blowdown ring in safety valve quotation

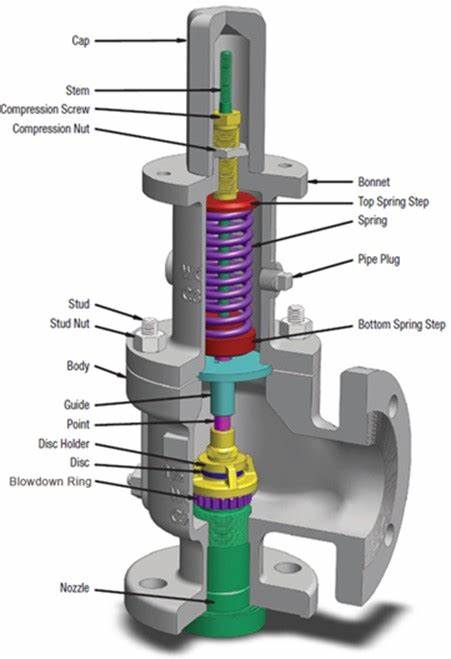

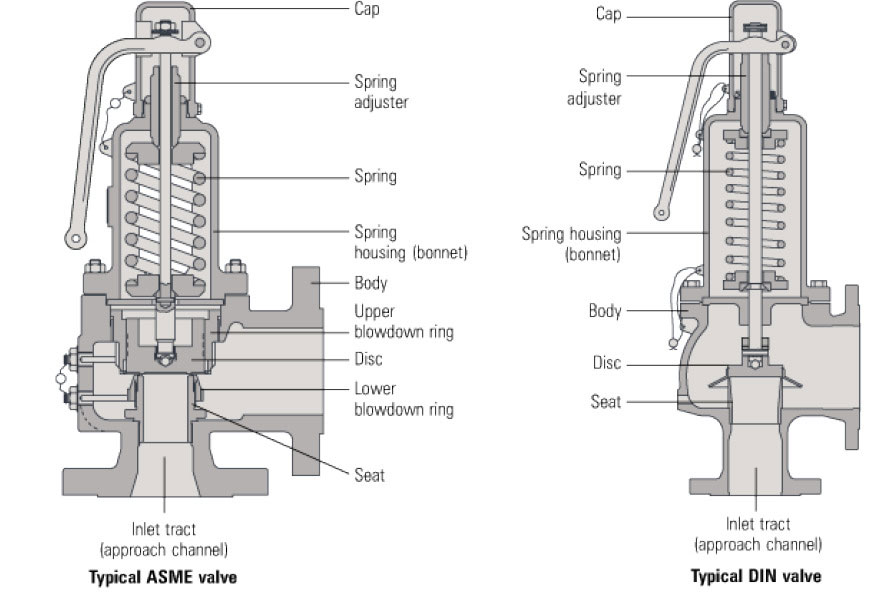

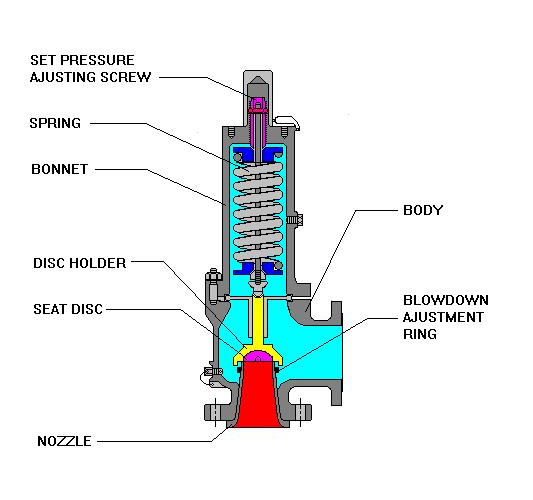

Unless you are dealing with a Power Boiler, chances are you have a one ring design safety-relief valve. bill_bill_2000"s commnets were germain to a two ring design Power Boiler Safety Valve. On compressible fluids, the adjusting ring in a one ring design Safety-Relief Valve, must perform three functions. First it needs to be close enough to the disc to direct flow against the disc & disc holder in order to create a reaction force which combines with the inlet force to overcome spring force and cause the valve to pop open. Second, it must be far enough from the disc to allow fluid an escape path so that the valve does not remain open below normal system operating pressure, typically 10% below set pressure. Long blowdown can cause other problems in the system. Thirdly, the ring provides a cushioning effect as the disc reseats. Acting like a retro-rocket, the reaction forces keep the disc from slamming into the nozzle and damaging the seating surfaces.

