difference between pressure relief valve and pressure safety valve supplier

As you already know, there are a multitude of pressure relief valves out there. In the industry, we tend to use terms like safety valve and relief valve interchangeably. And for the most part, this makes sense. Most pressure relief valves are designed to do the same thing — release pressure in a system.

But is there a difference between some of these commonly used terms, and if so, what does it mean for you? Here’s a quick breakdown of two popular terms: safety valve vs. relief valve.

While both terms refer to valves used to release pressure from a pressurized system, their technical definitions are a bit different. In general, the term relief valve refers to a valve within a pressurized system that is used to control pressure for the optimal functionality of the system. Relief valves are designed to help your facility avoid system failures, and protect equipment from overpressurized conditions.

The term safety valve, on the other hand, refers to pressure valves that are designed to protect people, property, and processes. In other words, the term safety valve refers to a failsafe, last resort valve that will release pressure to prevent a catastrophe, usually in the event that all other relief valves have failed to adequately control pressure within a system.

The general purpose of both safety valves and relief valves are the same. Both are pressure relief valves, and they are designed to let off pressure in any situation where a system becomes overpressurized. That said, relief valves and safety valves do function slightly differently:

Relief Valves are designed to control pressure in a system, most often in fluid or compressed air systems. These valves open in proportion to the increase in system pressure. This means they don’t fly all the way open when the system is slightly overpressure. Instead, they open gradually, allowing the system to return to the preset pressure level. When that level is reached, the valve shuts again.

Safety Valves are used for one reason — safety. Instead of controlling the pressure in a system, they’re designed to immediately release pressure in the event of an emergency or system failure. Unlike relief valves, safety valves open immediately and completely to avoid a disaster, rather than to control the pressure of a system.

While both safety valves and relief valves work to release excess pressure, the way they go about it is a little different. Check out this table, courtesy of Difference Between, for a little more information about the differences between the two valves:

Industrial equipment often uses either safety or relief valves to prevent damaging pressure levels from building up. Though they perform similar functions, there are some critical differences between safety and relief valves. Understanding these two valves’ differences is essential for proper pressure system operation. So here we discuss the pressure safety valve vs pressure relief valve.

A pressure relief valve is a device that releases pressure from a system. The relief valve is generally immune to the effects of back pressure and must be periodically stripped down. Pressure relief valves are one the essential parts of a pressure system to prevent system failures. They are set to open at a predetermined pressure level. Each pressure system has a setpoint that is a predetermined limit. The setpoint determines when the valve will open and prevents overpressure.

Pressure relief valves are typically used in gas or liquid systems where there is a need to prevent excessive pressure from building up. When the pressure in the system reaches a certain level, the valve will open and release the pressure. Pressure relief valves are an essential safety feature in many designs and can help to prevent damage to the system or components.

PRVs are generally considered to be safe and reliable devices. However, before installing a PRV in a system, some potential disadvantages should be considered. Here are five pros and cons of pressure relief valves:

Pros: Pressure relief valves are anessential safety feature in many systems. They protect against over-pressurization by relieving excess pressure from the system. This can help to prevent severe damage or even explosions.

Pressure relief valves can help to improve the efficiency of a system. The system can operate at lower overall pressure by relieving excess pressure and saving energy.

Pressure relief valves can be used as a safety device in systems that are susceptible to overpressurization. By relieving pressure before it builds up to a dangerous level, they can help to prevent accidents and injuries.

Cons: Pressure relief valves can be a potential source of leaks. If not properly maintained, the valve may not seat properly and can allow fluids or gasses to escape.

Pressure relief valves can sometimes cause problems if they do not open or close properly. This can lead to process disruptions and may cause safety issues.

A pressure safety valve is a device used to release pressure from a system that has exceeded its design limit. This safety valve is a fail-safe device. This type of valve is typically used in systems that contain fluids or gasses under high pressure. Pressure safety valves are designed to open and release pressure when the system has exceeded its maximum pressure limit. This helps to prevent the system from rupturing or exploding.

Pressure safety valves are an essential part of many different types of systems and can help keep both people and property safe. If anyone is ever in a situation where they need to release pressure from a system, it is essential to know how to use a pressure safety valve correctly.

A pressure safety valve (PSV) is a type used to relieve a system’s pressure. PSVs are commonly used in chemical and process industries, as well as in some kinds of pressure vessels. There are both advantages and disadvantages to using a PSV. Some of the pros of using a PSV include: PSVs can help to prevent overpressurization, which can be dangerous.

A safety valve is a pressure relief device used to prevent the over-pressurization of a system. On the other hand, a relief valve is a device used to relieve pressure from a system that is already overpressurized. Function Of Pressure Relief Valve Vs Safety Valve

The function of a pressure relief valve is to protect a system or component from excess pressure. A safety valve, on the other hand, is designed to protect from overpressurization. Both types of valves are used in various industries, but each has unique benefits and drawbacks.

Pressure relief valves are typically used in systems where a small amount of overpressure can cause damage. On the other hand, safety valves are designed for systems where overpressurization could be catastrophic. Both valves have advantages and disadvantages, so choosing the right type of valve for the specific application is essential.

