consolidated safety valve distributors in stock

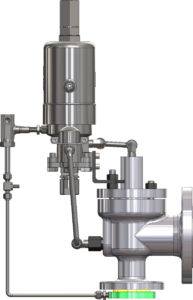

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

Pioneer’s cutting-edge Baker Hughes Consolidated relief valves offer Green Tag Center (GTC) support to help your high-pressure safety valve operate efficiently. We offer comprehensive audit programs to validate your product, so the solution we provide for your facility is built to last. Safety relief valves function as the main protection point against dangerous substances; it’s crucial the system you have in place is operating to its optimal potential. Baker Hughes Consolidated safety valves offer styles, sizes, options, and configurations to fit seamlessly into your existing environment for optimal performance.

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

ASME Codes require that a lifting lever must be supplied with the valve for steam, air, and hot water service over 140ºF. The ASME Codes recommend that packed lifting levers be used. However, they are not mandatory. Threaded caps can be used on non-code gas and liquid applications. Select options from drop down menu, enter set pressure, then add to cart.

We stock all Kunkle safety valve and pressure relief valve products in large quantities for immediate shipment. Although Kunkle Valve is our largest inventory item, we also stock Consolidated safety valves and pressure relief valves, Farris, Crosby, Conbraco, and many others. Another option is our remanufactured valves and safety valve parts.

VSI is your premier source for control valves, pressure relief valves, and safety relief valves. Our factory-certified experts are on-call 24/7 for repairs, testing, sizing & selection, replacement, and installation.

As your trusted source for factory-certified service solutions and consistent value and quality, VSI offers excellent customer service and world-class products and services. VSI has been focused on a legacy of quality and service since its inception in 1975 in Oklahoma City by founder Bill Campbell. Over the years, VSI has expanded its footprint to include four locations, offering service, repair, installation, and custom solutions across the United States. We offer excellent customer service, best-in-class products, and a wide variety of solutions for the process industry. VSI is the premier source for safety valves, pressure relief valves, control valves, and actuation products and services. Contact us to find out how we can help you.

Adapt almost any rotary actuator to a linear valve. Converting pneumatic actuation to electric helps increase operational efficiency and lower emissions.

VSI is a Consolidated™ Green Tag Center™ offering factory-certified repairs, installation, maintenance, and the full range of Consolidated pressure and safety relief valves. We have in-house certified technicians and product experts, and a large inventory to ensure fast delivery.

Our factory-certified and safety-trained, field service technicians are ready to be dispatched to your site. Capabilities include optimization, repair, and maintenance on pressure relief valves, safety valves, control valves, line valves, and actuation.

With decades of shop and field service experience, VSI is an extension of your process control team. VSI is a Consolidated™ Green Tag Center™ and holds a VR Stamp from the National Board of Boiler and Pressure Vessel Inspectors for our Tulsa, OK, location.

The entire team at VSI has always been able to meet my needs and always exceeds my expectations. I have a great relationship with both the sales and service teams they are always ready to answer technical questions and provide excellent advice on ways to solve problems in the field and are always ready with solutions no matter how obscure or unusual the problem. VSI is more than ready and able to meet all my valve needs at any given moment.

VSI has been helpful in many ways, from greasing valves, valve repair, valve replacement, and training our guys as well. We can’t say enough about quotes, labor support, material delivery time, and billing. Aaron has helped us out of several jams over the years and we appreciate it.

Valve Sales Inc. provides outstanding service and support for all of our valve needs. Their dedication to quality and consistency allows our equipment to run more reliably and improves overall performance of our facility. Our goal is to provide consistent high performing products to our customers and VSI allows us to achieve this goal.

VSI has rebuilt our pressure relief valves here at [our processing plant] for several years now and I have always been very pleased with their service and quality of work. The work is always completed on time and we have had no reliability issues with the valves they’ve worked on. It’s always a pleasure working with VSI and I look forward to continuing the relationship.

