api safety valve factory

LESERs solution against corrosionIn the last 10 years LESER, The Safety Valve Company, from Hamburg in Germany has installed more than 1800 safety valves in Urea plants located in almost all countries in the world.

The specification and purchase of valves in general can be a very complicated task depending on the time available that the instrumentation engineer has in a project and his own experience in developing this task. It starts with the fact that academic training, at least in Brazil, has very few courses aimed at industrial instrumentation and goes through the fact that each valve is, in essence, an engineering solution dedicated to an exclusive application. The probability of using a valve that has been specified and purchased incorrectly in another application is very low.

The need for use, selection, sizing, specification and, lastly, the purchase of valves usually arise within a multidisciplinary project; where several other very important instruments and equipments are allocating human resources that may even be working on parallel and independent projects and almost always with very lean HH. The result of this combination of factors is little time to sizing and specify a valve, be it for control or safety. This leads many engineers not to question why they adopt some requirements, especially when it is clear in the standard of the final customer that you have to follow it. When it comes to adopting API STD 526 in relation to the specification of safety valves, it is not very different.

Petrobras, which is one of the biggest motivating companies for the development of engineering in Brazil, has defined in its instrumentation standard N-1882D - Criteria for Elaboration of Instrumentation Projects; that safety valves must, among several requirements:Have the discharge orifices according to API STD 526;

API STD 526 requires the same above mentioned, so it´s clear that N-1882 was elaborated using as a basis, the API STD 526 guidelines and the adoption of this constructive standard proves to be practical since it meets at least four items of the N-1882D. This generated a culture within Brazilian engineering to adopt API STD 526 as a requirement in the design of the safety valve at least as a recommended practice.

The purpose of this short article is to present what the API 526 is about; why we must adopt and use this standard and also, because we must not follow blindly the requirements and guidelines of this standard. By reading this article you will be able to answer the following questions:What is the scope of API STD 526?

API STD 526 is a standard with the objective of guiding engineers, manufacturers, end users and buyers in the selection, specification, manufacturing standardization and purchase of safety valves. These valves can be operated by spring with or without balancing bellows (conventional or self-operated); or operated by a pilot valve (pilot-operated).

All valves according to API STD 526 must have inlet and outlet flanged connections in accordance with ASME B16.5. The pressure and temperature limits are defined in tables 3 to 16 for spring-operated valves and in tables 17 to 30 for pilot-operated valves. It is worth noting that, even though the flanges are in accordance with ASME B16.5; we must not adopt the pressure x temperature limits of this standard, because these limits are higher than those defined by API STD 526.

It refers to the possibility of exchanging the safety valve of one manufacturer for another without compromising the protection of the equipment or requiring greater interference in the equipment or pipeline. This is possible for a few reasons.

The first one is the standardization of the discharge orifice areas, which defines maximum flow capacity values very close even for different manufacturers. The orifices are designated by letters that start in "D" and go up to "T". If one manufacturer “A” presents as a protection solution for an equipment, a safety valve 1D2 (one inch for inlet connection, orifice D and two inches for outlet connection) and manufacturer “B” presents another valve 1D2; we can say that “A” and “B” have interchangeable solutions.

Another reason that allows interchangeability is that API STD 526 also defines the distance from the face of the input flange to the center of the output flange; the distance between the face of the outlet flange and the center of the inlet flange and the connection patterns of the inlet and outlet flanges including the diameters and pressure classes themselves. In this way, it is possible to replace one valve with another with practically zero impacts on the piping and on existing equipment. Example: To replace a 1D2 valve from manufacturer A with a 1D2 valve from manufacturer B, there is no need to change flanges or pipe rearrangements.

Interchangeability also brings the benefit to the end user not being dependent on a single supplier that could, for different reasons, stop its commercial operations in a country, complicating or stopping the supply of valves or spare parts.

It is worth noting that, different manufacturers supplying interchangeable valves for the same application; may have different maximum certified discharge flow rates. The discharge orifice area calculations for API STD 526 valves are according to API STD 520 Part 1, but these are preliminary calculations that use recommended discharge coefficient (Kd) in the equations described in the items 5.6 to 5.10 of API STD 520 Part 1 as a starting point for making calculations possible. Each manufacturer has its certified discharge coefficient. Fortunately, most manufacturers have a certified discharge coefficient lower than that determined by the standard, which results in an area larger than the effective one defined by API STD 526. However, as not all manufacturers are; it is prudent then, when purchasing the valve, the instrumentation engineer requires the sizing report with the value of the maximum discharge flow certified from the manufacturer that is selling the solution.

API STD 526 defines the materials that must be used in the main parts of the safety valve such as body, bonnet, spring, flange and nozzle depending on the temperature and pressure that the valve is subjected at the opening moment.

Materials that are normally used in the manufacture of valves of all types such as carbon steel ASME SA-216 Gr. WCB and stainless steel ASME SA-351 Gr. CF8M are placed as minimum requirements for safety valves to be used in certain parts of the valve like body and the bonnet. This guarantees valves with similar performance, weight, mechanical strength and corrosion resistance from different manufacturers.

The requirements above does not restrain any supplier from adopte another material to produce his valve, that for many reasons, may be economically more attractive, since, it has higher pressure x temperature limits than those materials standardized by API STD 526. After all, the Instrumentation Engineer has to evaluate any material used regarding chemical compatibility with the process fluid.

