blowdown ring in safety valve pricelist

www.controlglobal.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 49aa4de84ffe7587c78dee4984bc4222 63.210.148.230 01/29/2023 09:00 AM UTC

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

EMERSON.BIRKETT WB SERIES SAFETY RELIEF VALVESSpring loaded safety relief valves with a fuff lift and fuff nozzle to relieve excess pressure safefy in a variety of process vesselsFEATURES GENERAL APPLICATION The WB series is designed to refieve excess pressure safefy in pumps, pipe work, tanks, caforifiers, gas and oif separators and other process vessefs. Modefs are avaifabfe for gas, steam, vapor and fiquid appfications. TECHNICAL DATA Materiafs: Carbon steef, stainfess steef DN 2001 Connections Ffanged ANSI 150# to Pressure: Up to 6000 psig (414 barg) • Fuff nozzfe, fuff fift provides high discharge coefficients and high capacities. • Broad sefection of vafve types: conventionaf or beffows for gas or fiquid service enabfes optimum vafve sefection. • Wide range of materiafs provides sofutions for any appfication. • Lightweight construction reduces handfing and shipping costs and benefits offshore service. • Seat feakage integrity minimizes fugitive emissions. • Interchangeabfe parts enabfe simpfe modification from gas to fiquid and conventionaf to beffows. • In-situ testing capabifity reduces maintenance costs. • Reduced number of parts minimizes inventory and reduces maintenance costs. • Vafves conform to API 526 pressure/ temperature ranges, orifice areas and dimensions. • Extensive accessory range enabfes vafves to be adapted to meet specific code and appfication requirements. • Optionaf cfeaning for cryogenic and oxygen services avaifabfe. Emerson.com/FinalControl © 2017 Emerson. Aff Rights Reserved VCTDS-03791-EN 18/01

BIRKETT WB SERIES SAFETY RELIEF VALVES OVERVIEW MODEL OPTIONS The WB Series is available in four different valve types to suit differing service requirements: WB400 - conventional gas type. WB300 - bellows gas type. WB200 - conventional liquid type. WB100 - bellows liquid type. CONVENTIONAL SAFETY RELIEF VALVES These valves can be used on systems where the discharge is relatively simple. The pressure in the discharge system can be atmospheric, at a constant level or where it may build up to a maximum of 10% of the set pressure. When a constant back pressure exists, the valve should be set...

BIRKETT WB SERIES SAFETY RELIEF VALVES FEATURES 3. High performance springs 4. Bellows back up piston (not shown) 5. Guiding 6. Bellows (not shown) 7. Trim 8. Seat integrity 9. Adjustable blow down 10. Nozzle design 11. API 526 face to face dimensions Valves can be supplied suitable for application of ‘in-situ’ set pressure verification devices. Wide accessories range to comply with international codes and suit system requirements. High performance springs designed specifically to guarantee set point repeatability. Optional auxiliary back-up piston for balanced bellows valves ensures...

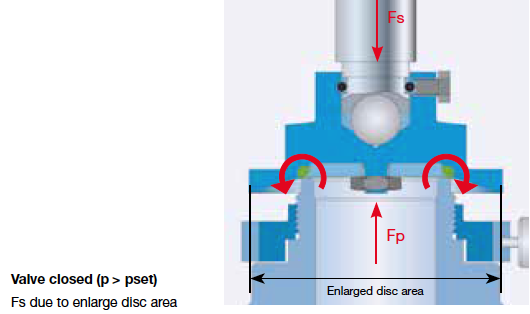

BIRKETT WB SERIES SAFETY RELIEF VALVES OPERATION PRINCIPLE OF OPERATION Spring force Safety relief valves use a spring force to hold a disc against a nozzle. Under normal system operating pressure, the valve will remain closed as the spring force is greater than the inlet system pressure force. The valve opens when the system pressure force becomes greater than the closing force of the spring. The WB Series are designed to have a short simmer, open rapidly to full lift position and then re-seat at a controlled shut off pressure. This is demonstrated in the graph below, which shows the valve...

BIRKETT WB SERIES SAFETY RELIEF VALVES OPERATION LIFT CYCLE Stage 1 - Closed Inlet pressure < set pressure Huddling chamber Inlet pressure is below the set pressure. The valve is closed and there is no flow through the valve. Reaction hood Exit area Blowdown ring Stage 2 - Simmering Inlet pressure is = > set pressure and < popping pressure Inlet pressure increases to set pressure. At this point, the spring force and system pressure force are equal; a further rise in inlet pressure will then begin to lift the disc slightly. A small amount of fluid is released into the huddling chamber (the...

