cryogenic safety valve in stock

The Generant Series Brass CRV, Cryogenic Relief Valve is a spring reference over pressure protection device. The CRV incorporates Generant’s exclusive “Dirt Guard” feature which increases the valves ability to tolerate particulate contamination. This device is ideally suited for use as a “Blocked Line Safety” in cryogenic systems. The CRV is supplied cleaned and packaged for oxygen service. Relief pressure can not be altered or adjusted in the field. Seat and poppet geometry combined with optimized spring ranges provide high flow rates with minimum pressure accumulation. The Generant Cryogenic Relief Valve has a compact design and availability of a variety of inlet and outlet configurations reduces size and piping requirements. Relief pressure can be discharged to atmosphere or to a downstream connection. The CRV is supplied with Flourosilicone seals for set pressures from 10 – 49 Psig (0.7 – 3.4 Bar) and PCTFE seals for set pressures greater then 50 – 750 Psig (3.5 – 51.7 Bar)

Pressure Relief Valves are spring-loaded valves designed to open and relieve excess pressure, then immediately close, preventing any loss of flow of fluid after normal conditions have been restored. Pressure Relief Valves are designed as, and made to act as a safety measure in your pressurized gas or liquid system.

Ratermann Manufacturing believes high quality safety relief valves are the foundation of any industrial system, as the relief valves prevent injury to personnel and unnecessary damage to equipment. Our safety valve experts keep our inventory up to date with pressure relief systems matching the most recent requirements from ASME (American Society of Mechanical Engineers) and ANSI (American National Standards Institute).

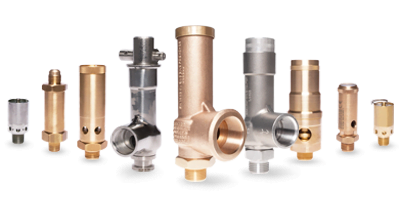

A wide variety of pressure relief safety valves are in our inventory, ready to ship. We specialize in the application of safety valves to High Pressure systems, Cryogenic Gas or Liquid, as well as valves specific to particular Dewars or systems in need of a Dual Relief Kit safety valve. You"ll find our brands of choice to be Herose, Generant and Rego, all known for their high quality standards and durability making the equipment a worthwhile investment.

Ratermann Manufacturing is dedicated to provide you with the right size and style of pressure relief valve, related fittings, and other safety equipment, so that your system is safe and efficient. If you have any questions regarding the type, size, or style of pressure relief valve you need, do not hesitate to contact our support staff at 800-264-7793. They have extensive experience in the industry, and would be happy to help you find the Pressure Relief Equipment you need for top performance.

Scroll down and click on the Pressure Relief Valve category that matches your system. Ordering is quick and easy from our online store - prices available for registered users only.

If you want to place an order over the phone, or would like to ask a technical question regarding a Pressure Safety Valve or related product, call us at 800-264-7793 and we"ll be happy to help.

As your leader in moving molecules in the industrial gas industry for over 50 years, we can offer technical assistance for your pipe system design, as well as cryogenic valves and cryogenic fittings, regardless of your level of experience. Our sales engineers have over 40 years of combined experience. Our product management, engineering, and quality departments work closely together to provide a steady flow of new features and expanded product offerings without compromising the reliability and performance that we are known for. Our manufacturing team has decades of experience and work in our newly-expanded valve-specific manufacturing area, located in our Allentown, PA headquarters.

Cryogenic liquid relief valves are not only useful, but they are also necessary for safety purposes as well. When pressure builds up within pipes, these liquid relief valves are there to prevent damage from occurring when liquefied gas expands. Make sure you have the highest quality when you purchase a cryogenic liquid relief valve.

Compressed Gas Valve is always here to make sure you are stocked with every gas valve you could possibly need. No matter if you need pressure relief, acetate, or chlorine valves, we have what you need when it comes to industrial valves.

Manufacturers rep. & stocking distributor of industrial process equipment. Products include analytical equipment, bio-pharmaceutical equipment, control products, electric heat trace products, flow equipment, gas detection products, level instrumentation, pressure gauges, pressure instruments, regulators, sanitary products, temperature instruments, valves & wireless products. Analyzers such as total hydrocarbon analyzers, BTU analyzers, gas detection analyzers, process photometric analyzers, trace (ppm/ppb) moisture analyzers & on-line analyzers are available. Control products include valves, pressure/temperature regulators, actuators, monitoring systems, single & multi-loop controllers, pressure/temperature transmitters, pneumatic positioners, air sets, volume boosters, relays, process control systems, liquid & solid level controls & weigh feeders. Capabilities include assembly, customization, calibration & repair.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale cryogenic pressure relief valve on Alibaba.com. When you search for cryogenic pressure relief valve and related items, you will be able to find many types of cryogenic pressure relief valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of cryogenic pressure relief valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

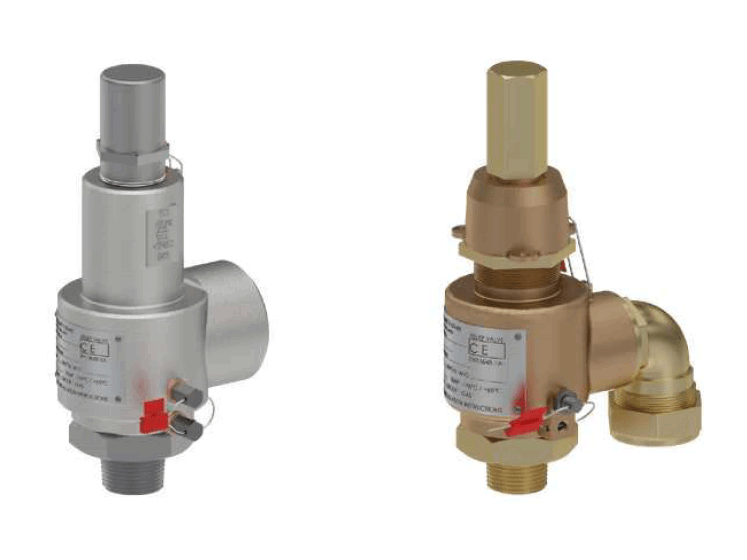

Parker Bestobell’s cryogenic safety relief valves are designed to protect cryogenic static and road-going storage tanks or capital equipment from damage caused by over-pressure.