Blowdown Ring is a specific Part Nomenclature for Farris because it controls reseat. It is referred to as a Nozzle Ring by Crosby for its location (threaded onto the o.d. of the nozzle. Dresser calls it an Adjusting Ring and Knukle refers to it as a Warn Ring. Warn is an older term for simmer. The PRV simmers just prior to pop, therefore simmer is also called warn. SO, 4 major manufacturers with 4 different trems for the same part. The blowdown ring is an important part of PRV Maintenance and Testing. It is what sets PRV repair apart from other mechanical disciplines. DIsassmbly, inspection, machining, lapping and reassembly are common to all valves, pumps, etc. But Blowdown Ring Adjustment is unique to Pressure Relief Valves. Many PRV manufactuerers give ring setting positions in their maintenance manuals. Liquid Settings are typically set very close to the disc during reassembly and require no further adjustment during testing. However, for air/gas/vapor service, the Manufaturers Settings will usually yield long blowdown, because short blowdown may result in insufficient capacity and in a two ring design in chatter. You do not typically see ring setting induced chatter in a one ring design. Most of the time, chatter is a result of an installation problem, i.e. reduced inlet piping, extremely long inlet piping, excessive pressure drop at the PRV inlet. I hope this is helpful

In 1986, the NRC issued the Information Notice (IN) 86-05 "Main Steam Safety Valve test failures and ring setting adjustments". Shortly after this IN was issued, the Code was revised to require that a full flow test has to be performed on each CL.2 MSSV by the manufacturer to verify that the valve was adjusted so that it would reach full lift and thus full relieving capacity and would re-close at a pressure as specified in the valve Design Specification. In response to the concern discussed in the IN, the Westinghouse Owners Group (WOG) performed extensive full flow testing onmore »PWR MSSVs and found that each valve required a unique setting of a combination of two rings in order to achieve full lift at accumulation of 3% and re-closing at a blowdown of 5%. The Bopp and Reuther MSSV type SiZ 2507 has a "fixed blowdown" i.e. without any adjusting rings to adjust the "blowdown" so that the blowdown is "fixed". More than 1000 pieces of this type are successfully in nuclear power plants in operation. Many of them since about 25 years. Therefore it can be considered as a proven design. It is new that an optimization of this MSSV type SiZ 2507 fulfill the requirements of part NC-7512 of the ASME Section III although there are still no adjusting rings in the flow part. In 2000, for the Qinshan Candu unit 1 and 2 full flow tests were performed with 32 MSSV type SiZ 2507 size 8"" x 12"" at 51 bar saturated steam in only 6 days. In all tests the functional performance was very stable. It was demonstrated by recording the signals lift and system pressure that all valves had acceptable results to achieve full lift at accumulation of 3% and to re-close at blowdown of 5%. This is an advantage which gives a reduction in cost for flow tests and which gives more reliability after maintenance work during outage compared to the common MSSV design with an individual required setting of the combination of the two rings. The design of the type SiZ 2507 without any adjusting rings in the flow path is presented. The stable performance depends on the interaction of flow force and spring force. The optimization of the flow path to create a suitable flow-force-curve was managed by Computational Fluid Dynamics (CFD) and flow-force-characteristic-measurements at a model 1: 2.5. The method of the flow-force-characteristic-measurement permits systematic dimensioning of valve spring forces by means of measurement of the fluid mechanical forces occurring on the valve spindle during flow. A special procedure was established to verify a spring force versus lift curve with an accuracy of 1% for each production valve. This gives high reliability at required stable performance and this can not be influenced by wrong setting of any adjusting ring during maintenance work. (authors)« less

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

www.controlglobal.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 49aa4de84ffe7587c78dee4984bc4222 63.210.148.230 01/29/2023 09:00 AM UTC

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Forged from heavy-duty cast steel with a stainless steel nozzle, these safety valves are certified for air, gas and steam. Used in steam boilers, steam generators, air compressors, gas compressors, pressure tanks, pressure receivers, intercoolers, and oil/gas separators, these sturdy valves contain a bolted yoke design for easy maintenance.

