principles of electromagnetic conductivity and magnetic detection, this non-contact electronic sensor provides safe and accurate detection of valve position compared to conventional proximity sensors. It provides enhanced reliability and longer service life for valve position sensing in any operating environment.

To connect equipment and processes where clean conditions are essential, Alfa Laval supplies a comprehensive range of tubes, which provide maximum hygiene. All products meet key criteria for tight tolerances, a variety of finishes and uniform wall thicknesses. To provide customers with greater flexibility and fast, efficient delivery, Alfa Laval provides a tiered supply chain to ensure tubes meet customer demands for high quality at competitive prices.

All Alfa Laval Hygienic Tubes undergo strict quality control procedures at every stage of manufacturing at Alfa Laval facilities. All products meet ISO 9001 and ISO 14001 standards, which define the requirements for quality management systems and environmental management systems, respectively.

Throughout sourcing, manufacturing and distribution, Alfa Laval adheres to stringent quality-control procedures. Alfa Laval labels all product packaging with bar code, product information and manufacturing date. As a seal of quality, the Alfa Laval brand mark is permanently etched onto the external surface.

Alfa Laval offers a comprehensive range of hygienic tubes with smooth, crevice-free design, superior corrosion-resistance and secure, self-aligning joints to ensure trouble-free flow. This includes unions, clamp fittings, flanges, bends, tees, reducers and tubes.

To ensure that exactly the right match for the process, Alfa Laval offers a wide variety of high quality uniform weld end fittings for all tube combinations. To match tolerances, Alfa Laval provides exact angles and uniform tube, bend and tee connections.

To connect equipment and processes where clean conditions are essential, Alfa Laval supplies a comprehensive range of fittings, which provide maximum hygiene. All products meet key criteria for tight tolerances, a variety of finishes and uniform wall thicknesses. To provide customers with greater flexibility and fast, efficient delivery, Alfa Laval provides a tiered supply chain to ensure fittings meet customer demands for high quality at competitive prices.

All Alfa Laval Hygienic Fittings undergo strict quality control procedures at every stage of manufacturing at Alfa Laval facilities. All products meet ISO 9001 and ISO 14001 standards, which define the requirements for quality management systems and environmental management systems, respectively.

Throughout sourcing, manufacturing and distribution, Alfa Laval adheres to stringent quality-control procedures. Alfa Laval labels all product packaging with bar code, product information and manufacturing date. As a seal of quality, the Alfa Laval brand mark is permanently etched onto the external surface.

Alfa Laval offers a comprehensive range of hygienic fittings with smooth, crevice-free design, superior corrosion-resistance and secure, self-aligning joints to ensure trouble-free flow. This includes unions, clamp fittings, flanges, bends, tees, reducers and tubes.

To ensure that exactly the right match for the process, Alfa Laval offers a wide variety of high quality uniform weld end fittings for all tube combinations. To match tolerances, Alfa Laval provides exact angles and uniform tube, bend and tee connections.

On-time delivery and supply chain visibility is vital to business success. As a true global supplier, Alfa Laval provides fast, efficient worldwide delivery of high quality products at competitive prices.

To meet customer requirements, Alfa Laval is the first supplier to offer a four-tier supply chain for fittings. Upon order receipt, Alfa Laval factories and distribution centres can supply:

"We"re committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Alfa Laval Tank Bottom Valve , alfa laval tank bottom valve , Tank Bottom Valve , Now we have been trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price we will be the market leader make sure you don??¥t hesitate to contact us by phone or email if you are interested in any of our solutions.

In 2023, the sales of Pressure Relief Valve in Global Market is expected to reach US$ 4,509.8 Mn. and is projected to expand steadily at a CAGR of 4.6% to reach a market valuation of close to US$ 7,070.9 Mn by 2033.

