cryogenic safety valve factory

Conventional Safety Relief Valve is used in many industries for protection against high pressure. This valve is used in the gas or liquid industries to control the pressure for high safety standards. Conventional Safety Relief Valve is used for the safety of various pressure devices like a tank, piping, boiler etc. Mainly the Conventional Safety Relief Valve is used to save property and life.

Cryogenic Safety Valves Type 06011 is made with stainless steel. It is provided as a safety device for protection against thermal expansion in pipework ...

HEROSE cryogenic safety valves are certified to global certifications for CN, TR CU and ASME. Thus they can be used worldwide, regardless of where the system is installed later. Cryogenic safety valves are available in sizes from DN6 to DN50 and secure pressures up to 550 bar, at operating temperatures of -270°C to +400°C. The safety valves are manufactured primarily in stainless steel but also in bronze and brass.

Please find the cryogenic safety valves in the product choice below. You can combine different product characteristicsto find your cryogenic safety valve better.

The Cryogenic Relief Valve series is designed for use on Air Force and Navy liquid oxygen converters as well as other cryogenic systems. Valves are vailable in a wide range of pressure settings to accommodate a variety of system requirements. Meets all MIL-PRF-9050 requirements. Stainless steel ball and a Teflon seat arrangement provides zero leakage at re-seat pressures. ANPT threaded inlet and outlet ports, internal filter and corrosion resistant steel construction.

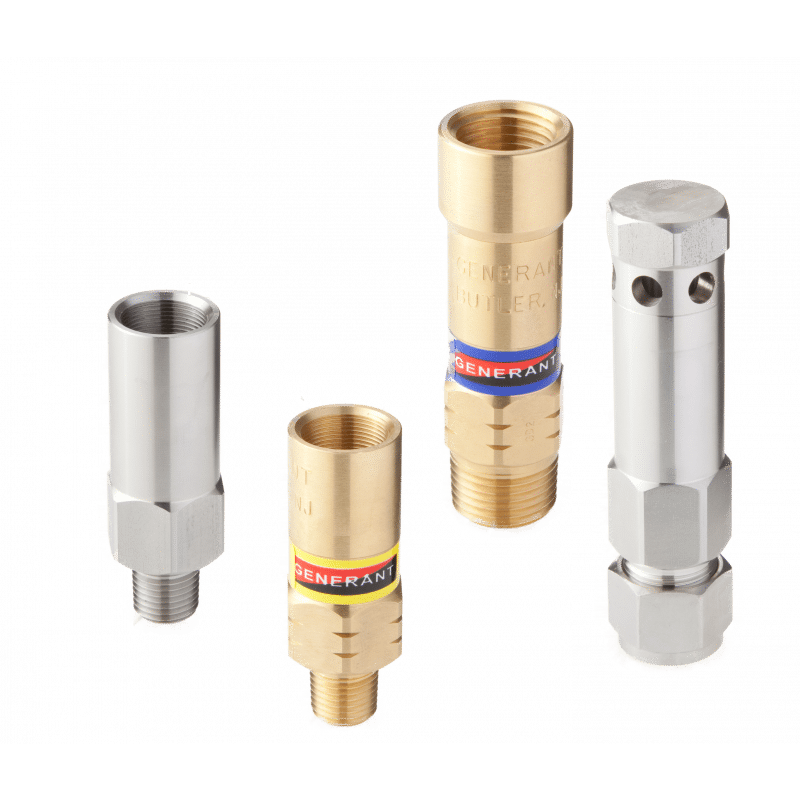

The Generant Series Brass CRV, Cryogenic Relief Valve is a spring reference over pressure protection device. The CRV incorporates Generant’s exclusive “Dirt Guard” feature which increases the valves ability to tolerate particulate contamination. This device is ideally suited for use as a “Blocked Line Safety” in cryogenic systems. The CRV is supplied cleaned and packaged for oxygen service. The valve can be ordered with set pressures ranging from 10 to 750 Psig (0.7 to 51.7 Bar) and come factory preset and permanently locked. Relief pressure can not be altered or adjusted in the field. Seat and poppet geometry combined with optimized spring ranges provide high flow rates with minimum pressure accumulation. Compact design and availability of a variety of inlet and outlet configurations reduces size and piping requirements. Relief pressure can be discharged to atmosphere or to a downstream connection. The CRV is supplied with Flourosilicone seals for set pressures from 10 – 49 Psig (0.7 – 3.4 Bar) and PCTFE seals for set pressures greater then 50 – 750 Psig (3.5 – 51.7 Bar)

Parker Bestobell’s cryogenic safety relief valves are designed to protect cryogenic static and road-going storage tanks or capital equipment from damage caused by over-pressure.

These cryogenic safety relief valves feature an innovative proportional lift action which ensures that when the pressure in a tank rises, the safety relief valve activates and releases pressure gently to enable it to drop back to a safe pressure.