API STD 526 also establishes that valves manufactured in accordance with this standard, must also comply with API STD 527. This last standard deals with the seat lekage while the valve is closed; or in other words; while the pressure scenario in the vessel or pipe is normal. All valves from all suppliers that will be involved in a purchasing process will have the same performance related to the seat leakage.

Although API STD 526 standardizes important parts of the valve, it does not defines all parts. It is still possible to find opportunities for innovation to deliver to the user, the best cost-benefit solution without neglecting the pressurized system protection that is so important.

The scope of the standard makes it clear that API STD 526 is a standard that should be used to purchase a safety and/or relief valve and defines minimum criteria to be met in order to be successful.

By standardizing all these criteria and requiring all suppliers of safety valves to produce a large amount of valves in accordance with API STD 526, a favorable scenario for bidding is created, cause the solutions become very similar. This way, the manufacturers will compete to get the lowest price.

It also facilitates the analysis of the engineer who always spends a good HH with the technical advice of the valve supply proposals. With a wide standardization, the time and cost necessary to evaluate, adjust and approve technical solutions is reduced. The standard itself presents in its appendix A, a data sheet containing the minimum information that must be specified in order to allow a technical and commercial consultation to manufacturers for the supply of spring and pilot operated safety valves. Annex B shows the minimum information that must appear on the nameplate.

Standardization allows the manufacture and strategic stock of nozzles, flanges, bonnets, bellows, caps and other components. In this way, it´s possible to assemble, test and ship the safety valve in the shortest possible time. It is not always necessary to cast parts or make more complicated adjustments that are not foreseen in the standard.

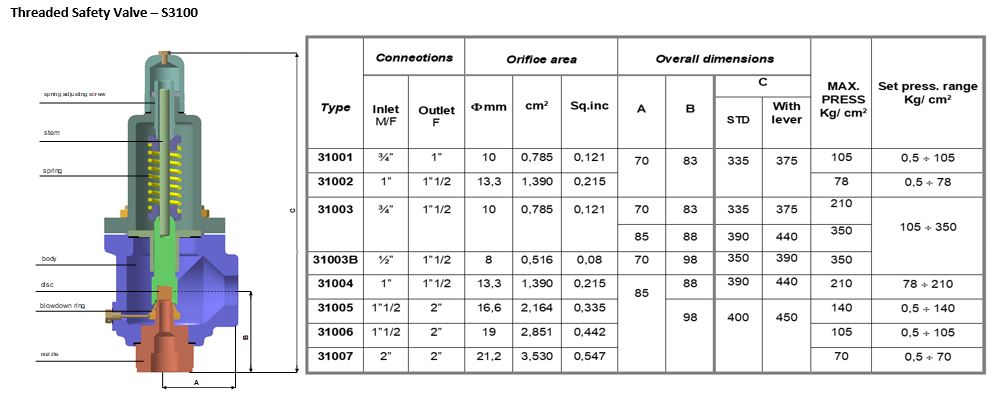

For small equipments such as pump sealing systems, pump recycles, air tanks for control valves, pig receivers and launchers, among others, that have a small volume of fluid to be relieved to normalize their pressure; using compact small valves is advantageous as they are easier to install. Usually threaded with ¾ ”NPT inlet and 1” NPT outlet, they are cheaper and have a discharge orifices with areas smallers than the D equivalent of API STD 526, which avoids making use of a oversized valve just to meet a construction standard. Oversized pressure safety valve can lead the valve to chattering, as the flow may be too small to be able to open the safety valve at once and the disc will again hit the inlet nozzle seat repeatedly, damaging the assembly and compromising the tightness or worse, compromising performance expected at the time of opening.

With simple design and with fewer parts, the safety valves for thermal relief (or compact), allows a good cost reduction. Since others legal requirements such as the National Board flow certificate and / or the ASME authorization certificate for the manufacturing site be part of the supply documentation; there is no greater cause for concern for the end user.

If the user still wants to replace an existing safety valve that does not comply with API STD 526, with another one according to API STD 526, he will have to evaluate whether the installation follows the recommendations of API RP 520 Pt 2. This evaluation that already has a cost, can lead to the conclusion that the pipes and connections need to be replaced and / or rearranged which would mean even more costs.

If costs is always an important factor in the projects; we can also verify that a valve according to API STD 526 does not always present the best cost benefit for the customer.

There are some good reasons for large companies to adopt API STD 526, if not as a requirement, at least as a recommended practice. All the criteria to be followed and the advantages presented, make API STD 526 kind of a guide to acquire a safety valve with the best cost benefit. It should not be forgotten, however, that the ultimate purpose of a safety valve is to open to guarantee the relief of a system that is in a pressurization scenario and to close when the situation is normalized. The construction according to API STD 526 does not replace the correct sizing and the need for ASME authorization certificates for the factory and the National Board certificate regarding the flow capacity of the tested model for the manufactured site.

Nivz Valves & Automation manufacturing range all Pressure Safety Relief Valves are designed as per API 526. They also conform to ASME Section – VIII. Dimensions of valves meet to API 521/521. Metal seated Safety Valves Testing is carried our as per API 527 for Set Pressure & Leakages.

A Safety Relief Valve is a mechanical, self actuating, pop design, spring loaded angle type valve, which is being used for the automatic release (on a set pressure) of a substance from a Pressure Vessel, Boiler, Overpressure of Pipeline or any Industrial System when the Pressure or Temperature exceeds required limits.

Pressure Relief valves also being used to Control the Pressure in an Industrial System, Process Pipeline or Pressure Vessel which can develop by a failure of equipment, instrument or process upset.