In recent past valve costs have increased globally, which can be attributed to growing tariffs from the North American region, particularly the US. Leading players from the European and American regions have facilities in both high- and low-income nations. In contrast, labor-intensive production processes like the creation of rough castings for valves and valve components take occur in low-cost manufacturing nations like China. These processes include design, research and development, and testing. Due to low prices and quality maintenance, OEMs are able to do so. However, growing US government tariffs on steel and aluminum imports from China have had a substantial negative influence on pressure relief valve profit margins and costs.

However, the rapid growing industrialization and increasing safety precaution are the factors that are expected to fuel the market growth of Pressure relief valves across the globe during the assessment period, the Pressure relief valve market is expected to experience demand growth with CAGR of 4.6% during the forecasted period.

From 2017 to 2022, the Global Pressure Relief Valve Market expanded at a CAGR of around 2.4%. The advancement in product technology to connect the valves digitally enables end users to monitor pressure in various applications digitally which has generated significant demand from the various industry sector during the forecasted period.

Numerous applications where pressure levels are crucial for continuous and efficient machinery performance demand for the utilization of pressure relief valves. These include the various sectors operating with steam, air, gas, or liquid such as oil and gas, power generation and the petrochemicals industry. Multiphase applications and chemical processing systems both have high installation rate of pressure relief valves. With rapid development industrial sector & expansion of oil & Gas pipelines across the developing as well as developed economies the demand for PRV is also expected to expand, Persistence Market Research expects the market to expand at a 4.6% CAGR through 2033.

Both emerging and advanced regions have seen a surge in oil and gas consumption. In order to meet the rising demand and supply for oil and gas, industries are concentrating on expanding their production facilities through onshore and offshore exploration. Since the oil and gas sector is one of the key end uses for the global pressure relief valves market thus expanding oil & gas Sector is generating lucrative opportunity for the demand growth of PRVs in upcoming period.

Furthermore, growing regulation for use of pressure relief valves in power generation sector is further set to create opportunities for the market. For instance, there are currently about 50 nuclear reactors under development. By safeguarding turbines, super heaters, and boilers to enable the stations to operate at prescribed pressures, pressure relief valves play a crucial part in the successful and safe operations of nuclear facilities.

Manufacturing businesses will be significantly and directly impacted by the Asia Pacific region"s volatile and uncertain markets. The operational costs of the manufacturing processes, which are the main concern of manufacturers, will be directly impacted by rising tariffs and raw material costs used to manufacture valves. Rising raw material costs immediately impact the integrity of the supply chain and the selling price of a product. Manufacturers in the Asia Pacific region are becoming increasingly concerned about the steady growth in cost of the raw materials used to make pressure relief valves. This is expected to, restrain the market"s expansion for pressure relief valves.

With an absolute dollar opportunity of around US$ 600.0 Mn, North America is expected to be the most lucrative market for pressure relief valves suppliers. U.S is leading the North American market, and is expected to witness a 1.5X growth during 2023-2033. The market for pressure relief valves has recently experienced considerable growth in sales as a result of growing industrialisation and advancements in urban waste water management systems. Apart from that U.S. is also second largest importer & Exporter of Pressure relief valves, which makes it a targeting region for the manufacturers & Suppliers.

In 2023, the German Pressure Relief Valve market is likely to hold around 25% of the market by value share in Europe. Germany"s extensive remanufacturing capabilities are likely to play a crucial part in development of industrial growth. Sales growth for pressure relief valves is anticipated to be boosted in the upcoming years as manufacturers are planning to invest more in safety & developments of industrial Sites.

With a CAGR of 5.9%, India is expected to lead the South Asian market throughout the assessment period and experience significant expansion. Pressure relief valve demand is anticipated to increase as a result of India"s low production and labour costs, as well as less regulations & certifications required for PRVs, which are encouraging various industry players, including oil & gas, pharmaceutical, chemical, and textile manufacturers, to expand their manufacturing facilities in India.

