consolidated safety valve distributors factory

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Pioneer’s cutting-edge Baker Hughes Consolidated relief valves offer Green Tag Center (GTC) support to help your high-pressure safety valve operate efficiently. We offer comprehensive audit programs to validate your product, so the solution we provide for your facility is built to last. Safety relief valves function as the main protection point against dangerous substances; it’s crucial the system you have in place is operating to its optimal potential. Baker Hughes Consolidated safety valves offer styles, sizes, options, and configurations to fit seamlessly into your existing environment for optimal performance.

Chalmers & Kubeck –provides prompt delivery from one of the largest pressure relief valve inventories available anywhere. We have in excess of $10 Million in new Baker Hughes Consolidated * pressure and safety relief valves and OEM replacement parts in our C&K family of companies plus an additional $50 Million available from our Green Tag network associates. Strategically located,our knowledgeable, factory trained technicians, are available 24/7 to provide prompt, factory authorized repair service in both our shops or at the customer’s plant site. Territorial restrictions apply.

The Consolidated Series 3500 Electromatic Ball Valve (EBV) is designed to provide automatic or manual overpressure protection for steam boilers, and can also be used to assist start-up and shut-down…

ASME Section I and VIII approved, the Consolidated Type 2700 steam safety valve is configured to meet the specific requirements of the co-generation and waste-to-energy segments.

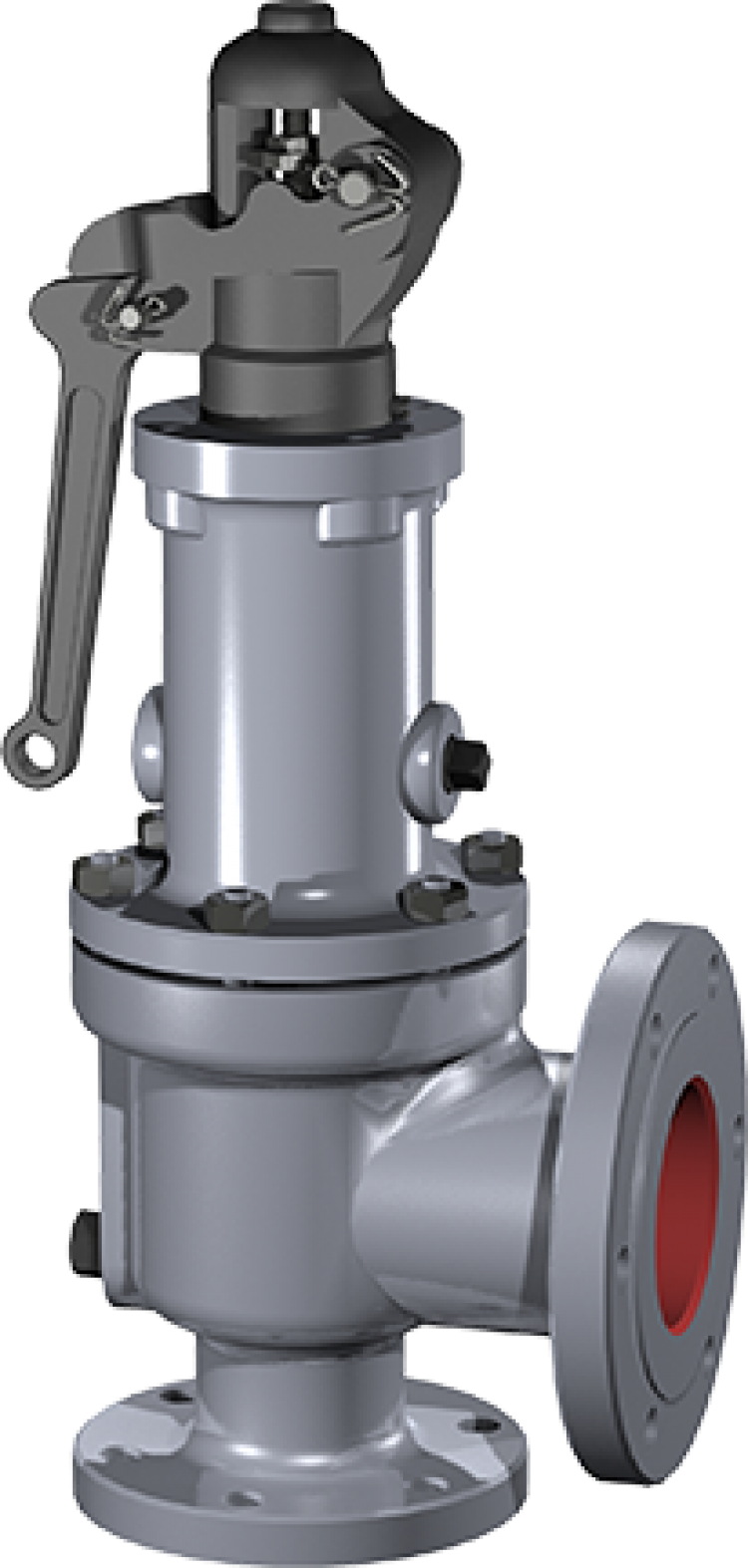

The Consolidated Type 1811 is a cost effective, high capacity flanged steel safety valve that offers seat tightness and high performance making it a solution well-suited for steam service applications.

