do propane tanks have a safety valve in stock

A certified pressure relief valve testing contractor must perform all inspections. That’s where Foster Fuels comes in. Our inspectors can advise when testing is necessary and when a replacement would be a more cost-effective option. We also offer comprehensive preventative maintenance programs that can extend the life of your pressure relief valves and related safety equipment, saving you money over the long term with services such as:

Reminding you valves over 10 years old must be tested or replaced prior to the following scheduled inspection, which is two years from the current inspection.

Virginia has its own set of requirements for pressure relief valve testing and certification. These are primarily based on NFPA 58 and the Virginia Department of Labor and Industry. State requirements establish a propane pressure relief valve testing frequency of once every 10 years for most equipment. The state code also sets a compliance schedule of two years from the initial inspection date. For more information, contact Foster Fuels directly.

State and NBIC requirements present several challenges for businesses that rely on propane in their facilities. Organizations with multiple tanks may find the time and money required for pressure relief valve testing—including downtime and flaring of vapor, if necessary—to be overly burdensome. The limited time allotted to ensure all tanks are inspected and tested is an additional difficulty.

Safety relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If the pressure in the tank rises to that of the spring, the valve will open, which results in a hissing sound outside of the tank. If the If tank pressure rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially results in a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

The majority of propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Typically, internal relief valves are placed near the end of the propane tank on above ground containers.

External relief valves are found primarily on older tanks. They operate in the same manner as an internal relief valve with the spring mechanism being outside of the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older propane tanks with an external relief valve installed on the container are typically replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

The safety relief valve performs a vital role in the protection of the propane tank, so it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If you encounter a relief valve that seems to be “hissing” (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85 percent, spray some water from a hose on the tank. This may cool it down and reduce the expansion of liquid in the tank. Contact your propane company immediately and inform them of the situation.

If your propane relief valve is leaking, contact your propane company immediately. Do not try to fix this issue yourself. AS a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let your propane company or LPG professional handle any issues with the safety relieve valve.

If you use a gas grill, heat your home or spend time in an industrial facility, chances are you have used propane. It’s a well-established gas for many uses, but it can be dangerous.

Below are some rules to practice safety in the household and the workplace by following regulations set by the Occupational Safety and Health Administration (OSHA) and the Compressed Gas Association.

Cylinders used for forklifts can be stored in either the vertical or horizontal position. If stored horizontally, the relief valve must be positioned at 12 o’clock. These cylinders do not require an overfill prevention device (OPD).

Risk Managers and Safety Directors: If you would like to schedule an introductory call with an Oswald professional fill out the form below or learn more about Oswald Risk Consulting: Safety & Loss Control services.

Oswald OnTrack is a secure, web-based risk management and safety platform designed toease compliance, improve risk prevention efforts and results, and relieve regulatory pain points for any industry. The programs are simple to set up and easily create a comprehensive and cost-effective risk management and safety program that can be utilized by all departments.

Oswald OnTrack, powered by Succeed Management Solutions, enables the oversight and management of multiple locations and departments, making it a perfect resource for the safety-conscious organization.

Note: This communication is for informational purposes only.Although every reasonable effort is made to present current and accurate information, Oswald makes no guarantees of any kind and cannot be held liable for any outdated or incorrect information. View our communications policy.

The safe storage of propane cylinders has always been an issue for propane consumers in the residential and industrial LP Gas cylinder markets. It is important to know that the location as well as the position of the cylinder both are part of essential safety practices. Storing propane cylinders with or close to other flammable or combustible materials is considered extremely unsafe and is not advisable under any circumstance. NEVER STORE PROPANE CYLINDERS INDOORS, IN A HOUSE, OR IN A GARAGE.

Cylinders awaiting use should be stored in a well ventilated area away from heavy traffic. Propane cylinders stored upright should be placed on a flat surface such as concrete or other non-flammable material that will not collect water. Cylinders that are stored in places that such as damp grass or mud risk exposing the cylinder to conditions that may cause rust and/or pitting that may render the cylinder useless. Storing any propane container indoors is not advisable. It is recommended that a propane bottle be stored outside on a firm surface and away from any source of ignition.

Propane cylinders should always be positioned so that the relief valve is in direct communication with the vapor space of the container. Cylinders that are stored vertically upright will have the relief valve communicating with vapor space. Regarding the cylinder relief valve, it is important to keep the safety relief valve pointed away from anything that escaping propane could come in contact with possibly causing a fire or accident. If cylinders are stored improperly, such as on their side with the relief valve in contact with propane liquid and the safety relief valve opens for any reason, liquid will be escaping instead of vapor posing a much greater danger. In short, be sure the relief valve is communicating with the vapor space of the tank. All consumer propane cylinders should be stored vertically upright in all circumstances.