BIRKETT WB SERIES SAFETY RELIEF VALVES OPERATION THE EFFECT OF BACK PRESSURE The configuration of a closed discharge pipework system, typically for toxic or hazardous duty, can generate back pressure. When applied to the valve outlet, this will affect its performance adversely, unless it is addressed. Back pressure can take three forms: 1. Superimposed constant back pressure This exists permanently and a conventional or bellows valve can be used. A conventional valve can be set at the differential pressure so that the spring load is adjusted to take account of the back pressure. 2. Built up...

BIRKETT WB SERIES SAFETY RELIEF VALVES MATERIALS OF CONSTRUCTION WB 400 - CONVENTIONAL GAS TYPE (up to and including class 600) Part Body Casing Cap Nozzle Disc Disc holder Blowdown ring Guide assy Spindle Lower spring plate Adjusting screw Locking nut Setting screw Setting screw rod Stud Nut Spring Body gasket Cap gasket Set screw gasket Ball Upper spring plate Data plate Hammer drive screw Grooved pin Drain plug Circlip Carbon steel SA 216-WCB CARB ST SA 216-WCB CARB ST SA 216-WCB CARB ST 316 ST ST 316 ST ST ASTM A479-316L SA 351-CF8M ST ST CARBON ST/17-4 ST ST ASTM A479-431 ASTM...

PARTS LIST Item Part 11 Lower spring plate 32 Upper spring plate 34 Hammer drive screw Carbon steel SA 216-WCB CARB ST SA 216-WCB CARB ST SA 216-WCB CARB ST 316 ST ST 316 ST ST Included in item 23 SA 351-CF8M ST ST CARBON ST/17-4 ST ST ASTM A479-431 ASTM A108-1021/Ni PLT ASTM A479-410 ASTM A108-1021 ASTM A479-431 ASTM A479-316L SA 193-B7 CR/MOL ST SA 194-2H CARB ST Carbon steel ASTM A479-316L/SA240-316L ST-706 ST-706 ST-706 AISI 440C ST ST ASTM A108-1021/NI PLT 321 ST ST Electro brassed ST ASTM A479-431 HTS holo-krome ASTM A313-316 Stainless steel SA 351-CF8M ST ST SA 351-CF8M ST ST SA...

BIRKETT WB SERIES SAFETY RELIEF VALVES MATERIALS OF CONSTRUCTION WB 400 - CONVENTIONAL GAS TYPES (class 900 and above) Part Body Casing Cap Nozzle Disc Disc holder Reaction hood Blowdown ring Guide plate Spindle Lower spring cap Adjusting screw Locking nut Setting screw Setting screw rod Tabwasher Pinning screw Body stud Body nut Casing stud Casing nut Spring Spindle head Body gasket Cap gasket Setting screw gasket Ball Upper spring cap Data plate Hammer drive screw Grooved pin Drain plug Carbon steel SA 216-WCB CARB ST SA 216-WCB CARB ST SA 216-WCB CARB ST 316 ST ST 316 ST ST ASTM...

safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India

safety valve, safety relief valve, pressure relief valves, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve

safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

We provide superior quality valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are specially designed to offer high durability and optimum performance. Using materials like pure aluminum, cast iron and stainless steel trim these valves are made to high resistance to temperature and corrosion. Functionally different valves like Safety Valve, Safety Relief Valve, Pressure Reducing Valves, Breather Valves, Globe & Ball Valves, Pipeline Specialty Valves, Flush Bottom Valves and Float Valves are available with us.

Manufactured to API/ASME codes. Full Life, "Pop" type, Full Nozzle. Screwed/Flanged Models. Sizes : 15NB to 300 NB. Standardised orifice. Angle/Straight Patterns. Inverted-Bottom spring mounted types. Procured in castings and fabrication (Bar Stock), special trims provided. Set pressure and hydro tests as per specification or standard carried and provided.

Fluidyne carried out an extensive market research to manufature durable and effective safety relief valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are highly suitable for most chemical, petrochemical, oil, pharmaceutical, phartilizer, power industries and more. These industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves have high reliability and are approved by factory inspectors, inspectors under Indian Boiler Regulation (IBR), B.V., Lloyds and Chief Controller of Explosives. Citizen Metal safety and relief valves are in used in above industries for over 50 years.Flanged Safety Relief Valves

Our range of small bore safety valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves offer superior performance and maximum functionality. They are available in Screwed, Socket weld, Flanged Construction type or flanged-inlet, Screwed-outlet connection type. Their simplicity in construction makes them pretty cost effective and easy to use.

