do propane tanks have a safety valve factory

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

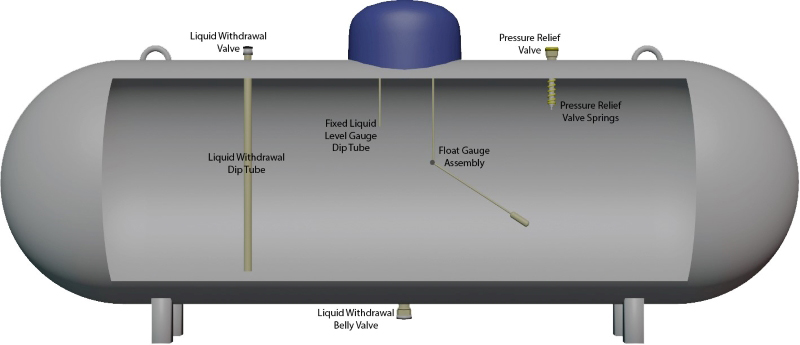

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

One thing you should pay attention to is the propane tank’s safety relief valve. All propane tanks, including the cylinders you use for your BBQ grill, are required by law to have pressure relief devices to allow for the release of excess pressure in the tank.

A spring keeps the safety relief valve closed as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear pop if that occurs.

Your propane tank needs to have room for the propane inside it to expand. That is why your propane tank is filled to 80% of its capacity. The 20% of the tank that is empty space allows the propane to safely expand.

That expansion is why propane tanks are white or beige. Light colors reflect heat to minimize expansion. Dark colors retain heat and can cause the propane inside your tank to expand to dangerous levels. So, even if your propane tank doesn’t go with the color of your siding, leave it alone.

A certified pressure relief valve testing contractor must perform all inspections. That’s where Foster Fuels comes in. Our inspectors can advise when testing is necessary and when a replacement would be a more cost-effective option. We also offer comprehensive preventative maintenance programs that can extend the life of your pressure relief valves and related safety equipment, saving you money over the long term with services such as:

Reminding you valves over 10 years old must be tested or replaced prior to the following scheduled inspection, which is two years from the current inspection.

Virginia has its own set of requirements for pressure relief valve testing and certification. These are primarily based on NFPA 58 and the Virginia Department of Labor and Industry. State requirements establish a propane pressure relief valve testing frequency of once every 10 years for most equipment. The state code also sets a compliance schedule of two years from the initial inspection date. For more information, contact Foster Fuels directly.

State and NBIC requirements present several challenges for businesses that rely on propane in their facilities. Organizations with multiple tanks may find the time and money required for pressure relief valve testing—including downtime and flaring of vapor, if necessary—to be overly burdensome. The limited time allotted to ensure all tanks are inspected and tested is an additional difficulty.

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

Pressure relief valves are critical to the safe operation of propane storage tanks & bulk plants. As such, they are closely regulated in most states and subject to both National Board Inspection Code (NBIC) and NFPA requirements, which call for testing and replacement at regular intervals.

In the state of Virginia, regulations for pressure relief valve testing and certification call for routine inspections to verify an appropriate device is installed on all tanks in addition to rigorous testing to confirm their proper working condition in accordance with Virginia Department of Labor & Industry (DOLI) and NFPA 58 recommendations, including:

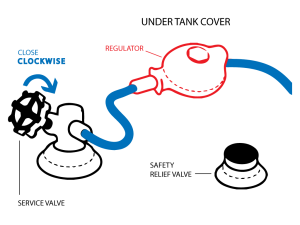

Houses or buildings utilizing gas energy require a gas piping system to power heaters, ovens, and other heating appliances. One of the most important elements of a gas piping system is the propane service valve, which controls propane gas flow in and out of a building. While there may be many other valves within gas plumbing, this valve functions as an on/off switch and serves as the main point of control for cutting off or allowing for the flow of gas into a piping system.