The pictures below depict unsafe positions of cylinders while in storage. The first picture assumes that the 20 lb. cylinder has a little over 50% propane. Even with the tank around half full, the liquid inside is above the level of the safety relief valve. The relief valve needs to be in communication with the vapor space of the cylinder in case it opens. For this reason, consumer propane cylinders such as this should be stored in an upright position. The second picture shows forklift cylinders stored with the relief valve beneath the liquid propane level of the tank. Although industrial type cylinders are allowed to be stored horizontally, they need to be stored with the safety relief valve above the liquid level of the tank if stored on their side, as depicted in the third picture. Additionally, improper storage of bottles can lead to container damage.

Everyone knows that propane cylinders need to be kept standing, even though there might be times when it would seem more convenient to have them lied down. Safety Engineer Magnus Olsson explain if and why it really is crucial to store propane cylinders in an upright position.

Keeping your propane cylinders upright really does matter. In fact it¡¯s absolutely essential. The propane cylinders are equipped with a safety valve, which is there to ensure that, when the propane is released, it is only ever released in its gaseous form. However, when the cylinder is stored lying down, the safety valve can get clogged up, potentially causing it to malfunction.

The valve is there as a safety precaution in case the cylinder gets too hot. In high temperatures, pressure can build inside the cylinder and that¡¯s when the safety valve comes into play by releasing a small amount of excess gas to reduce the pressure. If the valve doesn¡¯t work, the worst-case scenario could be a cylinder rupture or gas explosion. A propane leak is never desirable but, if one should occur, the most seriuos thing to happen would be a leak of propane in its liquid form if the cylinder is lying down. Propane becomes highly flammable when mixed with air. If there¡¯s a spark it will explode.

The reason liquid propane is more hazardous is that propane expands in its liquid form to gaseous form when released into atmospherically conditions. One litre of liquid propane will expand into many litres of gaseous propane. As a rule of thumb, propane expands in a ratio of 1:250.

Liquid Propane is stored under pressure that increases as temperatures increase. Propane cylinders have pressure relief valves to vent propane gas if the internal pressure exceeds 250psi. Subjecting a cylinder to high temperatures can result in the unintentional release of propane vapor (like in a car in the summertime).

Propane tanks should always transported in an upright position. The pressure relief valve of a propane tank vents vapor when the tank is upright but it will vent liquid propane if the valve is in the liquid space of the tank.

DOT propane cylinders have a 12 year lifespan and can be re-certified for additional 5 year service periods. Re-certification requires a visual inspection of the tank, foot ring and collar in addition to being being in compliance with all current DOT standards.

Eagar Arizona, Springerville Arizona, Greer Arizona, Alpine Arizona, St Johns Arizona, Nutrioso Arizona, Reserve New Mexico, Alma New Mexico and Luna New Mexico.

Gardnerville Nevada, Minden Nevada, Wellington Nevada, Topaz Lake Nevada, Markleeville California, Coleville California, Walker California, Bridgeport California

Has your propane tank valve gotten stuck yet again? This can put a serious damper if you’ve planned a BBQ, or literally anything that requires your propane tank. But here’s some good news: this article will tell you exactly how to unstick a propane tank valve.

Before we move onto the meat of the matter, you need to understand how your propane tank works. This applies to anything that runs on propane: fireplaces, water heaters, stoves, gas grills, and even RVs. Knowing how your tank operates will make it easier to troubleshoot minor issues.

A basic tank is filled with propane liquid and uses a special machine that forces the propane gas into the tank under pressure, turning it into its liquid form. It remains pressurized in the tank until the valve is released. When the valve is turned, the pressure decreases and the gas converts to vapor and escapes through the opening.

The propane gas is allowed to escape the canister under a certain pressure determined by the size of the valve. Large commercial propane tanks have multiple valves and gauges.

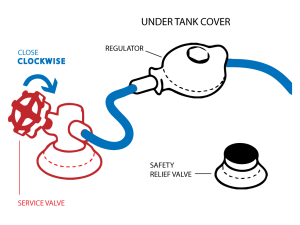

The main valves are the fill valves to refill the tank, a service valve to release the propane, and a relief valve. The relief valve prevents too much pressure from building up in the tank and exploding.

Tanks also have gauges that measure the level of liquid in the tanks called a float gauge, as well as a vapor recovery valve that can be used to release excess vapor in the tanks when getting it serviced.

