boiler safety valve regulations for sale

Boiler explosions have been responsible for widespread damage to companies throughout the years, and that’s why today’s boilers are equipped with safety valves and/or relief valves. Boiler safety valves are designed to prevent excess pressure, which is usually responsible for those devastating explosions. That said, to ensure that boiler safety valves are working properly and providing adequate protection, they must meet regulatory specifications and require ongoing maintenance and periodic testing. Without these precautions, malfunctioning safety valves may fail, resulting in potentially disastrous consequences.

Boiler safety valves are activated by upstream pressure. If the pressure exceeds a defined threshold, the valve activates and automatically releases pressure. Typically used for gas or vapor service, boiler safety valves pop fully open once a pressure threshold is reached and remain open until the boiler pressure reaches a pre-defined, safe lower pressure.

Boiler relief valves serve the same purpose – automatically lowering boiler pressure – but they function a bit differently than safety valves. A relief valve doesn’t open fully when pressure exceeds a defined threshold; instead, it opens gradually when the pressure threshold is exceeded and closes gradually until the lower, safe threshold is reached. Boiler relief valves are typically used for liquid service.

There are also devices known as “safety relief valves” which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service.

Nameplates must be fastened securely and permanently to the safety valve and remain readable throughout the lifespan of the valve, so durability is key.

The National Board of Boiler and Pressure Vessel Inspectors offers guidance and recommendations on boiler and pressure vessel safety rules and regulations. However, most individual states set forth their own rules and regulations, and while they may be similar across states, it’s important to ensure that your boiler safety valves meet all state and local regulatory requirements.

The National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation, and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulationsin order to provide guidance and encourage the development of crucial safety laws in jurisdictions that currently have no laws in place for the “proper construction, installation, inspection, operation, maintenance, alterations, and repairs” necessary to protect workers and the public from dangerous boiler and pressure vessel explosions that may occur without these safeguards in place.

The documents are meant to be used as a guide for developing local laws and regulations and also may be used to update a jurisdiction’s existing requirements. As such, they’re intended to be modifiable to meet any jurisdiction’s local conditions.

The American Society of Mechanical Engineers (ASME) governs the code that establishes guidelines and requirements for safety valves. Note that it’s up to plant personnel to familiarize themselves with the requirements and understand which parts of the code apply to specific parts of the plant’s steam systems.

High steam capacity requirements, physical or economic constraints may make the use of a single safety valve impossible. In these cases, using multiple safety valves on the same system is considered an acceptable practice, provided that proper sizing and installation requirements are met – including an appropriately sized vent pipe that accounts for the total steam venting capacity of all valves when open at the same time.

The lowest rating (MAWP or maximum allowable working pressure) should always be used among all safety devices within a system, including boilers, pressure vessels, and equipment piping systems, to determine the safety valve set pressure.

Avoid isolating safety valves from the system, such as by installing intervening shut-off valves located between the steam component or system and the inlet.

Contact the valve supplier immediately for any safety valve with a broken wire seal, as this indicates that the valve is unsafe for use. Safety valves are sealed and certified in order to prevent tampering that can prevent proper function.

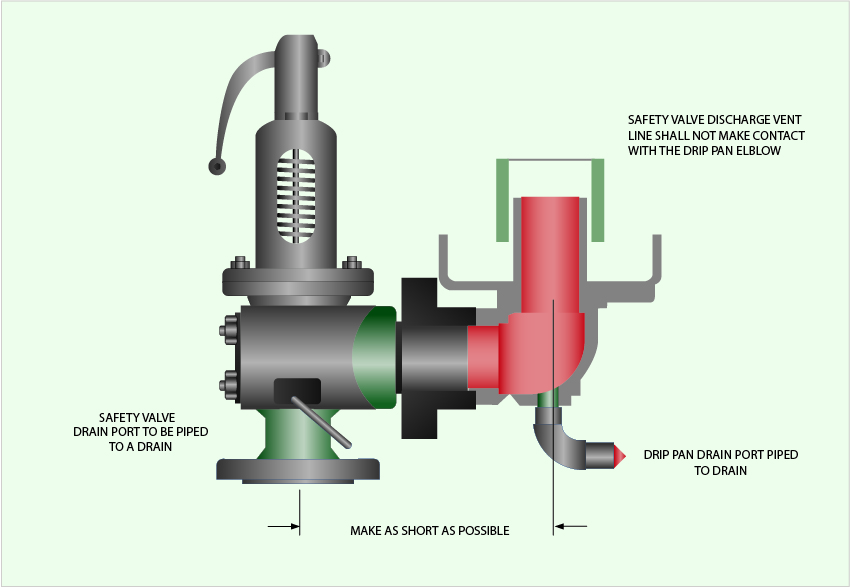

Avoid attaching vent discharge piping directly to a safety valve, which may place unnecessary weight and additional stress on the valve, altering the set pressure.

(a) Each power boiler, nuclear boiler, and high temperature water boiler shall have safety valves or pressure relieving devices constructed, stamped and installed in accordance with the applicable section of the Code, except:

(2) Upon written request by the employer, the Division may permit three-way two-port valves to be installed under two safety valves, each with the required relieving capacity, provided they are so installed that both safety valves cannot be closed off from the boiler at the same time and provided the three-way valve will permit at least full flow to the safety valve in service at all time.

(b) The user shall maintain all pressure relieving devices in good operating condition. Where the valves cannot be tested in service, the user shall maintain and make available to the inspector records showing the test dates and set pressure for such valves.

3. Change without regulatory effect inserting "(a)" immediately preceding the first paragraph and "(b)" immediately preceding the fourth paragraph, filed 1-24-91 pursuant to section 100, Title 1, California Code of Regulations (Register 91, No. 7).

Choose these valves for small steam-heating boilers requiring pressure relief between 5 psi and 12 psi. They spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. All have a bronze body for durability and a long service life.

Years ago, it was not uncommon to read news about tragic boiler explosions, sometimes resulting in mass destruction. Today, boilers are equipped with important safety devises to help protect against these types of catastrophes. Let’s take a look at the most critical of these devices: the safety valve.

The safety valve is one of the most important safety devices in a steam system. Safety valves provide a measure of security for plant operators and equipment from over pressure conditions. The main function of a safety valve is to relieve pressure. It is located on the boiler steam drum, and will automatically open when the pressure of the inlet side of the valve increases past the preset pressure. All boilers are required by ASME code to have at least one safety valve, dependent upon the maximum flow capacity (MFC) of the boiler. The total capacity of the safety valve at the set point must exceed the steam control valve’s MFC if the steam valve were to fail to open. In most cases, two safety valves per boiler are required, and a third may be needed if they do not exceed the MFC.