For Storage Tank, complete range of sizes :- 15 NB to 600 NB Flame and Detonation Arresters, Spark Arresters Free-Emergency-Conservation Vents Dip Gauges and Gauge HatchsVent nuts/Caps, Syphon bush, Fill caps, Lightning Arresters etc. Tyrus Valve, Vacuum Relief, Pressure Relief Valves. Available in : CS, CI, SS304, 316, AI etc. For more details on Tank Fittings, Flame / Spark Aresstors plz refer our section on "Safety Fittings"

Model PV - 1230 is one of our specially designed range of relief valves that has got connection flanged pallets of Al or Stainless Steel. This model comes with a tank accessory that is suitable for storage of chemicals and hydrocarbons. Model Pv 1230 is most suitable for low pressure and low vacuum operations.

Designed mostly like model PV 1220 our PV - 1240 range of vauts also offer high performance & durability. These efficient valves are commonly suitable for vacuum service. The disc available with these vaults is either weight loaded or spring loaded.

Safety Valves are designed and manufactured to meet the requirement of all a variety of applications as per API 526 and API 520. They also conforms to Standard VIII and the design requirement of Indian Boiler Regulations, they are of Full Lift type direct spring loaded, with a top guide, The full nozzle has the eliminating distortion of the seating surface, as body strain is not transmitted The Nozzle is made from a corrosion resistance stainless Steel material, When closed position, the fluid does not come in contact with the valve Body an therefore only subject to the outlet pressure which is very much lower pressure.

Similar to FTVC-520, but with closed bonnet & closed cap. Also available with same sizes and rating as FTVC - 520.Close Bonnet Safety Valve For Steam Application

Full lift safety relief valve, offers the combination of top guiding and unobstructed seat bore, producing a valve with maximum discharge capacity. Supplied with certificate confirming set lift pressure.

Tag : safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

Safety Relief Valves, Stainless Steel Forged Steel 304 Valve, Stainless Steel F321 Safety Relief Valves, F347 Safety Relief Valves, SS High Pressure Safety Relief Valves, Class 150, 300, 600, 900, 1/2 inch stainless steel Safety Relief Valves, 1/2" stainless steel Safety Relief Valves, 3/4 Size Safety Relief Valves, 4 inch stainless steel Safety Relief Valves, Industrial Safety Relief Valves, Stainless Steel 316 Safety Relief Valves Suppliers in India...Read more

Alloy Steel Safety Relief Valves, Chrome Moly Alloy A217 / SA217 Cast Valves, WC9 Alloy Steel Globe Valve, 4 Inch, 2500#, A350 LF3, A352 LC3, A182 F5A/F5, A217 C5, A182 F9, A217 C12, A182 F11, A217 WC6, A182 F22, A217 WC9, A182 F91, A217 C12A, 10 Inch, RF, WC9 Gate Valve, PSB, 12 Inch, 2500 LB, Alloy Steel Valves Dealers & Distributors in India.. Read more

Safety Relief Valves, Carbon Steel Safety Relief Valves, Carbon Steel Valve Material, ASTM A350 LF2 Safety Relief Valves, Carbon Steel ASTM A106 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34 ASTM A105N Safety Relief Valves, Cast Carbon Steel Safety Relief Valves, API 600 Cast Steel Safety Relief Valves, Forged Carbon Steel Safety Relief Valves Exporters & Suppliers In India.. Read more

Hastelloy Safety Relief Valves, Hastelloy C276 Safety Relief Valves, Hastelloy C22 Safety Relief Valves, Hastelloy B2 Safety Relief Valves, Hastelloy C276/C22 Valves, ASTM B 435 Hastelloy X Safety Relief Valves, Hastelloy B2 Safety Relief Valves, ASME B16.34 Safety Relief Valves, UNS N10665 Hastelloy B2 Safety Relief Valves, UNS N10276 Hastelloy C276/C22 Manufacturer / Suppliers in Mumbai India. Read more

Wholesale Various High Quality Industrial Safety Relief Valves Products from Citizen Metals, Largest Suppliers of Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Dealers, Alloy 20 Check Valve, UNS N08020 Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Suppliers, Alloy 20 Safety Relief Valves Manufacturer, Alloy 20 Safety Relief Valves Manufacturers in India. Read more

We supply broad range of Nickel 200/201 Safety Relief Valves, Leading Suppliers of Nickel 200/201 Valves, Ni-200 Safety Relief Valves, Ni-201 Safety Relief Valves, Uns N02200 Safety Relief Valves, Uns N02201 Safety Relief Valves, Nickel 200/201 Safety Relief Valves Dealers, Safety Relief Valves Suppliers, Nickel 200/201 Safety Relief Valves Manufacturer, Nickel 200/201 Safety Relief Valves Manufacturers in India. Read more

we supply Monel 400 Valves with high quality and best affordable rate., Monel 400 Safety Relief Valves, Monel DIN 2.4360, 2.4375 Safety Relief Valves, Monel UNS N04400 Safety Relief Valves, Monel UNS N05500 Safety Relief Valves, Monel Safety Relief Valves, Monel K500 Safety Relief Valves, Monel 400 Safety Relief Valves Distributors in India... Read more