Suitable for steam and other compressible fluid applications, the Consolidated Type 1541 and 1543 safety valves are ASME Section I and VIII approved. They are most commonly used in pharmaceutical,…

The Consolidated Type 1511 safety valves are designed for low pressure steam heating boilers, steam generators and air applications. This valve is ASME Section I and VIII approved.

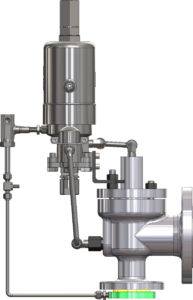

The Type 3900 modular pilot-operated safety relief valve (MPV) features a separate, non-flowing pilot sub-assembly design making it well-suitable for use with both compressible and incompressible fluids. Optional pilot valve…

The Consolidated Type 1982 conventional process safety relief valve provides seat tightness and blowdown performance for vapor, liquid and steam applications. It is well-suited for applications requiring high relief capacity…

The Consolidated 19000 Series valve provides quality performance in seat tightness, capacity, and blowdown on most media. It surpasses ASME code requirements and is CE compliant to European PED specifications…

The first valve of its size capable of handling liquid and gas interchangeably without adjustments while remaining stable, the Type 1900 safety relief valve offers an innovative solution for multi-phase…

Consolidated Maxiflow high pressure safety valves are premium products that are installed on many power generating stations worldwide to help protect boilers from overpressure conditions. With a proven design, the…

Features: Consolidated Maxiflow® high pressure safety valves are premium products used on a majority of power generating stations worldwide to protect boilers from overpressure conditions.

Maxiflow valves are high capacity, Thermodisc® seat, spring loaded safety valves designed for sub critical steam service of 3000 psig at 1200 degrees F, and also for supercritical steam service of 4500 psig at 1050 degrees F. All valves in this series are produced to exceed AME requirements to minimize steam losses.

Features: Consolidated Electromatic relief valves provide manual or automatic overpressure control by the plant operator. These electrically actuated safety devices are utilized on superheated and saturated steam applications at sub critical and supercritical pressures to 4500 psig.

Use of Electromatic relief valves provides the plant operator with a control system that can instantaneously open or close a pressure relief valve on a distantly located header or drum. This advantage results in the capability of accurately balancing boiler operations at peak load conditions, while extending operating life of super heater safety valves.

Features: Consolidated type 2700 safety valves are high capacity, spring loaded valves designed specifically for the co-generation, independent power production and industrial boiler markets. Consolidated’s well known Thermodisc Seat design provides leak tight operation at 94% of the valve’s set pressure. The valves are available in ANSI 900 and 2500 classes at temperatures up to 1050 degrees F. The 2700 is approved for ASME Code Section I and VIII applications.

Features: Consolidated 3900 series pilot operated valves are utilized for the process and general industrial market with inlet sizes ranging from 1″ to 8″. Pressure range is from 15 psig through 3750 psig.

Consolidated pilot operated valves are available in pop type non-flowing, and modulating type flowing and non-flowing designs to meet the most rigorous requirements of the process and gas transmission industries. This product line complies with ASME Code Section VIII.

Features: Consolidated 1900 series steel flanged safety relief valves are designed for gas, vapor, steam and liquid service. Pressure classes range from ANSI 150 to 2500, with temperature ratings up to 1000 degrees Fahrenheit.

Valves are available as standard with bellows for back pressure compensation as well as various soft seating materials for maximum seat tightness. Designs for H2S service are also standard. All 1900 series valves are provided with stainless steel internal parts, and are built to meet ASME Code Section VIII requirements.

Features: Consolidated safety relief valves are designed for general service applications. Sometimes referred to as “portable,” this valve series also may be supplied with flanged or other connections. Valves are closed bonnet, spring loaded with connections from 1/2′ to 2′.

The 1990/1982 series is available up to 800 degrees F with a pressure limit of 8500 psig. Specific models are supplied for H2S as well as all stainless steel construction. Valves comply with ASME Code Section VIII.

Dresser Flow Solutions is a full service provider of dependable pressure relief valve solutions meeting all applicable ASME requirements throughout the energy industry. Dresser offers Consolidated safety valves and safety relief valves for these extremely important applications.

The Consolidated product portfolio includes a broad range of spring-loaded and pilot-operated designs, including established market leading products such as the Maxiflow® high-pressure safety valve and the 1900 safety relief valve. These innovative and high-performance pressure relief solutions are based on over 100 years of successful application experience

The CONSOLIDATED Pressure Relief Valve has been a leader in the industry since 1879, thus offering over a century of experience in design, engineering and product manufacture.