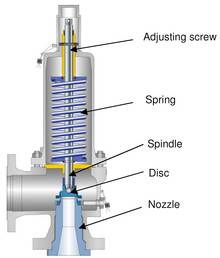

There are three main parts to the safety valve: nozzle, disc, and spring. Pressurized steam enters the valve through the nozzle and is then threaded to the boiler. The disc is the lid to the nozzle, which opens or closes depending on the pressure coming from the boiler. The spring is the pressure controller.

As a boiler starts to over pressure, the nozzle will start to receive a higher pressure coming from the inlet side of the valve, and will start to sound like it is simmering. When the pressure becomes higher than the predetermined pressure of the spring, the disc will start to lift and release the steam, creating a “pop” sound. After it has released and the steam and pressure drops below the set pressure of the valve, the spring will close the disc. Once the safety valve has popped, it is important to check the valve to make sure it is not damaged and is working properly.

A safety valve is usually referred to as the last line of safety defense. Without safety valves, the boiler can exceed it’s maximum allowable working pressure (MAWP) and not only damage equipment, but also injure or kill plant operators that are close by. Many variables can cause a safety valve on a boiler to lift, such as a compressed air or electrical power failure to control instrumentation, or an imbalance of feedwater rate caused by an inadvertently shut or open isolation valve.

Once a safety valve has lifted, it is important to do a complete boiler inspection and confirm that there are no other boiler servicing issues. A safety valve should only do its job once; safety valves should not lift continuously. Lastly, it is important to have the safety valves fully repaired, cleaned and recertified with a National Board valve repair (VR) stamp as required by local code or jurisdiction. Safety valves are a critical component in a steam system, and must be maintained.

All of Nationwide Boiler’s rental boilers include on to two safety valves depending on the size; one set at design pressure and the other set slightly higher than design. By request, we can reset the safeties to a lower pressure if the application requires it. In addition, the valves are thoroughly checked after every rental and before going out to a new customer, and they are replaced and re-certified as needed.

(a) The relief valve requirements for hot water boilers must be as indicated in article 4 of section IV of the ASME Boiler and Pressure Vessel Code (incorporated by reference; see 46 CFR 53.01-1) except as noted otherwise in this section.

(c) Hot water supply boilers. Each hot water supply boiler must have at least one safety relief valve and a temperature relief valve or a pressure-temperature relief valve. The valve temperature setting must not be more than 99 °C (210 °F).

As a design engineer responsible for developing and specifying boilers, dryers, furnaces, heaters, ovens and other industrial heating equipment, you face a daunting labyrinth of standards and industry regulations. Regulatory bodies sound a bit like alphabet soup, with acronyms like UL, FM, CSA, UR, AGA, ASME, ANSI, IRI, CE and NFPA tossed about. This article will help explain a common task for many thermal processing equipment specifiers: meeting the requirements of key codes — including Underwriters Laboratories (UL), Factory Mutual Insurers (FM) and the National Fire Protection Association (NFPA) — for safety valve equipment used in process heating applications.

Key to designing safety into your fuel train configurations are familiar technologies such as safety shutoff valves and vent valves as well as visual-indication mechanisms and proof-of-closure switches.

Your design skills come into play with how you take advantage of the wide range of products available. You can mix and match solenoid and safety shutoff valves — within designs from catalytic reactors to multi-zone furnaces — to create easily installed, cost-effective solutions that comply with all necessary standards. (See table.)

Make sure, however, that you start with a good grasp of valve element fundamentals. For example, examining a proof-of-closure (POC) switch underlines how reliably modern valves can ensure combustion safety. The POC unit provides an electrical contact interlocked with the controller safety circuit. In a typical design, the switch is located at the bottom of the valve, positioned to trace the stroke of the valve disc. When the disc seal reaches the fully closed position, it triggers the mechanism to push down on the contact, closing it and triggering the unit’s visual indicator to show open or closed status. As a result, the operator can act with full confidence in situations where it is critical that a safety valve be safely closed.

To provide ease of installation, many users prefer valves with modular capabilities. For example, to reduce mounting complexity, you can choose modular gas safety shut-off valves — combining a solenoid valve with an electrohydraulic motorized valve for a compact double-valve footprint, a slow-open feature and high flow rates. An accompanying actuator can provide on/off or high/low/off firing rates as well as visual indication and proof of closure for compliance with most industry standards.

Also, you may want to look for valves that include useful features such as pipe taps, which can facilitate accurate pressure readings and leakage testing.

Knowing your valve choices — and how they meet given codes and standards — can reduce the time required for design and production while facilitating compliance. This results in safer, more efficient and cost-effective heating process installations.

Tired of keeping track of your valve inventory’s annual certification records? We offer complete management of your safety relief valves. With an inventory of repair parts and in stock relief valves of all sizes, we can respond to any customer emergency. We offer annual certification services as well as repair of all major brands, including Kunkle, Conbraco, Consolidated, Dresser, Apollo and more.

The proposed regulations reflect changes that will reduce the likelihood of an incident involving the loss of life and property from a boiler or pressure vessel due to an explosion, equipment failure, or harmful exposure to carbon monoxide. The proposed regulations require owners of boilers located in places accessible to the public such as commercial businesses, churches, hospitals, and schools, to conduct monthly inspections of their boiler systems and record any maintenance, testing, or service performed on the boiler. The proposed regulations also require owners to hire a licensed heating, ventilation, and air conditioning technician to perform an annual service check on the boiler system.

The proposed regulations also amend the inspection and testing requirements for pressure vessels associated with air cannons. The thickness of the wall of the pressure vessels must now be checked using ultrasonic testing technologies to ensure that the wall is thick enough to sustain the maximum allowable working pressure originally assigned to the pressure vessel when it was manufactured. There are also requirements for owners to conduct penetrant testing and necessary repairs on the pressure vessel when a commissioned inspector detects cracks or surface defects during an inspection.