Relief valves are usually set to open at a specific pressure and will close once the pressure has been relieved. Safety valves are similar in that they are also used to protect equipment from excessive pressure. However, safety valves are designed to stay open until they are manually closed. This is because safety valves are typically used in applications where it is not safe to have a closed valve, such as in a gas line. Operation Of Safety Relief Valve Vs Pressure Relief Valve

Two types of valves are commonly used in industrial settings: relief valves and safety valves. Both of these valves serve essential functions, but they operate in different ways.

Relief valves are designed to relieve pressure build-up in a system. They open when the system pressure reaches a certain point, which allows excess pressure to be released. On the other hand, safety valves are designed to prevent accidents by preventing system pressure from getting too high. They open when the system pressure reaches a certain point, which allows excess pressure to be released before an accident can occur.

So, which valve is better? That depends on the situation. A relief valve is the better option to protect the system from pressure build-up. If anyone need to protect the system from accidents, then a safety valve is the better option Setpoint Of Pressure Relief Valve Vs Safety Relief Valve

The relief valve is made to open when it reaches a specific pressure, commonly described as a “setpoint”. Setpoints shouldn’t be misinterpreted as the pressure set. A setpoint on a relief valve is set to the lowest possible pressure rating, which means it is set to the lowest system pressure before an overpressure situation is observed. The valve will open as the pressure increases to a point higher than the setpoint. The setting point is determined as pounds per square inch (PSIG) and should be within the maximum allowed operating pressure (MAWP) limits. In safety valves, the setpoint is typically placed at about 3 percent over the working pressure level, whereas relief valves are determined at 10 percent.

No, the safety valve and relief valve can not be used interchangeably. Though both valves are seal butterfly valve and used for safety purposes, they serve different functions. A safety valve relieves excess pressure that builds up in a system, while a relief valve regulates the pressure in a system.

Knowing the difference between these two types of valves is essential, as using the wrong valve for the intended purpose can potentially be dangerous. If unsure which type of valve to use, it is always best to consult with a professional.

A few key points help us understand the safety valve vs pressure relief valve. Safety valves are designed to relieve pressure in a system when it gets too high, while relief valves are designed to relieve pressure when it gets too low. Safety valves are usually set to open at a specific pressure, while relief valves are generally open at a particular vacuum. Safety valves are typically intended for one-time use, while relief valves can be used multiple times. Choose the trusted valve manufactureraccording to the specific business needs.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Both the terms are used interchangeably in the process industry as every pressurized system requires safety devices to protect life, property, and environment. Relief valves and safety valves are the two principle safety devices designed to prevent overpressure conditions in process industries. Although, both the devices are used almost for the same purpose, the difference lies mainly in how they operate.

Relief valves, or commonly known as pressure relief valves (PRVs), belong to the family of protective devices specifically designed to protect pressure-sensitive systems and equipment from the damaging effects of overpressure conditions. A relief valve device is basically immune to the back pressure effects of a system and is subject to periodic stripdown. Pressure relief valves are one of the most critical parts of a pressure system that are set to open at a preset pressure level in order to avoid system failures. Every pressure system is set with a predetermined design limit called a setpoint, above which the valve begins to open to prevent overpressure conditions.

A safety valve is the last resort of people, property, and processes in the process industry comprising of power plants, petrochemicals, boilers, oil and gas, pharmaceuticals, and many more. It’s kind of a fail-safe device that actuates automatically in order to prevent the accumulation of pressure in a vessel or system beyond a preset limit. The device is so designed so that the safety valve trips automatically when the given pressure is attained. It simply allows the excess pressure to escape in order to prevent any damage to the vessel. Additionally, it also makes sure the pressure remains within the limits in the future. Even a slight increment in pressure lifts the safety valve and it closes as soon as the pressure is reduced to the prescribed limit.

A relief valve, also known as pressure relief valve (PRV) or safety relief valve, is type of a safety valve device used to limit or control the pressure level in a system within a safe threshold limit to avoid an overpressure condition. In simple terms, a relief valve is a device designed to control the pressure in a vessel or system to a specific set level. A safety valve, on the other hand, is a device used to let go excess pressure from a vessel or equipment when the pressure crosses a certain predetermined limit. It simply allows liquids or gases to escape if the pressure gets too high to prevent any damage.

Pressure relief valves are mainly used in hydraulic systems to limit the pressure in the system to a specific preset level and when the pressure reaches the safety design limit, the relief valve responds by releasing the excess flow from an auxiliary passage from the system back to the tank in order to prevent equipment failure. The main purpose of a safety valve is to protect life, property, and environment against failure in the control system pressure. Simply put, a safety valve opens when the pressure exceeds the designed set pressure limit.

For a safety relief valve, the opening is directly proportional to the increase in the vessel pressure. This means the opening of the valve is rather gradual than sudden, allowing it to open only at a preset pressure level and release fluids until the pressure drops to the desired set pressure. A safety valve, on the other hand, will open immediately when the system pressure reaches the set pressure level in order to system failure. It is safety device capable of operating at all times and is the last resort to prevent catastrophic failure in systems under overpressure conditions.

