boiler safety valve leaking in stock

The pressure relief valve of your boiler is a very important part of your heating system. This is because it is a safety valve that protects your heating system from building up too much pressure. When that happens, you are faced with leaks or even the possibility of your heating system blowing up. When you notice a leak coming from your boiler pressure relief valve, attend to it immediately. Here are possible causes and solutions to fix such a problem.

Eventually, everything will give in to wear and tear. This safety valve should be checked at least every three months. If you haven’t checked it for quite some time, check it right away because unchecked valves can become rusted and closed.

IMPORTANT:Make sure to turn the power of the boiler off and allow the water to cool for about two hours. Then check the temperature first before you pull the lever.

This pressure reducing valve is designed to allow only 12psi into the boiler. If it is allowing the pressure to reach 30psi or higher, leaks can occur. To check if the fill valve is the problem, turn the boiler off, allow it to cool, drain some of the water until the pressure reaches 10psi. Don’t turn the boiler back on and wait if the gauge starts to go up again. If it does, then the fill valve may be defective.

IMPORTANT:If the fill valve reaches up to 30psi or higher and there are no leaks, shut off your boiler and call a plumber immediately because this is a very dangerous situation.

This part allows water in the boiler to expand. Over time, it becomes logged with water or air starts to leak out of the tank, and when this happens the pressure relief valve will start to leak. Watch the pressure gauge when the boiler is heating, and if the pressure builds during the process, then the tank is most likely the problem and needs to be replaced.

This gauge is required in most area codes, so if you don’t have one, you should have one installed. If your aquastat or its backup (the aquastat relay) is defective, the temperature of your boiler can reach a very high point. This is extremely dangerous and can cause your relief valve to blow off. You must immediately turn off your boiler and call a plumber right away.

Some boilers have a tankless water heater or what is also known as a hot water coil. Sometimes, this coil will develop a pin in it, and this causes pressure to seep into the boiler and leads to leaks in the pressure relief valve. Turn off the water to the coil and check if the pressure stops rising. If it rises with the water off, the hot water coil is the problem.

REMINDER:Because repairing a leak in the relief valve of a boiler involves handling water that can be extremely hot or boiler parts that are sensitive, there is always a risk of endangering yourself or damaging your heating system. So if you are not too experienced with handling such repairs, it is best to call a professional plumber.

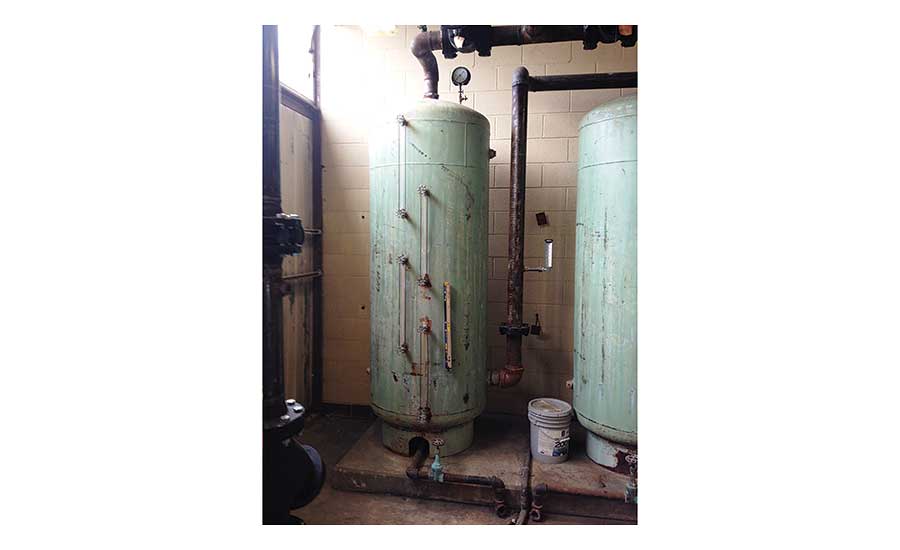

A common sight in a hydronic boiler room is water dripping from the discharge pipe of the boiler relief valve. While it may appear to be inconsequential, it could cause extensive damage to the heating system.

Some boiler rooms have a bucket under the relief valve discharge pipe to mask the problem. The following are some suggestions if you would like to resolve the problem.

Leaking water from a sealed hydronic system can reduce the life of the system by introducing untreated makeup water containing oxygen and solids to the system. The oxygen can attack and pit the boiler and piping, causing corrosion and leaks.

The solids can affect the efficiency and safety of the system. Solids form scale on the hottest surfaces in the boiler lowering the heat transfer ability and efficiency of the system. A leaking relief valve can allow solids to form on the seat of the relief valve increasing the rate of the leak.

A worse situation occurs when the solids form on the spring side of the relief valve as it could alter the opening pressure. A relief valve was a contributing factor in a fatal boiler accident as scale formed on the relief valve, prohibiting it from opening properly.

The relief valve, rated for 30 psig, was tested after the accident and did not open until the pressure reached 1,500 psig. Diagnosing the cause of the leaking relief valve is time-consuming and sometimes frustrating. I like to explain this to the customer to prepare them when the diagnosis and repair may take more than one visit.

The first thing I check is the system pressure. Most hydronic boilers have a gauge called a tridicator, or PTA (pressure, temperature, altitude) gauge. How much pressure do we need for the system? Each pound of system pressure will raise water 2.3 feet. The way to calculate how much pressure you need is to determine the height of the tallest radiator and divide the height by 2.3.

The next step is to verify the pressure rating of the relief valve. The pressure rating of the relief valve should be at least 10 psig higher than the operating pressure of the system but less than the maximum allowable working pressure (MAWP) of the boiler. Many hydronic boilers are shipped with a 30 psig relief valve from the factory. In this example, the relief valve should be at 40 psig or higher. If the system pressure is 30 psig and the relief valve, rated for 40 psig, is leaking, the relief valve is most likely defective.