The pressure safety valves are used to protect the equipment such as motors, pumps and compressors. The safety valve releases the excess pressure out that can affect the equipment harmfully.

The Pressure Safety Valve that will be produced in the design must refer to the applicable provisions or standards such as ASME, API or other code recommended in the plant or project process. Another thing to note is the construction of the body and material. he “part” design must consider the allowable tension of the material that will be used and must also conform to the standard specifications.

Valve bodies are usually the type of angle (angle type), usually has an outlet that is larger than the inlet. This is very important to “expand” the fluid such as gas, vapour. Safety or relief valves must always do a “relief” to a lower pressure (usually with atmospheric pressure). To achieve this can be done by increasing the size of the pipe outlet in such a way that it can obtain a back pressure of 10% below the inlet pressure price that is permitted to ensure that the valve will open at a predetermined set pressure price. The valve body must have a connection that is able to use its pressure and temperature of use and not only in its operating conditions but also in its relieving conditions.

Body material, for general use (general purpose), is carbon steel. The alloy steel will be used if the pipe specifications require it or for use in certain atmospheric conditions. For the fluid in the form of air, Bronze Alloy is used to pressuring relief devices that are installed in a storage tank (breather valve) usually will be used material made of aluminium material.

The arrangement of the nozzle on the pressure safety valve is divided into two types, namely full-nozzle and semi-nozzle. The full nozzle between the valve body and the nozzle becomes one so that before discharging all parts of the nozzle and disc are wetted by the fluid. Thus if a special material is needed for the nozzle and disc, it must be followed by the part of the valve body

Material spring specification influenced by fluid temperature of standard spring material for pressure safety valve is usually carbon steel or alloy steel (tungsten). For temperature between -240°C to 232°C. carbon steel material is used, for temperatures above 2320C tungsten alloy is used whereas for temperatures below -240C (cryogenic) stainless steel is used on closed bonnet.

When the pressure safety valve has reached the set pressure, it will tend to leak, this is due to the mechanical force balance coming from the bottom of the “disc-area” has reached or the same as the “operated spring” style that is on the top of the disc, leakage on this set pressure can be overcome by:

Bonnet is a housing and is a protective spring because therefore the material of the bonnet should be of the same material as the material of the body. so the bonnet is no longer needed to accommodate the spreading “escaping fluid”

Blowdown rings are made with the aim to solve two problems, namely: (1) together with the disc-holder to form a “huddling-chamber” which will prepare “pop-action” in the safety valve (2) by adjusting the blowdown ring will change the pressure difference between set pressure and reseating pressure from the valve.

Farris Relief Valves, Series 3800, 2600 and 2700 Farris Relief Valves are ASME NB Certified for air, steam and water. These valve models are European CE Approved. They come in sizes 1 X 2-12 X 16. Series 3800 Farris Relief Valves actual orifice areas range from 0.15-109 square inches and can handle pressures from 20-6170 psig and handle -450° F-500° F. We also offer Farris valve parts, Worcester valve parts, and Worcester positioners. Contact us to find out more about our Farris and Worcester brands. You can also browse our catalog.

The optional balanced bellows design isolates working parts and top-works from corrosion, and nullifies the effects of back pressure on valve performance. The "D" to "T" orifices of the Series 2600 Farris Relief Valves meet API Standard 526 covering orifice areas and center-to-face dimensions. Optional Farris Safety Valves construction materials include 316 stainless steel, Monel®, and Hastelloy® C. The Farris Safety Valves are available with Farris Valve Parts in compliance with NACE standards.