Safety Valve also known by the name of Pressure Relief Valve (PRV) and Pressure Safety Valve (PSV). Other names of Safety Valves are Safety Relief Valve, Thermal Relief Valve, Relief Valve, Spring Loaded Safety Valve, Angle Type Safety Valve, Pilot Operated Safety Relief Valve and Low Pressure Safety Relief Valves.

The difference in between Pressure Safety Valve (PSV) and Pressure Relief Valve is Pressure Safety Relief Valve have provided a manual lever with a cap to relieve the pressure in case of emergency.

Mostly two types of protection encountered in Industries which are Flow Protection & Thermal Protection. Flow protection is done by the using of Safety Relief Valves and Thermal Protection by Thermal Relief Valve.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

This standard includes basic definitions and information about the operational characteristics and applications of various pressure relief devices. It also includes sizing procedures and methods based on steady state flow of Newtonian fluids. Pressure relief devices protect a vessel against overpressure only; they do not protect against structural failure when the vessel is exposed to extremely high temperatures such as during a fire. See API 521 for information about appropriate ways of reducing pressure and restricting heat input.

Atmospheric and low-pressure storage tanks covered in API 2000 and pressure vessels used for the transportation of products in bulk or shipping containers are not within the scope of this standard.

valves or rupture disks may be used independently or in combination with each other to provide the required protection against excessive pressure accumulation. The term pressure relief valve includes

saferty relief valves used in either compressible or incompressible fluid service, and relief valves used in incompressible fluid service. It covers gas, vapor, steam, two-phase and incompressible fluid

This standard is a purchase specification for flanged steel pressure-relief valves. Basic requirements are given for direct spring-loaded pressure-relief valves and pilot-operated pressure-relief valves

This standard describes methods of determining the seat tightness of metal- and soft-seated pressure relief valves, including those of conventional, bellows, and pilot-operated designs.

This recommended practice (RP) supplements API 570 by providing piping inspectors with information that can improve skill and increase basic knowledge and practices. This RP describes inspection practices

for piping, tubing, valves (other than control valves), and fittings used in petroleum refineries and chemical plants. Common piping components, valve types, pipe joining methods, inspection planning processes,

inspection intervals and techniques, and types of records are described to aid the inspector in fulfilling their role implementing API 570. This publication does not cover inspection of specialty items,

API Recommended Practice 576 describes the inspection and repair practices for automatic pressure-relieving devices commonly used in the oil and petrochemical industries. As a guide to the inspection

and repair of these devices in the user"s plant, it is intended to ensure their proper performance. This publication covers such automatic devices as pressure-relief valves, pilot-operated pressure-relief

in tanks, explosion doors, fusible plugs, control valves, and other devices that either depend on an external source of power for operation or are manually operated. Inspections and tests made at manufacturers" plants,

This publication does not cover training requirements for mechanics involved in the inspection and repair of pressure-relieving devices. Those seeking these requirements should see API 510, which gives

This international standard covers design, material, face-to-face dimensions, pressure-temperature ratings, and examination, inspection, and test requirements for two types of check valves.

API 598 covers inspection, examination, supplementary examinations, and pressure test requirements for resilient-seated, nonmetallic-seated (e.g. ceramic), and metal-to-metal-seated valves of the gate,

This standard covers design, materials, face-to-face dimensions, pressure-temperature ratings, and examination, inspection, and test requirements for metallic plug valves.

This standard includes requirements for valves fitted with internal body, plug, and port linings or applied hard facings on the body, body ports, plug, and plug port. The extent of linings and the facing

This standard also provides additional requirements for plug valves that are in full conformance to the requirements of ASME B16.34 for Standard Class 150 through 2500. Ductile iron valves, Class 150

Plug valves covered in this standard belong to one of four general design groups that in many cases have different face-to-face and end-to-end dimensions. Some types of plug valves are not made to all

The standard nomenclature for valve parts is shown in Annex B. Figure B.1, Figure B.2, Figure B.3, and Figure B.4 illustrate typical plug valve designs and are not to be construed as precluding other

available designs that comply with the requirements of this standard. The only purpose of these figures is to identify part names. The construction of a valve is acceptable only when it complies with this

This International standard specifies the requirements for a heavy-duty series of bolted bonnet steel gate valves for petroleum refinery and related applications where corrosion, erosion and other service

This international standard specifies the requirements for a series of compact steel gate, globe and check valves for petroleum and natural gas industry applications.

This publication is applicable to valve end flanges in accordance with ASME B16.5, valve body ends having tapered pipe threads to ASME B1.20.1 or ISO 7-1, valve body ends having socket weld ends to

= 50) and pressure designations of Class 800 and Class 1500, and to bellows and bellows assembly construction as may be adaptable to gate or globe valves in sizes1/4 < or = NPS < or = 2 (8 < or

This standard specifies the requirements for corrosion-resistant bolted bonnet gate valves meeting the requirements of Standard Class, ASME B16.34 and having full port openings for use in process piping

This International Standard specifies fire type-testing requirements and a fire type-test method for confirming the pressure-containing capability of a valve under pressure during and after the fire

test. It does not cover the testing requirements for valve actuators other than manually operated gear boxes or similar mechanisms when these form part of the normal valve assembly. Other types of valve

actuators (e.g. electrical, pneumatic, or hydraulic) may need special protection to operate in the environment considered in this valve test, and the fire testing of such actuators is outside the scope

This standard applies to floating (seat-supported) ball (Figure B.1) and trunnion ball valve designs (Figure B.2). These figures are to be used only for the purpose of establishing standard nomenclature

for valve components - other floating and trunnion designs also exist. This standard establishes additional requirements for ball valves that are otherwise in full conformance to the requirements of ASME

alloy, or special alloy butterfly valves that provide tight shutoff in the closed position. The following two categories of butterfly valves are included.