The hearing record on the proposed amendments to 7DE Admin. Code1353 Boiler Safety Regulations For Boilers, Pressure Vessels, and Nuclear Installations was open on January 1, 2018 and remains open. Public comments will be accepted through March 15th 2018, pursuant to Section 10118 of 29 Del. Code Chapter 101, Administrative Procedures. Individuals may submit written comments regarding the proposed changes via e-mail to

1.2.11Any water heater, directly fired with oil, gas or electricity, which shall be equipped with American Society of Mechanical Engineers (ASME) stamped safety relief valves and which cannot exceed any of the following limitations:

1.2.12Any coil type hot water boiler without any steam space where water flashes into steam released through a manually operated nozzle unless 1 of the following limitations is exceeded:

1.2.13Any water heater, indirectly fired, which shall be equipped with American Society of Mechanical Engineers (ASME) stamped safety relief valves and which cannot exceed any of the following limitations:

1.2.15.2Electrically heated type shall bear the Underwriter???s Laboratory listing marking, are exempt provided that such sterilizers bear the UL label indicating the sterilizer meets the UL requirements. Possession or control of these sterilizers not bearing the UL label indicating the sterilizer meets the UL requirements shall constitute a violation of these regulations.

???an entity that is accredited by the National Board meeting NB 369,Qualifications and Duties for Authorized Inspection Agencies Performing In-service Inspection Activities and Qualifications for Inspectors of Boilers and Pressure VesselsRevision 7,Accreditation of Authorized Inspection Agencies (AIA) Performing Inservice or Repair/Alteration Inspection Activities;N B-3 71, NB371 Revision 8,Accreditation of Owner-User Inspection Organizations (OUIO)or NB-390, ForFederal Inspection Agencies (FIAs) Performing In-service Inspection ActivitiesRevision 7Accreditation of Federal Inspection Agencies (FIA).

???Boiler??? means a closed vessel in which water is heated, steam is generated, steam is superheated, or any combination thereof, under pressure or vacuum for use externally to itself by the direct application of heat from the combustion of fuels, or from electricity or nuclear energy. The term "boiler" shall include fired units for heating or vaporizing liquids other than water, where these units are separate from processing systems, and are complete within themselves.

???Heating Boiler??? means a steam boiler operating at pressures not exceeding fifteen (15) psi, or a hot water boiler operating at pressures not exceeding 160 psi and/or temperatures not exceeding 250 degrees F, which is supplied to an external heating system.

???Hot Water Supply Boiler??? means a vessel used to heat water for purposes other than space heating, where the water is used external to itself, at pressures not exceeding 160 psi, and/or temperatures not exceeding 250 degrees F. at or near the boiler outlet. ASME Stamping would be ASME Section IV, H.

???Thermal Fluid Heater??? means a boiler used to heat an organic fluid for heating and or processing that does not vaporize in the process. Object is considered a boiler in the State of Delaware and is required to be built to Section I or Section VIII of the ASME Construction Codes and registered with the National Board. Overpressure protection will be in accordance with ASME Section I Part PVG or ASME Section VIII as determined by the Department.

???Water Heater??? means a closed vessel in which water is heated by gas, oil, electric, or some other fuel supply, and the water is used externally to itself for potable water supply, or used for potable water and space heating (as outlined in Section 14.0 of these Rules and Regulations), operating at pressures not exceeding 160 psi and water temperatures not in excess of 210 degrees F. ASME Stamping would be ASME Section IV, HLW.

???Certificate of Competency??? means a certificate issued by the Boiler Safety Program to an inspector after passing the Delaware test for inservice in-service inspections, or to an inspector holding a valid National Board AI Commission for ???New Construction Inspector???. See Delaware Commission.

???Certificate of Inspection??? means a printed document, issued by the Boiler Safety Program, signifying the object has met Code requirements after receipt of a report from a National Board Commissioned or Owner/User Inspector, stating the conditions of the object are satisfactory to issue a certificate. The inspector will issue a current decal bearing a date of inspection. The certificate becomes valid upon payment of the required inspection and/or certificate fees. All Certificates expire on the last day of the expiration month listed on the certificate.

???Delaware Commission??? means a Certificate of Competency issued by the Boiler Safety Program to a National Board Commissioned Inspector employed by the State of Delaware; an insurance company licensed to sell boiler and machinery insurance in the State of Delaware; an owner/user inspector employed by a recognized Delaware Owner/User Agency; or an inspector employed by a Non-traditional Inspection Agency accredited by National Board- 369.

???Controls and Safety Devices (CSD-1)??? means ASME Standard adopted by the Boiler Safety Program in 1992 for controls on boilers with input capacity of less than 12,500,000 Btu/Hr.

"Delaware Commission" means a Certificate of Competency issued by the Boiler Safety Program to a National Board Commissioned Inspector employed by the State of Delaware; an insurance company licensed to sell boiler and machinery insurance in the State of Delaware; an owner/user inspector employed by a recognized Delaware Owner/User Agency; or an inspector employed by a Non-traditional Inspection Agency accredited by NB-369 Revision 7.

???Internal Inspection???means an inspection of the interior surfaces of a boiler or pressure vessel, as defined in the NBIC, with implementation of preparation and safety procedures.

???Manager of the Boiler Safety Program??? means a State of Delaware Employee responsible for the administration of Delaware???s Boiler Safety Program.

???NBIC???means National Board Inspection Code. The manual for boiler and pressure vessel inspectors, published by the National Board of Boiler and Pressure Vessel Inspectors. The NBIC is recognized for Repairs and Alterations, and Antique (Historical) boilers only (Part 3 only).

???Owner/User Agency??? means An an organization that is recognized by the Boiler Safety Program as having inspectors holding State of Delaware Owner/User Commissions that allow the inspectors to inspect pressure vessels owned and operated by the Delaware Owner/User Agency.

???Portable Boiler???means an internally fired boiler primarily intended for temporary location, and the construction and usage of which is obviously portable.

???Pressure Retaining Item (PRI)???means any boiler, pressure vessel, piping, or material used for the containment of pressure, either internal or external. The pressure may be obtained from an external source, or by the application of heat from a direct source, or any combination thereof.

???Shop Review???means a general survey and examination of a boiler or pressure vessel manufacturing or repair firm"s facilities, methods and records. The examination is performed by a designee of the ASME, and/or the National Board.

???Special Inspector???means a National Board Commissioned Inspector and/or an Authorized Inspector, employed by an insurance company authorized to write boiler and pressure vessel insurance in Delaware, or an inspector employed by a Non-traditional Inspection Agency.

???Standard Boiler or Pressure Vessel???means a boiler or pressure vessel which bears the stamp of the ASME and which are registered with the NB. Such items shall bear the appropriate ASME Code Symbol Stamp and the NB Registration number.

3.1The State of Delaware Boiler Safety Program has adopted the ASME Boiler and Pressure Vessel Codes for construction and stamping, including CSD-1 for controls and safety devices. Standards referenced by these rules are: ASME Code Sections I, II, III (all Sections), IV, V, VIII (Div. 1, 2 and 3), IX, X, XI, PVHO-1, CSD-1, B31.1 (for boiler external piping) and Code Cases.Interpretations are not part of the ASME and National Board Codes and will be handled on a case by case basis.