WARNING: Some of the products we sell can expose you to chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Contact your sales rep or go to www.P65Warnings.ca.gov for more information.

M&M Control Service, Inc. does not represent or claim any affiliation, association, connection or approvals with or from any manufacturer unless stated. We fully acknowledge all trademarks and/or names which are pictured and/or listed throughout the M&M Control Service, Inc. Website.

(PowersTM, also known as, POWERS REGULATOR, MCC POWERS, POWERS-FIAT, POWERS PROCESS CONTROLS, CRANE POWERS and POWERS, a Watts Industries Company. The POWERS trademark is owned by Powers, A Division of Watts Water Technologies, Inc. M&M Control Service, Inc. Is a Stocking Distributor for PowersTM)

In addition to the process control systems within a power plant or industrial process plant, safety systems play an important role in plant operation. With high pressure vessels, piping and system components, comes the need for protecting against overpressure, which can cause damage to equipment or harm to workers. Typically, overpressure protection is provided by safety relief valves which vent excess pressure before it becomes problematic.

CIRCOR Power & Process offers safety relief valves for steam and gas applications. These safety relief valves are used in commercial buildings, district heating systems, power plants and industrial applications controlling pressure of steam and industrial gases.

Our product line includes high temperature-capable relief valves as well as solutions for cryogenic fluids. CIRCOR Power & Process safety relief valves provide dependable, tight shutoff and reliable performance. Versions with a dual blowdown ring also provide for better adjustment and control of pop and blowdown.

CIRCOR Power & Process soft seated safety relief valves operate very close to set point pressure, providing reliable performance in services with high vibration, icing conditions or entrained particles.

In 1986, the NRC issued the Information Notice (IN) 86-05 “Main Steam Safety Valve test failures and ring setting adjustments”. Shortly after this IN was issued, the Code was revised to require that a full flow test has to be performed on each CL.2 MSSV by the manufacturer to verify that the valve was adjusted so that it would reach full lift and thus full relieving capacity and would reclose at a pressure as specified in the valve Design Specification. In response to the concern discussed in the IN, the Westinghouse Owners Group (WOG) performed extensive full flow testing on PWR MSSVs and found that each valve required a unique setting of a combination of two rings in order to achieve full lift at accumulation of 3% and reclosing at a blowdown of 5%. The Bopp & Reuther MSSV type SiZ 2507 has a “fixed blowdown” i.e. without any adjusting rings to adjust the “blowdown” so that the blowdown is “fixed”. More than 1000 pieces of this type are successfully in nuclear power plants in operation. Many of them since about 25 years. Therefore it can be considered as a proven design. It is new that an optimization of this MSSV type SiZ 2507 fulfill the requirements of part NC-7512 of the ASME Section III although there are still no adjusting rings in the flow part. In 2000, for the Qinshan Candu unit 1&2 full flow tests were performed with 32 MSSV type SiZ 2507 size 8” × 12” at 51 bar saturated steam in only 6 days. In all tests the functional performance was very stable. It was demonstrated by recording the signals lift and system pressure that all valves had acceptable results to achieve full lift at accumulation of 3% and to reclose at blowdown of 5% . This is an advantage which gives a reduction in cost for flow tests and which gives more reliability after maintenance work during outage compared to the common MSSV design with an individual required setting of the combination of the two rings. The design of the type SiZ 2507 without any adjusting rings in the flow path is presented. The stable performance depends on the interaction of flow force and spring force. The optimization of the flow path to create a suitable flow-force-curve was managed by Computational Fluid Dynamics (CFD) and flow-force-characteristic-measurements at a model 1: 2.5 ! The method of the flow-force-characteristic-measurement permits systematic dimensioning of valve spring forces by means of measurement of the fluid mechanical forces occurring on the valve spindle during flow [1], [2]. A special procedure was established to verify a spring force versus lift curve with an accuracy of 1% for each production valve. This gives high reliability at required stable performance and this can not be influenced by wrong setting of any adjusting ring during maintenance work.

safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India

safety valve, safety relief valve, pressure relief valves, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve

safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

We provide superior quality valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are specially designed to offer high durability and optimum performance. Using materials like pure aluminum, cast iron and stainless steel trim these valves are made to high resistance to temperature and corrosion. Functionally different valves like Safety Valve, Safety Relief Valve, Pressure Reducing Valves, Breather Valves, Globe & Ball Valves, Pipeline Specialty Valves, Flush Bottom Valves and Float Valves are available with us.