By the end of the assessment period, spring-loaded pressure relief valves will hold a value share of over 40% of the market for pressure relief valves worldwide. Due to its broad range of applications and other technological advantages over other valves, this valve is widely utilized. The design and use of pressure relief valves is covered by a number of international codes and standards, the most popular of which being the ASME (American organization for mechanical engineers) Boiler and Pressure Vessel Code, also known as ASME code. Despite the fact that this code varies by region.

In 2023, the demand for pressure relief valves is primarily driven by the Medium Pressure segment in Set Pressure segment of the market. By the end of the forecast period, it is projected that pressure relief valves with a medium pressure range will still be widely utilized in a variety of end use sectors. The market for medium pressure relief valves is expected to continue expanding due to rising end-use sectors including oil and gas, chemical, and others.

The new range comes with slimmer actuators and optimized lightweight cast valve bodies with options for economical operation. The enhanced DV-ST UltraPure range is fully customizable to meet virtually any aseptic process requirement across the food and pharmaceutical industries.

Slimmer, space-saving actuators and lightweight cast valve bodies for optimized performance are the innovations behind the enhanced DV-ST UltraPure range. These smaller aseptic diaphragm valves achieve lower total cost of ownership as well as tangible sustainability gains, the company said.

“These enhancements make our Unique DV-ST UltraPure diaphragm valves second to none,” said Paw Kramer, portfolio manager, valves and automation at Alfa Laval.

Alfa Laval said it is also more energy efficient due to reduced air consumption. Tested to perform a million strokes without service, these fully welded, maintenance-free actuators handle a wide range of pressures. Options include a stroke limiter, economical valve position indication, and comprehensive automated valve sensing and control.

Joining the DV-ST UltraPure family of valve bodies is the new ASME BPE-compliant Cast OP. Engineered based on computational fluid dynamics analysis, it is 36% lighter in weight, on average, than the standard cast valve body and features a smaller seat size. This translates into benefits including: reduced installation costs due to smaller footprint; faster, more energy-efficient cleaning cycles because there’s less steel to heat for sterilization in place; lower total cost of ownership due to smaller diaphragms, handles and/or actuators; and, safe, simple, low-cost maintenance.

To connect equipment and processes where clean conditions are essential, Alfa Laval supplies a comprehensive range of fittings, which provide maximum hygiene. All products meet key criteria for tight tolerances, a variety of finishes and uniform wall thicknesses. To provide customers with greater flexibility and fast, efficient delivery, Alfa Laval provides a tiered supply chain to ensure fittings meet customer demands for high quality at competitive prices.

All Alfa Laval Hygienic Fittings undergo strict quality control procedures at every stage of manufacturing at Alfa Laval facilities. All products meet ISO 9001 and ISO 14001 standards, which define the requirements for quality management systems and environmental management systems, respectively.

Throughout sourcing, manufacturing and distribution, Alfa Laval adheres to stringent quality-control procedures. Alfa Laval labels all product packaging with bar code, product information and manufacturing date. As a seal of quality, the Alfa Laval brand mark is permanently etched onto the external surface.

Alfa Laval offers a comprehensive range of hygienic fittings with smooth, crevice-free design, superior corrosion-resistance and secure, self-aligning joints to ensure trouble-free flow. This includes unions, clamp fittings, flanges, bends, tees, reducers and tubes.

To ensure that exactly the right match for the process, Alfa Laval offers a wide variety of high quality uniform weld end fittings for all tube combinations. To match tolerances, Alfa Laval provides exact angles and uniform tube, bend and tee connections.

On-time delivery and supply chain visibility is vital to business success. As a true global supplier, Alfa Laval provides fast, efficient worldwide delivery of high quality products at competitive prices.

To meet customer requirements, Alfa Laval is the first supplier to offer a four-tier supply chain for fittings. Upon order receipt, Alfa Laval factories and distribution centres can supply:

Sales channels using the Alfa Laval Anytime eBusiness portal can easily order fittings on-line, which streamlines order processing and saves both time and money.