Propane valves are simply used to turn gas on or off. Similar to that of a water faucet, propane valves consist of a handwheel that controls propane gas flow when turned. When the wheel is turned, a stem and seat mechanism located within the valve opens or closes to prevent or allow gas flow from the tank.

Using propane gas requires an LP gas regulator, which decreases the amount of pressure released into the gas line, keeping it at an acceptable and safe level while still meeting the needs of the application.

There are multiple different valves in any propane system, each of which has a particular job. At IPS Equipment, we provide some of the most common types of valves for propane systems, including:

A pressure or safety relief valve is a safety mechanism that every propane system needs. It allows excess pressure in the tank to be slowly and safely released. Without this valve, pressure can build up and cause the tank to crack or rupture.

The relief valve has a pressurized spring. If the pressure levels within the tank grow too high, the spring forces the valve open just enough to return the pressure levels to acceptable levels. Once the pressure decreases, the spring relaxes, and the valve automatically closes.

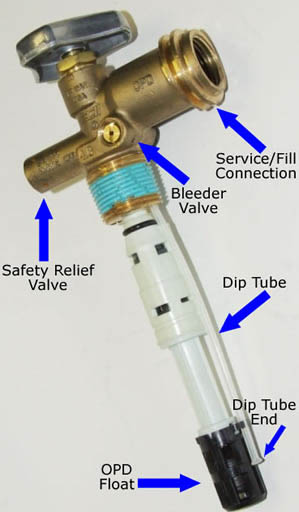

This valve is where gas delivery personnel add new gas to a propane tank. Propane delivery trucks have hoses that can be attached to the filler valve so propane can be pumped into the tank. This valve is also pressure-activated, and it opens automatically in response to the pressure in the hose.

Filler valves have gaskets that operators can push the hose end against to avoid propane leaks. They also only allow for unidirectional fluid movement, meaning that once the tank is full, there is no risk of propane escaping when the hose is withdrawn.

This shut-off valve prevents gas from entering the building and any attached appliances. You can use this central point of control like an on/off switch to completely halt the path of gas in the system.

This valve is also called a vapor return valve or vapor eliminator valve. It ensures that propane is delivered at the proper pressure levels from the propane delivery truck to a personal tank and returns any excess propane back to the delivery truck. This is similar to a safety valve, except the vapor equalizing valve ensures the propane is delivered at proper pressures for optimum use, not safety. This is especially crucial during hot weather or in warm environments, as that can increase the pressure.

This specialized valve is meant for use by propane companies only. It allows operators with the proper tools to drain liquid propane from the tank. Propane tanks must be drained to <5% capacity levels before they can legally be moved.

IPS Equipment specializes in supplying propane marketers with reliable valves, fittings, regulators, and more for propane systems. Contact us today to learn more about our comprehensive products or services, or browse through our catalog to start your order.

If you use a gas grill, heat your home or spend time in an industrial facility, chances are you have used propane. It’s a well-established gas for many uses, but it can be dangerous.

Below are some rules to practice safety in the household and the workplace by following regulations set by the Occupational Safety and Health Administration (OSHA) and the Compressed Gas Association.

Cylinders used for forklifts can be stored in either the vertical or horizontal position. If stored horizontally, the relief valve must be positioned at 12 o’clock. These cylinders do not require an overfill prevention device (OPD).

Risk Managers and Safety Directors: If you would like to schedule an introductory call with an Oswald professional fill out the form below or learn more about Oswald Risk Consulting: Safety & Loss Control services.

Oswald OnTrack is a secure, web-based risk management and safety platform designed toease compliance, improve risk prevention efforts and results, and relieve regulatory pain points for any industry. The programs are simple to set up and easily create a comprehensive and cost-effective risk management and safety program that can be utilized by all departments.

Oswald OnTrack, powered by Succeed Management Solutions, enables the oversight and management of multiple locations and departments, making it a perfect resource for the safety-conscious organization.