The tanks are often closed very tightly to prevent leaks. If your propane tank won’t open after you bring it home the first time, try using a wrench or a pair of pliers. You can also unhook the tank from your stove and apply a bit of oil to the valve, before trying to yank it open with pliers.

Before you try to fix a propane safety valve (or any other tank valve), you need to identify the cause of the blockage. This will determine what you need to do to correct the issue.

The most important thing to bear in mind is that propane is highly combustible. When correcting a faulty tank valve, make sure you don’t puncture the tank and cause more damage. Safety is always a priority, so work in a ventilated area and do not light matches or lighters near your tank.

Set the propane tank on a steady, level surface. Make sure you are in a dry and cool area. Carefully check the tank for any signs of obvious damage and try to find the source of any possible leaks.

Wrap the rubber band around the outer edges of the valve to get a better grip on the blocked valve. Once you get a firm grip, twist firmly to loosen and dislodge the valve with your hand.

If this doesn’t work, spray a bit of oil or lubricant on the valve. Shake the valve back and forth to loosen it up, and then try to twist it open once again.

If the valve is still stuck, use a pair of pliers or a wrench to force it open. Grasp the edge of the valve with your pliers firmly and twist counterclockwise to open the valve. Try not to use too much pressure or as this can break the valve instead.

If your valves have rust or water damage, assess the situation. If it is still in the early stages, you can use baking soda and vinegar to get rid of the rust. However, if it is too far gone, you will need to replace the valve.

To avoid the fuss of a propane tank valve that needs to be dislodged, you can follow a few simple steps to prevent it from happening in the first place.

Don’t twist the valve closed too tightly. This might sound obvious, but people tend to close the valve really tightly, especially after a refill. Shut it tight, but don’t overdo it.

After buying a new tank or refilling your old one, smack the bottom of the tank on the ground once or twice. This will loosen the valve so you can open it more easily.

Don’t open the valve of a new cylinder rapidly as this can make it get jammed the next time. Instead, test the water and work it slowly and carefully.

If your propane tank leaks when connected, you most likely need a new valve. Check for the site of the leak by spraying soapy water at the valve, connection point, and pipes. If you see bubbles at the valve or connection, the gasket is broken and the valve requires replacing.

Soak the hose for a few minutes in warm soapy water to clean it. Use grease-cutting dish soap or something similar to break down accumulated oil and debris. Rinse the hose thoroughly under running water and allow it to dry.

The propane tank shut-off valve is your best bet during leaks if the hose or valve isn’t the one behind the leaks. The service or shut-off valve is the metallic spigot-like dial located under the tank cover and hooked to the top of the tank.

You need to use this valve to turn the gas off at the tank in the event of an emergency or leak. Always turn this valve to the right (clockwise), completely to shut off the gas.

This kind of valve is required on all large 4-to-40-pound commercial cylinders in vapor service. The OPD valve is a protective device and is exactly what it sounds like. It prevents the tank from overfilling.

Place the open jaws of the crescent wrench over the large bolt of the tank’s gas regulator. This is located at the meeting point of the propane tank and the gas regulator. Use the thumbscrew to grip the jaws around the large nut.

Then, loosen the nut with the wrench. Continue to remove the nut by hand until you can pull the neck of the regulator from the propane tank connection. You may catch a small whiff of gas as the regulator’s neck is pulled from the propane tank, but this is nothing to be worried about.

Remove the tank from the grill’s cart. In some models, you might have to loosen a safety strap. Store the empty tank in a safe and dry location, outdoors and well away from any flames.

It is perfectly normal to smell a little propane as tiny amounts can leak when the tank is in use. You can also smell the gas when the tank is nearly empty.

It is common for a propane tank to hiss. Hearing this sound is an indication that your tank is leaking so shut off all the valves and check for the location of the leak.

It is always a little scary when dealing with gas tanks, as we are well aware of the risks. However, knowing how to handle any kind of malfunctioning will make it much easier to deal with.

Once you know how to unstick a propane tank valve, you can loosen the valve or spigot without any trouble. And this will make the process of grilling much easier. Happy cooking!

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

As fall rolls along and some RVers are thinking about winterizing and storing their rigs for the winter, we thought this would be a good time to address the question, “Does propane go bad?”

We’ve previously investigated gasoline and diesel in our posts entitled “Does Gasoline Go Bad?” and “Does Diesel Go Bad?” But we’ve never written a post about the shelf life of propane.

Not only do some RVers store their rigs for the winter (often with partially full propane tanks), but lots of people store partially full portable propane gas tanks used for summer barbequeing.