4.1.1.1Submit completed boiler or pressure vessel reports to the Boiler Safety Program within 30 days of inspection. First time inspections shall be submitted on the National Board Form NB-7 or the Delaware First Inspection Report, or filed electronically,. Electronic reporting does not require submission of hard copies.

4.1.1.2Report immediately to the Chief Inspector of the Boiler Safety Program the name of the owner or user who is operating any boiler or pressure vessel (a) without a valid certificate of inspection, or, (b) in an unsafe condition.

4.1.1.3Report to the Chief Inspector of the Boiler Safety Program all accidents involving boilers and pressure vessels when informed of such accidents by the owner/user.

4.1.2It shall be the duty of the insurance company to notify the Boiler Safety Program of installations on which insurance is accepted, refused, cancelled, or suspended. Such reports shall give detailed account of any unsafe conditions and shall be submitted within 30 days of such insurance acceptance or refusal.

4.2.1The shop inspections required by any applicable section of the ASME Boiler & Pressure Vessel Code shall be made by an Inspector who holds a valid AI commission issued by the National Board of Boiler & Pressure Vessel Inspectors, and having a valid "A" or "B" endorsement. A Certificate of Competency card, issued by the Boiler Safety Program, is required for all inspectors. An AI inspecting nuclear components requires the "N" endorsement.

4.3.1ASME and National Board Shop reviews shall be conducted by an ASME representative, a National Board representative, or the Boiler Safety Program ASME Designee.

4.5.1The Manager of the Boiler Safety Program may suspend or revoke a Certificate of Competency or a Delaware Commission, after due investigation for willful falsification of any matter or statement contained in his application, or in a report of any inspection made by him/her, and for any other finding of improper conduct. Written notice of any such suspension or revocation as required by 29Del.C.??1031(c)10131(c), shall be given by the Manager of the Boiler Safety Program to the inspector and his employer. An inspector whose Certificate of Competency or Delaware commission Commission has been suspended or revoked shall be given ten days to appeal the decision to the Secretary of the Department of Natural Resources and Environmental Control. The notice of any proceedings shall conform to 29Del.C.??10122.

4.5.2Appeal from decision of Inspectors. If the owner or user of any boiler, pressure vessel or nuclear installation disagrees with the Inspector, as to the necessity for shutting it down for making repairs or alterations to it, or taking any other measures for safety that may be requested by the Inspector, the owner or user may appeal the decision of the Inspector to the Manager of the Boiler Safety Program within an acceptable time limit as determined by the Manager of the Boiler Safety Program according to the severity of the violation. The owner/user will be notified of the time limit for appeal in the notice of violation. In case of a disagreement with the Manager of the Boiler Safety Program, an appeal may be filed with the Secretary, who will review the decision and may order another inspection, as the Secretary may deem necessary to decide the issue.

4.6Accident. The owner or user shall notify the Boiler Safety Program when an accident occurs that renders a boiler or pressure vessel inoperative. In the case of a serious accident, as in a personal injury or an explosion, notice shall be given immediately by telephone. No boiler, pressure vessel, or parts thereof involved in the accident, shall be removed or disturbed before an investigation can be conducted, except for the purpose of conserving human life and limiting consequential damage.

5.1Construction Standards. Boilers, pressure vessels, nuclear components and component parts to be installed for use in the State of Delaware, shall be designed, fabricated, inspected, stamped and installed in accordance with current applicable Sections of the ASME Boiler and Pressure Vessel Code, and these Rules and Regulations.

5.2Stamping. Boilers, pressure vessels and nuclear components shall be stamped with the applicable ASME Code stamping and a National Board number, or the ASME Code Symbol and the word ("USER"), and if electrically heated a nationally recognized testing agency, such as, but not limited to the Underwriters Laboratory. Note: Cast Iron or cast aluminum boilers do not require National BoardRegistration. The required stamping shall be visible for inspection and not permanently covered.

5.3State Special. If a boiler, pressure vessel or nuclear component is of special design and can not be built to the ASME Code, and have the ASME Code Symbol, and National Board or USER stampings, a permit for a State Special must be applied for in writing by the Delaware user. Blueprints, design data, calculations and specifications shall be prepared by a Registered Professional Engineer, knowledgeable in the appropriate Code of Construction, and submitted to the Boiler Safety Program prior to construction.

6.1A new boiler or pressure vessel installation, including a reinstalled or secondhand boiler or pressure vessel, shall be installed in accordance withthe current Edition:

6.1.3.1Part CF of CSD-1 shall be met when the installing contractor submits an operational test form CSD-1 or a form containing the same information. This is for boilers over 400,000 Btu/hr.

6.4Installation Registration. The installation of any boiler or pressure vessel within the scope of these rules, and installed in a place of public assembly, shall be registered with the Boiler Safety Program by the installer before the operation of the boiler or pressure vessel. The boiler may be operationally tested prior to obtaining a certificate.

6.5Clearances. All boiler installations shall have adequate clearance which should be 30 inch clearance on all sides or the distance stated in the manufacturer???s specifications. Piping and other obstructions which may impede maintenance or inspection activities shall not be permitted in the clearance area. If the Manufacturer specified minimum clearance is not available, a variance must be obtained from the Manager of the Boiler Safety Program prior to the boilers being installed. All pressure vessels shall have adequate clearance for safe maintenance and inspection.

6.6.1.1Ladders and runways. Steel runway or platform, at least twenty four (24") inches wide, and provided with standard handrails and toe boards on either side, with at least 7" 6" head room, shall be installed across the tops of adjacent boilers, or at some other convenient level, for the purpose of affording safe access to the boilers. All runways shall have at least two (2) means of exit, each exit to be remotely located from the other and connected to a permanent stairway or inclined ladder leading to the floor level.

6.6.1.2Exit from boiler rooms. all All boiler rooms exceeding five hundred (500) square feet of floor area and containing one or more boilers having a fuel burning capacity of 1,000,000 BTU"s shall have at least two (2) means of exit, one of which shall lead outside.

6.7When a standard boiler, pressure vessel, or nuclear component located within this jurisdiction is to be moved outside the jurisdiction for repair, alteration, or modification, it shall be documented on the appropriated "R" form. Copies of all "R" forms shall be forwarded to the Boiler Safety Program. Routine Repairs are not required to be filed with the division.