Note: This communication is for informational purposes only.Although every reasonable effort is made to present current and accurate information, Oswald makes no guarantees of any kind and cannot be held liable for any outdated or incorrect information. View our communications policy.

From powering home barbeques to torches and warehouse forklifts, propane is a useful and versatile gas. But it’s also a hazardous flammable material that carries huge amounts of explosive force because it’s pressurized. This is why the proper storage, handling and transportation of propane according to the regulations set by OSHA and CGA (Compressed Gas Association) is so essential.

Although the list of OSHA’s storage and handling regulations is very long, the basic rules of handling and storing propane can be condensed as follows:

Industrial facilities can store propane in cylinders within buildings not frequented by the public (such as industrial buildings) with the limit capped at 300 lbs. of propane. However, if the facility has special buildings or rooms dedicated to propane storage, the amount of propane allowed is 10,000 pounds. Designated rooms need to fulfill a number of very specific requirements listed on OSHA’s website.

They should be stored in cylinder safety cages or cabinets in flat areas that don’t collect water. They should be placed off the ground, on top of a surface that will not burn.

Cylinders must be protected from falling by using a chain or another adequate support systems. Consider securing each cylinder separately to prevent them all from falling when only one is removed from storage.

The dates on the cylinder collar should be checked periodically to ensure that the cylinder is not past its requalification date and to replace or exchange cylinders that are out of date.

Cylinders need to be checked for leaks and signs of rust and wear—even if they’re under their requalification date, they may still need to replaced if they’re in poor condition.

Container valves must be protected while in storage by setting them into the container’s recess to prevent the possibility of being struck if the container is dropped, or by fastening to the container a ventilated cap or collar that is constructed so that a blow would not be transmitted to a valve or other connection.

Whether using propane at home, on holiday or at work, following the manufacturer’s instructions can keep everyone safe. It doesn’t matter if the cylinders are small enough to fit in the car or if they require a forklift to transport them, their use and inspections should always be handled with care.

Appropriate face and eye protection and gloves(loose fitting, such as insulated neoprene) must be worn when connecting and disconnecting propane cylinders from their hoses due to the possibility of freezer burn, which propane can cause instantaneously.

Never use matches or a flame to check for leaks. Use a leak detector or soap (brush a 50% liquid dish soap and 50% water solution onto all hose connections and valves; bubbles indicate a leak). If you encounter a leak, shut off the propane at the tank if it’s safe to do so, tighten hose connections and check again for leaks using the dish soap and water solution.

Do not let the cylinder get too hot. Additionally, don’t paint propane cylinders a dark color—they are painted a light or reflective color to reduce heat absorption from the sun.

Do not leave LPG-powered trucks near heat sources, stairways, exits or other busy areas. Turn the service valve off when parking LPG-powered trucks for a long time.

Propane cylinders are built to withstand a huge amount of pressure and they’re meant to last. But they still require gentle and careful handling when transported, because they could be faulty and, despite their sturdy appearance, they can still be easily damaged.

During unloading, the transport truck mustn’t be parked on public thoroughfares and it must be at least 5 feet from storage containers, positioned so that shutoff valves are readily accessible.

Storing and handling propane tanks properly is an important part of remaining compliant. Many factors need to be taken into consideration, including nearby buildings, other flammable objects and awnings.

Too often, facilities using propane tanks have them stacked indoors, stored improperly and with no safety cages or protection. A lax attitude towards propane storage is often the result of complacency—other human factors can also compromise safety during the transportation and use of propane. Although the list of OSHA requirements is long, it’s worth taking a look to ensure that your facility is compliant, and to also assess whether human factors are affecting how workers handle propane and propane-powered devices.

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Spartanburg resident Bill Edge supports recent legislation that reverses a law enacted in April requiring all propane tanks made before September 1998 to have safety valves installed.