Another troubleshooting task I perform is watching the tridicator (or PTA gauge) while the boiler is firing and heating the water. When water is heated from 65° F to 180°, the water volume expands by 3%. If the pressure gauge starts creeping up as the water heats, I would suspect a flooded compression tank or plugged piping to the compression tank.

In some instances, it may take several days for the pressure to build and open the relief valve and these are the most difficult to troubleshoot. The first place I would look is the compression tank. If the tank is flooded, there are a couple of reasons.

The most common causes are leaking gauge glass fittings above the water line of the tank, excessive system pressure, undersized tank, or the tank has a leak above the water line. If the system has been operating correctly for years, I would be hesitant to believe the tank is undersized.

A pinhole leak on top of the tank may be impossible to find and one of the ways to test the integrity of the tank is to valve off the water feeder to the system and check the tank in a few days to see if it flooded. If the tank is flooded, you might have to replace the tank.

Another culprit that can cause the pressure to rise and open the relief valve is if the boiler has an indirect water which uses the boiler water to heat the domestic water using a water to water heat exchanger. A leaking heat exchanger could allow the higher city water pressure to enter the space heating side and increase the system pressure. To test this idea, shut the valves from the domestic water side and see if the pressure still rises.

The last item to check is the pressure-reducing valve (PRV). This is a brass valve with an adjustment screw. Some models have a quick-fill feature, which allows you to pull a lever and quickly fill the system. A stethoscope is sometimes used to trouble shoot the PRV to detect if water is leaking through the valve.

Another way to test for leaking is to feel the downstream pipe and see if it is cold. In many instances, the water is fed slowly and difficult to detect. Another way to test to see if the PRV is leaking through is to shut off the valves on the feed water pipe and see if the pressure still rises. If it does, I will suspect the piping to the compression tank is restricted or the tank is flooded. If the pressure does not rise, it could be the pressure reducing valve.

This article describes the causes of leaks, drips, or discharges from pressure relief valves, temperature/pressure relief valves, or TP valves found on heating boilers, water heaters, or the simpler pressure relief valves found on water pressure tanks.

We list the wide variety of possible TP Valve leaks and how to find and fix each of those problems, including how to fix a leaky pressure relief valve or leaky TP valve on a boiler, water heater, or water tank - what are the possible causes of leaks at these safety devices. Safety Hazard Warnings About Dripping or Leaking Pressure Relief Valves.

How to use an expansion tank to relieve high water pressure. T&P Valves Installed on Gas Sidearm Heaters: special problems. Closed Hot Water System & Thermal Expansion Problems.

So if you see water actually spilling or even if it"s just dripping at the temperature/pressure relief valve on your heating boiler or water heater, the cause needs to be found and fixed promptly, and it may be appropriate to install a new T&P valve (also called TPR valve) after those repairs are complete.

Boiler limit control problems: On a heating boiler, the boiler temperatures are excessive, possibly due to an improperly set limit control, lack of contact between the limit switch sensor and its mounting well, or a defective control.

Gas sidearm heater TP valves: The T&P valve is installed on a sidearm gas heater that is causing an overheat condition at the sensor point of the valve (This thermal expansion is discussed

Expansion tank defects or problems: if the expansion tank or compression tank on a hydronic heating system boiler or on other thermal expansion systems is itself defective (waterlogged, leaky, damaged internal bladder) system pressures will be excessive due to otherwise normal pressure & temperature variations during system operation, resulting in spillage at the relief valve.

Leaks into the heating boiler or water heater: leaks into a heating of water from a higher pressure building source can cause recurrent TP valve leaking. For example, if the tankless coil in a heating boiler is leaky, higher pressure water inside the tankless coil may leak out of the coil into the heating boiler.

Similarly, an internal leak in the heat exchanger coil of an indirect water heater can send water from the water heater"s potable water into the coil and thence into the heating boiler.

This same leak problem can cause high water pressure in a heating boiler that is used to heat water in an indirect-fired water heater. In that case, a coil containing boiler water (typically at 12-29 psi) that develops a leak may accept higher building pressure water from the building water supply to the indirect water eater tank (or cylinder) that is typically between 20 psi and 70 psi.

Diagnose this problem by observing that when the boiler is left OFF and its own water feeder is left OFF but building water supply is left ON into the tankless coil on the boiler or ON into the indirect water heater, boiler pressure will creep up several hours. With a reader we discuss this possible TP valve leak cause in the FAQs section of this article.

Watch out: under normal conditions, because building water supply pressures are above boiler pressures, an internal leak in the tankless coil or indirect water heater"s heat exchanger coil will cause boiler pressures to rise. But there can be exceptions in the direction of water leakage, as we explain

A deteriorated gasket inside the relief valve or corrosion on the valve seat can cause leaking at the valve; we find this mess occurring when someone lifts the "test lever" on a older P/T valve that has not been tested or operated for some time. A brittle piece of gasket can be spit out of the valve and it will then keep leaking.

The wrong T&P valve has been installed or set to too-low a working pressure. (Proper set pressure is at least 20-30 psi above the working pressure of the equipment to be protected).

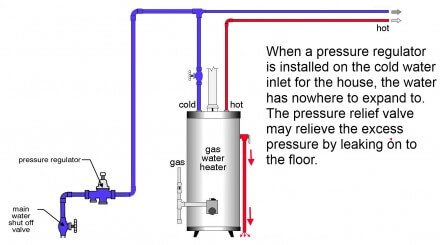

Thermal expansion problems: A closed water system with thermal expansion and no means of relief can cause leaks at the pressure/temperature relief valve, such as

Can occur on a hot water heater (hot water cylinder, calorifier, hot water tank) with some building piping arrangements, particularly where a check valve or pressure reducing valve are used.

