define safety valve theory quotation

The Supreme Court has reinforced the theory of the First Amendment as a "safety valve," reasoning that citizens who are free to to express displeasure against government through peaceful protest will be deterred from undertaking violent means. The boundary between what is peaceful and what is violent is not always clear. For example, in this 1965 photo, Alabama State College students participated in a non-violent protest for voter rights when deputies confronted them anyway, breaking up the gathering. (AP Photo/Perry Aycock, used with permission from the Associated Press)

Under the safety valve rationale, citizens are free to make statements concerning controversial societal issues to express their displeasure against government and its policies. In assuming this right, citizens will be deterred from undertaking violent means to draw attention to their causes.

The First Amendment, in safeguarding freedom of speech, religion, peaceable assembly, and a right to petition government, embodies the safety valve theory.

These and other decisions rest on the idea that it is better to allow members of the public to judge ideas for themselves and act accordingly than to have the government act as a censure. The Court has even shown support in cases concerning obscenity or speech that incites violent action. The safety valve theory suggests that such a policy is more likely to lead to civil peace than to civil disruption.

Justice Louis D. Brandeis recognized the potential for the First Amendment to serve as a safety valve in his concurring opinion in Whitney v. California (1927) when he wrote: “fear breeds repression; . . . repression breeds hate; . . . hate menaces stable government; . . . the path of safety lies in the opportunity to discuss freely supposed grievances and proposed remedies; and the fitting remedy for evil counsels is good ones.”

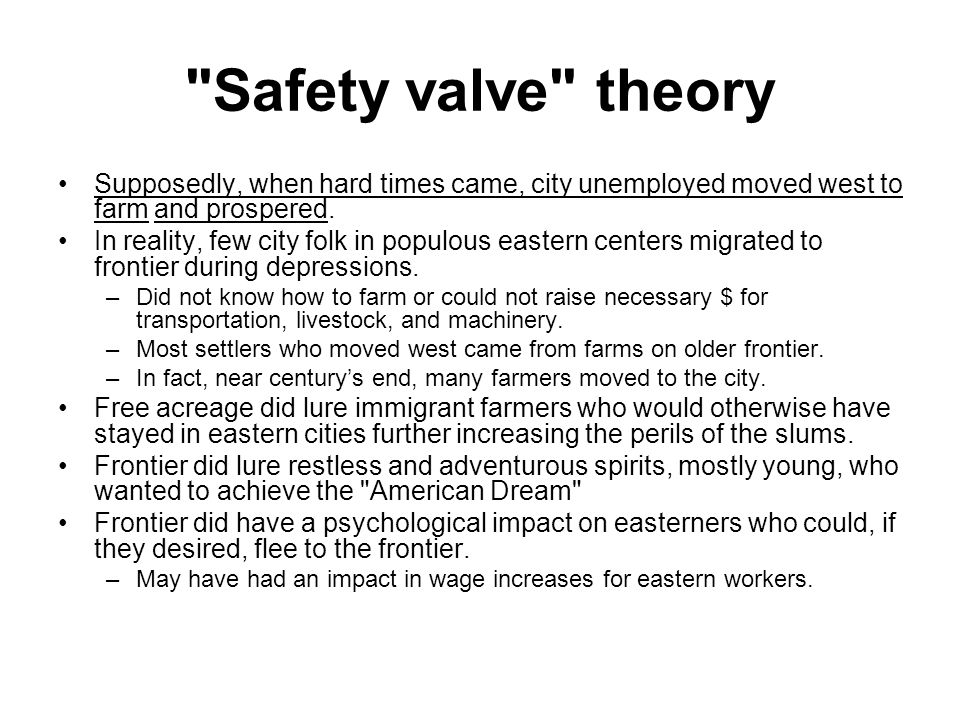

The safety valve theory was a theory about how to deal with unemployment which gave rise to the Homestead Act of 1862 in the United States. Given the concentration of immigrants (and population) on the Eastern coast, it was hypothesized that making free land available in the West would relieve the pressure for employment in the East. By analogy with steam pressure (= the need for work), the enactment of a free land law, it was believed, would act as a safety valve. This theory meant that if the East started filling up with immigrants, they could always go West until they reached a point where they could not move any farther.

A distinction has to be made between (1) the safety valve theory as an ideal and (2) the safety valve theory as embodied in the Homestead Act of 1862.

There is a dispute whether and to what extent the Homestead Act did or did not succeed as a safety valve in ameliorating the problem of unemployment in the East.

The extremist leader Lala Lajpat Rai called the Congress a safety valve. According to this theory, it was alleged that the Congress acted as a safety valve that informed the British about growing discontent in India and helped to prevent any other situation like the revolt of 1857.