We specialize in the oil & gas industries and offer specialty Duplex Steel Safety Relief Valves, UNS S31803 Safety Relief Valves Suppliers in India, DIN 1.4410 Super Duplex Steel Safety Relief Valves, ASME B 16.10 UNS S32760 Safety Relief Valves, ASTM A351 Duplex Steel UNS S31803, ASME SA494 Duplex Steel UNS S31803, Duplex Steel UNS S31803 Class 900 Safety Relief Valves Exporters in India. Read more

Safety Relief Valves, 254 Smo Safety Relief Valves, Cryogenic 254 SMO gate valve, ASME B16.34 SS 254 SMO Safety Relief Valves, Stainless Steel 254 SMO Safety Relief Valves, ASTM A351 SS SMO 254 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34, 254 SMO Industrial Valves, Stainless Steel 254SMO Safety Relief Valves Suppliers in India.. Read more

Safety Relief Valves, 904l Stainless Steel Safety Relief Valves, 904l Stainless Steel Industrial Safety Relief Valves, SS 904L ASTM A351 Safety Relief Valves, ASME B 16.10 Safety Relief Valves, ASME B 16.5, ASME B 16.25, ASME B 16.34, UNS N08904, 1.4539, BS 904S13, JIS SUS 890L Safety Relief Valves

Safety Relief Valves, Inconel Safety Relief Valves, Inconel 600 Safety Relief Valves, INCONEL WERKSTOFF NR. 2.4816 Safety Relief Valves, Inconel 600N06600 Safety Relief Valves, Inconel 2.4816 Safety Relief Valves, UNS N06600 Safety Relief Valves, Inconel 600 Safety Relief Valves, API 600/ BS1414, ALLOY 600 Safety Relief Valves, ASME B 16.5 Safety Relief Valves Dealers in India.. Read more

We are the one of the top most manufacturers of different types of Industrial Safety Relief Valves, We have a large inventory of Safety Relief Valves in a variety of options., Largest Suppliers of Titanium Gr2(B367 Gr C2) Safety Relief Valves, Titanium Gr3(B367 Gr C3) Safety Relief Valves, Titanium TA1, TA2, Titanium Gr.5, Gr6 Safety Relief Valves,Gr7 ,Gr12, Titanium TC4,TA9,TA10 Dealers in India.. Read more

Brass Safety Relief Valves, brass Safety Relief Valves price list in India, brass Safety Relief Valves 1/2, 1 inch brass Safety Relief Valves, brass Safety Relief Valves 3/4, brass Safety Relief Valves price list india, 3 inch brass check valve, brass Safety Relief Valves price list, 1/2 inch Safety Relief Valves, 4 brass Safety Relief Valves, 3/4 brass Safety Relief Valves, 4 inch brass Safety Relief Valves, 2 inch brass Safety Relief Valves Read more

Experience Of 50 Years In Copper Knife Gate Valve, We have a large inventory of Copper Safety Relief Valves, Copper 90/10 Safety Relief Valves, Copper 70/30 Safety Relief Valves, Copper Cu-Ni 70/30 Safety Relief Valves, Copper 90/10 Safety Relief Valves Dealers, Copper 70/30 Safety Relief Valves Suppliers, Copper Cu-Ni 70/30 Safety Relief Valves Manufacturer, Copper Cu-Ni 90/10 Safety Relief Valves Manufacturers in India. Read more

CONSULTANTS : Tawafiq Engineering Consultant office and Al-Tawfeek Office, SAUDI ARABIA (Through Jash Schutte Industrie service GmbH,Germany

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch Dealers, Distributors, Exporters, Suppliers india, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions,

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

Stainless Steel Safety Relief Valve is a safety mechanism deployed in applications to prevent them from bursting under pressure. Suraj Metal Corporationis a leading manufacturer and supplier of the different types such as the Brass Safety Valveand others in various sizes and dimensions. The valves are fitted with the pipelines in a way that when the pressure goes above the threshold level, the Stainless Steel Air Safety Valveopens up and relieves the system of pressure.

This is important to prevent the pipes from being damaged or bursting under high pressure. The Stainless Steel Safety Exhaust Ball Valveis used in the exhaust systems where the temperature plays major role. When the temperature exceeds certain point, it increases pressure and the safety valve opens and balances the pressure in the system. The spring loaded boiler safety valveis used in boilers and heat exchanger systems where steam and hot water are circulated through pipes. There are different gas safety valvetypes and each of these differ in their purpose and functions. Please feel free to contact us for more information on the different types of air compressor pressure relief valveand others with pricing.