Alfa Lavalsaid it introduced the latest version of the Alfa Laval ThinkTop, the company’s best-selling valve-sensing and control unit for hygienic valves used in the dairy industry. The second-generation units — Alfa Laval ThinkTop V50 and V70 — provide real-time information about valve-operating status while helping to improve production performance. They also have an up to 90% faster setup, reduce water consumption by up to 90%, instantly identify valves, prevent external corrosion and contamination, and feature a clean geometric design.

Coperion’s ZRD Hygienic (heavy-duty premium) rotary valve is especially designed for sanitary dairy powder applications where contamination is a constant concern and frequent disassembly and cleaning are required. The unit is designed to avoid contamination with product contact surfaces constructed from DIN 1.4404 (AISI 316L) stainless steel. When coupled with Coperion’s added Rotorcheck feature, the valve can detect metal or foreign material contact between the blades. Valve housing ensures safe operation and processing of dairy powders, the company said.

Burkert Fluid Control Systems presented a completely new body type for diaphragm valves aimed at applications in hygienic environments. The body, manufactured through the use of a patented manufacturing procedure called hydroforming technology, satisfies the highest requirements imposed on materials and cleanability. According to the company, the Burkert tube valve body is manufactured with high-quality 316L stainless steel, the same material often used in other plant or system lines. This enables hygienic tube-to-tube welding of virtually identical materials.

Dixon Sanitary introduced the DX60 Series hygienic tanker valve. It is used on food-grade stainless-steel bulk transport trailers to safely load and unload milk and other food-grade products. According to Dixon, a patent-pending closure system eliminates the pinch point. A hygienic single-acting wiper seal increases seal life and decreases the need for any seal maintenance or replacement, which equals less down time. The easy-lock plunger prevents the valve from slamming shut during operation.

Rieger Flow Products LLC said the success of its PMO mix proof valve N2 influenced the development of the hygienic mix proof change-over valve N32. The N32 has the same unique sealing principle of the N2, but also has a metallic stop as an additional safety feature and includes an additional change-over function. The valves are easy to clean in place, and assembly/disassembly can be done without special tools.

Laufer Valve Technology’s LIAG free-flow shutter valves were invented in 1996 and were custom-made for viscous, hygienic processing. Laufer said no other valve features the cleanability, full-bore or low and infrequent maintenance inherent to LIAG’s valve design. The LIAG valves have only five wearing parts and don’t require any special tools, so plant managers can rely on them to keep their lines running at full efficiency and drastically reduced downtime. LIAG shutter valves regularly replace less-than-sanitary, high-maintenance ball, plug, stem, seat, diaphragm and butterfly valves.

Nelson-Jameson said it offers the Alfa Laval OS twin screw pump, which is designed for optimal reliability and quick and easy maintenance. The pump provides the ability to pump both process media and clean-in-place supply with just one pump. It features a front-loading cartridge shaft seal and a rigid stainless-steel gearbox with timing gears located between bearings. This pump range provides balanced loading of the shaft assembly and an oil chamber design with enhanced lubrication to the bearings and gears. It is available in nine models based on three frame sizes. Each frame size is available with three different screw profiles for varying pressure, flow and solids-handling capabilities.

Lee Industries said it has the industry’s first 3A Sanitary Certified ball valve. The valve is USDA-listed and is an ideal choice when ball valves must be specified for sanitary applications in demanding process operations. Lee’s exclusive two-piece ball valve design simplifies teardown, cleaning and service compared to conventional three-piece ball valves, which require more time and tools to maintain. Lee’s design delivers faster turnaround in batch production, shorter downtime intervals and lower maintenance costs. Lee’s valves are designed to meet the highest safety standards for critical processing applications and add efficiency to both production and maintenance.