"It was just a political thing to fatten their pockets," Edge said. "It"s amazing to me how I can use propane tanks for 40 years and all of a sudden they are unsafe to use." State legislators rescinded the safety valve requirement three weeks ago and Gov. Jim Hodges signed it into law. The safety valve prevents tanks from overfilling when they are being refilled. State Sen. Glenn McConnell, R-Charleston, had pushed to have the new requirement rescinded after constituents complained about the cost of putting the valves on old tanks or having to buy new tanks. "It"s just an example of government overreacting," McConnell said. He noted that no accidents have been reported in South Carolina because of an overfilled tank. South Carolina was one of many states that agreed earlier this year to prohibit 4-to 40-pound propane tanks from being refilled if they did not have the safety valves installed. The tanks are normally used for gas grills and recreational vehicles. Tanks made since 1998 include an overfill prevention device (OPD) that allows the tank to be filled to 80 percent capacity. The remaining 20 percent leaves space for the gas to expand when it heats up. Without the room to expand, propane tanks can explode. Although state law no longer requires the safety valves, a local gas company manager said it still is a good idea to get them. Ideal Fuel Company Manager Wayne Camp said his company still will refuse to refill old tanks unless they have the new safety valve. "We are doing this primarily because it is a safety issue," Camp said. "The valve not only will prevent tanks from being overfilled but it also protects propane gas from being released into the atmosphere." A new 20-pound tank costs about $28 locally.

If you smell gas (an odor similar to rotten eggs or sulfur) or think you may have a gas leak, exit the premises immediately and contact Arrow Propane at

Stay away from the property until a trained professional gives you an all-clear. Gas leaks can be a life-or-death situation and demand serious attention.

A propane tank is full when the gauge reads 80% (the empty 20% allows for expansion of the propane vapor). If the meter reads below 20%, contact us immediately atfor a new propane tank delivery.

If you think your portable propane tank or grill tank is leaking, and it is safe to turn off the tank valve, turn it to the right (clockwise). If you cannot turn off the valve, leave the area and dial 911 or call your local fire department.

Storing propane tanks outdoors is safe, but choosing a spot away from living areas is best. You must always hold propane tanks in an upright position on stable surfaces. Ensure that the gas valve is in the off position when not using your tank, and never store your propane tank inside your home or vehicle.

Propane is not affected by freezing temperatures. The best policy is to keep your tanks in locations away from direct sunlight for extended periods. Do not expose the tank to temperatures at or above 120°F (49°C).

You can still store propane tanks outdoors on stable surfaces when the weather reaches high temperatures. Essential rules for propane storage include:

Re-lighting your pilot light can be dangerous. Contact a trained professional or our customer service team for further guidance. Follow the manufacturer’s instructions and warnings concerning the appliance.

If you are going to be away from your home for an extended time, consider shutting off all of your propane supply valves, including the main supply valve on your propane tank and the gas supply valves on each appliance.

When you return, it is critical that you call us at Arrow Propane to conduct a leak check before turning on your propane supply again. After we confirm no leaks, we can also re-light your pilot lights if you need help.

In extreme, dry heat conditions, keep the 10-foot radius around your propane tank and grill clear of any dry materials that could ignite. In flood or stormy conditions with very high winds, propane tanks can shift, damaging gas lines and the tanks themselves.

A large propane tank can float away, hitting objects in its path. Water and debris can find their way inside regulators and controls, causing potential safety issues.

If you question the safety of the current conditions, leave the area immediately, alert Arrow Propane, and have your property inspected by a trained professional before re-entering.

To reduce the risk of carbon monoxide, have a trained professional check your appliances and venting systems routinely and consistently practice the following steps:

If you cook using a gas grill fueled by propane, you may have noticed a change in how the valve on the propane tank looks. Also, if you bought a gas grill in the last couple of years, the tank that came with the grill and the connection on the grill probably look different from what you are accustomed to seeing.

A safety note for you: Propane tanks of any design must be transported and stored in an upright position so the pressure relief device will function properly. Laying the tank on its side in the trunk of your car is a potentially very dangerous situation.