We Keep Bulk Stock of CF8 stainless steel Pressure Safety Valve at our stockyard, contact us for Free Sample & stock list, View Brass Safety Valve Dimension chart

find Stainless Steel Safety Exhaust Ball Valve Dimensions, price list, size chart here, Buy ASTM A351 CF8M 316 temperature safety valve at best price in India

A fire-tube boiler can be fitted with one or more safety valves on the top of its shell, with each set to open when the boiler reaches its design pressure. Noisolation valvesor restrictions should be integrated between the safety valve(s) and boiler. If the valves are not installed directly onto the boiler shell, the pipework connecting the valves to the boiler must be kept clear of blockagesand water, and this must be confirmed by periodic testing.

Once a safety valve opens, steam is discharged via the exhaust pipe. Exhaust pipes must be designed to encounter as few bends as possible, be as short as possible, to have no reduction in pipe section (no internal pipe diameter reduction), and should lead to asafe point of discharge(typically outside the boiler house).

Water must be drained from the safety valve or exhaust pipework via a drainpipe. Drainpipes may be connected to holes drilled into the lowest section of the exhaust pipework, or, directly to drain holes in the safety valve body; these drains are not to be confused with the blowdown ring locking bolt, if one is fitted.

Where two safety valves are fitted, it is common that one is set just belowthe boiler’s design pressure. It is vital that each safety valve permits the full flow of steam produced when the boiler is operating at maximum capacity i.e. when the boiler is producing the maximum amount of steam it can possibly produce. If safety valves are sized correctly, a boiler can be firing at full capacity without the steam pressure exceeding design limits (because the safety valve(s) relieves pressure at a faster rate than it is accumulated).

There are various types of safety valve, including high lift and improved high lift valves, which use the force of escaping steam to open a winged valve plug to achieve greater steam flow rates. In addition to this, some valves integrate a pistonat the bottom of the spring chamber. The piston has a larger surface area than the valve plug, which leads to the valve opening with a definitive ‘pop’ sound.

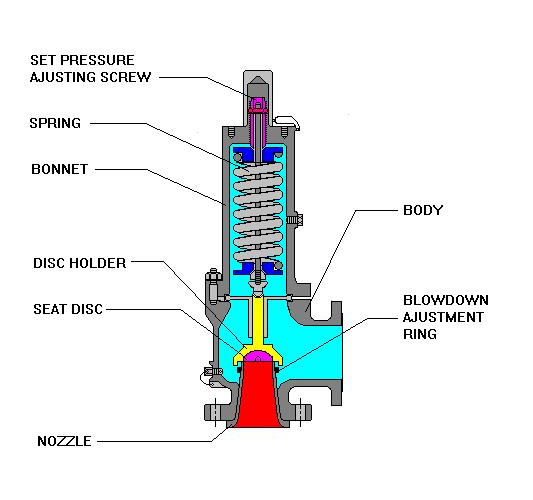

Some boiler safety valves include a blowdown ring. The blowdown ring can raise or lower the valve seat ring and is used to control the amount of blowdown through the valve. This ring is locked by a bolt that protrudes through the valve and into the adjusting ring segments.

Boiler safety valves should be fitted with an easing gear (looks like a handle), used, when necessary, to rapidly release boiler pressure. Easing gears can also be used for testing a safety valve, ensuring the spindle has freedom of movement and that the valve operating mechanism functions as intended. Easing gear testing is often not conducted due to operators having difficulty with the valves resealing, but this is generally only the case with valves that are not tested often enough. Actuating the easing gear several times is often all it takes to dislodge debris from the sealing area and allow the valve to seal again. For safe operation, the easing gear handle is usually connected via steel cables to an area neighbouring the boiler.

Like pressure gauges, all safety valves should be stripped, inspected, and calibrated, at least once a year; maintenance usually occurs during statutory inspections. Calibration of each valve should be conducted by a competent person, and any valve adjustment (including the blowdown ring) should be approved and sealed by the authorised inspector. After testing and calibration, all valves should be correctly marked, suitable certificates issued, and accurate records maintained.

An accumulation test can be conducted to ensure a safety valve can relieve over-pressure steam when the boiler burner is operating at maximum capacity. Accumulation testing of safety valves must be repeated after any alterations are made to the boiler e.g. replacement of a safety valve, fuel change, or changes to the control system. If, during an accumulation test, boiler pressure rises by more than 10% of its design pressure, the test must be aborted. Before the boiler is re-tested, amendments must be made to either the safety valve relieving capacity, thesafety valve exhaust pipework, or the boiler’s steaming capacity, to ensure the 10% limit is never exceeded.