They are available in three basic sizes defined by the throat diameter and are available with a variety of inlet and outlet connections. The valves are designed and factory set to lift repeatedly within +/- 2% of the set pressure and to re-seat above 92% of set pressure. Spring pre-compression and blow-down ring settings are securely sealed and factory set after testing to inhibit unauthorised tampering, as these are Category Four safety products. Flow rates at 10% above set pressure are measured to ensure compliance with stated flow capacities as an additional safety precaution.

• Designed to comply with ISO 4126 (Safety Valves General Requirement), Ad-Merkblatt A2 (Safety Devices against Excess Pressure) and TUV requirements.

WARNING:Inspection and maintenance of pressure relief valves is very important. Failure to properly inspect and maintain pressure relief valves could result in personal injuries or property damage. The useful safe service life of a pressure relief valve may be significantly affected by the service environment.

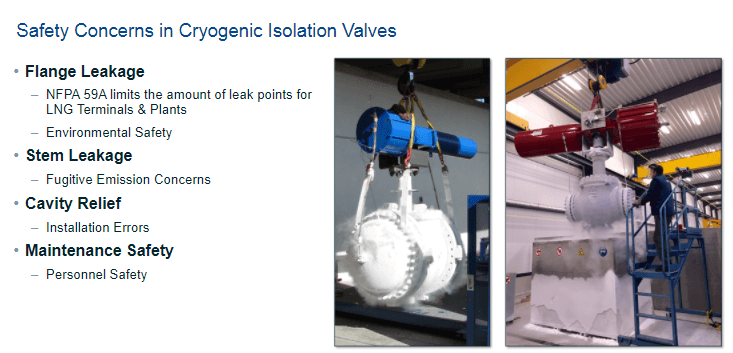

Pressure relief valves (PRVs) are a necessary requirement for overpressure protection within the LNG industry. However, not all PRVs are created equally when it comes to performance within cryogenic applications, and design temperatures as low as -320˚F (-196˚C). These applications require PRVs with enhanced sealing features to address the cryogenic conditions and perform their safety function.

In this article published in the August 2020 edition of LNG Magazine, Author Matt Byers, Senior Product Manager, Baker Hughes, USA, outlines the engineering best practices used today to optimize the design of pressure relief valves operating under cryogenic conditions.

Demaco Demaco is a leading knowledge-driven cryogenic infrastructure partner for industrial gas companies, scientific institutes, and EPC contractors worldwide. Demaco manufactures systems with measure and control technologies for cryogenic applications. All cryogenic systems are double walled where high vacuum is applied as an ultimate insulator. ...

Since 1955, MECA-INOX is an European leading signature for high quality ball valves dedicated to cryogenic gases, fine and green chemistry, corrosive fluids, and food industry with more than 3 million valves installed all over the world. Based on 15 years’ experience in design and ...

Dohmeyer is a leading global manufacturer of cryogenic refrigeration systems for the food processing, pharmaceutical, aeronautic, plastics and steel industries. For more than a decade, Dohmeyer has continued to develop innovative chilling and freezing solutions with its own team of dedicated engineers specializing in cabinet, ...

FasTest’s high-pressure, gas filling connectors have a proven track record with over two decades of service in the field. FasTest gas quick connectors provide a simple single handed approach to filling cylinders. Under pressure, a secure, leak-tight seal is established with our patented safety locking ...

Chart D&S Europe manufactures a wide portfolio of state-of-the-art distribution and storage gas cryogenic solutions produced in multiple facilities, Chart Ferox, Gofa, Flow Instruments. Its products include, stationary bulk tanks, a complete array of mobile cryogenic equipment with unique “Flowcom 3000” measurement system, transportable liquid ...

Dohmeyer is a leading global manufacturer of cryogenic refrigeration systems for the food processing, pharmaceutical, aeronautic, plastics and steel industries. For more than a decade, Dohmeyer has continued to develop innovative chilling and freezing solutions with its own team of dedicated engineers specializing in cabinet, ...

Founded in 1963, Control Devices is a leading designer and manufacturer of specialty valves and other high-quality flow control products. Control Devices’ ISO 9001:2008 certified facility boasts a dedicated and skilled work force utilizing automatic machining, assembly and final test equipment to support our production ...

Since 1999 we’ve been bringing our extensive knowledge, great service and an unrivalled safety record to the global valve and ancillaries market. Herose supply the top international industrial gas companies and original equipment manufacturers (OEM), and our products are used in over 100 countries. You’ll ...

Established in 1949, with over 70 years of experience, Habonim is committed to engineering, manufacturing, and supplying superior products and providing excellent personal service to our customers. We take pride in incorporating quality, innovation, reliability, and safety into our products. We provide the best professional ...

For six decades CPC‑Cryolab has been a world leader in the development, design and supply of high-quality cryogenic valves and equipment to support the ever growing needs and standards required by the Industrial Gas industry. The CPC-Cryolab team expertly provides highly engineered, long-term solutions that ...