Category A-Manufacturer"s rated cold working pressure (CWP) butterfly valves, usually with a concentric disc and seat configuration. Sizes covered are NPS 2 to NPS 48 for valves having ASME Class

Category B-ASME Class and pressure-temperature rated butterfly valves that have an offset seat and either an eccentric or a concentric disc configuration. These valves may have a seat rating less than

API Specification 6D is the (proposed) national adoption of ISO 14313.. 1999, Petroleum and Natural Gas Industries-Pipeline Transportation Systems-Pipeline Valves. This International Standard specifies

requirements and gives recommendations for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline systems.

It is the purpose of this document to establish the requirements for testing and evaluating the pressure-containing performance of API Specs 6A amd 6D valves when exposed to fire. The performance requirements

of this document are intended to establish standard limits of acceptabliltyregardless of size or pressure rating.This document establishes acceptable levels for leakage through the test valve and also

of API Specs 6A and 6D valves when exposed to specifically defined fire conditions. However, this standard is not intended to cover check valves or end connections.

This document establishes the requirements for testing and evaluating the pressure-containing performance of API Specification 6A and API Specification 6D automatic backseating valves when exposed to

This document establishes acceptable levels for leakage through the test valve and also external leakage after exposure to a fire for a 30-minute time period, both before and after reworking the stuffing

Intended to set guidelines for continuous flow gas lift installation designs using injection pressure operated valves. The assumption is made that the designer is familiar with and has available data

Applies to repair, testing, and setting gas lift valves and reverse flow (check) valves. It presents guidelines related to the repair and reuse of valves; these practices are intended to serve both

repair shops and operators. The commonly used gas pressure-operated bellows valve is also covered. Other valves, including bellows charged valves in production pressure (fluid) service should be repaired

The Pressure Safety Valve Inspection article provides you information about inspection of pressure safety valve and pressure safety valve test in manufacturing shop as well as in operational plants.

Your pressure safety valve is a direct spring-loaded pressure-relief valve that is opened by the static pressure upstream of the valve and characterized by rapid opening or pop action.

Your construction code for pressure safety valve is API Standard 526 and covers the minimum requirements for design, materials, fabrication, inspection, testing, and commissioning.

These are:API Recommended Practice 520 for Sizing and SelectionAPI Recommended practice 521 Guideline for Pressure Relieving and Depressing SystemsAPI Recommended Practice 527 Seat Tightness of Pressure Relief Valves

For example if there is pressure vessel need to be installed in the state of Minnesota then the pressure vessel nameplate shall be U stamped and pressure vessel safety valve shall be UV stamped.

National Board Inspection Code (NBIC) have own certification scheme for pressure safety valves and using NB symbol. The NBIC code book for this certification is NB 18.

There are some other standards and codes which are used in pressure safety valve such as:ASME PTC 25 for pressure relief devices which majorly is used for assessment of testing facility and apparatus for safety valvesBS EN ISO 4126-1, 4126-2 and 4126-3 which is construction standard similar to API STD 526.

This API RP 527 might be used in conjunction of API RP 576 as testing procedure for seat tightness testing of pressure safety valve for periodical servicing and inspection.

These are only important points or summery of points for pressure safety valve in-service inspection and should not be assumed as pressure safety valve inspection procedure.

Pressure safety valve inspection procedure is comprehensive document which need to cover inspection methods to be employed, equipment and material to be used, qualification of inspection personnel involved and the sequence of the inspection activities as minimum.

You may use following content as summery of points for Pressure Safety Valve Inspection in operational plantDetermination pressure safety valve inspection interval based API STD 510 and API RP 576 requirementsInspection of inlet and outlet piping after pressure safety valve removal for any foulingInspection of pressure safety valve charge and discharge nozzles for possible deposit and corrosion productsTaking care for proper handling of pressure safety valves from unit to the valve shop. The detail of handling and transportation instruction is provided in API RP 576.Controlling of seals for being intact when the valves arrived to the valve shop.Making as received POP test and recording the relieving pressure.

If the POP pressure is higher than the set pressure the test need to be repeated and if in the second effort it was near to the set pressure it is because of deposit.If in the second effort it was not opened near to the set pressure either it was set wrongly or it was changed during the operationIf the pressure safety valve was not opened in 150% of set pressure it should be considered as stuck shut.If the pressure safety valve was opened below the set pressure the spring is weakenedMaking external visual inspection on pressure safety valve after POP test. The test need contain following item as minimum;the flanges for pitting and roughness

Making body wall thickness measurementDismantling of pressure safety valve if the result of as received POP test was not satisfactoryMaking detail and comprehensive visual and dimensional inspection on the dismantled valve parts (after cleaning)Making special attention to the dismantled valves seating surfaces inspection e.g. disk and seat for roughness, wear and damage which might cause valve leakage in serviceReplacing the damaged parts in dismantled valves based manufacture recommendation and API RP 576 requirementsMaking precise setting of the pressure safety valve after reassembly based manufacture recommendation or NB-18 requirements

Making at least two POP test after setting and making sure the deviation from set pressure is not more than 2 psi for valves with set pressure equal or less than 70 psi or 3% for valves with set pressure higher than 70 psiMaking valve tightness test for leakage purpose after approval of the setting pressure and POP tests. The test method and acceptance criteria must be according to the API RP 576.The API RP 527 also can be used for pressure safety valve tightness test.Recording and maintaining the inspection and testing results.