Reliefand safetyvalves prevent equipment damage by relieving over-pressurisation of fluid systems. The main difference between a relief valve and a safety valve is the extent of opening at the set-point pressure.

A relief valve gradually opens as the inlet pressure increases above the set-point. A relief valve opens only as necessary to relieve the over-pressure condition. Relief valves are typically used for liquid systems.

A safety valve rapidly‘pops’ fully openas soon as the pressure setting is reached and will stay fully open until the pressure drops below the reset pressure. The reset pressure is lower than the actuating set-point pressure. The difference between the actuating pressure set-point, and the pressure at which the safety valve resets, is called blowdown. Safety valves are typically used for gas or vapour systems.

A safety relief valve may open fully, or proportionally, once the pressure setting is reached. SRVs may be used for any fluid system (gas, liquid, or vapour).

Unless you are dealing with a Power Boiler, chances are you have a one ring design safety-relief valve. bill_bill_2000"s commnets were germain to a two ring design Power Boiler Safety Valve. On compressible fluids, the adjusting ring in a one ring design Safety-Relief Valve, must perform three functions. First it needs to be close enough to the disc to direct flow against the disc & disc holder in order to create a reaction force which combines with the inlet force to overcome spring force and cause the valve to pop open. Second, it must be far enough from the disc to allow fluid an escape path so that the valve does not remain open below normal system operating pressure, typically 10% below set pressure. Long blowdown can cause other problems in the system. Thirdly, the ring provides a cushioning effect as the disc reseats. Acting like a retro-rocket, the reaction forces keep the disc from slamming into the nozzle and damaging the seating surfaces.

Blowdown Ring is a specific Part Nomenclature for Farris because it controls reseat. It is referred to as a Nozzle Ring by Crosby for its location (threaded onto the o.d. of the nozzle. Dresser calls it an Adjusting Ring and Knukle refers to it as a Warn Ring. Warn is an older term for simmer. The PRV simmers just prior to pop, therefore simmer is also called warn. SO, 4 major manufacturers with 4 different trems for the same part. The blowdown ring is an important part of PRV Maintenance and Testing. It is what sets PRV repair apart from other mechanical disciplines. DIsassmbly, inspection, machining, lapping and reassembly are common to all valves, pumps, etc. But Blowdown Ring Adjustment is unique to Pressure Relief Valves. Many PRV manufactuerers give ring setting positions in their maintenance manuals. Liquid Settings are typically set very close to the disc during reassembly and require no further adjustment during testing. However, for air/gas/vapor service, the Manufaturers Settings will usually yield long blowdown, because short blowdown may result in insufficient capacity and in a two ring design in chatter. You do not typically see ring setting induced chatter in a one ring design. Most of the time, chatter is a result of an installation problem, i.e. reduced inlet piping, extremely long inlet piping, excessive pressure drop at the PRV inlet. I hope this is helpful

V, VB, and VL series 2-, 3-, and 5-valve instrument manifolds; VE series 2-, 3-, and 5-valve direct-mount manifolds; 2-valve remote-mount manifolds;Mod 85 modular instrumentation systems

Packless valves with all-metal seal to atmosphere; Working pressures up to 3500 psig (241 bar); Temperatures up to 400°F (204°C); VCR® face seal fitting, Swagelok® tube fitting, and weld end connections

Features: Working pressures up to 10 000 psig (689 bar); 1/8 to 1/2 in. and 6 to 12 mm Swagelok® tube fitting or NPT end connections; 316 stainless steel materials

Features: Modified PTFE wetted components meet SEMI Standard F57-0301 for ultrahigh-purity system components; Fine thread flare and Nippon Pillar® Super 300 end connections; Low cracking and reseal pressure

Rugged, all-stainless steel construction; Reverse flow coefficient less than 0.1 % of forward flow coefficient; No springs or elastomers; Compact size

Features: Working pressures up to 3000 psig (206 bar); Temperatures up to 400°F (204°C) with standard PTFE packing, up to 600°F (315°C) with optional Grafoil® packing; Straight and angle-pattern valves

Features: High-purity PFA material; Working pressures up to 180 psig (12.4 bar); Temperatures up to 300°F (148°C); 1/4, 3/8, and 1/2 in. Swagelok® PFA tube fitting end connections

Swagelok thermal-immersion diaphragm valves offer high-speed actuation and are designed for optimum performance at 220 degrees C (428 degrees F) for high-temperature processes.