6.8The installation or operation of nonstandard boilers, pressure vessels, or nuclear components in this jurisdiction without prior permission from the Manager of the Boiler Safety Program is prohibited.

6.9.1Blowoff piping from a power boiler shall not discharge directly into a sewer or interconnected system. A blowoff tank shall be used where conditions do not provide adequate and safe open discharge and shall be placed between the boiler and the sewer or other such system.

6.9.2.1A blowdown tank subject to possible maximum steam boiler pressure shall be constructed for the boiler pressure and stamped in accordance with the ASME Code.

6.9.3.1The outlet from the blowdown tank shall be not less than twice the area of the boiler blowdown pipe, and made to extend internally to within six inches of the bottom of the tank.

6.9.3.2A vent pipe at least twice the diameter of the inlet shall lead to the outside atmosphere. Vents shall be as direct as possible to the outside atmosphere and discharge at a point not less than seven feet above grade. No valve, water pocket, or other obstruction shall be in this line.

6.11.1Owners of Boilers shall conduct preventive maintenance that includes all of the maintenance requirements listed in the boiler, boiler unit, burner, and control device assembly manufacturer"s instructions as well as the monthly inspection requirements of this section. Monthly inspections shall be conducted at least 28 days apart. If any of the requirements conflict with the manufacturer"s instructions, the requirement in the manufacturer"s instructions shall apply.

6.11.4The owner shall record the results of any Boiler testing, inspections, and repairs in a boiler maintenance log. Owners of Boilers shall keep this maintenance log in close proximity to the boiler and make it readily available upon inspection.

7.1Nonstandard high-pressure boilers, which were installed in the State of Delaware prior to January 1, 1924, shall be subject to the rules of the ASME Boiler Code for calculations and installation. Nonstandard pressure vessels installed prior to June 30, 1974, shall be calculated and installed in accordance with ASME Code Section VIII, and the following rules:

7.1.1Factors of Safety. The minimum factor of safety may not be less than 4 for existing installations. The factor of safety may be increased when it is considered necessary by the inspector to insure the operation of the vessel within safe limits. The condition of the vessel and the particular service to which it is subject shall be the determining factors.

7.1.3When a nonstandard boiler, pressure vessel, or nuclear component is removed from this jurisdiction for reason other than repair or alteration, it shall not be brought back and installed within this State.

7.1.5A State Special number may be assigned to a boiler or pressure vessel of nonstandard design. All designs and specifications must be submitted to the Boiler Safety Program for approval and must include:

7.1.5.6If any of the above documentation has been lost, it will be necessary to fulfill the basic requirements by some other means acceptable to the Chief Inspector of the Boiler Safety Program.

8.1.1The Secretary, Chief Inspector of the Boiler Safety Program, Deputy Inspector, Special Inspectors, or members of the Council on Boiler Safety, shall have full access during reasonable hours to any premises in the State, where a boiler, pressure vessel or nuclear component within the scope of these Rules and Regulations is being constructed, installed, connected for use or operated, to ascertain compliance with these Rules and Regulations. Immediate access must be provided upon event of an accident.

8.2.1High-pressure boilers, miniature boilers and high-pressure high temperature water boilers shall receive a certificate of inspection annually. They shall also be inspected internally annually. The external (in service) inspection should be done within six months of the internal inspection.

8.2.2Low-pressure steam heating boilers, hot water heating boilers, hot water supply boilers, and lined water heaters, shall be given a certificate of inspection biennially. This inspection may be an external inspection, unless the Inspector requires an internal inspection. The Inspector, due to operating conditions, may require additional inspections.

8.2.3.2.1Owners of pressure vessels used as air cannons shall maintain manufacturer, ASME, and National Board of Boilers and Pressure Vessels records associated with the air cannon and make them available to the Department within 14 days upon request. Owners of any air cannons introduced to competition after the effective date of these regulations, shall submit such records to the Department with the initial registration documents for the air cannons.

8.2.3.2.7Owners of pressure vessels used as air cannons shall maintain them in a manner that prevents corrosion, such as using compressed air for drying and storing them with the drain valve open when not in use.

8.2.4Thermal Fluid Heaters (Boilers) shall receive a certificate inspection annually. They shall also be externally inspected annually. During the annual inspection, the Relief Devices test history shall be reviewed and safety controls checked. The inspector may require additional inspections due to conditions found.

8.2.5Inspectors shall document the condition of the boiler or pressure vessel at the time of inspection using an inspection report format approved by the Department. This will include taking photographs at the time of inspection when a problem that threatens the life and health of others is identified. These photographs shall be submitted to the Department as part of the inspection report and maintained by the Department.

8.3.1Certificate inspections will be allowed a grace period of one month beyond the normal inspection date, with extensions to the above, granted only by the Manager of the Boiler Safety Program. A current Certificate of Inspection must have a decal attached by the Inspector using the decals provided by the Boiler Safety Program. Violation of this paragraph will subject the owner/user to the penalty, as provided in 7Del.C.Ch 74B.

8.3.2If, at the discretion of the Inspector, a hydrostatic test or any other test is deemed necessary, it shall be made by the owner or user of the boiler or pressure vessel.

8.3.3Sufficient covering of the boiler or pressure vessel shall be removed to satisfy the Inspector that he may determine the conditions of the boiler or pressure vessel. If the covering cannot be removed at that time, the inspector may order the operation of the boiler or pressure vessel stopped until such time as the covering can be removed and proper examinations made.

8.4.1High-pressure boiler internal inspection may be extended to 24 months; and 48 months for waste heat boilers, if the following requirements are met:

8.4.1.2.2Daily analysis of water samples that will adequately show the condition of such water and any elements or characteristics which are capable of producing corrosion or other deterioration of the boiler or its parts.

8.4.1.4Applicable NDE, if required by the Inspector. Records are to be maintained at least six (6) years. In order to qualify for such an extension, a written request to the Manager of the Boiler Safety Program must be made. This extension, when granted, is good until revoked.

8.6.1If an owner or user of equipment, specified by this Section, obtains an insurance policy on such equipment from an insurance company licensed by the Delaware Insurance Commissioner"s Office to insure boilers and pressure vessels, the Special Inspector employed by that insurance company shall conduct the inspection required by this Section.

9.1.1If upon making the requiredinspection, the Inspector finds the boiler,pressure vessel or nuclear installation to be in a safe working order, including all necessary safety devices shall submit a report to the Boiler Safety Program. When the Boiler Safety Program receives the report, either electronically or upon receipt of the inspection report(hard copy) from said Inspector, andthe fee mentioned hereafter paid, shall issue a Certificate of Inspection. The certificate shall be posted on or near the object.

