define safety valve theory pricelist

The Supreme Court has reinforced the theory of the First Amendment as a "safety valve," reasoning that citizens who are free to to express displeasure against government through peaceful protest will be deterred from undertaking violent means. The boundary between what is peaceful and what is violent is not always clear. For example, in this 1965 photo, Alabama State College students participated in a non-violent protest for voter rights when deputies confronted them anyway, breaking up the gathering. (AP Photo/Perry Aycock, used with permission from the Associated Press)

Under the safety valve rationale, citizens are free to make statements concerning controversial societal issues to express their displeasure against government and its policies. In assuming this right, citizens will be deterred from undertaking violent means to draw attention to their causes.

The First Amendment, in safeguarding freedom of speech, religion, peaceable assembly, and a right to petition government, embodies the safety valve theory.

These and other decisions rest on the idea that it is better to allow members of the public to judge ideas for themselves and act accordingly than to have the government act as a censure. The Court has even shown support in cases concerning obscenity or speech that incites violent action. The safety valve theory suggests that such a policy is more likely to lead to civil peace than to civil disruption.

Justice Louis D. Brandeis recognized the potential for the First Amendment to serve as a safety valve in his concurring opinion in Whitney v. California (1927) when he wrote: “fear breeds repression; . . . repression breeds hate; . . . hate menaces stable government; . . . the path of safety lies in the opportunity to discuss freely supposed grievances and proposed remedies; and the fitting remedy for evil counsels is good ones.”

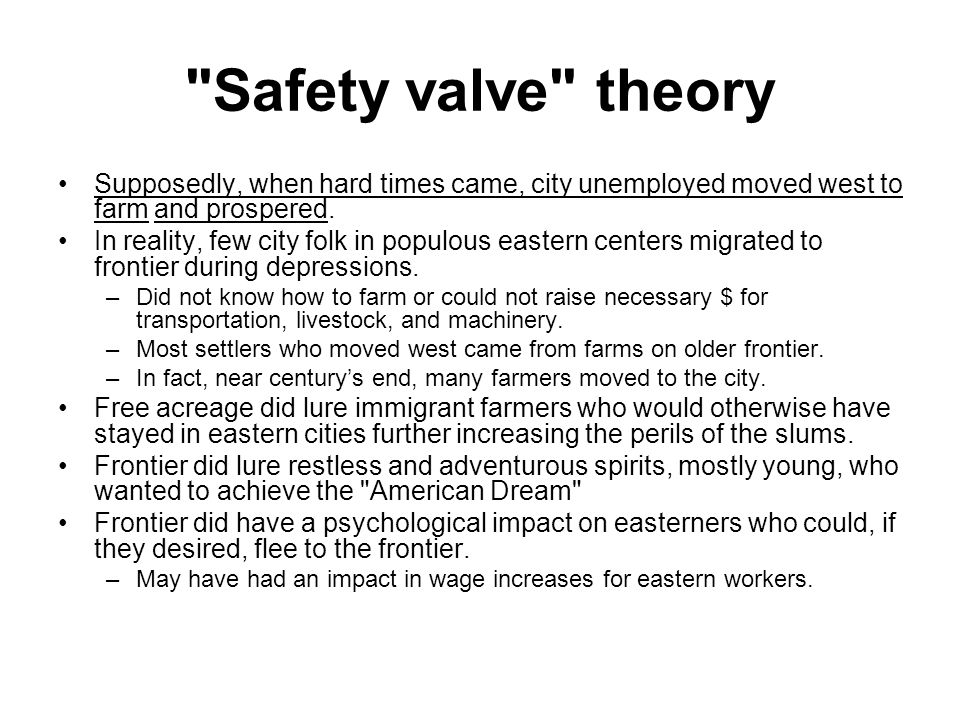

The safety valve theory was a theory about how to deal with unemployment which gave rise to the Homestead Act of 1862 in the United States. Given the concentration of immigrants (and population) on the Eastern coast, it was hypothesized that making free land available in the West would relieve the pressure for employment in the East. By analogy with steam pressure (= the need for work), the enactment of a free land law, it was believed, would act as a safety valve. This theory meant that if the East started filling up with immigrants, they could always go West until they reached a point where they could not move any farther.

A distinction has to be made between (1) the safety valve theory as an ideal and (2) the safety valve theory as embodied in the Homestead Act of 1862.

There is a dispute whether and to what extent the Homestead Act did or did not succeed as a safety valve in ameliorating the problem of unemployment in the East.

and PSV valve mechanismPressure Safety valve or PSV Valve is the most importantvalve on a boiler used to relief excess pressure toatmosphere let’s see how psv valve is important, Let’sdiscuss about Pressure safety valve theory installationrules and PSV valve mechanism, Sv setting, testing and thetypes.

The maximum allowable working pressure (MAWP) for the mostof the boilers is 10 bar. That is, the pressure of the steamin the boiler can not go above 10 bar. The purpose of thesafety valve, then, is to prevent the pressure in the boilerfrom climbing above its MAWP. If the pressure were to riseabove the MAWP, the safety valve would pop open and preventany increase in pressure that might lead to a boilerexplosion. The safety psv valve location should be thehighest part of the steam side, in case of water tube atsteam drum or directly to the top of the shell for fire tubeboiler. There are no valves between the safety and theboiler.