A pressure relief valve is designed to open at a certain pressure level which is generally called as a “setpoint”. A setpoint should not be confused with the set pressure. In fact, a setpoint of a relief valves is adjusted to the lowest maximum pressure rating meaning it is set below the maximum system pressure allowed before the overpressure condition occurs. The valve begins to open when the pressure reaches up to some level above the setpoint. The setpoint is measured in pounds per square inch (PSIG) and must not exceed the maximum allowable working pressure (MAWP). In safety valves, the setpoint is usually set at 3 percent above the working pressure level whereas in relief valves, it is set at 10 percent.

Both relief valves and safety valves are high-performance pressure-sensitive safety devices so designed to control or limit the pressure inside the system or vessel by releasing the excessive pressure from the auxiliary passage out of the system. Although both are common terms used for safety valves, the difference lies mainly in the capacity and setpoint. While the former is operator-assisted and is designed to relieve pressure in order to avoid overpressure condition, the latter is a self-operated device which opens automatically when the maximum allowable pressure is reached. Relief valves are mostly used in fluid or compressed air systems, whereas safety valves are mainly used to release vapor or steam into the atmosphere.

Sagar Khillar is a prolific content/article/blog writer working as a Senior Content Developer/Writer in a reputed client services firm based in India. He has that urge to research on versatile topics and develop high-quality content to make it the best read. Thanks to his passion for writing, he has over 7 years of professional experience in writing and editing services across a wide variety of print and electronic platforms.

Outside his professional life, Sagar loves to connect with people from different cultures and origin. You can say he is curious by nature. He believes everyone is a learning experience and it brings a certain excitement, kind of a curiosity to keep going. It may feel silly at first, but it loosens you up after a while and makes it easier for you to start conversations with total strangers – that’s what he said."

Whenever we talk about the pressure in the process industries we come across two types of safety equipments and that is the safety v/v and the relief v/v.

Most of us think that both are same thing but that’s not the case. Though their functions are same yet there are certain differences among them. Both of them are used in the industry to prevent the accumulation of excess pressure, but there are operational differences between them.

Relief valves which are also known as Pressure relief valves are one of the protective devices which are used to protect a pressurize working system and equipments from getting damaged due to an over-pressure or excessive pressure conditions.

In every pressurized working system there is a set pressure under which the system works properly and efficiently, this set pressure is known as set point and when the pressure is above set point the relief valve opens and the excess pressure is released.

It is made very sensitive such that even for a slight increment in the pressure lifts the safety valve and gets closed quickly as soon as the pressure is released to maintain the desired pressure in the vessel.

1. A relief valve is a device used to limit the pressure in the system within certain specified limit or a set level.A safety valve is a device designed to actuate automatically when the pressure becomes excess.

2. The opening of a relief Valve is directly proportional to the increase in the vessel pressure.2. A safety valve opens almost immediately and fully in order to prevent over pressure condition.

3. A relief valve opens when the pressure reached the specific limit and it is usually operated by an operator.3. The purpose of the safety valve is mainly to safeguard people, property and the environment. It operates without any human intervention.

4. The set point of a relief valve is usually set at 10% above working pressure.4. The set point of safety valve is usually set at 3 % above working pressure.

5. Relief valves are categorized into pop-type, direct-operated, pilot-operated, and internal relief valves.5. Safety valves are divided into wide variety of types based on their applications and performance in different areas of use.

From the definition of both the valves we can conclude that the relief v/v which is also known as the pressure relief v/v is a safety device which is used to maintain a proper preset pressure in the vessel or the system within a prescribed limit condition to prevent a situation of over pressure.

On the other hand, the safety valve is a protective device which is used in a system to control the pressure inside the system under a predetermined limit.

The pressure relief valves are generally used in the hydraulic systems to control the pressure within specified limit and when the pressure increases than the preset value.

It lifts up and provide an escape of the excess pressure through an alternate channel or bypass provided in the system back to the source from where the input is coming or may be a different chamber provided to accept the excess of the liquid.

On contrary in case of safety valve, the main function of the safety valve is to provide safety to the property, life, and the environment which can get damaged due to failure of the system because of the excess pressure.

The pressure relief valves are generally used in the hydraulic systems to control the pressure within specified limit and when the pressure increases than the preset value, it lifts up and provide an escape of the excess pressure through an alternate channel or bypass provided in the system back to the source from where the input is coming or may be a different chamber provided to accept the excess of the liquid.

On contrary in case of safety valve, the main function of the safety valve is to provide safety to the property, life, and the environment which can get damaged due to failure of the system because of the excess pressure.

We used the set point in case of the relief valve, the “Set Point” basically refers to a point set to the lowest maximum pressure rating which means that the pressure is set below the maximum operative pressure which is allowed for a system to operate without being get into the state of overpressure.

In Simple words we can say that the relief valve pressure is set to maintain and control the pressure inside the system, the set pressure is dependent on the working pressure of the system.

On the other hand , the pressure of safety valve is set on the basis of various factors of consideration like the material used, the environment in which it has to be used, the type of work it has to perform.

The boilers material used for 6 Bar will have the materials which can withstand upto 12 Bar (it depends on the manufacturer) So the Safety valve will be set to 7-8 bar so as to prevent the boiler failure.