Many RVers rely on propane for heating, cooking, and hot water. As the fall nights get chilly, some are getting ready to bring out their portable propane-powered heaters for winter camping. But, they’ve been stored away for a long time.

For all of these people, it’s important to know whether propane degrades over time. More important, however, is whether a stored propane tank presents a risk. Can propane tanks explode in the cold, for example?

Propane, (LPG or liquefied petroleum gas), is a component of natural gas that is compressed and stored as a liquid. And, it has a very long shelf life.

When you see an expiration date on a propane tank or gauge, what you’re actually seeing is the date when the tank’s safety inspection expires. Essentially, the date on the tank is a reminder to get the tank itself inspected because it’s the tank that needs to be replaced – not the propane.

In the United States, PORTABLE propane tanks/cylinders with a capacity of 100 pounds or less will have an expiration date 12 years out from the manufacturing date, as required by the DOT standard they are certified to. (They have a 10-year expiry in Canada.)

After that date, you’ll need to have the tank inspected to determine if it needs to be replaced or requalified/recertified. Requalified/recertified tanks will receive a new expiration date of 5, 7, or 12 years out, depending on the type of recertification and the method.

Brand new, larger, BUILT-IN RV propane tanks are manufactured with thicker walls and are certified by ASME (just like permanently installed propane cylinders for residential use), not the DOT, and don’t need to be recertified. However, it’s still a good to check regularly them for signs of rust and leaks.

Propane tanks can rust and leak. Since a gas leak is never a good thing, it’s important to prevent rust and to monitor tanks for the development of rust. It’s also why propane tanks have an “expiry” date – a reminder that it’s time to get the tank inspected.

There are safety mechanisms built into propane tanks. As long as you maintain your tanks and respect the propane as you use it, your propane tank exploding (or imploding) is highly unlikely.

Leaks can develop around valves, of course, but if rust penetrates the tank, you’ve got a real problem on your hands. The important thing is to make sure your tank never gets to that point!

It’s also important to make sure that a propane tank isn’t exposed to extreme heat for long periods of time. If temperatures outside the tank are so high that they cause the temperature inside to rise excessively, the tank can explode if the built-in safety release systems fail.

However, this is an unusual situation and would require the liquid propane inside a faulty tank to come to a boil and expand. That expansion could cause the tank to explode. For this to happen, your tank would need to be stored in a place with temperatures of 120℉ or higher for an extended period.

It’s always best to store a propane tank (or a rig with a built-in propane tank!) in a place that is cool and dry. Lower storage temperatures ensure the tank, and the LP inside it, remain at a safe, low temperature. Again, it’s best to store propane at temps below 120 degrees Fahrenheit.

When storing a propane tank (or an RV with a propane tank onboard) be sure to shut the valve off prior to storing. You don’t want a gas leak developing.

Yes, you can! If you don’t have a working gauge on your propane tank, the best way to check the level of propane in the tank is actually quite simple.

Join our newsletter to learn about all things RV-related. Every week we offer free tips, tricks, product reviews, and more to our online community of RVers. So, whether this is your first time on the road or you’re a seasoned expert, we’d love for you to geek out with us!

Liquid propane (LP) gas is a petroleum product as are gasoline and natural gas. In normal temperatures and pressures, LP gas is a gas. When moderate pressure is applied, inside a cylinder, LP gas becomes a liquid. As the pressure is released the liquid readily vaporizes and boils off as a gas.

Propane gas is denser than air, if a propane tank purges to relieve pressure build-up, the propane will collect in low lying areas. These areas can be easily ignited and are highly flammable. Use caution when dealing with a propane tank that may have recently self-purged.

Big John Grills & Rotisseries uses high quality Worthington Cylinders in 30 lb. and 40 lb. sizes. These tanks are protected with a rust-resistant white powder coat finish.

Cylinders are designed to function with the valve completely open or completely closed, there is no in-between. Never open the valve just a “crack” or “half way”.

DO NOT store a liquid propane cylinder in/on any part of an appliance not intended for such use. Improper storage of a cylinder could lead an explosion, fire, personal injury, or death.

Shut off unit and all gas sources if the odor of unburned gas is detected. Make no attempt to use the unit until gas leaks are fixed and/or the odor is accounted for.

Gauges, regulators, valves … welcome to your propane tank! If you’ve only used propane to power a gas grill in the past, the larger tanks may be intimidating. It can seem like a whole new world at first, especially if you’re used to powering your home using other fuel sources like natural gas, whose components may not be as visible. And while your propane supplier often handles a lot of the periodic propane tank maintenance and refilling, it’s a great idea to know the basics — especially if you own your own tank. No worries — we’ll make it easy for you. So you can feel confident and secure managing the day-to-day operations of living with propane.