Features: Working pressures up to 6000 psig (413 bar); Flow coefficients (Cv) from 4.0 to 13.8; Fractional and metric Swagelok tube fittings; ISO and NPT pipe end connections available; 316 stainless steel body and end connections; Manual and pneumatic actuation

Features: Suitable for ultrahigh-purity applications;316L VIM-VAR stainless steel body; Low-pressure and high-pressure models; VCR®, tube butt weld, and modular surface-mount end connections; Manual or pneumatic actuation

Features: Quarter-turn operation and full flow design; Light in weight; High-purity PFA material with low extractables for chemical resistance; 1/4 in. Swagelok® PFA tube fitting end connections for consistent performance

Features: Straight-pattern flow coefficients (Cv) from 0.004 to 0.15; Low- and high-pressure service; Repeatable vernier handles available; Brass and 316 stainless steel materials

Features: Provides double-block-and-bleed (DBB) operation in a single compact module; Conventional NPT and ANSI/ISA 76.00.02 compatible designs; System pressures to 250 psig (17.2 bar) with 40 psig (2.8 bar) actuation pressure; Integrated flow loop to provide consistent outlet

ALD 3, 6, and 7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

Features: 316L stainless steel and modified PTFE wetted parts; Variety of compact multivalve, multiport configurations; Choice of sanitary clamp and butt weld end connections; Choice of pneumatic or manual actuators in plastic or aluminum; Five sizes from 1/2 to 2 in.

Features: Working pressures up to 600 psig (41.3 bar); Temperatures up to 300°F (148°C); Straight and angle patterns; Vee stem standard; regulating stem available

Features: Pneumatic and quarter-turn manual 2-way and 3-way models; pneumatic and manual models with adjustable flow and bypass features; DuPont® Teflon® modified PTFE wetted parts and polypropylene actuator; Meet SEMI Standard F57-0301 for ultrahigh-purity system components; Fine thread flare and Nippon Pillar® Super 300 end connections standard; space saver and other end connections available; Custom manifolds and subassemblies available

Features: Working pressures up to 10 000 psig (689 bar); Temperatures from –65 to 450°F (–53 to 232°C) with PTFE packing; up to 1200°F (648°C) with Grafoil® packing; 316 stainless steel; alloys 400, 20, 600, and C-276; and titanium materials

Features: All-welded design provides reliable containment of system fluid; Forward flow starts at less than 2 psig (0.14 bar) pressure differential; Valve closes with less than 2 psig (0.14 bar) back pressure; 316L SS body offers enhanced material purity

Features: Working pressures up to 300 psig (20.6 bar); Shutoff, bulk-gas distribution, and isolation service; Cast, forged, and bar stock stainless steel body material; 1/4 to 1 in. and 12 to 25 mm end connections

Features: stainless steel, carbon steel, and duplex stainless steel materials; pressure ratings in accordance with ASME B16.5; flanged connections compatible with ASME B16.5; ball valve bore sizes from 3/8 to 2 in. (9.5 to 50.8 mm)

Features: Secondary containment system above the bellows; Working pressures up to 2500 psig (172 bar); Temperatures up to 1200°F (648°C); 1/4, 3/8, 1/2, 3/4, and 1 in.; 6, 10, and 12 mm end connections; Stainless steel material

Features: Packless valves with all-metal seal to atmosphere; Working pressures up to 500 psig (34.4 bar); Temperatures up to 200°F (93°); 1/4 to 1/2 in. and 6 to 12 mm end connections

Features: Working pressures up to 3000 psig (206 bar); Swagelok® tube fitting and NPT and ISO tapered pipe end connections; 1/8 through 1/2 in. and 6 through 12 mm sizes; Brass and 316 stainless steel materials

Features: Roddable, straight-through orifice for maximum flow; Working pressures up to 6000 psig (413 bar); Packing below the threads; Replaceable seat and stem tip design

Features: The Swagelok® compact gauge valve provides fast, convenient installation and installation and gauge maintenance in a lightweight package and smaller footprint than conventional assemblies.

Features: On-off, switching, and crossover flow paths; Working pressures up to 3000 psig (206 bar); Temperatures from –65 to 300°F (–53 to 148°C); Environmental and heated-process applications; 1/16 to 3/4 in. and 3 to 12 mm end connections

Features: 316 stainless steel construction; Temperatures up 1000°F (537°C); Medium-pressure (MP) fittings, Size range—1/4 to to 1 in., Pressure rating—up to 20 000 psig (1378 bar); High-pressure (HP) fittings, Size range—1/4 to 9/16 in., Pressure rating—up to 60 000 psig (4134 bar); NACE® MR0175/ISO15156 compliance available

Features: Compact, packless valve switches flow from one line to another. Torlon® stem guide ensures proper alignment for consistent shutoff performance. Manual and spring-return and double-acting pneumatic actuators are available. End connections include 1/4 in. Swagelok® VCR® metal gasket face seal fittings and 1/4 in. Swagelok tube fittings.