What happens if you have an older grill and have to replace the tank and get one with the Acme valve? Use it. They are compatible, as the left-hand-thread fitting on your older grill will screw into the internal threads on the Acme valve.

Also, there is another type of valve not widely available yet. This one is a quick disconnect, somewhat like a fitting that attaches an air hose to a pneumatic tool. This fitting will be covered later in this article.

All new cylinders from 4 pounds up to 40 pounds propane capacity must have the OPD valve. All cylinders from 4 pounds up to 40 pounds will have to have an OPD valve by April 1, 2002, or it will be illegal to fill them. It will not be illegal to use or transport them, only to fill them.

Now that you know how to make the connection between the grill and the tank, you need to know what the difference is in getting your tank refilled. If you take it to a place that fills your tank, you will notice no difference in filling the tank. The same piece of equipment that fills tanks with the POL valve will also fill through the Acme valves or OPD valves because of those internal threads. But there is a difference you need to recognize after you get your tank filled. As you get ready to travel with your newly-filled tank, instead of screwing a plug into the internal threads, you may press the optional dust cap over the external threads. The Acme valves and OPD valves have some built-in safeguards that prevent the escape of gas when the tank is not attached to the grill, even if the valve is open. This is the reason for the valve body being slightly larger. However, if you screw a plug into the valve, you defeat these safeguards. So be sure to leave the plug out of the Acme valves and OPD valves!

There are some other safeguards in the valve and connector combination that stop the gas flow if the tank is involved in a fire, even if the tank is still attached to the grill and even if the valve is wide open. Another safeguard limits the flow of gas from the tank should the hose break or leak.

The safety devices require you to open the valve on the tank before you open the burner valve. Otherwise, all you will get is enough gas to run a pilot light. If your grill will not light, try this:

You need to be attentive if you go to a cylinder exchange cabinet to turn in your empty tank for a filled one. If you have the old-style connector on your grill, you can use both of the widely-available screw-on valves. However, if you have a new grill with the connector that needs the new external threads, be sure to get a tank with the new Acme valve. Some of the exchange cabinets offer many tank styles. Get the one you need. Remember, the Acme valve will work on both styles of grill connectors discussed so far.

You may still see some non-OPD-equipped cylinders after April 1, 2002. This is legal. As mentioned earlier, you may use and transport non-OPD cylinders after this date. But you cannot have them filled.

As mentioned earlier, there is also a quick-disconnect valve and fitting combination available. (Some Weber gas grills use this fitting.) To make the connection with this combination, you simply pull back slightly on the collar ring on the valve and press the fitting firmly into the hole in the valve until it "clicks" into place. It will remain in place until you slide back the collar on the end of the valve. This valve and connector combination also has the safeguards mentioned earlier for the Acme valve. Your refueling choices are more restricted with this combination. These are rarely stocked in exchange cabinets. When you bought the tank with the quick-disconnect valve, you probably received a special fitting to be used to fill the tank. The fitting has the internal POL threads that allows the refiller to attach his equipment to your tank. Your refiller may or may not have this fitting. Be sure you have the fitting with you when you go to the refiller and when you leave with your full tank.

Propane tanks make grilling easy and convenient. In most cases, grilling is a pleasant way to spend a summer evening or weekend outdoors with family and friends. There have been few problems with propane tanks in these situations, but the potential for problems exists, as it does with any source of energy. To reduce the possibility of these problems, follow these steps:

If the tank becomes corroded or looses its collar ring (the carrying handle) or its foot ring (the support ring on the bottom), replace the tank immediately.

If you have questions about propane containers or propane use, contact your propane dealer or Richard Fredenburg, LP-Gas Engineer with the Standards Division, North Carolina Department of Agriculture and Consumer Services. Our address is 1050 Mail Service Center, Raleigh, NC 27699-1050. Our telephone number is (919) 733-3313.

8613371530291

8613371530291