Although I agree with the notion that catharsis is beneficial due to the fact that it allows one to release their suppressed emotions, I would argue that desensitization is a far more accurate theory in regards to what effect it has upon the general population. The resources present day electronic media provides us with has drastically changed our world as well as the way its population behaves on a daily basis, particularly in how we act upon our emotions. The safety valve theory of catharsis suggests that exposure to said events benefits the audience by allowing them to purge themselves of repressed emotions, therefore providing relief from acting upon these emotions with actions in the real world. However, the theory of desensitization indicates that as exposure to said events increases, the audience will have an increasingly diminished emotional stimulus to said events. It could be argued that catharsis is an accurate theory regarding how humans choose to cope with their emotions, however, I propose that the theory of desensitization more accurately characterizes the effect exposure to traumatic experiences has upon the general population.

Viewing this topic, there are always two different main thoughts about the influence of the sex media exist. One of them called “the trigger hypothesis” and the other one is named “safety valve theory” according to the second one, some scientists considered sexually explicit materials as a tool of blowing off. Researchers holding this thought believe that watching pornography (refer to almost any explicit depiction) will satisfy whatever urges might cause a person to commit a sex crime. And if this is a correct or false positive (we say A exist, but A is actually not) answer, then we might be able to see a decrease in sex crimes in society that have already availability to those materials. Standing in the opposite side, “the trigger hypothesis” claims that some individuals would response to sexually explicit materials in such a way that it may lead to a sex crime like a rape or incident exposure.

Responding to those two main theories, one researcher named Berl Kutchinsky reveals that the decrease in sex crimes may attribute to one fact that the public attitudes become more and more lenient these days, and one truth about the going on situation across countries, is that the incidence of rape does not decrease when pornography is allowed to flow freely. So in here, although the safety value theory makes some sense, it’s still an existence of mundane realism (things that don’t match situations encountered outside the laboratory). Compared to that, the trigger hypothesis is more useful in real world. Here’s a experimental research named “ the electric shock paradigm”, which support the trigger theory properly. If any one is interest in more information, Google will tell you this story better than I did!

Solenoid valves are used wherever fluid flow has to be controlled automatically. They are being used to an increasing degree in the most varied types of plants and equipment. The variety of different designs which are available enables a valve to be selected to specifically suit the application in question.

Solenoid valves are used wherever fluid flow has to be controlled automatically. They are being used to an increasing degree in the most varied types of plants and equipment. The variety of different designs which are available enables a valve to be selected to specifically suit the application in question.

Solenoid valves are control units which, when electrically energized or de-energized, either shut off or allow fluid flow. The actuator takes the form of an electromagnet. When energized, a magnetic field builds up which pulls a plunger or pivoted armature against the action of a spring. When de-energized, the plunger or pivoted armature is returned to its original position by the spring action.

According to the mode of actuation, a distinction is made between direct-acting valves, internally piloted valves, and externally piloted valves. A further distinguishing feature is the number of port connections or the number of flow paths ("ways").

With a direct-acting solenoid valve, the seat seal is attached to the solenoid core. In the de-energized condition, a seat orifice is closed, which opens when the valve is energized

Two-way valves are shut-off valves with one inlet port and one outlet port (Fig. 1). In the de-energized condition, the core spring, assisted by the fluid pressure, holds the valve seal on the valve seat to shut off the flow. When energized, the core and seal are pulled into the solenoid coil and the valve opens. The electro-magnetic force is greater than the combined spring force and the static and dynamic pressure forces of the medium.

Three-way valves have three port connections and two valve seats. One valve seal always remains open and the other closed in the de-energized mode. When the coil is energized, the mode reverses. The 3-way valve shown in Fig. 2 is designed with a plunger type core. Various valve operations can be obtained according to how the fluid medium is connected to the working ports in Fig. 2. The fluid pressure builds up under the valve seat. With the coil de-energized, a conical spring holds the lower core seal tightly against the valve seat and shuts off the fluid flow. Port A is exhausted through R. When the coil is energized the core is pulled in, the valve seat at Port R is sealed off by the spring-loaded upper core seal. The fluid medium now flows from P to A.

Unlike the versions with plunger-type cores, pivoted-armature valves have all port connections in the valve body. An isolating diaphragm ensures that the fluid medium does not come into contact with the coil chamber. Pivoted-armature valves can be used to obtain any 3-way valve operation. The basic design principle is shown in Fig. 3. Pivoted-armature valves are provided with manual override as a standard feature.

With direct-acting valves, the static pressure forces increase with increasing orifice diameter which means that the magnetic forces, required to overcome the pressure forces, become correspondingly larger. Internally piloted solenoid valves are therefore employed for switching higher pressures in conjunction with larger orifice sizes; in this case, the differential fluid pressure performs the main work in opening and closing the valve.