See THERMAL EXPANSION TPR VALVE LEAKS for an explanation of why thermal expansion leaks occur at the relief valve on hot water systems & what to do about it

Can occur also a hot water heating boiler (used for building heating) at which the boiler"s thermal expansion tank has become waterlogged or has a ruptured internal bladder.

Water expansion pressure (thermal expansion) increases in any closed plumbing system, particularly where a check valve installed close to the water heater.

Watts suggests installing a bypass model water pressure regulator that lets the excessive pressure head back to the street main or building water supply system - a solution that only works if the supply pressure is lower than the T&P relief valve spill pressure - which it usually is.

Water hammer: The building plumbing system suffers from water hammer. Water hammer in buildings causes surging in the water piping that in turn can cause leaks at pressure/temperature or other pressure relief valves, particularly at the pressure safety valve found at water pressure tanks.

Water pressure too high: The building water supply pressure is too high or periodically water pressure fluctuates and is too high at times. Pressures over 70 psi in a typical building tend to cause leaks at plumbing fixtures and higher pressures are likely to cause or contribute to leaks at TPR valves.

Water pressure reducing valve / water feed valve problems: On a hot water hydronic heating system, if the water pressure reducer/feeder valve is not working properly it may over-feed water into the heating system causing overpressure.

Combinations of factors causing TP Valve Leaks: OK so this is more than 12 causes of TPR valve leaks, but keep in mind that the temperature/pressure relief valve leak causes listed above can also occur in combination. For example high incoming water pressure alone may not cause a TPR valve to leak but if we add water hammer then the valve may be leaky.

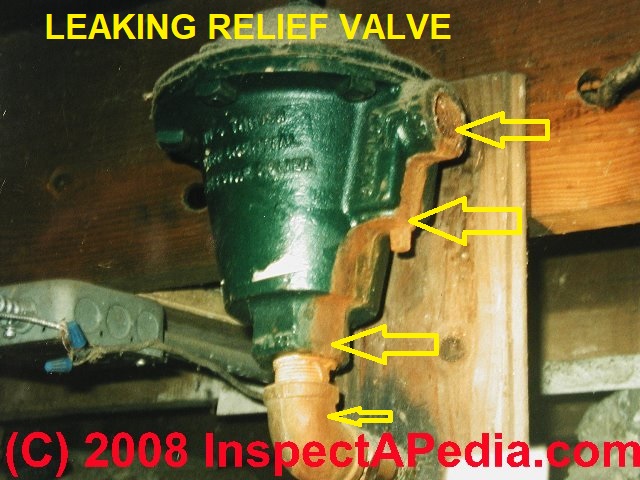

As our photo shows (above left), mineral salts left behind as hot water evaporates from the mouth of a pressure or temperature relief valve can completely clog the spring that is intended to allow the relief valve to open under excess (unsafe) pressure.

The impaction of the relief valve spring with copper and calcium salts in this photo means that the valve is almost certainly not going to open should the heater"s internal pressure become unsafe.

The drip shown at the mouth of this relief valve demonstrates that a relief valve can drip and leak for a long time without anyone observing this dangerous condition.

Technical note: why must the TP Valve point "down"? Take a look at the photo above. If a relief valve is dripping the deposit of minerals inside the valve will accumulate still more rapidly if the valve points to the side or upwards. The result is a clogged valve as we explain above - a dangerous situation that risks an explosion.

Watch out, serious safety hazards can be caused by dripping at the TP discharge line: often the dripping is caused by thermal expansion of hot water.

For details please see THERMAL EXPANSION TPR VALVE LEAKS - an explanation of why thermal expansion leaks occur on hot water systems & what to do about it

Also see HOT WATER PRESSURE EXPANSION RATE - for an explanation of just how much pressure increase to expect when heating water. In explaining why the relief valve on a water heater may be dripping

With a sidearm gas heater a common problem is frequent T&P valve opening even though there is very little hot water in the hot water storage tank. That"s because an overheated condition exists right at the sensor point of the T&P valve - most of the overheated water is "congested" at the top of the tank.

In turn this congestion (think of it as a hot water traffic jam) causes overheating right where the T&P valve sensor is located, thus causing the valve to spill hot water repeatedly.

Because there is just a small volume of "too hot" water where the valve is located, the valve opens, spills the small amount of hot water, then is cooled and closes after just a short interval.

RELIEF VALVE LEAKS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

[6] A.O. Smith"s Form No. 4778* All about Deliming Coil-Type/Tube-Type Commercial Water Heaters and Hydronic Boilers *Normally supplied when ordering Part No. 4930 Motorized Deliming Pump Kit

[7] "Building Owner Water Heater Safety Notice", Building Department, City of Colleyville TX, web search 09/24/2010, original source: http://www.colleyville.com/dmdocuments/Building%20

Water heater safety is imperative to the occupants of a building or structure. If improperly installed, water heaters can be detrimental to the structure, as well as being potentially fatal to its occupants. The proper installation of a water heater is so important that according to Texas State Law all water heater installations must be inspected by a state licensed plumbing inspector.

[9] Watts, 815 Chestnut Street, North Andover, MA, USA 01845-6098, web search 09/18/2010 original source: http://www.watts.com/pages/learnAbout/reducingValves.asp?catId=64

In small scale testing, the Mythbusters started with a small six gallon water heater and disabled all of its safety features under the theory of poor installation or neglect. While the water heater eventually ruptured, it did not explode like a rocket. The Mythbusters then upgraded to larger thirty gallon water heater which exploded with significantly greater force, sending the water heater several hundred feet into the air. In order to confirm the stated myth, the Mythbusters obtained a full size fifty two gallon water heater and built a shack around it with a roof that followed standard California building codes. The water heater eventually exploded, shooting through the roof five hundred feet into the air and disintegrating the shack. In light of these results, and the fact that there is documented evidence corroborating the myth, the Mythbusters deemed it confirmed.