Safety valves are designed to automatically pop open onpressure and stay open until there is a definite drop inpressure inside of the boiler. The pressure at which a PSVvalve operates is known as blow down of safety valve &reseating pressure is called blow back, without chattering(opening and closing quickly). In most states, the only typeof safety valve allowed on every steam boiler is the springloaded type. You can calculate force acting to operate asafety valve Force= Pressure × Area. I recommend you to readBoiler codes to better under standing of safety valvetheory.

lt is the best practice to directly mount the safety valvein vertical position on a nozzle of the pressure vessel or ashort connection which allows smooth flow of fluid. Whererounded or beveled approaches can not be provided ahead ofthe safety valve, it is recommended that one size largerriser or fitting be used. The pressure drop in the valveinlet piping should not exceed 3 % of the set pressure.Valves are sometimes badly damaged just as they go intoservice because of failure to clean the connections. It isessential that the boiler, pressure vessel, valve inlet, andall connections be cleaned thoroughly before the valve ismounted. For the gasket used for installation of a flange-type valve, an article whose gasket width is correctsuitable for the flange bearing surface shall be used takingcare not to allow displacement when bolt clamping takes place.

In Hydrostatic testing of a boiler flanged safety valves areusually blanked and Welded safety valves are closed with aninternal plug called gagging. Gag plug should not be used incase of normal operation. SV should operate withoutchattering or any trouble.

Every steam, hot water boiler should have at least one PSVvalve. Two are more Pressure safety valves are required fora boiler having heating surface above 500 f 2 , in case ofelectric boiler two psv valves are required above input of1100kw.

Boiler pressure should not increase 6% of the set pressureof SV.If two or more PSV are used, the max setting of PSV valveshould not increase 3% of MAWP of the boiler.

If MAWP of a boiler is 200 Psi & we want to install 3 PSVvalves two on the drum and one on the super heater, thesetting will be as according to ASME codes.

Safety valve must be subjected to an annual periodicinspection 1n accordance with the applicable laws Boiler &Pressure Vessel Code and other national standards. As forvalves to which the rules of periodic inspection are notapplicable, disassemble and overhaul them as follows

Accessories and mountings are necessary for the boiler to produce energy efficiently. Accessories include economizers, superheaters, feed pumps, controllers, and air preheaters. Mountings include feed check valves, steam stop valves, fusible plugs, blow off cocks, critical safety valves, and water level indicators.

The water level indicator provides a reading of the level of the water in the boiler and is a safety device. Most boilers have two water level indicators. A water level indicator has three cocks and a glass tube. The first cock keeps the glass tube connected to the steam, while the second cock connects the glass tube to the water. The third cock indicates whether cocks one and two are clear.

The safety valve protects the boiler against extreme high pressure inside the drum. It allows for blowoff when the working pressure gets too high. As an extra precaution, and as the steam is released, it makes a loud, uncomfortable noise to warn people in the area. The varieties of safety valves are lever, dead weight, high steam low water, and spring loaded (as seen in the image below).

A stop valve controls the flow of steam and can completely stop it. It manages the steam supply to use and can be operated manually or be part of the control system.

The feed check valve monitors the water supply as it enters the boiler and prevents water from escaping if the pump fails or has low pressure. It is also known as a no return valve and is placed just below the water level in the boiler.

Though high pressure boilers are essential to the production of energy and provide excellent power, they are a potentially dangerous piece of equipment and have to be monitored closely. Regardless of the many safety features on a high pressure boiler, if the pressure is not contained, the steam energy will cause the boiler to explode and release metal and superheated steam.

The purpose of a boiler is to create steam pressure, which has to be closely monitored. All boilers are required to have safety measures in place to prevent this from happening.

During blowdown, the water in the gauge glass should fill quickly when the blowdown valve is closed. If it happens slowly, there may be a blockage in the water flow.

The capacity of a safety valve is measured in the pounds per hour that it can handle. Its capacity has to be the same or more than the boiler‘s pounds per hour rate. Safety valves are tested by activating the try lever. When the try lever is released, the disk of the safety valve should move to the closed position.

When doing a blowdown, the boiler should have a light load and be at a normal operation water level. Opening of the valve should happen slowly and with caution to avoid injury.

When opening a steam valve, safety glasses or shields should be worn as well as gloves. The valve should be opened very slowly to equalize the pressure and warm the downstream equipment. Traps should be drained as well.

The above listed measures are a few of the actions that need to be taken when dealing with a high pressure boiler. Each organization and manufacturer has their own safety standards that should be strictly followed.

The Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have strict guidelines and regulations for high pressure boiler safety.

The oversight groups for boiler standards and regulations include OSHA, NFPA, and the American Society of Mechanical Engineers (ASME). OSHA and NFPA have developed safety protocols and regulations regarding proper handling of high pressure boilers in specific situations.

NFPA 85 specifies the operating safety and preventive measures for uncontrolled fires, explosions, and implosions as part of Section 1.1. It establishes the requirements for design, installation, operation, training, and maintenance of boilers and pressure devices.

The ASME Boiler Code is the national standard for public safety, product reliability, and industrial efficiency and has increased research efforts in industrial groups as well as provided stability to contractual relations and certification. It has become the international standard for accreditation programs.

8613371530291

8613371530291