9.1.3On subsequent inspections, the Inspector will attach the decal to the Certificate of Inspection. Any corrections or changes to this inspector"s request form will be circled and changes noted and returned to the Boiler Safety Program. If reports are submitted electronically, no decals or hard copies of report have to be submitted to the Boiler Safety Program.

9.1.4In the event of a violation of these regulations or unsafe condition, the Inspector will indicate on the decal the object ???failed??? and return the inspection request to the Boiler Safety Program. No decal or hard copy of report is required to be submitted if the report is submitted electronically. A decal marked ???failed??? will be left at location if object does not meet requirements for issuance of a certificate.

9.2Certificates for boilers, pressure vessels or nuclear installations. Every Inspector inspecting boilers, pressure vessels or nuclear installations in the State of Delaware shall file with the Manager of the Boiler Safety Program the applicable inspection report within thirty (30) days, after the date of inspection. The report can be submitted either electronically or by a hard copy.

9.3Certificate withdrawn, withheld, or revoked. If an Inspector finds that the boiler, pressure vessel or nuclear installation is not in safe working condition, or is not provided with the necessary safety appurtenances, or if the appurtenances are improperly arranged, the inspector shall immediately notify the owner or user, and the person in charge of the boiler, of the code violations. He The inspector shall report the same to the Manager of Boiler Safety Program. If in the inspector???s judgment, the boiler, pressure vessel, or nuclear installation presents an imminent danger to human health, safety, or property then the inspector may shutdown the unit and place a ???Do Not Operate??? tag on the unit. The owner and/or user shall not operate it the unit or permit it to be operated, until such Certificate has been granted or restored. The owner/operator shall be subject to the Department???s enforcement authorities if code violations are not remedied within 30 days. Upon request the Program Manager may grant an extension.

10.1Installation of pressure relief valves, safety valves and rupture disks shall be in accordance with the appropriate Section of the ASME Code. A hot water supply boiler, including lined water heaters stamped HLW shall have a pressure temperature relief valve marked 210 F.

10.2When any of the safety/relief valves require repairs or adjustments, these adjustments must be made by the manufacturer or an appropriate "VR" stamp repair company, and tested either before reinstallation or immediately upon placing the boiler, pressure vessel or nuclear installation in service.

10.3No person shall load or adjust safety/relief valves in any matter to maintain a working pressure in excess of that stated on the certificate of inspection.

10.6All high pressure boiler safety valves shall be hand tested or bench tested for set pressure and blowdown at the time of inspection or within the maximum allowable inspection interval provided by these regulations. In lieu of bench testing, the hydraulic lift system is acceptable. All high-pressure boiler safety valves for pressures over 400 PSIG shall be overhauled every five(5) years.

10.7All pressure vessel relief valves shall be hand tested or bench tested for set pressure at the time of inspection or within the allowable inspection interval permitted by these regulations. In lieu of bench testing, the hydraulic lift system is acceptable. The frequency may be extended when supported by performance records of the individual user. For liquids or gasses, which are hazardous or costly and in-service testing is impractical, bench testing/ replacement frequency shall be done every five (5) years and documented.

10.8Bench testing is only acceptable if the bench testing apparatus can deliver proper pressure and volume. Sufficient volume should be enough to lift the pressure relief valve fully open.

10.9Pressure vessel relief valves on installations must be overhauled or replaced every four (4) years where there is documented corrosion, deterioration of valve parts, product build up, or the possibility of plugging in the inlet or outlet, or sticking of the disc to the seat.

11.1Antique boilers include any closed vessel manufactured prior to January 1, 1924, and used solely for display and demonstration purposes, in which water is heated or steam is generated by the direct application of heat from the combustion of fuels.

11.1.1An AI Delaware Commissioned Inspector shall inspect antique boilers and remaining material thickness will be determined by a method acceptable to the AI Inspector. The MAWP based on these Rules and Regulations, as determined by a Registered Professional Engineer knowledgeable in power boiler fabrication, shall be submitted to the Manager of Boiler Safety Program for his review and acceptance.

11.1.2.3A safety valve meeting current ASME and National Board requirements set at or below the MAWP, with required relieving capacity, and tested, as required by these regulations. The seals on the valve shall be intact. The outlet of safety valve shall be piped to a safe point of discharge.

11.1.3Approval for operation of an antique boiler will be granted upon successful completion of the above inspection requirements and payment of the fee required. A Certificate will be issued and shall be valid for a period not to exceed 12 months. A fee of $15.00 shall be charged for inspections and a fee of $15.00 shall be charged for the certificate. A current operating certificate shall be posted while in operation.

11.1.4Alternate approval may be given to operate an antique boiler having a valid certificate from another State, whose requirements have been determined by the Boiler Safety Program to meet or exceed the current Edition and Addenda of the NBIC and these requirements National Board Inspection Code 2017, NBBI NB23-2017.

12.2All repairs or alterations to boilers, pressure vessels or piping within jurisdictionallimits,shall be approved by a Delaware commissioned AI an Inspector that has the appropriate National Board Commission & R endorsement. If the shop is located in Delaware then the inspector shall also have a current Delaware Commission and the work shall be performed under his their guidance.

12.5An R2 "Report of Alteration" with a copy of the manufacturer"s data report shall be filed with the Boiler Safety Program, with the Delaware jurisdiction number clearly identified.

12.6Repairs of a routine nature as defined by the NBIC need not have a "Report of Welded Repair" submitted to the Manager of Boiler Safety Program, but this repair documentation must be retained by the owner/user as long as the object remains in service. "Routine Repair" shall be entered in "Remarks" section of the R-1 Form.

12.7Lap Seam Cracks. The shell or drum of a boiler or pressure vessel in which a lap seam crack is discovered along a longitudinal riveted joint shall be immediately condemned and permanently removed from service. Repairs of this type defect are prohibited.

12.9Repair, modification or replacement of nuclear components. Repair, modification or replacement of nuclear components shall be made only by an organization which holds a valid Certificate of Authorization for use of the appropriate National Board nuclear "NR" symbol stamp. Repair, modification or replacement of ASME stamped "NV" pressure relief valves shall be made only by an organization which holds valid National Board Certificates of Authorization for use of the "NR" and "VR" symbol stamps.

12.10Restamping of Boilers and Pressure Vessels shall be in accordance with the current Edition of the NBIC National Board Inspection Code 2017, NBBI NB23-2017 and jurisdictional requirements.

13.1.1The owner and/or user of a boiler, pressure vessel or nuclear installation required to be inspected under these Rules & Regulations shall pay the required fees.