Manufactured to API/ASME codes. Full Life, "Pop" type, Full Nozzle. Screwed/Flanged Models. Sizes : 15NB to 300 NB. Standardised orifice. Angle/Straight Patterns. Inverted-Bottom spring mounted types. Procured in castings and fabrication (Bar Stock), special trims provided. Set pressure and hydro tests as per specification or standard carried and provided.

Fluidyne carried out an extensive market research to manufature durable and effective safety relief valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are highly suitable for most chemical, petrochemical, oil, pharmaceutical, phartilizer, power industries and more. These industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves have high reliability and are approved by factory inspectors, inspectors under Indian Boiler Regulation (IBR), B.V., Lloyds and Chief Controller of Explosives. Citizen Metal safety and relief valves are in used in above industries for over 50 years.Flanged Safety Relief Valves

Our range of small bore safety valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves offer superior performance and maximum functionality. They are available in Screwed, Socket weld, Flanged Construction type or flanged-inlet, Screwed-outlet connection type. Their simplicity in construction makes them pretty cost effective and easy to use.

For Storage Tank, complete range of sizes :- 15 NB to 600 NB Flame and Detonation Arresters, Spark Arresters Free-Emergency-Conservation Vents Dip Gauges and Gauge HatchsVent nuts/Caps, Syphon bush, Fill caps, Lightning Arresters etc. Tyrus Valve, Vacuum Relief, Pressure Relief Valves. Available in : CS, CI, SS304, 316, AI etc. For more details on Tank Fittings, Flame / Spark Aresstors plz refer our section on "Safety Fittings"

Model PV - 1230 is one of our specially designed range of relief valves that has got connection flanged pallets of Al or Stainless Steel. This model comes with a tank accessory that is suitable for storage of chemicals and hydrocarbons. Model Pv 1230 is most suitable for low pressure and low vacuum operations.

Designed mostly like model PV 1220 our PV - 1240 range of vauts also offer high performance & durability. These efficient valves are commonly suitable for vacuum service. The disc available with these vaults is either weight loaded or spring loaded.

Safety Valves are designed and manufactured to meet the requirement of all a variety of applications as per API 526 and API 520. They also conforms to Standard VIII and the design requirement of Indian Boiler Regulations, they are of Full Lift type direct spring loaded, with a top guide, The full nozzle has the eliminating distortion of the seating surface, as body strain is not transmitted The Nozzle is made from a corrosion resistance stainless Steel material, When closed position, the fluid does not come in contact with the valve Body an therefore only subject to the outlet pressure which is very much lower pressure.

Similar to FTVC-520, but with closed bonnet & closed cap. Also available with same sizes and rating as FTVC - 520.Close Bonnet Safety Valve For Steam Application

Full lift safety relief valve, offers the combination of top guiding and unobstructed seat bore, producing a valve with maximum discharge capacity. Supplied with certificate confirming set lift pressure.

Tag : safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

Safety Relief Valves, Stainless Steel Forged Steel 304 Valve, Stainless Steel F321 Safety Relief Valves, F347 Safety Relief Valves, SS High Pressure Safety Relief Valves, Class 150, 300, 600, 900, 1/2 inch stainless steel Safety Relief Valves, 1/2" stainless steel Safety Relief Valves, 3/4 Size Safety Relief Valves, 4 inch stainless steel Safety Relief Valves, Industrial Safety Relief Valves, Stainless Steel 316 Safety Relief Valves Suppliers in India...Read more