A pressure relief valve is one that is used to limit the pressure in a system within a specific set level. However, a pressuresafety valveactuates automatically to release excessive pressure.Relief valveopens only when the pressure reaches the specific set pressure limit and is usually operated by an operator. It does not require operator assistance to release excessive pressure.

The similarity between thepressure relief valveand thesafety valveis that they both are spring-loaded valves. Usually, the valve is forced shut by the spring. When the pressure increases, the force of the spring has overcome that forces the valve to open.

Pressure Relief Valves are essential for controlling the flow rate of fluid, thereby facilitating the practical use of the system and providing additional safety to pressurized vessels or systems. There are three types of Pressure relief Valves.

Relief valve: – A valve that is used in a hydraulic system as pressure over sill devices. They can further be into adjustable relief valves and safety relief valves. They are usually used in naval ships for generating thermal electricity.

Safety Relief valve: – A valve that is used either for liquid or compressible fluids in a pressurized vessel is called a safety relief valve. These are generally used in boilers.

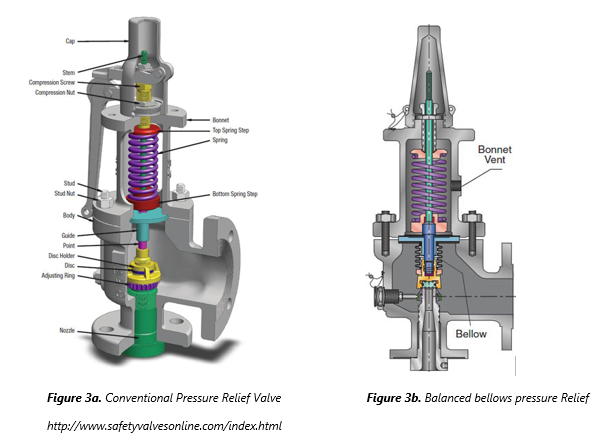

Conventional(spring-loaded):- The main components of traditional spring-loaded safety relief valve are the nozzle, seat disc, disc holder, bonnet, spring, set pressure adjusting screw, body, and blowdown adjustment ring.

Pilot operated:-The main component of pilot-operated hydraulic valve is inlet from the system, orifice, main spool spring, dart, pilot spring, adjustment screw, pilot drain, the skirt of the spool, and

Balanced bellows:-The essential components of Balanced bellows relief valve are nozzle, body, adjusting ring, disk, seating surface, bellows, balanced piston, bonnet, spring, adjusting screw, stem, and cap.

SKG Pneumatics is the best supplier ofindustrial valves in Delhi. The company has been into pneumatic industries for several years. The company manufactures different types of relief and safety valves that can be used in the industrial production unit. The pressuresafety relief valvecan prevent damage to property, life, and environment to a great extent and shall be used in every industry for additional safety. The pressure relief valves can be used in pressurized vessels, boiler, and other pressurized systems.

In the process industry, both terms refer to safety devices, which generally come in the form of valves, cylinders, and other cylinders that protect people, property, and the environment. Safety valves and relief valves are integral components of process safety. However, they are used for almost identical purposes. Their main difference lies in their operating mechanisms.

In the event of an overpressure, a safety valve or pressure relief valve (PRV) protects pressure-sensitive equipment. It is recommended to strip down relief valves regularly and prevent serious damage due to backpressure. Pressure relief valves are a crucial part of any pressurized system. In order to prevent system failures, you can set the pressure to open at predetermined levels. A setpoint, also known as a predetermined design limit, is set for all pressure systems. When the setpoint is exceeded, an overpressure valve opens.

There are various types of safety valves used in several types of industries, including power plants, petrochemical plants, boilers, oil and gas, pharmaceuticals, and more. Using safety valves helps to prevent accidents and injuries that can harm people, property, and processes. Pressure builds up in vessels and systems automatically when the device is activated above a preset level. Safety valves must be configured so that their prescribed pressure is exceeded in order for them to function (i.e., relieve pressure). Ideally, excess pressure should be released either to the atmosphere or back into the pneumatic system to prevent damage to the vessel. In addition, excess pressure should be released to keep pressure within a certain range. As soon as a slight increase in pressure above the desired limit has lifted the safety valve, it opens.

Valve relief removes excessive pressure from a system by limiting its pressure level to a safe level. Often referred to as pressure relief valves (PRVs) or safety relief valves, these valves provide relief from pressure. The purpose of a relief valve is, for example, to adjust the pressure within a vessel or a system so that a specific level is maintained. The goal of a relief valve, unlike a safety valve, is not to prevent damage to the vessel; rather, it is to control the pressure limit of a system dynamically depending on the requirements. Conversely, safety valves have a maximum allowable pressure set at a certain level, which allows escaping liquid or gas whenever the pressure exceeds it, eliminating damage to the system. It is imperative that safety valves are installed in a control system to prevent the development of pressure fluctuations that can cause property damage, life loss, and environmental pollution.

The hydraulic system relies on a pressure relief system in order to regulate the running pressure. By allowing excess pressure to escape from the pressurized zone, pressure relief valves and safety valves prevent overpressure when the pressure in the system reaches a predefined limit. By venting excess pressure through a relief port, or returning it through a return line, a pneumatic system can enable the excess pressure to escape into the atmosphere. Pump-driven pressure generators and control media that cannot be vented into the atmosphere are typical examples of this type of application.