Features: 316 stainless steel materials; Union-bonnet construction for safety; Grafoil® packing for high-temperature performance; Swagelok® tube fitting, female NPT, and tube or pipe socket weld end connections

Features: Limits access to manually actuated valves;Lockout accessory enables compliance with OSHA Lockout/Tagout, Standard 29 CFR Part 1910.147, Control of Hazardous Energy Bright safety orange color promotes high visibility. Other colors are available.

Stop uncontrolled release of system media if downstream line ruptures. Features: Pressures up to 6000 psig (413 bar); Temperatures up to 400°F (204°C); 1/8 to 1/2 in. and 6 to 12 mm end connections; Stainless steel construction

Features: Straight and angle patterns; Pressures up to 6000 psig (413 bar); Temperatures up to 450°F (232°C) with PTFE packing; up to 650°F (343°C) with Grafoil® packing

Features: Micrometer handle for precise, repeatable flow settings; Working pressures up to 700 psig (48.2 bar); Temperatures up to 900°F (482°C); 316 stainless steel construction

GB series ball valves; Working pressures up to 6250 psig (430 bar) with temperatures from –40 to 248˚F (–40 to 120˚C); Swagelok® tube fitting end connections, 3/8 in. to 1 in. female pipe, and fractional or metric (12 mm to 25 mm); Corrosion-resistant body materials: 316/316L, Alloy 2507, 6-Moly, Alloy 625, Alloy 825, Alloy C-276; Optional API 607 for fire-safe applications and NACE MR0175/ISO 15156 for sour gas

Features: 1/8 to 2 in. and 6 to 25 mm sizes; Stainless steel, carbon steel, brass, and special alloy materials; On-off (2-way) and switching (3-way) valves; Compensating seat design; Live-loaded, two-piece stem packing

Features: Working pressures up to 6000 psig (413 bar); Adjustable and fixed cracking pressures;Variety of end connections; 316 stainless steel and brass materials

Features: Gas and liquid service; Working pressure: 6000 psig (413 bar); Set pressures from 145 to 6000 psig (10.0 to 413 bar); All 316L stainless steel construction; 1/4 through 1 in. NPT and ISO/BSP parallel thread end connections; Certified to PED 97/23/EC Category IV

Features: 3/8 to 1 in. sizes; alloy 625, alloy 825, Alloy 2507, and alloy 6-moly materials; On-off (2-way) valves; Compensating seat design; Live-loaded, two-piece stem packing

Bleed Valves: Working pressures up to 10 000 psig (689 bar); Temperatures up to 850°F (454°C); 316 stainless steel, carbon steel, alloy 400, or alloy C-276 materials. Purge Valves: Working pressures up to 4000 psig (275 bar); Temperatures up to 600°F (315°C); 316 stainless steel, brass, or carbon steel materials

Features: Working pressures up to 10 000 psig (689 bar); Temperatures from –65 to 450°F (–53 to 232°C) with PTFE packing; up to 1000°F (537°C) with Grafoil® packing; Alloy 625, alloy 825, Alloy 2507, and 6-moly materials

Features: 1.125 in. C-seal and W-seal designs; Available in two- and three-port configurations; Compact pneumatic and manual actuators; Pneumatic actuator indicator ball: red for normally closed, green for normally open; Fixed orientation of actuator to body for consistency of installation; Corner chamfers on outlet side of body for visual indication of flow direction

Features: Working pressures up to 1000 psig (68.9 bar); Temperatures up to 900°F (482°C); 1/4, 3/8, 1/2, and 3/4 in.; 6, 10, and 12 mm end connections; Brass, stainless steel, and alloy 400 materials

Features: Working pressures up to 6000 psig (413 bar); Temperatures from −40 to 302°F (−40 to 150°C); High-flow capacity in a compact design; 1/4 to 3/8 in. and 6 to 8 mm end connections; 316 stainless steel construction

Features: Rack and pinion pneumatic actuators, solenoid valves, and limit switches; ISO 5211-compliant pneumatic actuators, solenoid valves, limit switches, and position sensors; Complete actuated assemblies and kits for field assembly available

Features: Alloy 625, alloy 825, and Alloy 2507 super duplex stainless steel materials; Available for CH4 adn Ch8 series check valves; Working pressures up to 6 000 psig (413 bar); 1/4 to 1/2 in. Swagelok tube fitting or NPT end connections;

Features: Alloy 625, alloy 825, and Alloy 2507 super duplex stainless steel materials; Working pressures up to 6 000 psig (413 bar); 1/4 to 1/2 in. Swagelok® tube fitting or NPT end connections; Compact, maximum-flow design

8613371530291

8613371530291