Alloy Steel Safety Relief Valves, Chrome Moly Alloy A217 / SA217 Cast Valves, WC9 Alloy Steel Globe Valve, 4 Inch, 2500#, A350 LF3, A352 LC3, A182 F5A/F5, A217 C5, A182 F9, A217 C12, A182 F11, A217 WC6, A182 F22, A217 WC9, A182 F91, A217 C12A, 10 Inch, RF, WC9 Gate Valve, PSB, 12 Inch, 2500 LB, Alloy Steel Valves Dealers & Distributors in India.. Read more

Safety Relief Valves, Carbon Steel Safety Relief Valves, Carbon Steel Valve Material, ASTM A350 LF2 Safety Relief Valves, Carbon Steel ASTM A106 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34 ASTM A105N Safety Relief Valves, Cast Carbon Steel Safety Relief Valves, API 600 Cast Steel Safety Relief Valves, Forged Carbon Steel Safety Relief Valves Exporters & Suppliers In India.. Read more

Hastelloy Safety Relief Valves, Hastelloy C276 Safety Relief Valves, Hastelloy C22 Safety Relief Valves, Hastelloy B2 Safety Relief Valves, Hastelloy C276/C22 Valves, ASTM B 435 Hastelloy X Safety Relief Valves, Hastelloy B2 Safety Relief Valves, ASME B16.34 Safety Relief Valves, UNS N10665 Hastelloy B2 Safety Relief Valves, UNS N10276 Hastelloy C276/C22 Manufacturer / Suppliers in Mumbai India. Read more

Wholesale Various High Quality Industrial Safety Relief Valves Products from Citizen Metals, Largest Suppliers of Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Dealers, Alloy 20 Check Valve, UNS N08020 Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Suppliers, Alloy 20 Safety Relief Valves Manufacturer, Alloy 20 Safety Relief Valves Manufacturers in India. Read more

We supply broad range of Nickel 200/201 Safety Relief Valves, Leading Suppliers of Nickel 200/201 Valves, Ni-200 Safety Relief Valves, Ni-201 Safety Relief Valves, Uns N02200 Safety Relief Valves, Uns N02201 Safety Relief Valves, Nickel 200/201 Safety Relief Valves Dealers, Safety Relief Valves Suppliers, Nickel 200/201 Safety Relief Valves Manufacturer, Nickel 200/201 Safety Relief Valves Manufacturers in India. Read more

we supply Monel 400 Valves with high quality and best affordable rate., Monel 400 Safety Relief Valves, Monel DIN 2.4360, 2.4375 Safety Relief Valves, Monel UNS N04400 Safety Relief Valves, Monel UNS N05500 Safety Relief Valves, Monel Safety Relief Valves, Monel K500 Safety Relief Valves, Monel 400 Safety Relief Valves Distributors in India... Read more

We specialize in the oil & gas industries and offer specialty Duplex Steel Safety Relief Valves, UNS S31803 Safety Relief Valves Suppliers in India, DIN 1.4410 Super Duplex Steel Safety Relief Valves, ASME B 16.10 UNS S32760 Safety Relief Valves, ASTM A351 Duplex Steel UNS S31803, ASME SA494 Duplex Steel UNS S31803, Duplex Steel UNS S31803 Class 900 Safety Relief Valves Exporters in India. Read more

Safety Relief Valves, 254 Smo Safety Relief Valves, Cryogenic 254 SMO gate valve, ASME B16.34 SS 254 SMO Safety Relief Valves, Stainless Steel 254 SMO Safety Relief Valves, ASTM A351 SS SMO 254 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34, 254 SMO Industrial Valves, Stainless Steel 254SMO Safety Relief Valves Suppliers in India.. Read more

Safety Relief Valves, 904l Stainless Steel Safety Relief Valves, 904l Stainless Steel Industrial Safety Relief Valves, SS 904L ASTM A351 Safety Relief Valves, ASME B 16.10 Safety Relief Valves, ASME B 16.5, ASME B 16.25, ASME B 16.34, UNS N08904, 1.4539, BS 904S13, JIS SUS 890L Safety Relief Valves