Excess pressure may be relieved from the system using relief valves and safety valves. The valve opening increases proportionally as the vessel pressure increases with the relief valve. Gradually opening the valve rather than abruptly releases only a prescribed amount of fluid. As pressure is reduced, the release proceeds at this rate until the pressure drops. By contrast, an emergency safety valve operates automatically when a predetermined pressure is reached in the system, preventing a catastrophic system failure. When the system is under excessive stress, the safety valve regulates the pressure within the system and prevents overpressure.

Defining a “setpoint” is the process of defining a pressure level which triggers the device to vent excess pressure. Setpoint is different from pressure. Overpressure is prevented by setting these devices lower than the highest pressure the system can handle before overpressure occurs. Setting the device below this pressure prevents overpressure. The valve opens when pressure rises above the setpoint. A setpoint also known as the maximum allowable working pressure (MAWP) cannot be exceeded when deciding the pressure in pounds per square inch (PSIG). The adjustment points for safety valves are generally 3 percent above working pressures, while adjustment points for relief valves are 10% above working pressures.

Pressure in an auxiliary passage can be controlled by a safety valve as well as a relief valve by releasing excess pressure. Safety valves of this type are pressure-sensitive and reliable. Safety valves can be categorized according to their capacity and setpoint, although both terms often refer to safety valves. Self-opening devices open automatically when maximum allowable pressure has been reached rather than being manually activated to prevent over-pressurizing. Contrary to relief valves, safety valves are typically used for venting steam or vapor into the atmosphere. Relief valves regulate fluid flow and compressed air pressure and gases, whereas safety valves typically regulate steam and vapor venting. Put simply, relief valves are used for more gradual pressure control requiring accurate, dynamic systems, whereas safety valves are used for one set to prevent damage to a system.

For pressure control applications that require dynamic setpoints and therefore varying pressure limits, our Electronic Relief Valve is the appropriate solution. This device accepts a control voltage to dynamically set the relief pressure setpoint. Traditional relief valves are set manually, so that a technician must adjust the relief valve and have a pressure gauge to find the accurate setpoint. The Kelly Pneumatic Electronic Relief Valve allows an electronic control system to quickly and safely command a dynamic maximum pressure based on feedback from current system specifications. The Kelly Electronic Relief Valve also has an optional feedback signal representing the current pressure in the system. This allows the control system to dynamically respond to changing conditions.

Pressure Relieving Devices (PRD) are components used in refineries, chemical plants, and other similar facilities to prevent pressure vessels and other equipment from over pressurization by relieving excess pressure when necessary. They can be used to release gas, steam, liquids, or vapours. Properly functioning pressure relief devices are essential for protecting plant personnel and equipment, since unexpected overpressure events can potentially cause equipment damage, loss of containment, and result in costly plant shutdowns.

Pressure relieving devices include mechanisms such as Pressure Safety Valves (PSV) and Pressure Relief Valves (PRV), although there are other types of pressure relieving devices as well, such as Rupture Disk Devices and Pin-Actuated Devices. These devices can come in many different sizes and shapes and allow pressurized fluids or gasses to escape through a secondary passage out of the system so that pressure cannot build up beyond safe operating limits.

A Pressure Safety Valve (PSV) is a type of valve used to quickly release gasses from equipment in order to avoid over pressurization and potential process safety incidents. PSVs are activated automatically when pressure exceeds prescribed pressure limits in order to return equipment pressure to a safe operating level.

A Pressure Relief Valve (PRV) is a type of valve used to release stored gas in various equipment in order to maintain an optimal pressure level. PRVs open gradually as pressure builds up in order to release the necessary amount of pressure. While the term PRV is sometimes used interchangeably with PSV, there is a difference between the two. A PRV opens gradually in relation to the pressure, while a PSV is opened suddenly once the pressure hits a certain level in order to avoid over pressurization and a potential process safety incident.

The function of both PSV and PRV is that they relieve the excess pressure from the system by opening automatically and they get closed automatically when the pressure in the system normalizes.

The valve has a spring which is attached to adjusting screw. The screw can be adjusted to compress the spring thus imparting flexibility in adjusting the spring force. The spring is attached to a disc using a spindle. The location of the disk is where the fluid enters the valve when the system is over pressurized.

If the pressure force is less than the spring force then the fluid will not be able to move the disc. Such condition represents normal operating condition. If the pressure force is equal to the spring force then the disc starts to move. The fluid enters from the equipment to the valve and starts moving out of the system.

In case of PSV, when the pressure force becomes greater than the spring force the valve opens instantly and a ‘pop’ sound occurs whereas the PRV opens proportionally to the increasing pressure. It can be said that the opening is relatively gradual as compared to PSV.

The escaping fluid results in decrease of the pressure. When the pressure force becomes smaller than the spring force again then the disc returns to the same location again and seals the equipment.