HRS Heat Exchangers’ HRS BP series positive-displacement pumps feature adjustable flow rates, ranging between 80 and 5,250 gallons per hour, as well as high pressure drop of up to 435 pounds per square inch. This makes them suitable for a wide range of high-viscosity, shear-sensitive and large-particle-containing fluids, including creams, custards, yogurts and compotes. Clap valves allow the pumping of whole fruits, further increasing flexibility.

The Alfa Laval OS Twin Screw pump range combines process flexibility with the highest quality standards. The Alfa Laval OS range has been certified by EHEDG and conforms to the 3A standard. Consequently, it is designed for use in applications within the Dairy, Beverage and Food industries where cleanability is paramount. With a front loading cartridge shaft seal, a rigid stainless steel gearbox with timing gears located between bearings, providing balanced loading of the shaft assembly and an oil chamber design with enhanced lubrication to the bearings and gears the Alfa Laval OS Twin Screw pump is designed for optimal reliability and quick and easy

The Alfa Laval OS Twin Screw pump is available in nine models based on three frame sizes. Each frame size is available with three different screw profiles for varying pressure, flow and solids handling capabilities.

WarrantyExtended 3-years warranty on Alfa Laval OS pumps. The warranty covers all non-wear parts on the condition that genuine Alfa Laval Spare Parts are used.

We are not the manufacturer, authorised distributor or authorised representative of the Alfa Laval brand Ireland. The private labels and part numbers shown on this website are the property of their respective owners.

With Alfa Laval Unique Sampling Valves you can take representative samples in a variety of hygienic processes including food and beverage, personal care and biopharm. These reliable single and double-seat valves provide the high accuracy, exceptional reproducibility and excellent reliability required for high quality, cost-effective sampling. The ergonomically designed handle ensures exceptional control and convenience during operation. Aseptic and sterilizable solution for safe sample collection Design ensures hygienic and contamination-free sampling

Enhanced cleanability - valve body made of single piece of stainless steel provides smooth, crevice-free surfaces eliminating bacterial build-up risk Certification, specification and standards: All Unique Sampling Valves are designed, tested and approved according to EHEDG guidelines and certified to carry the 3-A symbol. All product-wetted components are made of 1.4404 (316L). EN10204 3.1 included with valve. For more information, please consult Documentation. The Alfa Laval Unique Sampling Valve consists of a valve body, an actuator and membrane seal. The rubber membrane seal is placed on the stem of the actuator and acts as a stretchable plug. The valve body made of single piece of stainelss steel eliminates need for welding. As such, this prevents pore formation and cracking in the welds, and subsequently risk of bacterial build-up. Product range and accessories The Unique sampling valves are available as single and double-seat with working pressures up to 6 bar and maximum temperatures of 130 °C. Membrane seals are made of FDA-approved EPDM or silicone. Choice of manual or pneumatic actuators is available. Other options include types of valve bodies, connections, actuators and accessories. Valve Type Size Product type Max. Particle size