Because of built in safety devices most water heaters safely operate day in, day out without any major problems. But don"t let the excellent safety record of water heaters lull you into forgetting about the explosive potential of these marvels of convenience. When a water heater explodes, it releases a tremendous blast force which can easily demolish a building.

Randall Hilton and crew, with help from the Service Roundtable has prepared this video of a water heater explosion as a demonstration of the explosive power of a simple water heater. The hot water tank explodes using the steam pressure that any water heater can generate when the thermostat and temperature pressure relief valve (T&P valve or PT valve) malfunction. We were impressed by how far the tank flew after the water heater exploded. Click on the links below to view the video. Then, visit the Q&A page for warning signs as well as simple steps which can help you prevent your own water heater from exploding.

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

You may have a defective boiler feed water pressure regulator. (Looks like this.) This device takes water from your plumbing system and feeds it into the boiler until the pressure in the boiler reaches a certain level, typically 12 PSI. Then it stops adding water unless the pressure again drops below 12 PSI for any reason, such as a leak or the intentionally draining of some water. When the boiler heats up, expansion takes place and the water pressure rises a bit above 12 PSI. This excess pressure is absorbed by the expansion tank so the final pressure of the hot boiler may go up to 15-20 PSI typically, which is below the usual 30 PSI setpoint of the pressure relief valve.

Some regulators include a backflow preventer and some use a separate backflow preventer that is installed between the regulator and the boiler. The backflow preventer prevents boiler water from backing up into your household plumbing and potentially poisoning you.

If the regulator is faulty, it may be allowing water to continue to flow slowly into your boiler, raising the boiler pressure until it reaches 30-40 psi. At that point, the pressure relief valve would start dripping.

The water heater is known for its high heat and high pressure. The water heater temperature-pressure relief valve (TPR Valve), protects us from this high heat and pressure. So what is the TPR valve, why does it leak, and what should you do about it?

The TPR valve, also called, a pressure relief valve is a specialized valve at your water heater. This valve is typically on the top or side of your water heater.

The valve functions by releasing water if your water heater becomes too pressurized. Since heated water expands, the water heater can become a ticking time bomb if we were to continually build pressure in your water heater.

As seen in the featured image, a TPR valve is required to have a discharge pipe/tube. This tube should be aimed straight to the ground and never go up. This is because hot water will come out of the TPR valve as it releases water. Therefore, extremely hot water should discharge to the ground for safety.

Additionally, if a pipe were to go up, water will have to work against gravity to empty. So, it is possible a slow drip of the TPR valve will collect water in the tubing and ultimately rust out the valve rather than empty it to the floor.

Be one nominal size larger than the size of the relief valve outlet, where the relief valve discharge piping is installed with insert fittings. The outlet end of such tubing shall be fastened in place.

However, if you find the relief valve to continue to leak even after replacement, you should contact a plumber for assistance. A licensed plumber will be able to evaluate your system and decide on installing an expansion tank or other solutions.

Check out our short how to video. This video details just how easy it is to fix a leaking over pressure relief valve. We saved hundreds of dollars by doing this easy DIY project ourselves. All you need is a couple simple tools, some teflon tape and about one hour. The video gives complete step by step instructions.

Boiler over pressure relief valve. If water is leaking from this valve it could be the valve or more likely the expansion tank. Both are easy to replace.

A boiler leaking water is usually a sign that a seal or a valve has developed a fault. However, if the problem is left untreated, a leaking boiler can cause other components to erode as well as cause damage to the electrical components within the boiler. Your best option when you notice a leak is to fix the problem quickly to prevent further damage.

Before you can do anything with your boiler, you need to find out why it’s leaking, but this isn’t always easy. The first thing to do is find where the water is coming from, as this will give you a better idea of why. Below, we’ve listed some of the main causes of a leaking boiler.

Have you ever noticed the gauge on the front of your boiler? This is important as it tells you how much water pressure there is in the system. Too little or too much pressure can cause a problem, so you should check the valve regularly and add or remove water as required.

If your boiler is leaking, you should check the pressure gauge to see if the pressure is too high. If this is the case, it’s likely that the pressure relief valve is trying to release some of the water in the system to bring the pressure back down to a comfortable level, which can lead to your boiler dripping water. The valve needle should be between 1 and 1.5 bar (usually shown on the gauge as a green zone). If the needle is higher than this, or in the red zone, you may need to bleed the radiators to release extra water.

Corrosion can be a problem in older boiler systems as it can cause rust and other debris to build up within your radiators and pipework. As the water runs around the system, it can pick up this debris and return it to your boiler. The older the system, the more likely you are to have issues with corrosion, which in turn can lead to your boiler leaking water from the bottom. Unfortunately, many people don’t know corrosion is there as it can’t be seen.

Corrosion can break the rubber seals around the joints of pipes, so water may be leaking through here. If the corrosion is on an individual component, an experienced contractor will be able to replace this with ease. However, if the corrosion is widespread, then you may need to replace the boiler completely.

A contractor will be able to advise you if a new system is required or if a new boiler and a flush of the system would be adequate. If you have an old boiler, replacing it with a newer model could make your home more efficient and could save money on your gas bills, too.

Boilers are wonderful home heating systems that have stood the test of time. Instead of heating air like furnaces do, boilers heat water and turn it into steam. Because boilers contain a lot of water, what should you do when you notice the system leaking?

Depending on where the leak is and how much water is coming out of the boiler can determine your state of panic. Theboiler experts at Poston Brothers are here to help you troubleshoot your leaking boiler and let you know when to call us for boiler services.