Both pressure relief valves and pressure control valves have their own unique uses within fluid control and gas control applications. Pressure control valves and pressure relief valves have unique attributes that make them best suited to a number of very distinct and different applications. If you’ve found yourself wondering what a pressure control valve is, and the difference between the two pressure valve types, read on to learn more. Here, the fluid handling experts at Fluid Controls explain the difference between the two components; explaining the features, safety information and benefits of each valve type.

A pressure relief valve is a type of safety valve that is used in a process control system to limit or control the pressure in a system. This prevents pressure from building up, which could cause a devastating process breakdown, including equipment failure.

This means that pressure relief valves are designed to be set at a specific pressure to protect the equipment from reaching a pressure that could damage expensive equipment.

Pressure Relief Valves (PRV) were first used on steam boilers during the industrial revolution. Early boilers without them were prone to accidental Explosion due to their lack of safety features.

A pressure relief valve is a static device that can reduce pressure even if there is no flow coming out of the reservoir. They are designed to open proportionally to increasing pressure and therefore are not recommended for applications requiring immediate full valve flow at a set pressure.

The full flow of the relief valve is defined at 10% over set pressure and the two general types of protection encountered in industry are thermal protection and flow protection. These precision valves are designed for pressure gas systems, cryogenic systems, petrochemical applications and other special systems. The pressure relief valve features are designed to EN ISO 4126-1 standard, they have a lower whole lifetime cost and they optimise outlet flow for faster relieving. These valves usually release in to the drain or environment meaning that the steam or fluid that goes into the pressure release valve is naturally lost to the system.

Similar to a pressure relief valve, a pressure control valve can protect a system from the damages which is caused by excessive pressure. These valves are often found in hydraulic systems and are used to protect the hydraulic system.

Hydraulic systems employ pressure control valves in order to limit the level of maximum pressure which can protect the pump or system from overpressure.

A Pressure Control Valve (PCV) on the other hand, acts to change resistance to the flow of the fluid, but does not alter its destination. Fluid that passes through the Pressure Control Valve is still going to the destination it was proposed for and is not lost.

These valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit.

The pressure control valve features guarantee the performance of the system and optimisation of energy usage. Exact and precise control of differential pressures eliminates overflows at partial conditions and controls the temperature at low load conditions.

Here at Fluid Controls, we are proud to be able to offer a range of control valves from some of the leading names in process and fluid controls, including Burkert and Welker.

The main difference between PRV and PCV is that the PCV is called a first-line defence which is meant for primary safety. The PRV is not used as a pressure control device but as a backup of last resort. Pressure Control Valves are ideal for applications requiring a reduced pressure to a cylinder whereas Pressure Relief Valves are used to maintain a preset downstream pressure.

Here at Fluid Controls, we don’t just have the knowledge and expertise to explain what a pressure control valve is, and its difference from a pressure relief valve. We can also support you in making the correct choice of pressure control valve and pressure relief valve for your application. For more information about any of our products at Fluid Controls call us today on 0118 970 2060

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

The pilot is designed to open gradually, so that less of the system fluid is lost during each relief event. The piston lifts in proportion to the overpressure.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

In order to ensure that the maximum allowable accumulation pressure of any system or apparatus protected by a safety valve is never exceeded, careful consideration of the safety valve’s position in the system has to be made. As there is such a wide range of applications, there is no absolute rule as to where the valve should be positioned and therefore, every application needs to be treated separately.

A common steam application for a safety valve is to protect process equipment supplied from a pressure reducing station. Two possible arrangements are shown in Figure 9.3.3.

The safety valve can be fitted within the pressure reducing station itself, that is, before the downstream stop valve, as in Figure 9.3.3 (a), or further downstream, nearer the apparatus as in Figure 9.3.3 (b). Fitting the safety valve before the downstream stop valve has the following advantages:

• The safety valve can be tested in-line by shutting down the downstream stop valve without the chance of downstream apparatus being over pressurised, should the safety valve fail under test.

• When setting the PRV under no-load conditions, the operation of the safety valve can be observed, as this condition is most likely to cause ‘simmer’. If this should occur, the PRV pressure can be adjusted to below the safety valve reseat pressure.

Indeed, a separate safety valve may have to be fitted on the inlet to each downstream piece of apparatus, when the PRV supplies several such pieces of apparatus.

• If supplying one piece of apparatus, which has a MAWP pressure less than the PRV supply pressure, the apparatus must be fitted with a safety valve, preferably close-coupled to its steam inlet connection.

• If a PRV is supplying more than one apparatus and the MAWP of any item is less than the PRV supply pressure, either the PRV station must be fitted with a safety valve set at the lowest possible MAWP of the connected apparatus, or each item of affected apparatus must be fitted with a safety valve.

• The safety valve must be located so that the pressure cannot accumulate in the apparatus viaanother route, for example, from a separate steam line or a bypass line.

It could be argued that every installation deserves special consideration when it comes to safety, but the following applications and situations are a little unusual and worth considering:

• Fire - Any pressure vessel should be protected from overpressure in the event of fire. Although a safety valve mounted for operational protection may also offer protection under fire conditions,such cases require special consideration, which is beyond the scope of this text.

• Exothermic applications - These must be fitted with a safety valve close-coupled to the apparatus steam inlet or the body direct. No alternative applies.

