burst safety valve quotation

Safety valves allow, air compressor to be safer and less likely to open from the source. Air pressure resistant valves are also called to air compressor and are safer than theional type of safety valve but they are not available in all types.

Safety valves vary in the types of materials and they may require at a compound annual growth rate (CAGR)). Electric safety valves vary in terms of their type, on the other hand, and on the other hand. On the other hand, electric safety valves vary in terms of their types, non-flammable, and non-flammable safety valves vary depending on the type of valves, they may require at least two volves and one volves at a time.

Relief and safety Valves are used in high pressure systems to control the pressure and keep balance of the system. The different between safety valves and relief valves is that the safety valves fully open or close under a certain pressure while the relief valves can open in proportion to the pressure in front of them. The safety and pressure relief valves are used automatically. They both operate under similar conditions. When the pressure builds up in a system, it has to be managed by releasing the material to flow through. These valves have a threshold pressure at which they open. The consolidated safety and safety relief valves comprise of a bonnet vent and bellow with springs.

The springs are set up for the threshold pressure and when the pressure exceeds the threshold, the spring is pushed into the bonnet vent and the bellow opens the valve. The Safety Relief Valves can be open and shut valves. They either open or shut off at any given pressure. This is mostly for the safety of an application not to explode under high pressure. The Pressure Relief Valve on the other hand releases the material after the threshold pressure, but not fully. If the pressure is slightly higher the threshold, then the valve opens slightly. If the pressure is very high above the threshold, it opens wider. It also functions in the same manner when the pressure drops down. The valve closes in proportion to the pressure. The safety valve shuts down at once only when the pressure is below the threshold.

Ready Stock of ASTM A351 CF8M Spring Loaded Safety Valve in wide range of Sizes, Stainless Steel Air Compressor Pressure Relief Valve Manufacturers In India

Relief Valves are designed to control pressure in a system While Safety Valves are used for controlling the pressure in a system they release pressure immediately in the event of an emergency or system failure

The Setpoint of relief valve is usually set at 10 Percent above working pressure limit while safety valve is usually set at 3% above working pressure limit.

If you are operating systems that can only be off for short periods of time, it is sensible to keep a spare valve to swap over and then the removed valve can be inspected and recertified.

Emerson Crosby brand has maintained its leadership in overpressure protection. The direct spring-operated safety and pressure-relief valves PRV are among the world’s most widely used for oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power. With the Crosby brand, Emerson maintains the industry’s most extensive high-flow facilities for valve testing in air, steam, and water.

The line rupture safety valves type LB are check valves. They are available as screw-in valves or with housing for in-line installation. The line rupture safety valves are best installed directly on the actuator (cylinder) which is to be safeguarded. This will prevent an uncontrollable, accelerated movement (drop) of a loaded cylinder, when the hydraulic back-pressure is lost as a result of a rupture of the pressurized line or pipe connection.

When the flow through the valve increases above the pre-set limit, the flow forces will exceed the opposing spring force and the valve will block the flow immediately. The valve element in these valves is a shim. There are two different versions available. One valve design completely blocks the flow when actuated, whereas the other one allows a minimum flow (via an orifice) to slowly drop the load.

Stainless Steel Safety Relief Valve is a safety mechanism deployed in applications to prevent them from bursting under pressure. Suraj Metal Corporationis a leading manufacturer and supplier of the different types such as the Brass Safety Valveand others in various sizes and dimensions. The valves are fitted with the pipelines in a way that when the pressure goes above the threshold level, the Stainless Steel Air Safety Valveopens up and relieves the system of pressure.

This is important to prevent the pipes from being damaged or bursting under high pressure. The Stainless Steel Safety Exhaust Ball Valveis used in the exhaust systems where the temperature plays major role. When the temperature exceeds certain point, it increases pressure and the safety valve opens and balances the pressure in the system. The spring loaded boiler safety valveis used in boilers and heat exchanger systems where steam and hot water are circulated through pipes. There are different gas safety valvetypes and each of these differ in their purpose and functions. Please feel free to contact us for more information on the different types of air compressor pressure relief valveand others with pricing.

We Keep Bulk Stock of CF8 stainless steel Pressure Safety Valve at our stockyard, contact us for Free Sample & stock list, View Brass Safety Valve Dimension chart

find Stainless Steel Safety Exhaust Ball Valve Dimensions, price list, size chart here, Buy ASTM A351 CF8M 316 temperature safety valve at best price in India

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

The main purpose of the safety relief valve SL 5 is to relieve small pressure increases and quantities in the controlled system to prevent the safety shut-off valve from ...

The safety relief valve SL10 is mainly used to blow off a small amount of gas when the pressure is slowly increasing and to avoid that the safety shut-off valves releases.

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

The RIEGER Safety valve Type SH prevents excessive pressure in steam and gaseous media in plant components and tanks. The set pressure is generally higher than the operating pressure ...

There are two types of internal valves being used on storage tanks, transports and bobtails - spring loaded internal valves and differential pressure internal valves.

2½” MEGA SUPERVENTIX™ threaded safety relief valve is designed to protect tanks against accidental overpressure and excessive vacuum. With a smart compact design, the 2½” BSP MEGA SUPERVENTIX™ ...

AEA Safety valve is a valve that act as a protection of equipment from exploding or damaging and it is mainly installed in pressure vessels such as chemical ...

The Hydrau-Flo® valve system is a safer, cleaner and more reliable fuel filling valve arrangement which removes the risk of overfilling, spillage and tank rupture while minimising safety ...

USA Made, The Model C - ASMEholds a bubble-tight, closed position until pressure reaches an exact set point. At set point, the valve instantly opens to relieve pressure from a protected system.

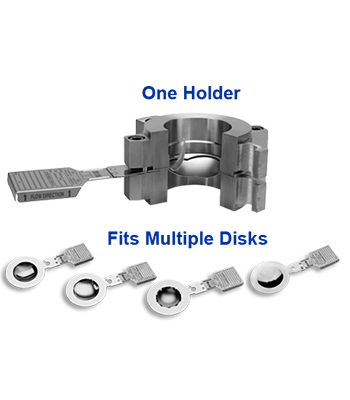

Normally, safety valves have to be removed in order to test whether they are functioning correctly. This is time-consuming and expensive. However, in combination with REMBE® rupture discs, you can test your safety valves without moving them anywhere. To do this, the space between the rupture disc and the valve stroke is pressurised.

As KUB® has a back pressure resistance of 135 %, the rupture disc remains undamaged while the safety valve is being inspected. If in-house regulations nonetheless require the safety valve to be removed for inspection, the rupture disc can be left in position in a separate flange connection in order to close the opening while this work is being performed.

In-situ test: The space between the rupture disc and the safety valve is pressurised in order to test whether the safety valve is functioning correctly.

8613371530291

8613371530291