burst safety valve for sale

Improved Safety:This blow off valve which is designed for old brass style bottle valves provides a layer of protection against rising bottle pressure. If the nitrous bottle pressure reaches 3000 PSI the relief disk will burst allowing the nitrous to exit the bottle reducing pressure.

Meet NHRA Regulations:NHRA regulations require nitrous bottles to be outfitted with a pressure relief valve that releases bottle pressure when it becomes to high. This relief valve and rupture disk meet the requirements of the NHRA and is required to pass tech inspection at most tracks.

Application:This valve is easily installed on an accessory port of a nitrous bottle valve and includes a rupture disk that opens at 3000 PSI. A blow down tube can be added to the valve using the 8AN external threads on the exposed end.

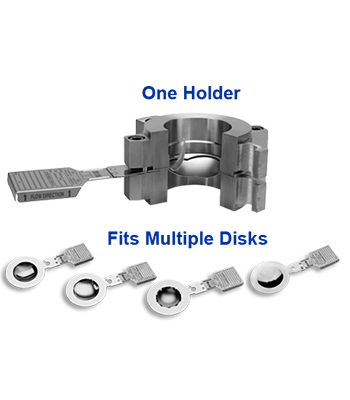

Standard rupture discs are available from stock in burst pressures as listed in the chart below. All pressures through 20,000 psi are shaded. These discs are 316 stainless steel (except for 1,000 psi which are inconel) and may be used with any of the safety heads shown. Note that these rupture discs are supplied with a range of plus 6% and minus 3% of specified burst pressure. Samples of each batch are then tested and typically the actual average burst pressure is stamped on an accompanying metal tag. There is a +/- 5% burst tolerance applied after the burst pressure has been established. Factors influencing rupture disc life include corrosion, metal fatigue, and cyclic effects. Periodic replacement is recommended to prevent premature failure.

Normally, safety valves have to be removed in order to test whether they are functioning correctly. This is time-consuming and expensive. However, in combination with REMBE® rupture discs, you can test your safety valves without moving them anywhere. To do this, the space between the rupture disc and the valve stroke is pressurised.

As KUB® has a back pressure resistance of 135 %, the rupture disc remains undamaged while the safety valve is being inspected. If in-house regulations nonetheless require the safety valve to be removed for inspection, the rupture disc can be left in position in a separate flange connection in order to close the opening while this work is being performed.

In-situ test: The space between the rupture disc and the safety valve is pressurised in order to test whether the safety valve is functioning correctly.

Hansen rupture disc assemblies (RDAs) are used to indicate which pressure-relief valve has discharged. A pressure-relief valve will re-seat after discharging. However, a rupture disc remains open after bursting. (A rupture disc is not a stand alone safety device.) An installed pressure gauge or switch (required by code) provides a visual or electronic indication that the rupture disc has burst.

Also, rupture disc assemblies provide a hermetic seal to help eliminate any possibility of minute losses of refrigerant via pressure-relief valve seat materials. Hansen rupture disc assemblies are designed with a double-weld construction. There are no gaskets to leak. The rupture disc inside the assembly is patented hermetically welded to the body and mechanically isolated from any pipe stress. A separate body weld seals the assembly. This design helps eliminate internal and external leaks and ensures that the disc will burst at its design pressure.

Hansen rupture disc assemblies (RDAs) are used to indicate which pressure-relief valve has discharged. A pressure-relief valve will re-seat after discharging. However, a rupture disc remains open after bursting. (A rupture disc is not a stand alone safety device.) An installed pressure gauge or switch (required by code) provides a visual or electronic indication that the rupture disc has burst.

Depending on the application, relief valves can vary in connection size from DN20 (¾”) to DN125 (5”) and can provide pressure only or combined pressure and vacuum relief.

Standard connections are flanged or threaded and we have a selection of hygienic fittings. We can manufacture lined and coated relief valves for corrosive cargoes, and we supply a wide range of ancillaries such as flanges, flame arresters, cowls, burst discs and manometers.

The primary purpose of a pressure relief valve is to protect life, property and the environment. Pressure relief valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of pressure relief valves differs depending on the main type or loading principle of the valve. The main types of pressure relief valves are spring-loaded, weight-loaded and controlled pressure relief valves.

Regardless of the type or load, pressure relief valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

8613371530291

8613371530291