• Safety valves used as warning devices - Sometimes, safety valves are fitted to systems as warning devices. They are not required to relieve fault loads but to warn of pressures increasing above normal working pressures for operational reasons only. In these instances, safety valves are set at the warning pressure and only need to be of minimum size. If there is any danger of systems fitted with such a safety valve exceeding their maximum allowable working pressure, they must be protected by additional safety valves in the usual way.

In order to illustrate the importance of the positioning of a safety valve, consider an automatic pump trap (see Block 14) used to remove condensate from a heating vessel. The automatic pump trap (APT), incorporates a mechanical type pump, which uses the motive force of steam to pump the condensate through the return system. The position of the safety valve will depend on the MAWP of the APT and its required motive inlet pressure.

This arrangement is suitable if the pump-trap motive pressure is less than 1.6 bar g (safety valve set pressure of 2 bar g less 0.3 bar blowdown and a 0.1 bar shut-off margin). Since the MAWP of both the APT and the vessel are greater than the safety valve set pressure, a single safety valve would provide suitable protection for the system.

However, if the pump-trap motive pressure had to be greater than 1.6 bar g, the APT supply would have to be taken from the high pressure side of the PRV, and reduced to a more appropriate pressure, but still less than the 4.5 bar g MAWP of the APT. The arrangement shown in Figure 9.3.5 would be suitable in this situation.

Here, two separate PRV stations are used each with its own safety valve. If the APT internals failed and steam at 4 bar g passed through the APT and into the vessel, safety valve ‘A’ would relieve this pressure and protect the vessel. Safety valve ‘B’ would not lift as the pressure in the APT is still acceptable and below its set pressure.

It should be noted that safety valve ‘A’ is positioned on the downstream side of the temperature control valve; this is done for both safety and operational reasons:

Operation - There is less chance of safety valve ‘A’ simmering during operation in this position,as the pressure is typically lower after the control valve than before it.

Also, note that if the MAWP of the pump-trap were greater than the pressure upstream of PRV ‘A’, it would be permissible to omit safety valve ‘B’ from the system, but safety valve ‘A’ must be sized to take into account the total fault flow through PRV ‘B’ as well as through PRV ‘A’.

A pharmaceutical factory has twelve jacketed pans on the same production floor, all rated with the same MAWP. Where would the safety valve be positioned?

One solution would be to install a safety valve on the inlet to each pan (Figure 9.3.6). In this instance, each safety valve would have to be sized to pass the entire load, in case the PRV failed open whilst the other eleven pans were shut down.

If additional apparatus with a lower MAWP than the pans (for example, a shell and tube heat exchanger) were to be included in the system, it would be necessary to fit an additional safety valve. This safety valve would be set to an appropriate lower set pressure and sized to pass the fault flow through the temperature control valve (see Figure 9.3.8).

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect pressure vessels and other equipment from being subjected to pressures that exceed their design limits. When the set pressure is exceeded, the relief valve becomes the "path of least resistance" as the valve is forced open and a portion of the fluid is diverted through the auxiliary route. In systems containing flammable fluids, the diverted fluid (liquid, gas or liquid-gas mixture) is either recapturedvapor recovery system or is routed through a piping system known as a flare header or relief header to a central, elevated gas flare where it is burned, releasing naked combustion gases into the atmosphere.blowdown is usually stated as a percentage of set pressure and refers to how much the pressure needs to drop before the valve reseats. The blowdown can vary roughly 2–20%, and some valves have adjustable blowdowns.

In high-pressure gas systems, it is recommended that the outlet of the relief valve is in the open air. In systems where the outlet is connected to piping, the opening of a relief valve will give a pressure build-up in the piping system downstream of the relief valve. This often means that the relief valve will not re-seat once the set pressure is reached. For these systems often so-called "differential" relief valves are used. This means that the pressure is only working on an area that is much smaller than the area of the opening of the valve. If the valve is opened the pressure has to decrease enormously before the valve closes and also the outlet pressure of the valve can easily keep the valve open. Another consideration is that if other relief valves are connected to the outlet pipe system, they may open as the pressure in the exhaust pipe system increases. This may cause undesired operation.

In some cases, a so-called bypass valve acts as a relief valve by being used to return all or part of the fluid discharged by a pump or gas compressor back to either a storage reservoir or the inlet of the pump or gas compressor. This is done to protect the pump or gas compressor and any associated equipment from excessive pressure. The bypass valve and bypass path can be internal (an integral part of the pump or compressor) or external (installed as a component in the fluid path). Many fire engines have such relief valves to prevent the overpressurization of fire hoses.

In other cases, equipment must be protected against being subjected to an internal vacuum (i.e., low pressure) that is lower than the equipment can withstand. In such cases, vacuum relief valves are used to open at a predetermined low-pressure limit and to admit air or an inert gas into the equipment to control the amount of vacuum.

In the petroleum refining, petrochemical and chemical manufacturing, natural gas processing and power generation industries, the term relief valve is associated with the terms pressure relief valve (PRV), pressure safety valve (PSV) and safety valve:

Pressure relief valve (PRV) or Pressure Release valve (PRV) or pressure safety valve (PSV): The difference is that PSVs have a manual lever to activate the valve in case of emergency. Most PRVs are spring operated. At lower pressures some use a diaphragm in place of a spring. The oldest PRV designs use a weight to seal the valve.