Internally piloted solenoid valves are fitted with either a 2- or 3-way pilot solenoid valve. A diaphragm or a piston provides the seal for the main valve seat. The operation of such a valve is indicated in Fig. 4. When the pilot valve is closed, the fluid pressure builds up on both sides of the diaphragm via a bleed orifice. As long as there is a pressure differential between the inlet and outlet ports, a shut-off force is available by virtue of the larger effective area on the top of the diaphragm. When the pilot valve is opened, the pressure is relieved from the upper side of the diaphragm. The greater effective net pressure force from below now raises the diaphragm and opens the valve. In general, internally piloted valves require a minimum pressure differential to ensure satisfactory opening and closing. Omega also offers internally piloted valves, designed with a coupled core and diaphragm that operate at zero pressure differential (Fig. 5).

Internally piloted 4-way solenoid valves are used mainly in hydraulic and pneumatic applications to actuate double-acting cylinders. These valves have four port connections: a pressure inlet P, two cylinder port connections A and B, and one exhaust port connection R. An internally piloted 4/2-way poppet valve is shown in Fig. 6. When de-energized, the pilot valve opens at the connection from the pressure inlet to the pilot channel. Both poppets in the main valve are now pressurized and switch over. Now port connection P is connected to A, and B can exhaust via a second restrictor through R.

With these types an independent pilot medium is used to actuate the valve. Fig. 7 shows a piston-operated angle-seat valve with closure spring. In the unpressurized condition, the valve seat is closed. A 3-way solenoid valve, which can be mounted on the actuator, controls the independent pilot medium. When the solenoid valve is energized, the piston is raised against the action of the spring and the valve opens. A normally-open valve version can be obtained if the spring is placed on the opposite side of the actuator piston. In these cases, the independent pilot medium is connected to the top of the actuator. Double-acting versions controlled by 4/2-way valves do not contain any spring.

All materials used in the construction of the valves are carefully selected according to the varying types of applications. Body material, seal material, and solenoid material are chosen to optimize functional reliability, fluid compatibility, service life and cost.

Neutral fluid valve bodies are made of brass and bronze. For fluids with high temperatures, e.g., steam, corrosion-resistant steel is available. In addition, polyamide material s used for economic reasons in various plastic valves.

All pressure figures quoted in this section represent gauge pressures. Pressure ratings are quoted in PSI. The valves function reliably within the given pressure ranges. Our figures apply for the range 15% undervoltage to 10% overvoltage. If 3/2-way valves are used in a different operation, the permitted pressure range changes. Further details are contained in our data sheets.

The flow rate through a valve is determined by the nature of the design and by the type of flow. The size of valve required for a particular application is generally established by the Cv rating. This figure is evolved for standardized units and conditions, i.e. flowrate in GPM and using water at a temperature of between 40°F and 86°F at a pressure drop of 1 PSI. Cv ratings for each valve are quoted. A standardized system of flowrate values is also used for pneumatics. In this case the air flow in SCFM upstream and a pressure drop of 15 PSI at a temperature of 68°F.

A common feature of all Omega solenoid valves is the epoxy-encapsulated solenoid system. With this system, the whole magnetic circuit-coil, connections, yoke and core guide tube - are incorporated in one compact unit. This results in a high magnetic force being contained within the minimum of space, insuring first class electrical insulation and protection against vibration, as well as external corrosive effects.

The current consumption of an AC solenoid is determined by the inductance. With increasing stroke the inductive resistance decreases and causes an increase in current consumption. This means that at the instant of de-energization, the current reaches its maximum value. The opposite situation applies to a DC solenoid where the current consumption is a function only of the resistance of the windings. A time-based comparison of the energization characteristics for AC and DC solenoids is shown in Fig. 9. At the moment of being energized, i.e. when the air gap is at its maximum, solenoid valves draw much higher currents than when the core is completely retracted, i.e., the air gap is closed. This results in a high output and increased pressure range. In DC systems, after switching on the current, flow increases relatively slowly until a constant holding current is reached. These valves are therefore, only able to control lower pressures than AC valves at the same orifice sizes. Higher pressures can only be obtained by reducing the orifice size and, thus, the flow capability.

A certain amount of heat is always generated when a solenoid coil is energized. The standard version of the solenoid valves has relatively low temperature rises. They are designed to reach a maximum temperature rise of 144°F under conditions of continuous operation (100%) and at 10% overvoltage. In addition, a maximum ambient temperature of 130°F is generally permissible. The maximum permissible fluid temperatures are dependent on the particular seal and body materials specified. These figures can be obtained from the technical data.

The small volumes and relatively high magnetic forces involved with solenoid valves enable rapid response times to be obtained. Valves with various response times are available for special applications. The response time is defined as the time between application of the switching signal and completion of mechanical opening or closing.

The relative duty cycle (%) is the percentage ratio of the energized period to the total cycle period. Continuous operation (100% duty cycle) is defined as continuous operation until steady-state temperature is reached.

The coding for the valve operation always consists of a capital letter. The summary at left details the codes of the various valve operations and indicates the appropriate standard circuit symbols

8613371530291

8613371530291