Specification for Pipeline Valves. API Specification 6D is an adoption of ISO 14313: 1999, Petroleum and Natural Gas Industries-Pipeline Transportation Systems-Pipeline Valves. This International Standard specifies requirements and gives recommendations for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline systems.

Flanged Steel Pressure Relief Valves. The standard is a purchase specification for flanged steel pressure relief valves. Basic requirements are given for direct spring-loaded pressure relief valves and pilot-operated pressure relief valves as follows: orifice designation and area; valve size and pressure rating, inlet and outlet; materials; pressure-temperature limits; and center-to-face dimensions, inlet and outlet.

Seat Tightness of Pressure Relief Valves R(2002). Describes methods of determining the seat tightness of metal- and soft-seated pressure relief valves, including those of conventional, bellows, and pilot-operated designs.

Check Valves: Flanged, Lug, Wafer and Butt-welding. API Standard 594 covers design, material, face-to-face dimensions, pressure-temperature ratings, and examination, inspection, and test requirements for two types of check valves.

Valve Inspection and Testing. The standard covers inspection, supplementary examination, and pressure test requirements for both resilient-seated and metal-to-metal seated gate, globe, plug, ball, check, and butterfly valves. Pertains to inspection by the purchaser and to any supplementary examinations the purchaser may require at the valve manufacturer"s plant.

Metal Plug Valves - Flanged, Threaded and Welding Ends. A purchase specification that covers requirements for metal plug valves with flanged or butt-welding ends, and ductile iron plug valves with flanged ends, in sizes NPS 1 through NPS 24, which correspond to nominal pipe sizes in ASME B36.10M. Valve bodies conforming to ASME B16.34 may have flanged end and one butt-welding end. It also covers both lubricated and nonlubricated valves that have two-way coaxial ports, and includes requirements for valves fitted with internal body, plug, or port linings or applied hard facings on the body, body ports, plug, or plug port.

Compact Steel Gate Valves - Flanged, Threaded, Welding, and Extended-Body Ends. The standard covers threaded-end, socket-welding-end, butt-welding-end, and flanged-end compact carbon steel gate valves in sizes NPS4 and smaller.

Corrosion-Resistant, Bolted Bonnet Gate Valves - Flanged and Butt-Welding Ends. The standard covers corrosion-resistant bolted bonnet gate valves with flanged or butt-weld ends in sizes NPS 1/2 through 24, corresponding to nominal pipe sizes in ASME B36.10M, and Classes 150, 300, and, 600, as specified in ASME B16.34.

Fire Test for Soft-Seated Quarter Turn Valves. The standard covers the requirements for testing and evaluating the performance of straightway, soft-seated quarter-turn valves when the valves are exposed to certain fire conditions defined in this standard. The procedures described in this standard apply to all classes and sizes of such valves that are made of materials listed in ASME B16.34.

Butterfly Valves: Double Flanged, Lug- and Wafer-Type. The standard covers design, materials, face-to-face dimensions, pressure-temperature ratings, and examination, inspection, and test requirements for gray iron, ductile iron, bronze, steel, nickel-base alloy, or special alloy butterfly valves that provide tight shutoff in the closed position and are suitable for flow regulation.

Specification for Fire Test for Valves. The standard covers the requirements for testing and evaluating the performance of API Spec 6A and Spec 6D valves when exposed to specifically defined fire conditions.

Fire Test for Valve with Automatic Backseats. The standard covers the requirements for testing and evaluating the performance of API Spec 6A and Spec 6D valves with automatic backseats when exposed to specifically defined fire conditions.

Design of Continuous Flow Gas Lift Installations Using Injection Pressure Operated Valves. The standard sets guidelines for continuous flow gas lift installation designs using injection pressure operated valves.

Recommended Practice for Repair, Testing, and Setting Gas Lift Valves. The standard applies to repair, testing, and setting gas lift valves and reverse flow (check) valves.

Inspection Practices for Piping System Components. The standard covers the inspection of piping, tubing, valves (other than control valves) and fittings used in petroleum refineries.

Metal Ball Valves - Flanged and Butt-Welding Ends. The standard covers Class 150 and Class 300 metal ball valves that have either butt-welding or flanged ends and are for use in on-off service.