Set pressure: When the system pressure increases to this value, the PRV opens. The accuracy of the set pressure may follow guidelines set by the American Society of Mechanical Engineers (ASME).

Safety relief valve (SRV): A relief valve that can be used for gas or liquid service. However, the set pressure will usually only be accurate for one type of fluid at a time.

Pilot-operated relief valve (POSRV, PORV, POPRV): A device that relieves by remote command from a pilot valve which is connected to the upstream system pressure.

Low-pressure safety valve (LPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small and near the atmospheric pressure.

Vacuum pressure safety valve (VPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small, negative, and near the atmospheric pressure.

Low and vacuum pressure safety valve (LVPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small, negative, or positive, and near the atmospheric pressure.

Pressure vacuum release valve (PVRV): A combination of vacuum pressure and a relief valve in one housing. Used on storage tanks for liquids to prevent implosion or overpressure.

Snap acting: The opposite of modulating, refers to a valve that "pops" open. It snaps into a full lift in milliseconds. Usually accomplished with a skirt on the disc so that the fluid passing the seat suddenly affects a larger area and creates more lifting force.

In most countries, industries are legally required to protect pressure vessels and other equipment by using relief valves. Also in most countries, equipment design codes such as those provided by the American Society of Mechanical Engineers (ASME), American Petroleum Institute (API) and other organizations like ISO (ISO 4126) must be complied with and those codes include design standards for relief valves.

Formed in 1977, the Design Institute for Emergency Relief SystemsAIChE) that developed methods for the design of emergency relief systems to handle runaway reactions. Its purpose was to develop the technology and methods needed for sizing pressure relief systems for chemical reactors, particularly those in which exothermic reactions are carried out. Such reactions include many classes of industrially important processes including polymerizations, nitrations, diazotizations, sulphonations, epoxidations, aminations, esterifications, neutralizations, and many others. Pressure relief systems can be difficult to design, not least because what is expelled can be gas/vapor, liquid, or a mixture of the two – just as with a can of carbonated drink when it is suddenly opened. For chemical reactions, it requires extensive knowledge of both chemical reaction hazards and fluid flow.

DIERS investigated the two-phase vapor-liquid onset/disengagement dynamics and the hydrodynamics of emergency relief systems with extensive experimental and analysis work.

H.G. Fisher; H.S. Forrest; Stanley S. Grossel; J. E. Huff; A. R. Muller; J. A. Noronha; D. A. Shaw; B. J. Tilley (1992). Emergency Relief System Design Using DIERS Technology: The Design Institute for Emergency Relief Systems (DIERS) Project Manual. ISBN 978-0-8169-0568-3.

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk.

Safety valves were first developed for use on steam boilers during the Industrial Revolution. Early boilers operating without them were prone to explosion unless carefully operated.

Vacuum safety valves (or combined pressure/vacuum safety valves) are used to prevent a tank from collapsing while it is being emptied, or when cold rinse water is used after hot CIP (clean-in-place) or SIP (sterilization-in-place) procedures. When sizing a vacuum safety valve, the calculation method is not defined in any norm, particularly in the hot CIP / cold water scenario, but some manufacturers

The earliest and simplest safety valve was used on a 1679 steam digester and utilized a weight to retain the steam pressure (this design is still commonly used on pressure cookers); however, these were easily tampered with or accidentally released. On the Stockton and Darlington Railway, the safety valve tended to go off when the engine hit a bump in the track. A valve less sensitive to sudden accelerations used a spring to contain the steam pressure, but these (based on a Salter spring balance) could still be screwed down to increase the pressure beyond design limits. This dangerous practice was sometimes used to marginally increase the performance of a steam engine. In 1856, John Ramsbottom invented a tamper-proof spring safety valve that became universal on railways. The Ramsbottom valve consisted of two plug-type valves connected to each other by a spring-laden pivoting arm, with one valve element on either side of the pivot. Any adjustment made to one of valves in an attempt to increase its operating pressure would cause the other valve to be lifted off its seat, regardless of how the adjustment was attempted. The pivot point on the arm was not symmetrically between the valves, so any tightening of the spring would cause one of the valves to lift. Only by removing and disassembling the entire valve assembly could its operating pressure be adjusted, making impromptu "tying down" of the valve by locomotive crews in search of more power impossible. The pivoting arm was commonly extended into a handle shape and fed back into the locomotive cab, allowing crews to "rock" both valves off their seats to confirm they were set and operating correctly.

Safety valves also evolved to protect equipment such as pressure vessels (fired or not) and heat exchangers. The term safety valve should be limited to compressible fluid applications (gas, vapour, or steam).

For liquid-packed vessels, thermal relief valves are generally characterized by the relatively small size of the valve necessary to provide protection from excess pressure caused by thermal expansion. In this case a small valve is adequate because most liquids are nearly incompressible, and so a relatively small amount of fluid discharged through the relief valve will produce a substantial reduction in pressure.

Flow protection is characterized by safety valves that are considerably larger than those mounted for thermal protection. They are generally sized for use in situations wher

8613371530291

8613371530291