As soon as you notice your boiler leaking water, clean up the water to prevent water damage. Then, monitor the leak to see how fast it is leaking water. See if you can identify where the leak is coming from. A leaking boiler will need to be fixed by an HVAC technician, but doing some troubleshooting yourself can help save time. Not every leaking boiler needs to be replaced, but having the professional team at Poston Brothers look at your boiler is the only way to be sure.

Leaks are never a good sign, but there are a few steps you can take to stop them. Boilers use both gas and very hot water to supply heat to your home. If you are not comfortable being around these elements, call Poston Brothers right away.

The pressure relief valve on your boiler can get clogged with sediment and cause leaks. Boilers need to release pressure regularly, and if it cannot release steam, it will release water instead. Turn off your boiler and let it cool. Then open the pressure relief valve to release the water for 3-4 seconds. The water should come out clean. If you shut the valve and it continues to leak, that means there’s more sediment inside. Repeat this process until the boiler leaks stop. If they don’t stop, then call Poston Brothers.

Corroded pipes and tanks are a common reason your boiler is leaking water. Corrosion is a problem, and you’ll need to consult with a technician to see how bad the corrosion is and what repairs you’ll need.

If your boiler was recently installed and you’re noticing leaks, then there’s a good chance that the installation was done incorrectly. Occasionally, some joints and pipe fittings aren’t installed correctly, and that can cause a leaking boiler. Poston Brothers is always happy to provide a second opinion on boiler installation.

Just like pipes, seals and parts can break down over time. A broken seal will spray a lot of water, so you’ll notice it right away. It’s important to turn off your boiler if the leaking water is constant to prevent water damage.

The temperature control valve regulates the temperature of the water in the boiler. If your temperature valve is malfunctioning and setting your boiler temperature too high, it could be causing boiler issues like leaks.

Boilers, like any central heating system, need to be maintained on an annual basis. If it’s been a long time since you’ve had a reputable HVAC company like Poston Brothers look at your boiler, now is the time. If it’s hard to remember to schedule your yearly maintenance, then join our Poston Club maintenance plan.

When you’re a member, we’ll remind you when your boiler is due for service and then we’ll schedule your appointment around your schedule. Member benefits also include a discount on all repairs, replacement credits, and discounts on service calls. Call Poston Brothers today for boiler repairs, and ask your technician about joining the Poston Club maintenance program.

Although an occasional droplet of water around your heating system is normal, a boiler blow-off valve leak can signal a serious problem, so you shouldn’t ignore it.

The blow-off valve releases air from your boiler so pressure doesn’t build up, reducing the risk of an explosion and protecting tanks, pipes and other sensitive components from damage caused by over-pressurization. They can also minimize the accumulation of sediment to help keep your equipment running properly.

Boiler blow-off valves, which are sometimes referred to as pressure-relief valves, open when your heating system reaches unsafe pressures. They close as the pressure drops, shutting completely once the pressure reaches an acceptable level.

Boiler blow-off valves may leak a few droplets of water when they release pressure during normal operation. However, if you’re seeing a more significant leak, the cause likely falls into one of two categories: blow-off valve problems or boiler pressure issues.

Depending on the type of unit you have, a boiler can last 10 to 15 years or longer. However, components, such as valves, may begin to wear down long before then. If a boiler valve is defective, old or improperly installed, it can malfunction, leading to leaks — or worse, pressure problems. Additionally, if these valves aren"t regularly maintained, they can rust or accumulate sediment, resulting in leaks or boiler breakdowns.

If there’s too much pressure inside your boiler system, the blow-off valve may leak. This can happen for several common reasons:Fill valve malfunction: The fill valve should permit only 12 psi into the boiler. If this component malfunctions and the pressure increases to 30 psi or higher, a leak can occur.

Leaking or waterlogged expansion tank: The expansion tank, which lets water in your heating system expand, can become waterlogged over time. When this happens, water can no longer expand, and the blow-off valve begins releasing pressure.

Failing aquastat or aquastat relay: The aquastat, which is required by law in most areas, helps control the temperature in your heating system. If it malfunctions, it can result in the boiler temperature increasing to dangerous levels, causing the blow-off valve to leak.

Holes in the hot water coil: Even small holes in the hot water coil can cause water to leak into your boiler, resulting in unsafe pressure levels and spillage from the blow-off valve.

High temperature settings: If the temperature setting in your boiler is too high, it can create steam in the system, increasing the pressure, which may result in a leaking valve.

Before you can decide whether to fix the problem yourself, you’ll first need to determine what"s wrong. Although an inexperienced homeowner may not have the knowledge or training to diagnose a boiler problem, you may be able to see if a rusty or worn valve is the problem with a simple visual and mechanical inspection.

To do so, locate the blow-off valve, which is usually found on the top or side of the boiler, and check it for wear or corrosion, making sure to inspect the connection between the valve and the tank. You can also test the valve’s functionality by moving it up and down several times. If the valve is working properly, the movement should raise the attached brass stem, resulting in a gurgling sound and flow of hot water from the drainpipe. If no water is released or there’s just a trickle, your valve probably needs to be replaced.

When you attempt a boiler repair, you’ll often have to handle extremely hot water, and safety should always come first. Individuals with no plumbing experience should call a professional rather than risk injury to themselves or damage to the heating system. If you suspect the leak is caused by a systemic pressure issue, or if the pressure gauge is in the red, contact a plumber right away.

When carrying out water leak detection work something which frequently comes into consideration is understanding Pressure Relief Valves (PRVs) on boilers, Which are not to be confused with pressure reducing valves (also called PRVs in the plumbing world!), which we will explain about later.

Pressure relief valves especially come into the equation when someone has a boiler pressure dropping causing it to turn off and central heating not to work. In such situations people sometimes find themselves needing to top up their boiler pressure in order to get it working again.