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

1 Piece Ball Valve1 Piece Cast Iron Screwed Ball Valve1 Piece Flanged Ball Valve1 Piece Screwed Ball Valve2 Piece Ball valve2 Piece Cast Steel Ball Valve2 Piece Flanged Ball Valve2 Piece Forged Steel Ball Valve2 Piece Screwed Ball Valve3 Piece Ball Valve3 Piece Cast Iron Ball Valve3 Piece Cast Steel Ball Valve3 Piece Flanged Ball Valve3 Piece Forged Steel Ball Valve3 Piece Reduced Port Ball Valve3 Piece Screwed Ball Valve3 Way Converging and Diverging Control Valve3 Way Plug Valve3 Way Pneumatic Diaphragm Control ValveAir ValveAlloy 20 2 Piece Ball ValveAlloy 20 2 Piece Screwed Ball ValveAlloy 20 3 Piece Ball ValveAlloy 20 3 Piece Screwed Ball ValveAlloy 20 Ball ValveAlloy 20 Dual Plate Lug Type Check ValveAlloy 20 Floating Ball ValveAlloy 20 Swing Check ValveAlloy 20 Trunnion Mounted Ball ValveAlloy 20 ValvesAlloy 20 Wafer Butterfly ValveAlloy Butterfly ValveAlloy Check valveAlloy Dual Plate Wafer Check ValveAlloy Flanged Gate ValveAlloy Flanged Globe ValveAlloy Gate ValveAlloy Gate ValvesAlloy Globe ValvesAlloy Lug Butterfly ValveAlloy Plug ValveAlloy Pressure Seal Globe ValveAluminium Bronze 3 Piece Ball ValveAluminium Bronze Ball ValveAluminium Bronze Butterfly ValveAluminium Bronze Check ValveAluminium Bronze Floating Ball ValveAluminium Bronze Gate ValveAluminium Bronze Lug Butterfly ValveAluminium Bronze Swing Check ValveAluminium Bronze Triple offset Lug Butterfly ValveAluminium Bronze Trunnion Ball ValveAluminium Bronze valvesAluminium Bronze Wafer Butterfly ValveAluminium Dual Plate Wafer Check ValveAluminum Bronze Globe ValveAngle Globe ValveANSI Gate ValveANSI Globe ValveAPI Aluminium Bronze Triple offset Lug Butterfly ValveAPI Gate ValveAPI Globe ValveAustenitic Steel Big Size Ball ValveAustenitic Steel ValvesAWWA Butterfly ValveAWWA Gate ValveAWWA Non Rising Stem Gate ValveAWWA OS&Y Gate ValveAWWA StrainerAWWA Wafer Butterfly ValveAWWA Y StrainerBalancing ValveBall Float Steam TrapBall ValveBellow Seal Globe ValveBi Directional Knife Gate ValveBimetallic Steam TrapBlock and Bleed valveBrass Ball ValveBrass Ball ValvesBrass Check ValvesBrass Flanged Ball ValveBrass Flanged Gate ValveBrass Flanged Globe ValveBrass Gate ValveBrass Gate ValvesBrass Globe ValveBrass Globe ValvesBrass Safety ValveBrass Swing Check ValveBrass ValveBrass Vertical Check ValveBrass Y StrainerBronze Butterfly ValveBronze Check ValveBronze Flanged Gate ValveBronze Flanged Globe ValveBronze Floating Ball ValveBronze Gate ValveBronze Gate ValvesBronze Globe ValveBronze Globe ValvesBronze Swing Check ValveBronze ValveBronze Wafer Butterfly ValveBronze Wafer Check ValveBS Cast Iron Gate valveBS Cast Steel Gate ValveBS Ductile Iron Gate ValveBS Globe ValveBS Non Rising Stem Gate ValveBS NRS Carbon Steel Gate ValveBS NRS Cast Iron Gate ValveBS NRS Ductile Iron Gate ValveBS Rising Stem Gate ValveBS Soft Seat Gate ValveBS Stainless Steel Gate ValveButterfly ValveCarbon Steel Bellow Seal Globe ValveCast Floating Ball ValveCast Iron And Cast Steel Ball ValveCast Iron Diaphragm ValveCasting Trunnion Ball Valvecheck valveConnection Lift Plug ValveControl ValveCryogenic Ball ValveCryogenic Check ValveCryogenic Emergency Cut off ValveCryogenic Gate ValveCryogenic Globe ValveCryogenic Long Stem Globe ValveCryogenic Pneumatic Actuated Globe ValveCryogenic Short Stem Globe ValveCryogenic Steam Jacket Globe ValveCryogenic ValveDiaphragm ValveDIN Globe ValveDIN Non Rising Stem Ductile Iron Gate ValveDIN Non Rising Stem Gate ValveDIN NRS Cast Iron Gate ValveDIN Rising Stem Cast Iron Gate ValveDIN Rising Stem Ductile Iron Gate ValveDIN Rising Stem Gate ValveDIN Soft Seat Gate ValveDirect Acting Pressure Reducing ValveDouble Block and Bleed Ball ValveDouble Disc Gate ValveDouble Eccentric Butterfly ValveDouble Offset Butterfly ValveDouble Orifice Air Release ValveDouble Orifice Kinetic Air ValveDual Plate Lug Check ValveDual Plate Wafer Check ValveDuctile Iron Diaphragm ValveDuplex 1B 3 PC Ball ValveDuplex 3 Piece Ball ValveDuplex Basket StrainerDuplex Butterfly ValveDuplex Check ValveDuplex Dual Plate Lug Type Check ValveDuplex Dual Plate Wafer Check ValveDuplex Floating Ball ValveDuplex Gate ValveDuplex Globe ValveDuplex High Pressure Ball ValveDuplex Lug Type Butterfly ValveDuplex Steel Ball ValveDuplex steel ValveDuplex Swing Check ValveDuplex Top Entry Ball ValveDuplex Trunnion Mounted Ball ValveDuplex Wafer Butterfly ValveEccentric Plug ValveElectric 3 Way Control ValveElectric Actuated 2 Piece Ball ValveElectric Actuated 2 Piece Flanged Ball ValveElectric Actuated 2 Piece Screwed Ball ValveElectric Actuated Ball ValveElectric Actuated Butterfly ValveElectric Actuated Flanged Ball ValveElectric Actuated Floating Forged Ball ValveElectric Actuated Gate ValveElectric Actuated Globe Control ValveElectric Actuated Globe ValveElectric Actuated High Pressure Ball ValvesElectric Actuated High Pressure Direct Mounting Ball ValvesElectric Actuated Lug Butterfly ValveElectric Actuated Metal-Seated Trunnion-Mounted Forged Ball ValveElectric Actuated Three Piece Ball ValveElectric Actuated Three Way Ball ValveElectric Actuated Trunnion-Mounted Casting Ball ValveElectric Actuated ValvesElectric Actuated Wafer Butterfly ValveElectric Cage Type Control ValveElectric Control ValveElectric Double Seat Control ValveElectric O-type Shut-off Control ValveElectric Single Seat Control ValveF22/Alloy Steel Pressure Seal Globe ValveF317L Gate ValveF317L Globe ValveF317L ValvesF321 Gate ValveF321 Globe ValveF321 ValvesF347 3 Piece Ball ValveF347 Ball ValveF347 Butterfly ValveF347 Check ValveF347 Dual Plate Lug Type Check ValveF347 Dual Plate Wafer Check ValveF347 Floating Ball ValveF347 Gate ValveF347 Globe ValveF347 Lug Type Butterfly ValveF347 Swing Check ValveF347 Trunnion Mounted Ball ValveF347 ValvesF347 Wafer Butterfly ValveF44 Gate ValveF44 Globe valvesF44 ValvesF51 Super Duplex Ball ValveF53/F55 Super Duplex Globe ValveFeed Water Control ValveFlanged Butterfly ValveFlanged Knife gate ValveFloat Control ValveFloating Ball ValveFluorine Lined Single Seat Control