CONSOLIDATED�S history of dependable and reliable valve service assures that today�s products and designs are consistent with the industry�s current requirements. Rigid manufacturing standards controlled by an ASME approved Quality Assurance Program and a certified/registered ISO 9001 Quality Assurance Program ensure that each valve will be manufactured in accordance with established design criteria and tested for functional performance. This quality-controlled manufacturing and test program assures that each valve manufactured will provide long and reliable service.

CONSOLIDATED ASME Code Sections I and VIII Spring Loaded Pressure Relief Valves have been flow tested in accordance with the applicable ASME Code rules for the establishment of rated capacities and are listed in The National Board of Boiler and Pressure Vessel Inspectors publication Pressure Relieving Device Certifications.

Valve Sales Inc. (VSI), and Baker Hughes have partnered to distribute, service, and repair the complete line of Consolidated pressure relief valves. VSI’s service and distribution agreement with Consolidated covers the entire state of Oklahoma, southern Kansas, and the Northwest corner of Arkansas.

Announcing the new agreement, Chris Chernisky, President of VSI said, “Our customers have asked us for a valve line they can trust, and we are excited to be able to deliver on that request. The Tulsa-based Center of Operational Excellence will now become a Consolidated Green Tag Center. That means its customers can expect factory-trained technicians, expert technical support, and local inventory of OEM valves and parts for quick delivery.”

Consolidated has the most diversified portfolio of safety and pressure relief valves in the industry, including the innovative technologies of the 1900-DM (Dual Media), and 2900 Gen II pilot-operated safety relief valve. In addition to this best-in-class product line, VSI has the capability to service valves both in-house and on-site. The MOBILELAB is fully equipped with testing, machining, and repair capabilities. “We can dispatch the MOBILELAB quickly for tight turnarounds or emergency service, which is a very valuable resource to our customers,” Chernisky said.

VSI is your premier source for control valves, pressure relief valves, and safety relief valves. Our factory-certified experts are on-call 24/7 for repairs, testing, sizing & selection, replacement, and installation.

As your trusted source for factory-certified service solutions and consistent value and quality, VSI offers excellent customer service and world-class products and services. VSI has been focused on a legacy of quality and service since its inception in 1975 in Oklahoma City by founder Bill Campbell. Over the years, VSI has expanded its footprint to include four locations, offering service, repair, installation, and custom solutions across the United States. We offer excellent customer service, best-in-class products, and a wide variety of solutions for the process industry. VSI is the premier source for safety valves, pressure relief valves, control valves, and actuation products and services. Contact us to find out how we can help you.

Adapt almost any rotary actuator to a linear valve. Converting pneumatic actuation to electric helps increase operational efficiency and lower emissions.

VSI is a Consolidated™ Green Tag Center™ offering factory-certified repairs, installation, maintenance, and the full range of Consolidated pressure and safety relief valves. We have in-house certified technicians and product experts, and a large inventory to ensure fast delivery.

Our factory-certified and safety-trained, field service technicians are ready to be dispatched to your site. Capabilities include optimization, repair, and maintenance on pressure relief valves, safety valves, control valves, line valves, and actuation.

With decades of shop and field service experience, VSI is an extension of your process control team. VSI is a Consolidated™ Green Tag Center™ and holds a VR Stamp from the National Board of Boiler and Pressure Vessel Inspectors for our Tulsa, OK, location.

The entire team at VSI has always been able to meet my needs and always exceeds my expectations. I have a great relationship with both the sales and service teams they are always ready to answer technical questions and provide excellent advice on ways to solve problems in the field and are always ready with solutions no matter how obscure or unusual the problem. VSI is more than ready and able to meet all my valve needs at any given moment.

VSI has been helpful in many ways, from greasing valves, valve repair, valve replacement, and training our guys as well. We can’t say enough about quotes, labor support, material delivery time, and billing. Aaron has helped us out of several jams over the years and we appreciate it.

Valve Sales Inc. provides outstanding service and support for all of our valve needs. Their dedication to quality and consistency allows our equipment to run more reliably and improves overall performance of our facility. Our goal is to provide consistent high performing products to our customers and VSI allows us to achieve this goal.

VSI has rebuilt our pressure relief valves here at [our processing plant] for several years now and I have always been very pleased with their service and quality of work. The work is always completed on time and we have had no reliability issues with the valves they’ve worked on. It’s always a pleasure working with VSI and I look forward to continuing the relationship.

TULSA, OK – August 31, 2022 - Valve Sales Inc. (VSI), and Baker Hughes have partnered to distribute, service, and repair the complete line of Consolidated™ pressure relief valves. VSI’s service and… Read More

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

8613371530291

8613371530291