Single-seat Double-seat Type 25 High viscosity Up to 20 mm Sampling accessories Alfa Laval’s has a broad range of high quality sampling accessories to provide users with comprehensive sampling solutions. These include non-return valves, quick couplings, pressure relief valve for steam sterilization and the Alfa Laval Steam generator, which enables you to steam-sterilize where there is no permanent steam supply on hand. For further information on accessories, click to view product leaflets . How it works > Positions in the sampling process: read section on How it works Unique single-seat sampling valves Designed for standard hygienic sampling, the single-seat sampling valve has two positions: open and shut. It can easily be upgraded to a double-seat valve by replacing the handle or actuator with an upgrade kit. Open position to start the sampling process Manual valve: rotate the handle counter-clockwise to open the valve. Pneumatic valve: open the valve by activating the actuator. In the open position, the valve stem and the membrane are retracted, which enables the product to flow freely through the open valve. Shut position for sterilization Manual valve: to stop the sampling process and shut the valve rotate the handle clockwise Pneumatic valve: shut the air connection. This action shuts off the flow and makes the channel between the connecting hoses available for sterilization. If steam is used for Sterilization-in-Place, we recommend using an optional pressure relief valve on the outlet. A new level of accuracy with patented new technology Single-seat technology can pose challenges for complete sterilization. In the closed position, the membrane seal comes into contact with the valve seat. These points of contact are virtually impossible to clean due to tight surface compression and may therefore accumulate product residue and microorganisms. You can achieve an extra level of security using Alfa Laval’s unique double-seat technology. The single seat version can be simply upgraded to a Unique double-seat sampling valve with an easy-to-use upgrade kit. Unique double-seat sampling valves The specially engineered Unique double seat sampling valves are an excellent choice for applications that require higher cleanability. Its patented double seat technology ensures higher cleanability and sterilization of the valve seat and pipe connections. Designed for truly sterile sampling, the double-seat sampling valve has three positions: open, shut and sterilization. Open position to start the sampling process Manual valve: rotate the handle counter-clockwise to open the valve. Pneumatic valve: open the air supply air to the open connection. This retracts the valve stem and membrane seal and enables the product to flow freely through the open valve. Shut position to stop the sampling process Manual valve: rotate the handle clockwise. Pneumatic valve: shut off the air to the open connection. Sterilization position: Manual valve: rotate the handle clockwise to the steam position. Pneumatic valve: apply air to the steam connection. This extends the valve head’s inner spindle into the inner seat and stops product flow in the valve port. At the same time the outer spindle of the valve head retracts and lifts the membrane seal away from its normal seat. The hard-to-reach areas on the seat surface are now exposed, ensuring thorough sterilization and making the Unique double-seat sampling valve a solid and reliable choice for 100% representative sampling. Configuration with a pneumatic actuator Alfa Laval Unique Sampling valve can be configured with a manual or pneumatic actuator. The pneumatic actuator provides a remote sampling option, and an indication proximity switch can be added for valve positioning. In the single seat configuration, the pneumatic actuator opens and shuts the valve. When fitted with a double-seated sampling valve, the pneumatic actuator furthermore ensures total sterilization of the entire valve seat and pipe connections. . Part of a broad valve range Alfa Laval offers a comprehensive range of valves intended for hygienic applications in the dairy, food, beverage, home & personal care, biotechnology and pharmaceuticals. Alfa Laval SB Carlsberg Flask

Alfa Laval Unique Sampling Valve For a broader valve range, explorer the different product categories: ball valves, butterfly valves, control/check valves, diaphragm valves, double seal valves, double seat valves, regulating valves, sample valves, shutter valves and single seat valves. You might also be interested in... SB Carlsberg Flask Alfa Laval SB Carlsberg sterilizes wort and cultivates pure yeast cultures on a laboratory scale for use in yeast propagation plants in the brewery, food, dairy and beverage industries. SB Membrane Sampling Valve A compact, cost-effective way to take bulk or aseptic samples from tanks and pipework in breweries (and other hygienic processes such as food and dairy) under sterile conditions. SB Micro Sample Port Widely used within the brewery, food, dairy and beverage industries, the Alfa Laval SB Micro Sample Port enables representative aseptic and microbiological samples to be taken in small volumes from tanks and pipework. . Ten top tips - Valves Here are some tips and service videos to show how you keep your hygienic valves in tip top condition Food Logic Alfa Laval"s hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients. Keeping up with the food industry trends and addressing four key challenges, supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Our catalog contains the entire product line of the Alfa Laval manufacturer at good prices with door-to-door delivery to any region of United States Ireland

Croatia, including your area: Los Angeles. Our managers will help you to select and buy suitable Alfa Laval product or spare part, just right after sending an application form. To find out the prices and delivery time, please fill in the feedback form or send your inquiry to [email protected]

8613371530291

8613371530291