ValveFoot ValveForged Cryogenic Trunnion Ball ValveForged Floating Ball ValveForged Steel Ball ValveForged Steel Gate ValveForged Steel Globe ValveForged Steel Swing Check ValveForged Trunnion Ball ValveFull Lift Pressure Safety ValveFull Lift Safety ValveFully Welded Ball ValveGate ValveGlobe ValveHastelloy Ball ValveHastelloy C276 2 Piece Flanged Ball ValveHastelloy C276 2 Piece Screwed Ball ValveHastelloy C276 3 Piece Screwed Ball ValveHastelloy C276/B3 3 Piece Ball ValveHastelloy C276/B3 Butterfly ValveHastelloy C276/B3 Dual Plate Lug Type Check ValveHastelloy C276/B3 Dual Plate Wafer Check ValveHastelloy C276/B3 Floating Ball ValveHastelloy C276/B3 Gate ValvesHastelloy C276/B3 Globe ValveHastelloy C276/B3 Lug Butterfly ValveHastelloy C276/B3 Swing Check valveHastelloy C276/B3 Trunnion Mounted Ball ValveHastelloy C276/B3 ValvesHastelloy C276/B3 Wafer Butterfly ValveHastelloy Check ValveHeavy Duty Investment Casting Ball ValveHigh Performance Lug Butterfly ValveHigh Performance Wafer Butterfly ValveIncoloy 2 Piece Ball ValveIncoloy 3 Piece Ball ValveIncoloy Gate ValveIncoloy Globe ValveIncoloy ValvesInconel 2 Piece Ball ValveInconel 3 Piece Ball ValveInconel Ball ValveInconel Butterfly ValveInconel Check ValveInconel Dual Plate Lug Type Check ValveInconel Dual Plate Wafer Check ValveInconel Floating Ball ValveInconel Gate ValveInconel Globe ValveInconel Lug Butterfly ValveInconel safety relief valveInconel Swing Check ValveInconel Trunnion Mounted Ball ValveInconel ValveInconel Wafer Butterfly ValveInverted Bucket Steam TrapInvestment Casting Ball ValveJacketed Ball ValveJacketed Plug ValveKnife Gate ValveLift Check valveLow Lift Pressure Safety ValveLow Lift Safety ValveLubricated Plug valveLug Butterfly ValveMonel 2 Piece Ball ValveMonel 3 Piece Ball ValveMonel 400 2 Piece Flanged Ball ValveMonel 400 ValvesMonel Ball ValveMonel Butterfly ValveMonel Check ValveMonel Dual Plate Lug Check ValveMonel Dual Plate Wafer Check ValveMonel Floating Ball ValveMonel Forged Trunnion Mounted Ball ValveMonel Gate ValveMonel Globe ValveMonel High Pressure Ball ValveMonel Lug Type Butterfly ValveMonel Swing Check ValveMonel Top Entry Ball ValveMonel Trunnion Mounted Ball ValveMonel ValvesMonel Wafer Butterfly ValveNeedle valveNon Slam Swing Check ValveNon-Lubricated Sleeved Plug ValveNon-Rising Stem Gate ValveNon-Slam Swing Check ValveOrbit Plug ValvePilot Operated Pressure Reducing ValvePilot Operated ValvePressure Relief ValvePiston ValvePlug ValvePlunger ValvePneumatic Actuated 2 Piece Ball ValvePneumatic Actuated 2 Piece Flanged Ball ValvePneumatic Actuated Ball ValvePneumatic Actuated Butterfly ValvePneumatic Actuated Flanged Ball ValvePneumatic Actuated Flanged Butterfly ValvePneumatic Actuated Gate ValvePneumatic Actuated Globe type Control ValvePneumatic Actuated Lug Butterfly ValvePneumatic Actuated Three Piece Ball valvePneumatic Actuated Three Way Ball valvePneumatic Actuated Three Way Heavy Duty Ball ValvePneumatic Actuated Two Piece Ball ValvePneumatic Actuated ValvesPneumatic Actuated Wafer Butterfly ValvePneumatic Angle Control ValvePneumatic Angle Seat Control ValvePneumatic Angle Type High Pressure Regulating Control ValvePneumatic Bi Directional Knife Gate valvePneumatic Cage Control ValvePneumatic Control ValvePneumatic Double Seat Control ValvePneumatic Flow Control ValvePneumatic Knife Gate ValvePneumatic Metal Seat Flanged Ball ValvePneumatic Single Seat Globe Control ValvePneumatic Sleeve Type Control ValvePneumatic Three piece Ball ValvePneumatic Three Piece Flanged Ball ValvePneumatic Three Way Ball ValvePneumatic Three Way Flanged Ball ValvePneumatic Trunnion Casting Ball ValvePneumatic Trunnion Forged Ball ValvePneumatic Trunnion Forged Metal Seat Ball ValvePneumatic Unidirectional Knife Gate ValvePressure Reducing ValvePressure Safety ValvePressure Seal Gate ValvePressure Seal Globe ValvePressure Seal Swing Check ValveRotary Airlock ValveSafety ValveSimplex Basket StrainersSingle Orifice Air ValveSingle Plate Wafer Check ValveSlab Gate ValveSlurry Knife Gate ValveSoft Seal Gate ValveSpeciality ValveSS304 Bellow Seal Globe ValveSS316 Bellow Seal Globe ValveSS316L Gate ValveSS316L Lug Butterfly ValveSS316L Wafer Butterfly ValveSteam Pressure Reducing ValveSteam Safety ValveSteam TrapStrainersSuction DiffuserSuper Duplex 2 Piece Ball ValveSuper Duplex 3 Piece Ball ValveSuper Duplex 5A Flanged Gate ValveSuper Duplex 5A Globe ValveSuper Duplex 5A Swing Check ValveSuper Duplex Ball ValveSuper Duplex Butterfly ValveSuper Duplex Check ValveSuper Duplex Dual Plate Lug Type Check ValveSuper Duplex Dual Plate Wafer Check ValveSuper Duplex Floating Ball ValveSuper Duplex Gate ValveSuper Duplex Gate ValvesSuper Duplex Globe ValveSuper Duplex High Pressure Ball ValveSuper Duplex Knife Gate ValveSuper Duplex Lug Butterfly ValveSuper Duplex Pressure Reducing ValveSuper Duplex Top Entry Ball ValveSuper Duplex Trunnion Mounted Ball ValveSuper Duplex ValvesSuper Duplex Wafer Butterfly ValveSurge Anticipator ValveSwing Check ValveThermal Safety ValveThermodynamic Steam TrapThermostatic Steam TrapThree Piece Flanged Ball ValveThree Way Ball ValveThrough Conduit Knife Gate ValveTilting Disc Check ValveTitanium 3 Piece Ball ValveTitanium Ball ValveTitanium Butterfly ValveTitanium Check ValveTitanium Dual Plate Lug Type Check ValveTitanium Dual Plate Wafer Check ValveTitanium Floating Ball ValveTitanium Forged Trunnion Mounted Ball ValveTitanium Gate ValveTitanium Globe ValveTitanium Gr.2 2pc Flanged Ball ValveTitanium Gr.2 3pc Ball ValveTitanium Gr.5 2pc Flanged Ball ValveTitanium Gr.5 3pc Ball ValveTitanium Lug Butterfly ValveTitanium Swing Check ValveTitanium Trunnion Mounted Ball ValveTitanium valvesTitanium Wafer Butterfly ValveTop Entry Ball ValveTriple Duty ValveTriple Eccentric Butterfly ValveTriple Offset Butterfly ValveTrunnion Ball ValveTwin Seal Plug ValveUL/FM Approved ValvesUnidirectional Knife Gate ValveWafer Butterfly ValveWater Pressure Reducing ValveY StrainerY Type Globe ValveZirconium Floating Ball ValveZirconium Gate ValveZirconium Globe ValveZirconium Valves