Although this it is not an especially uncommon occurrence, doing it regularly suggests a problem with the central heating system, which could be associated with a water leak. As we have discussed before this can be caused by a number of factors one of which is possibly a problem with the pressure relief valve.

In some respects a pressure release valve explains itself what it does but let’s help with a simple explanation, other than ‘a device to relieve pressure’.

Pressure relief valves are effectively a safety mechanism for the boiler and central heating system To relieve pressure on the system when it gets too high. as you can see from the image below, pressure relief valves are set at a specific pressure level, often 3 bar, like this one below:

It is quickly worth mentioning as usual that exactly how boilers and central heating systems are set up will vary according to the type of boiler and how is being installed.

That said pressurised or sealed central heating systems should have a pressure relief valve. as we explained in our article about boilers losing pressure, pressurised boiler systems have an optimal range of pressure they operate in. The actual operating pressure of the boiler will vary from time to time including when it is on versus when it is off on many occasions

Basically, if the pressure on the system reaches the calibrated level it releases some water out of the system to reduce the pressure then sealing again once the pressure has reduced to normal levels. Notice how, given their importance as a safety feature that the have a CE Marking (CE1115).

With Pressure Relief Valves, some people call them pressure release valves, some even call them PRV valves (the ‘V’ obviously stands for valve already) but effectively they are talking about the same thing usually when it comes to boilers leaking a subset of which is combi boilers leaking if a pressure relief valve leaking on a combi boiler in particular.

Just to confuse matters more, some people refer to them as Safety Relief Valves (SRVs)or even Safety Release Valves! Remember also that these terms are used for applications other than central heating boilers, for example on an air compressor or even industrial machinery. More on that later.

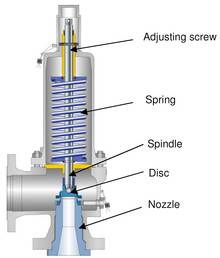

To help explain how a pressure relief valve works we have put together this basic diagram above showing the main component parts and how it works. This includes:

As we said previously, each pressure relief valve is calibrated to a specific pressure and the key component of this is the calibrated spring within the body of the PRV.

As a result of this, water will be being released from the pressurised system dropping the boiler system pressure which over time may cause it to stop working and require being repressurised.

In many situations the pressure relief valve itself is attached in and around the pipework close to the boiler, and although there are many different designs, commonly they look like the pictures shown in this article. They are usually accessible so that boiler engineers etc can’t access them to inspect, repair or replace them.

If a pressure relief valve has been triggered and released water that can in some instances be a trigger for debris to get into the mechanism / seal causing future issues, so be aware of this.

Along the way to drain outside, often close to the boiler will be a tundish drain which is a funnel shaped (often plastic), drain with an air gap. This air gap serves two purposes. Firstly it allows you to see if water is leaking from your PRV through the tundish. Secondly, the air gap prevents any, potentially contaminated water from drains etc being drawn back in to the boiler, which could cause damage.

Pressure relief valves are clearly there to serve a purpose and function for your central heating system and it wouldn’t be considered very unusual for them to be triggered from time to time in small amounts.

However, if you are seeing a lot of water being released, it is happening regularly or even constantly you likely have a fault that needs to be investigated. Otherwise, as we said above it will compromise the functioning of your central heating boiler system, this may show as an F1 boiler error or Vaillant F75 boiler error, also E119 boiler error and F22 Boiler errors.

Expansion vessels working conjunction / compliment pressure relief valves, in particular in handling smaller variances in water pressure / expansion and contraction. Expansion vessels can be integral or exterior to the boiler itself. There are different designs, shapes colours, etc.

Like pressure relief valves, expansion tanks can fail too, especially if the water and air tight seal between the air and water areas of the tank is broken. If that happens on a expansion vessel then water will enter the area for air and can cause the boiler pressure to drop, sometimes enough to stop the boiler working.

We thought it was worth adding a section about pressure reducing valves which are not the same as pressure relief valves. pressure reducing valves are commonly used in domestic and commercial properties to reduce water pressure into the building all part of the building this can be for a number of different reasons.

Some reasons for installing a pressure reducing valve in a property include – lowering the pressure and therefore strain on your pipework and appliances, sometimes to conserve water, to stop all reduce water hammer problems (knocking on paperwork) or just because people prefer to have lower pressure in their property.

As we said earlier pressure relief valves or safety relief valves can be found in other applications not just on boilers and heating systems. They can be used in devices and machinery where water, air, oil and gas are used. In general they are for safety purposes and to protect the machinery or devices themselves. This is a bit like isolation valves, which have a number of applications.

pressure relief valve can fail for a number of reasons including general wear and tear, broken seals, broken or damaged springs and also because debris has got into the mechanism compromising its effectiveness. most of these problems are resolved by either repairing or replacing the PRV.

if a pressure relief valve fails then not only will it potentially stop your central heating system boiler from working effectively or at all, plus it can mean that water is expelled from your central heating system, leaking out of the outlet pipe which is often found on the wall outside the boiler.

Pressure relief valves can be found number of areas but generally they are located in close proximity to the boiler on the connections between the pressurised central heating boiler itself. Remember that a non-pressurised or vented system will unlikely have one at all. They are often vented to a tank in the loft (or elsewhere) when there is expansion.

A tundish is a funnel shaped, often plastic, connection with a feed (usually from your PRV on your pressurised boiler) with a collection cup at the bottom feeding to a drain. There is a visible air gap between the top and bottom on a tundish to allow you to see any PRV boiler leaks and also to stop any water (from the drain) going back into the boiler system, which could cause issues. If you see your tundish leaking, you could have a problem.