These cryogenic safety relief valves feature an innovative proportional lift action which ensures that when the pressure in a tank rises, the safety relief valve activates and releases pressure gently to enable it to drop back to a safe pressure.

They are available in three basic sizes defined by the throat diameter and are available with a variety of inlet and outlet connections. The valves are designed and factory set to lift repeatedly within +/- 2% of the set pressure and to re-seat above 92% of set pressure. Spring pre-compression and blow-down ring settings are securely sealed and factory set after testing to inhibit unauthorised tampering, as these are Category Four safety products. Flow rates at 10% above set pressure are measured to ensure compliance with stated flow capacities as an additional safety precaution.

• Designed to comply with ISO 4126 (Safety Valves General Requirement), Ad-Merkblatt A2 (Safety Devices against Excess Pressure) and TUV requirements.

Kunkle delivers quality products from cryogenic to high temperature and vacuum to high pressure Steam, Air, Gas, and Liquid applications. Kunkle Valve provides code certifications that meet various global standards such as ASME, PED, CRN, TU and Chinese as well as non-code requirements.

As its name suggests, cryogenic valves are designed to be used in very cold applications. They are thus most popularly used by companies that work with Liquefied Natural Gas (LNG) or Compressed Natural Gas (CNG). For instance, the oil and gas industry frequently uses cryogenic temperature ranges starting at -150°C (-238°F). Additionally, some gasses aren"t labeled "cryogenic" because of their temperature, but rather because they require more than a simple pressure increase to compress their volume. Cryogenic valves are built to help transport and store such cryogenic gasses safely and efficiently.

Cryogenic valves are constructed to store such gases safely and also work great during transportation due to their ability to function efficiently in pressure settings as high as 52 bar (750 psi) and temperature as low as -196°C (-320°F).

Cryogenic valves are kept in a natural closed position to keep cryogenic gasses or other medium secure and safely contained. A cryogenic valve is generally designed to react to high pressure which pushes the valve into the open position to allow the gas or other media to flow readily through. Such open flow will continue until the pressure again decreases, at which point it will swing back nd become seal with a special metal seat bubble-tight shutoff to prevent any leaking.

Cryogenic gases and other media are extremely sensitive. Having it leak in an unwanted place can cause serious and very expensive damages, especially as it is a costly endeavor to transform standard temp gasses into cryogen.

Standard valves are sensitive to the extreme temperatures as they contract and expand at various rates when exposed to hot and freezing conditions, thus causing breaks in the seal and enabling the undesired leakage. It"s these heat gains that have long been a problem in the study, transport, and storage of cryogenic gas processing.

Ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas, liquefied petroleum, and other liquid media the cryogenic valve transfers are flammable and explosive. What is more, they are going to gasify and expand hundreds of times when the temperature rises.

The extended bonnet can prevent the stuffing box, which plays an important role in the cryogenic valve and other valves, from the damage of low temperature.

The pipes and valves are often installed in the so-called "cold box", but its "long neck" can go through the wall of the "cold box". Based on that, the extended stem makes it convenient to dismantle or replace the main parts of the valve quickly through the bonnet.

Hence,the valve body and the pipeline are welded together to reduce the leakage of the cold box as much as possible and ensure the sealing performance of the valve.

Today, we can find various shapes and sizes of cryogenic valves, suitable for working at various pressure ranges. Some of the most common are Ball, Butterfly, Gate, Globe, Check and Relief valves. In addition, they can be manual or automatic, which is indispensable in large systems.

Cryogenic ball valves also include a polytetrafluoroethylene body. Their flow rate is therefore better than that of globe valves. They are also very efficient when a tight seal is required in systems. However, it should be noted that they can easily wear around the seals and the ball itself. Therefore, their application is recommended in systems with unrestricted flow paths.

Cryogenic butterfly valves have a circular disc in the centre, which gives them a shorter length. They are lightweight, economical, simple to operate, and are used in systems that need fast opening and closing actions.

Cryogenic gate valves have a wedge-shaped gate that closes in line with the body mounting. This results in minimal pressure drop, even in its fully open position.

Cryogenic globe valves have a spherical shape and an internal moving disc that rotates at a 90-degree angle to the plane of its body mounting. In this way, they provide effective long-term sealing. However, they are not recommended for use in high flow systems.

Cryogenic relief valves protect against overpressure above a certain value and allow steam to escape if the safety limits are exceeded. In a similar vein, cryogenic check valves maintain pressure and prevent fluids from flowing back.

SHELL MESC stipulates a pressure equalizing hole of at least 3 mm in the ball. It states that the ball valve must have an automatic way to relieve overpressure. Cryogenic standard BS 6364 tells us the same.

We must always keep in mind that cryogenic gases are very sensitive and leakage can pose a serious risk. In this sense, a cryogenic valve is a guarantee for the proper functioning of the system.

8613371530291

8613371530291