Safety Relief Valves, Inconel Safety Relief Valves, Inconel 600 Safety Relief Valves, INCONEL WERKSTOFF NR. 2.4816 Safety Relief Valves, Inconel 600N06600 Safety Relief Valves, Inconel 2.4816 Safety Relief Valves, UNS N06600 Safety Relief Valves, Inconel 600 Safety Relief Valves, API 600/ BS1414, ALLOY 600 Safety Relief Valves, ASME B 16.5 Safety Relief Valves Dealers in India.. Read more

We are the one of the top most manufacturers of different types of Industrial Safety Relief Valves, We have a large inventory of Safety Relief Valves in a variety of options., Largest Suppliers of Titanium Gr2(B367 Gr C2) Safety Relief Valves, Titanium Gr3(B367 Gr C3) Safety Relief Valves, Titanium TA1, TA2, Titanium Gr.5, Gr6 Safety Relief Valves,Gr7 ,Gr12, Titanium TC4,TA9,TA10 Dealers in India.. Read more

Brass Safety Relief Valves, brass Safety Relief Valves price list in India, brass Safety Relief Valves 1/2, 1 inch brass Safety Relief Valves, brass Safety Relief Valves 3/4, brass Safety Relief Valves price list india, 3 inch brass check valve, brass Safety Relief Valves price list, 1/2 inch Safety Relief Valves, 4 brass Safety Relief Valves, 3/4 brass Safety Relief Valves, 4 inch brass Safety Relief Valves, 2 inch brass Safety Relief Valves Read more

Experience Of 50 Years In Copper Knife Gate Valve, We have a large inventory of Copper Safety Relief Valves, Copper 90/10 Safety Relief Valves, Copper 70/30 Safety Relief Valves, Copper Cu-Ni 70/30 Safety Relief Valves, Copper 90/10 Safety Relief Valves Dealers, Copper 70/30 Safety Relief Valves Suppliers, Copper Cu-Ni 70/30 Safety Relief Valves Manufacturer, Copper Cu-Ni 90/10 Safety Relief Valves Manufacturers in India. Read more

CONSULTANTS : Tawafiq Engineering Consultant office and Al-Tawfeek Office, SAUDI ARABIA (Through Jash Schutte Industrie service GmbH,Germany

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch Dealers, Distributors, Exporters, Suppliers india, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions,

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

Stainless Steel Safety Relief Valve is a safety mechanism deployed in applications to prevent them from bursting under pressure. Suraj Metal Corporationis a leading manufacturer and supplier of the different types such as the Brass Safety Valveand others in various sizes and dimensions. The valves are fitted with the pipelines in a way that when the pressure goes above the threshold level, the Stainless Steel Air Safety Valveopens up and relieves the system of pressure.

This is important to prevent the pipes from being damaged or bursting under high pressure. The Stainless Steel Safety Exhaust Ball Valveis used in the exhaust systems where the temperature plays major role. When the temperature exceeds certain point, it increases pressure and the safety valve opens and balances the pressure in the system. The spring loaded boiler safety valveis used in boilers and heat exchanger systems where steam and hot water are circulated through pipes. There are different gas safety valvetypes and each of these differ in their purpose and functions. Please feel free to contact us for more information on the different types of air compressor pressure relief valveand others with pricing.

We Keep Bulk Stock of CF8 stainless steel Pressure Safety Valve at our stockyard, contact us for Free Sample & stock list, View Brass Safety Valve Dimension chart

find Stainless Steel Safety Exhaust Ball Valve Dimensions, price list, size chart here, Buy ASTM A351 CF8M 316 temperature safety valve at best price in India

The SMS-7100 direct spring operated pressure relief valves has been designed to protect against excess pressure steam boilers and to provide superior performance.

Double blow-down ring guarantees the over-pressure and the reseating-pressure required on section I of the ASME code. Special design of the disc eliminates the distortion due to thermal stress for maximum seat tightness. Available with open or closed bonnet.

Flanged, Butt weld spring loaded, direct acting, full nozzle safety relief valves for steam service (ASME Sect.I). Media: steam (suitable also for gas).

8613371530291

8613371530291