13.3.4Nuclear Installations. The inspection fee is based on actual hourly inspection time at an hourly or daily rate determined by the Manager of the Boiler Safety Program, dependent on the type of qualified personnel necessary to perform the required safety inspections.

14.2Gas Water Heaters Suitable for Potable Water and Space Heating with Input Ratings of 75,000 BTU per Hour or less. In addition to the requirements in section subsection 14.1 of this Section, gas water heaters suitable for potable water and space heating with input ratings of 75,000 BTU per hour or less shall also be constructed and installed in accordance with the American National Standard for Gas Water Heaters, Volume 1, ANSI Z21.10.1, current edition and addenda, including, but not limited to Z21.10.la, current edition and addenda, CSA ANSI Z21.10.1-2014/CSA 4.1-2014 as well as all applicable Federal, State and local laws and regulations. Water heaters covered by this Section are not required to be constructed to the standards set forth in Section IV, ASME Boiler and Pressure Vessel Code, except to the extent required by ANSI Z21.10.1, current edition and addenda CSA ANSI Z21.10.1-2014/CSA 4.1-2014.

14.3Gas Water Heaters Suitable for Potable Water and Space Heating with Input Ratings in excess of 75,000 BTU per Hour but with a Maximum of 200,000 BTU per Hour. In addition to the requirements of subsection 14.1 of this Section, gas water heaters suitable for potable water and space heating, with input ratings in excess of 75,000 BTU per hour, but not more than 200,000 BTU per hour, shall be constructed and installed in accordance with the American National Standard for Gas Water Heaters, Volume III, ANSI Z21.10.3 current edition and addenda ANSI Z21.10.3/CSA 4.3 8th Edition, January 1, 2017, as well as applicable Federal, State and local laws and regulations.

15.1.2An ASME approved relief valve shall be installed set at or below the allowable working pressure of the jacketed cooking kettle with the minimum relieving capacity as required by the manufacturer.

15.1.5There shall be a separate connection, fitted with a stop valve, for venting air or adding water to the jacket (the water may be added while the vessel is not under pressure).

15.1.6There shall be an electric heater control or automatic gas valve controlled by pressure to maintain the steam pressure in the jacket below the safety valve setting.

The Manager of the Boiler Safety Program shall have the authority to grant a variance, on a case by case basis, to those rules and regulations that pertain to the installation of new boilers to replace existing boilers. The variance shall be in writing describing all pertinent information regarding the variance requested and the reason for the request.

When the Boiler Safety Program receives a complaint a boiler or pressure vessel is being operated in an unsafe condition or does not meet codes, an investigation shall be conducted by either a State Deputy Boiler Inspector, or by the inspector employed by the insurance company carrying boiler machinery insurance on the object. A report will be submitted to the Manager of the Boiler Safety Program, and appropriate action will be taken depending on the conditions found.

The application of a NB number to a boiler or pressure vessel after it has been placed in service is not permitted without prior approval of Boiler Safety.

19.1Owner/User Inspector. The Manager shall, upon the request of any company maintaining a Delaware Owner/User Inspection Agency and operating pressure vessels in this State, issue an Owner/User Delaware Commission to an inspector that meets the requirements stated in 20.2 subsection 19.2, the inspector is continuously employed by the company, and satisfactorily passes a written examination based on the requirements of the latest Edition of the Rules and Regulations of the Boiler Safety Program.

19.2.1Examination for a certificate competency as a Delaware Owner/User inspector of pressure vessels shall be held at the office of the Boiler Safety Program or at any location selected by the Manager of the Boiler Safety Program.

19.2.2.1A degree in mechanical engineering plus one year experience in the design, construction, operation, or inspection of high pressure boilers, pressure vessels, or nuclear installations.

19.2.2.2A degree in a branch of engineering, other than mechanical engineering, plus (2) years of experience in the design, construction, operation or inspection of high pressure boilers, pressure vessels, or nuclear installations.

19.2.2.3The equivalent of a high school education plus three (3) years of experience (1) in high pressure boiler, pressure vessel, nuclear construction or repair or (2) as an operating engineer in charge of a high pressure boiler, pressure vessel, or nuclear installation operation; or (3) as an inspector of high pressure boilers, pressure vessels, or nuclear installations.

19.2.3Applications for examination shall be in writing on a form furnished by the Boiler Safety Program stating the school education of the applicant, a list of employers, period of employment and position held with each employer. Applications containing willful falsifications or untruthful statements will be rejected. If the applicant???s history and experience meet with the approval of the Manager of the Boiler Safety Program, the applicant shall be given a written examination dealing with the construction, installation, operation, maintenance, repair and inspection of boilers, pressure vessels, and nuclear installations and their appurtenances. The applicant shall be accepted or rejected on the merits of this examination. If the applicant is successful in meeting the requirements of the examining Board, a Certificate of Competency will be issued by the Manager of the Boiler Safety Program.

19.3.1Within 6 months of the effective date of these regulations, any company which maintains a regularly established inspection department in the State of Delaware, has a written Quality Control manual that is accepted by the Manager of the Boiler Safety Program and reviewed every three years, employs owner/user inspectors qualified under the provisions of subsection 20.1.1 19.2, and desires to inspect pressure vessels for its own use and operation in the State of Delaware shall apply on its letterhead requesting registration.

20.1Non-traditional Inspection Agencies shall maintain a valid Delaware Business License to perform work required by these regulations in the State of Delaware.

20.2Non-traditional Inspection Agencies shall maintain two million dollars of Professional Liability Insurance and submit documentation of this insurance to the Boiler Safety Program annually to perform work required by these regulations in the State of Delaware.

20.3The State of Delaware Boiler Safety Program shall maintain a list of approved Non-traditional inspection agencies and only those approved by the State of Delaware???s Boiler Safety Program shall perform work required by these regulations in the State of Delaware.

If any part of these Rules and Regulations are held invalid, unconstitutional, or otherwise contrary to law, then it shall be severable and the remaining portions hereof shall remain and continue in full force and effect.

Article 1. In General.§ 40.1-51.5. Short title; definitions.As used in this chapter, which may be cited as the Boiler and Pressure Vessel Safety Act, the following terms shall have the meanings set forth in this section unless the context requires a different meaning:

(a) "Boiler" means a closed vessel in which water is heated, steam is generated, steam is superheated, or any combination thereof, under pressure or vacuum for use externally to itself by the direct application of heat from the combustion of fuels, or from electricity or nuclear energy. The term "boiler" shall include fired units for heating or vaporizing liquids other than water where these units are separate from processing systems and are complete within themselves.