After writing a blog post about leaking temperature and pressure relief (TPR) valves at water heaters, I learned that this particular issue seems to completely befuddle folks. In the two years that I allowed comments to be posted, that post received 245 comments, including my own. The majority of the comments were questions from readers who were trying to troubleshoot their own leaking TPR valves.

The good news is that while answering reader questions, I ended up doing a fair amount of research to help myself understand problems that people were having, and to make sure that the advice I was giving was correct. The purpose of this blog post is to give some troubleshooting advice to people with leaking TPR valves.

All water heaters are equipped with a temperature and pressure relief valve. This valve will allow water or steam to escape from the water heater if the temperature or pressure gets too high; these valves are set to open when the pressure reaches 150 psi, or when the temperature reaches 210 degrees fahrenheit. This prevents water heaters from exploding or turning into missiles.

The rest of this blog post is going to be about troubleshooting a leaking TPR valve. If a TPR valve leaks, either it’s defective or it’s not. If it’s not defective, it’s leaking because the temperature was too high or the pressure was too high. In other words, a leaking TPR valve indicates one of these things: a defective valve, excessive pressure, or excessive temperature.

As I mentioned earlier, the TPR valve on a water heater is set to go off at 150 psi, or 210 degrees Fahrenheit. These numbers will be printed right on the valve, or on a tag attached to the valve. See below.

If a pressure relief valve for a boiler is accidentally installed on a water heater, it will leak like crazy from the start. These valves may look identical, but they’re set to go off at 30 psi, not 150 psi.

As I mentioned in my original post about leaking TPR valves, an easy troubleshooting step is to replace the leaking valve. TPR valves cost less than $15 and they’re fairly easy to replace. If you’re not sure how to go about doing this, hire a plumber. If you’re trying to do this on the cheap because you can’t afford a plumber, search YouTube for videos of “relief valve replacement”. You’ll find a ton of ’em there.

If a new, proper TPR valve leaks, it’s probably just doing its job. It’s relieving excessive temperature or pressure. The next step is to find out which one it is.

This one is pretty simple. Run some hot water at a plumbing fixture and take a temperature reading with a meat thermometer. Make sure there are no tempering valves installed between the water heater and the faucet; whole-house tempering valves are typically installed at the water heater, and look like the type shown in the photo below, which I used in my blog post about safe water temperatures. If one of these valves is installed, the temperature you’ll get at the faucet will be less than the temperature inside the tank, by design.

New single handle bath tub faucets installed in Minnesota since 2013 also require tempering valves (http://www.structuretech1.com/2013/04/new-safety-requirements-for-bath-tub-faucets-in-minnesota/). Those valves are typically installed below the bath tub, but can sometimes be found near the water heater.

If the pressure is within the acceptable range, you play the waiting game. Once the temperature and pressure relief valve at the water heater leaks, go check the pressure gauge. If the ‘surge indicator’ shows something at or near 150 psi, the problem is excessive pressure. Excessive pressure is typically the result of a closed system; the water heats up and expands, but it doesn’t have anywhere to go, so the relief valve does it’s job and relieves the pressure. The solution, as I mentioned in my original blog post (http://www.structuretech1.com/2012/01/leaking-relief-valve/), is to install an expansion tank. If an expansion tank is already installed and there is still a problem with excessive pressure, either the expansion tank is not installed properly or it’s not charged properly.

If you’ve noticed water pooling around your hot water heater, this may be because of the water heater pressure release valve. Wondering what this means, and what you should do about it? Find out now!

It typically consists of a valve that attaches to the side of the tank with a long copper tube or PVC tube that runs vertically downward, allowing water to drain out of the valve when necessary.

If you are having trouble finding the valve on your unit, or cannot identify it, we recommend searching for the make and model of your water heater on the internet. The manufacturer’s schematics and manuals will help you locate the water heater pressure relief valve.

The water heater pressure release valve, also known as the “temperature and pressure” (T&P) valve is a valve that helps control the pressure and temperature of your water heater, preventing it from overheating, becoming too highly pressurized, and potentially exploding.

The way this valve works is by sometimes letting a little bit of water drip out of the tank. When there is too much pressure inside the tank, the valve opens up to relieve this pressure and some water will drip out of it. This is normal, and indicates that the valve is functioning properly.

However, if your water heater pressure release valve is constantly leaking a lot of water, the water contains debris, or your valve is making a lot of noise like whistling and screeching, this may indicate that it has failed, and is not operating properly.

If your water heater pressure release valve only leaks every once in a while, this is normal. It’s doing its job, and there’s nothing to worry about. Just keep an eye on it to make sure it’s not draining constantly.

But if you notice the aforementioned issues like lots of drainage coming from the valve, water flooding, or whistling and screeching sounds from the valve, you should:

Call G&C Plumbing to get help – Call us right away to get help. A damaged or failing water heater pressure relief valve could cause serious damage, so you need to work with a professional to repair or replace your water heater, as necessary.

We’ll check your water heater pressure relief valve, determine the source of the issue, and let you know your best option for restoring the proper, safe functionality of your hot water heater. Call today to get the help you need in Franklin or Bellingham, MA today.

Rather than get in an extended text message conversation, I called the person. In his usual animated way, he said, "That stupid valve on top of the boiler keeps opening, and I lose all my steam. It ruins my batch. I thought you said this was a good boiler."

There was a recent repair done in the asphalt parking lot which looked a pipe was replaced as it was a straight line. When I walked into the boiler room, I gasped. There was a wire connected to the safety valve and the pipe, preventing it from opening.

I also noticed the black iron pipe which was initially on the safety valve was replaced with a copper tube piped to and inside the floor drain. He saw me noticing it and said, "That old pipe was leaking all over the floor. Steam and water were going everywhere, so I piped it into the drain." He said proudly.