Kingston Valves, California-based industrial valve manufacturer, releases new stainless-steel soft seat models for the KSV Soft Seat Safety Valve line. The new low profile, stainless-steel KSVCR models offer long-lasting performance in corrosive environments.

The KSVCR ASME Section XIII and National Board-certified valves feature a stainless-steel body and components. They are available in a broad range of sizes, ranging from 1/4” to 1 ¼” and achieve some of the industry’s best flow rates. Additional options include oxygen cleaning, thread sealant, and steam service. Suitable for air, gas, and steam mediums, Kingston’s KSCVR valves provide application and design flexibility.

The stainless-steel models allow for maximum operating temperatures up to 400°F. Kingston safety valves are factory set to the designated pressure. Available now, with 5-to-7-day lead times.

Established in 1908, Kingston has been a leader in the safety relief valve manufacturing business; primarily focused on the brass industrial valve market, they have an expert understanding of industrial OEM and Distribution customer needs and challenges. The Kingston brand has a longstanding history within the compressed air/gas/steam/liquid markets. Kingston Valves is an ISO 9001 certified company with world class lead-times. Consolidated within The Storm Manufacturing Group, Kingston brand valves continue to represent the performance and reliability that have been the industry standard for over a century. For more information, visit www.kingstonvalves.com.

8613371530291

8613371530291