2. "High pressure, high temperature water boiler" means a water boiler operating at pressures exceeding 160 pounds per square inch gauge pressure or temperatures exceeding 250 degrees Fahrenheit.

3. "Heating boiler" means a steam or vapor boiler operating at pressures not exceeding 15 pounds per square inch gauge pressure, or a hot water boiler operating at pressures not exceeding 160 pounds per square inch gauge pressure or temperature not exceeding 250 degrees Fahrenheit.(b) "Unfired pressure vessel"

(h) "Contract fee inspector" means any certified boiler inspector contracted to inspect boilers or pressure vessels on an independent basis by the owner or operator of the boiler or pressure vessel.

1972, c. 237; 1974, c. 195; 1986, c. 211; 1993, c. 543; 1996, c. 294.§ 40.1-51.6. Safety and Health Codes Board to formulate rules, regulations, etc.; cost of administration.A. The Board is authorized to formulate definitions, rules, regulations and standards which shall be designed for the protection of human life and property from the unsafe or dangerous construction, installation, inspection, operation, maintenance and repair of boilers and pressure vessels in this Commonwealth.

1972, c. 237; 1973, c. 425; 1985, c. 40.§ 40.1-51.7. Installations, repairs and alterations to conform to rules and regulations; existing installations.(a) No boiler or pressure vessel which does not conform to the rules and regulations of the Board governing new construction and installation and which has been certified by the Board shall be installed or operated in this Commonwealth after twelve months from July 1, 1973. Prior to such date no boiler or pressure vessel shall be installed and operated unless it is in conformity with the rules and regulations established pursuant to this chapter which were in existence on July 1, 1972.

(b) This chapter shall not be construed as in any way preventing the use, sale or reinstallation of a boiler or pressure vessel constructed prior to July 1, 1972, provided it has been made to conform to the rules and regulations of the Board governing existing installations prior to its reinstallation or operation.

5. Hot water supply boilers, water heaters, and unfired pressure vessels used as hot water supply storage tanks heated by steam or any other indirect means when the following limitations are not exceeded:

13. Pressure vessels used for transportation or storage of compressed gases when constructed in compliance with the specifications of the United States Department of Transportation and when charged with gas marked, maintained, and periodically requalified for use, as required by appropriate regulations of the United States Department of Transportation;

16. Coil type hot water boilers without any steam space where water flashes into steam when released through a manually operated nozzle, unless steam is generated within the coil or unless one of the following limitations is exceeded:

1972, c. 237; 1977, c. 301; 1978, c. 355; 1986, c. 211; 1988, c. 289; 1990, c. 226; 1993, c. 543; 1999, c. 335; 2000, c. 898; 2012, c. 332; 2013, c. 171.§ 40.1-51.9. Employment and appointment of inspectors and other personnel; inspections; reports.The Commissioner is authorized to employ persons to enforce the provisions of this chapter and the regulations of the Board. He shall be authorized to require examinations or other information which he deems necessary to aid him in determining the fitness, competency, and professional or technical expertise of any applicant to perform the duties and tasks to be assigned.

The Commissioner is authorized to appoint a Chief Inspector and to certify special inspectors who shall meet all qualifications set forth by the Commissioner and the Board. Special inspectors shall be authorized to inspect specified premises and without cost or expense to the Commonwealth. Reports of all violations of the regulations or of this chapter shall be immediately made to the Commissioner. Other reports shall be made as required by the Commissioner.

1974, c. 195; 1986, c. 266; 1997, c. 212.§ 40.1-51.9:2. Financial responsibility requirements for contract fee inspectors.A. Contract fee inspectors inspecting or certifying regulated boilers or pressure vessels in the Commonwealth shall maintain evidence of their financial responsibility, including compensation to third parties, for bodily injury and property damage resulting from, or directly relating to, an inspector"s negligent inspection or recommendation for certification of a boiler or pressure vessel.

C. The Safety and Health Codes Board is authorized to promulgate regulations requiring contract fee inspectors, as a condition of their doing business in the Commonwealth, to demonstrate financial responsibility sufficient to comply with the requirements of this chapter. Regulations governing the amount of any financial responsibility required by the contract fee inspector shall take into consideration the type, capacity and number of boilers or pressure vessels inspected or certified.

G. It is not a defense to any action brought for failure to comply with the requirement to provide acceptable evidence of financial responsibility that the person charged believed in good faith that the owner or operator of an inspected boiler or pressure vessel possessed evidence of financial responsibility accepted by the Chief Inspector or the Board.

1996, c. 294.§ 40.1-51.10. Right of access to premises; certification and recertification; inspection requirements.A. The Commissioner, his agents or special inspectors shall have free access, during reasonable hours to any premises in the Commonwealth where a boiler or pressure vessel is being constructed, operated or maintained, or is being installed to conduct a variance review, an owner-user inspection agency audit, an emergency repair review, an accident investigation, a violation follow-up, and a secondhand or used boiler review for the purpose of ascertaining whether such boiler or pressure vessel is being constructed, operated or maintained in accordance with this chapter.

B. On and after January 1, 1973, no boiler or pressure vessel used or proposed to be used within this Commonwealth, except boilers or pressure vessels exempted by this chapter, shall be installed, operated or maintained unless it has been inspected by the Commissioner, his agents or special inspectors as to construction, installation and condition and shall be certified. A fee as set under subsection A of § 40.1-51.15 shall be charged for each inspection certificate issued. In lieu of such fees both for certification and recertification, an authorized owner-user inspection agency shall be charged annual filing fees as set under subsection A of § 40.1-51.15.

1. Power boilers and high pressure, high temperature water boilers shall receive a certificate inspection annually and shall also be externally inspected annually while under pressure if possible;

4. Pressure vessels not subject to internal corrosion shall receive a certificate inspection at intervals set by the Board, but internal inspection shall not be required of pressure vessels, the content of which are known to be noncorrosive to the material of which the shell, heads or fittings are constructed, either from the chemical composition of the contents or from evidence that the contents are adequately treated with a corrosion inhibitor, provided that such vessels are constructed in accordance with the rules and regulations of the Board;

F. If, at the discretion of the Commissioner, a hydrostatic test shall be deemed necessary, it shall be made by the owner or user of the boiler or pressure vessel.

G. All boilers, other than cast iron sectional boilers, and pressure vessels to be installed in this Commonwealth after the six-month period from the date upon which the rules and regulations of the Board shall become effective shall be inspected during construction as required by the applicable rules and regulations

8613371530291

8613371530291