"Oh, I did. This expert online said I would get a better batch if I ran the pressure that high." He said. I reminded him of one of my rules, The out of town or online expert may not always be an expert. I adjusted the pressures down to where they were when I started the boiler, 10 Psig.

The minimum pressure differential between the pressure relief valve set pressure and the boiler operating pressure is 5psi. Under no circumstances should this margin be less than five psig.

That would make the maximum boiler setpoint at ten psig. I also explained the warmest temperature allowed in a drain is 140 degrees F. Be careful operating the boiler too close to the upper limit.

The average lifespan of a boiler is roughly 20 years, however, suppliers recommend checking your machine every year to make sure there are no major problems. Those who put off this task might find themselves paying up to $5,000 for a new commercial boiler.

If you recently discovered your boiler is leaking water, don’t panic about that big replacement cost yet. There are still a few ways to troubleshoot the issue.

Sometimes boilers that are old need a few small tweaks to get back to normal. Other times, water coming out of your boiler can be a sign of a bigger issue.

Before you call your local handyman or boiler supplier, take a few minutes to check these three things. Pinpointing the cause for your boiler leaking can be easier than you think.

This is the most likely reason why you’re seeing water around your boiler. All boilers have a special outlet pipe that’s used to release extra pressure.

If you’re seeing large amounts of water coming out of the pressure outlet pipe, this could mean there’s too much pressure inside the boiler. Check to see if your boiler’s gauge needle is pointing to the green or the red. If it’s in the red, you’ll need a professional to bleed your boiler to lower the pressure.

Boilers contract and expand as the temperature changes from hot to cold. Because of this, it can cause the joints to loosen and leak water. Newly installed boilers may also need tightened joints.

Use a cloth to dry the area and then wait to see if water appears again. If the boiler pipework seems to be the issue, then a quarter turn might fix it. Otherwise, you’ll want to call a professional to make sure all the joints are nice and tight.

Over time, your boiler will repeatedly contract and expand. This can lead to cracks and damages that cause leakages. If you live in an old home and suspect a crack to the body, it’s time for a new replacement.

If you’ve recently installed a new boiler and suspect damaged seals, it could be that your boiler has been running overpressure. If you suspect this problem, it’s a good idea to call a professional.

Most boiler leaks come down to pressure issues, loose joints, or cracks. If you suspect a different problem, there are other things you can check. Remember that some issues are a simple fix, but your safest bet is to call in a professional right away.

Part of your boiler upkeep is a process called a “blowdown,” which is done when the water seems dirty. It uses a quick opening valve that can sometimes be damaged.

If this boiler valve seems to be damaged, it can cause a large pool of water to collect. This is why regular boiler checks are a good idea for damage prevention.

The most expensive and essential part of your boiler is its heat exchanger. This is the part of your boiler that takes heat from the hot gas to the water.

Unfortunately, over time the heat exchanger can corrode and split. This leads to a leaky boiler. When this happens, your best option is to replace your boiler.

When the pressure gets too high, your boiler will switch to the auto-air vent to release pressure. This auto-air vent uses a valve that opens and closes to let air out.

Sometimes the valve sticks, which leads to the air vent letting out both air and water. If you think your water leak is coming from the top of your boiler, then the problem could be valve leaks from the auto-air vent.

If you suspect that your leak is because of a faulty pressure valve, then it could be that there is sediment trapped inside the valve. When this happens, the valve can’t close properly.

There are steps you can take to check it yourself if you feel confident you can do it without the help of an experienced professional. Turn off your boiler, let it cool, then lift the valve to let out water.

The water should come out with force and should look clean. If water keeps coming out after you’ve closed the valve, then you might have trapped sediment. It’s a good idea to call a professional if you suspect problems with a boiler pressure relief valve.

The reasons for a boiler leaking can be either simple or complex, but either way, they require immediate attention. All boilers wear down over time and need regular upkeep in order to last through its expected lifetime.

Temperature pressure relief valves play a vital role in protecting the safety of your water heater and your home. So when the relief valve starts leaking, Bay Area homeowners can be quite concerned. Today we’re going to answer the question, “Why is my water heater’s relief valve leaking?” and explain what you should do if it happens in your home!

The temperature pressure relief valve is a safety mechanism that’s used to avoid this problem. If the temperature‘s or pressure in your tank exceeds a certain level (often times 210 degrees and 150 psi), the relief valve opens up and allows some water to drain out of the tank. Cold water is then added to the tank in order to lower the temperature and pressure inside.

Your water heater’s relief valve can start leaking for one of two reasons: either the valve was triggered to open because of excessive temperature or pressure, or the valve itself is faulty. In the first case, the valve will drain water out of the discharge pipe as explained above. This may seem like a “leak,” but it’s really just the relief valve doing its job.

If the problem is a faulty valve, then you might have an actual leak. The valve might not seal properly, for instance, or the valve can get stuck and remain open (allowing water to continuously drain out).

No matter what caused your relief valve to start leaking, you should contact a professional plumber like Cabrillo as soon as possible. If the valve is frequently being triggered, we can determine why the temperature or pressure is getting too high in your water heater and fix the problem. If the valve has a leak, we can replace it with a new relief valve (a very common water heater repair).

If you have any questions about why your water heater’s relief valve is leaking, or if you’d like a plumbing system serviced or installed in your home, contact Cabrillo, your Bay Area plumbing, heating and air conditioning contractor.

The bleeder valve will get a steam leak when corrosion results from purified waters, formulated waters, and hard waters. The valve gets stuck open and has a steam leak. Pinching the hsoe atatched to the bleeder valve after the machine is fully heated will confirm a steam leak once released after several seconds of holding.

The safety valve will also get corrosion to cause a steam leak OR the boiler is running hotter because the PID sensor has corrosion from the same aforementioned waters.

8613371530291

8613371530291