Equigas Group is dedicated to providing customers with impeccable service, high quality products, and customer minded warranties for the Americas and the Caribbean. Equigas International, Inc. is the subsidiary of the group that serves the Cryogenic & Compressed Gas, Specialty Gases, Medical Gases and LNG ...

With more than 140 years’ experience in the development, manufacture and sale of valves with a high level of innovation and modern production with certified quality management, our company is one of the world’s leading manufacturers and suppliers of globe, check and control valves as ...

Niagara Controls is a technical sales representative and stocking distributor for a number of world-class manufacturers of industrial valves and controls, pressure relief devices, and a wide variety of other engineered products. We pride ourselves on delivering laser focused customer service and our ability to ...

Cryogenic safety valves are manufactured primarily not only from stainless steel but also in brass and bronze. Safety valves are available in sizes from DN6 to DN50 and secure pressures up to 0.2 to 50 bar, at operating temperatures of -270°C to +225°C.

Pressure relief valves have high flow capacity in order to be capable of efficiently directing flow to tanks. They"re used in hydraulic systems, and limit system pressures at specific levels. When a prescribed set pressure limit is reached, a pressure relief valve will immediately respond by sending excess flow from the system back into the tank.

Evergreen Midwest is an authorized dealer of cryogenic pressure relief valves. These work appropriately on piping systems, mini bulk cryogenic containers, and liquid cylinders (alongside ASME relief valves).

B-19434B Series/C-19434B Series - B-19434B relief valves are suitable for use with oxygen and non-corrosive gases. C-19434B relief valves are designed for carbon dioxide service.

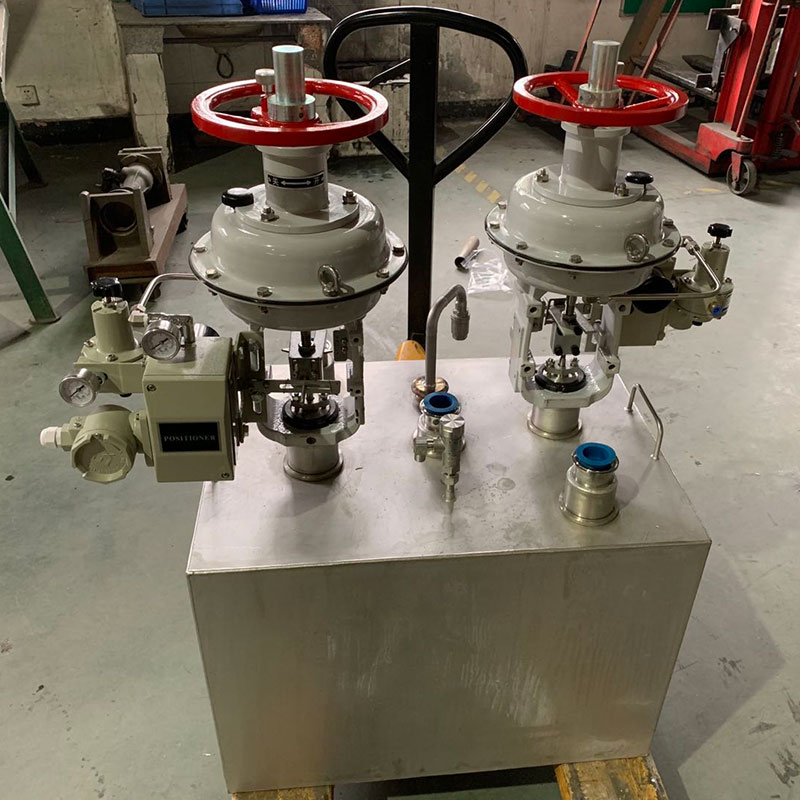

DA Series - A complete unitized solution for pressure relief devices assembled in factory settings, ready for attachment to cryogenic bulk tanks. Ideal for OEM applications where pre-fabricated assemblies are favored to streamline construction.

DR Series - A simple solution for the isolation of pressure relief devices during routine change outs relief valves w/out evacuating vessel. Excellent for protecting bulk liquid vessels, transport trailers, industrial pipelines, and LNG systems.

NR Series - Designed for indoor applications (such as labs) where relief valve discharge noise is an issue. RegO’s NR series provides excellent flow characteristics with a 50% reduction in outlet noise related to valve relief.

PRV 9400 Series - Brass or stainless steel, Non-ASME - these relief valves are designed for thermal safety relief applications and cryogenic liquid containers.

PRV 19430 Series - Brass relief valves/PRV 29430 Series stainless steel relief valves - these are designed for oxygen / other industrial gases and cryogenic service. Apply on piping systems, liquid cylinders, or mini-bulk cryogenic containers where ASME relief valves are needed.

UA3149A Series - “Pop-type” relief valves especially designed for use as a secondary relief valves in carbon dioxide transports and stationary storage tanks. Designed to protect tanks from excessive pressure in emergency events.

8613371530291

8613371530291