TULSA, OK – August 31, 2022 - Valve Sales Inc. (VSI), and Baker Hughes have partnered to distribute, service, and repair the complete line of Consolidated™ pressure relief valves. VSI’s service and… Read More

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

These valves come from many of the top brands, like Titan, Apollo, Milwaukee, Consolidated Safety Valves, Jayco and others, so you can always rely on us for high-quality options. In fact, with more than 10,000 SKUs in stock we can supply 97 percent of orders for pipes, valves, fittings and other pipefitting products in their entirety. We’ll also provide integrated supply services for any of the other supplies you need as a member of Affiliated Distributors and supplyFORCE. Through these organizations, you can find all the MRO materials you need with services from reliable, local suppliers like FIP, wherever your business operates.

For more information on our selection of relief valve products and other PVF supplies, contact FIP today. Our company proudly serves customers in Orlando, Miami, Clewiston, Tampa and all other Florida cities.

Renew-CVG specializes in industrial valve parts and repair services for the power, steel, refining, paper and chemical industries. Based in both Monroe, MI, and Cleveland, OH, our technical staff brings more than 100 years of combined experience to every customer we serve. We have earned a trusted reputation in the industry by maintaining close working relationships with our customers" engineering and maintenance staffs in order to address fluid handling challenges and provide customized process solutions.

Established in 1960 by Oscar "Dale" Blair, the original Renew Valve began repairing valves for Detroit Edison at the two local power plants. Over the next 20 years, it became a valuable supplier to the entire Detroit Edison system, both in machining and valve repair and new valve replacements. The company built up a complete machine shop and testing facility, manufacturing parts when needed for the valves, pumps, and boilers for the growing number of customers in the Detroit area.

Founded in Cleveland by the George Ruf family in 1857, the original Cleveland Steam Gauge Company manufactured a line of steam and vacuum pressure gauges and maintained a complete machine shop which manufactured parts when needed for the valves, pumps and boilers for the growing number of steamships then navigating the Great Lakes.

In 1965, Vernon Schill, Dan Cardina and Anthony Brock purchased the company and focused more on valve repair – becoming the recognized authority on all types of gate, globe, ball, check, plug and control valves. It became a founding member of the National Board "VR" Safety Relief Valve Repair certification program.

In 2004, Renew Valve & Machine Company and Cleveland Valve & Gauge joined forces. Together they have become the recognized authority on all types of gate, globe, ball, check, plug and control valves in Michigan, Ohio and Indiana. It was a founding member of the National Board "VR" Safety Relief Valve repair certification program as well as an early constructive Green Tag Service Center for Dresser Industries and their Consolidated, Dewrance, and Hancock valve product lines.

Whether it"s a specific valve component, a complex Infield machining project, an obsolete valve part fabrication, a pre-shutdown valve survey or a packing or gasketing solution, our team is available to address you flow control challenge on-site or at our repair facility.

Baker Hughes announces that Valve Sales Inc. (VSI) will now distribute, service, and repair its complete line of Consolidated pressure relief valves. VSI’s service and distribution agreement with Consolidated covers the entire state of Oklahoma, southern Kansas, and the Northwest corner of Arkansas.

Announcing the new agreement, Chris Chernisky, President of VSI said, “Our customers have asked us for a valve line they can trust, and we are excited to be able to deliver on that request. The Tulsa-based Center of Operational Excellence will now become a Consolidated Green Tag Center. That means its customers can expect factory-trained technicians, expert technical support, and local inventory of OEM valves and parts for quick delivery.”

Consolidated has a diversified portfolio of safety and pressure relief valves, and has the capability to service valves both in-house and on-site. The company’s MOBILELAB is fully equipped with testing, machining, and repair capabilities. “We can dispatch the MOBILELAB quickly for tight turnarounds or emergency service, which is a very valuable resource to our customers,” Chernisky said.

“Many variations in valve and actuator dimensions and characteristics have come into play especially now that we have worldwide vendors,” said Paul Souza, training manager at AUMA Actuators in a presentation at the Valve Manufacturers Association Virtual Valve Forum in November 2020.

While presenting in a recent VMA Valve Basics 101 Course in Houston, I found myself in a familiar role: explaining solenoid valves (SOVs) to attendees. (I work with solenoids so much that one VMA member at that conference joked that I needed to be wearing an I Heart Solenoids t-shirt). During the hands-on “petting zoo” portion of the program, which involves smaller groups of attendees, one of the most frequently asked questions I get from people came up: What’s the difference between direct-acting and pilot-operated SOVs, and how do we make a choice?

8613371530291

8613371530291