Here’s a quick glossary ofpropane tank parts along with their functions — plus a few tips for making sure your propane tank stays in good working order.

PropaneFill Valve: When your propane is delivered, this is the valve that the technician attaches to the fuel hose. The hose from the truck connects to this valve. The hose end coupling screws into the valve with a gasket to create a reliable seal that prevents gas from escaping.

Service (Shut Off) Valve: Essentially the master switch to the propane supply, the service valve is the point at which propane gas enters the piping system to supply all the appliances that connect to it.

Float Gauge Assembly:The float gauge shows the volume of propane in the tank. Sometimes called a dial gauge, the float gauge is made of several parts: a mechanical float that lives inside the tank (much like the float you’d see if you lift the lid off your toilet’s water tank) connected to a reader on the outside of the tank that displays the liquid level (this may be a numeric gauge or a visual one color coding for safe, under-, and over-fill levels). It doesn’t show the exact amount of liquid in the tank, but it is reliable for everyday monitoring of your tank’s propane level.

To check the approximate propane level in your tank, look at the float gauge. It will be a round (or roundish) device on the tank (see image above) with a needle over a range of numbers or graphic indicators. The numbers will range from 5 to 95—indicating a percentage of volume, not the number of gallons remaining. If you see a level below 30, it means that your tank is getting low and needs to be refilled.

If you’re an AmeriGas customer, you may also have a remote tank monitor that automatically transmits the tank’s percentage to us every day. You can check your tank’s current status—without looking at your tank—by logging into your AmeriGas account.Learn more about our online services.

Relief Valve: This is the safety relief mechanism designed to vent propane in the event that pressure builds — for example, if the heat rises very suddenly to an extreme temperature (as might happen in a forest fire or other emergency situation). A spring inside the valve is designed to release if the pressure inside the tank builds to a certain level, at which point the valve will open slightly and start to hiss. If pressure rises excessively, the valve will open completely. The relief valve allows pressure to be released quickly and safely. All propane tanks are required by law to have a relief valve. You may also hear it called a pop-off valve or a pressure-venting valve.

FixedLiquid Level Gauge: Also known simply as a fixed liquid level gauge or the bleeder valve, this is the only tank component that gives a precise measure of how much liquid propane is in the tank. It’s used only by certified propane service providers when filling the tank — and even then, it’s used only to monitor, not to refill (propane goes into the tank through the fill valve).

Vapor Return Valve: Also known as the vapor equalizing connection or vapor equalization valve, this feature is required on all ASME propane tanks. They are usually deployed in the event that the liquid in the container becomes very overheated and must be evacuated from the container.

Liquid Withdrawal Valve: Used by technicians to withdraw liquid propane from the tank so it can be moved or disposed of. Note: Never attempt to remove liquid propane from a tank on your own. This should only be done by a professional using specialized equipment.

PropaneRegulator:Though they come in many shapes and sizes, the function of all propane regulators is the same — they maintain a safe and effective level of pressure on propane within the tank. This helps keep the flow steady and usable. These components make a persistent humming noise when operating — don’t worry, it’s normal.

You’re aware of what your tank should look like when it’s “all systems go” — as well as some important warning signs that will tell you it’s time to contact a professional. Armed with these basic terms and tips, you’re set up for propane success.

Safety Note: We do not recommend attempting any propane system adjustments, repairs, or maintenance on your own. Only certified propane professionals are equipped with the gear and knowledge to properly assess and address propane systems safely.Please contact us for more information and service.

Check for leaks— buy a small spray bottle and keep a mixture of a small amount of dish soap and water in the bottle. When you connect your tank to your grill and open the valve, spray the soap water on your tank connection and look for bubbling that indicates a leak. If you see bubbles increasing in size or quantity, you have a leak. Close the valve and check your connections. Don’t light your grill until your connection is leak-free.

Know your grill— when it comes to getting great results and staying safe around your gas grill, there is no substitute for reading your owners manual. Study your owners manual for proper safety guidelines. If you can’t find your manual, search for the manufacturer on the Internet and download the manual. Make safety your first priority!

Have a fire extinguisher nearby— if your grill flares up and you have to shut off your gas, you may still have to put out a fire. Have a handy extinguisher in the event your fire gets the best of your food. Keep in mind that the first step to eliminate the fire is to deny the oxygen (close the grill top) and the second is to deny the fuel (shut off the gas).

Keep your cylinder valve closed when not in use – it is a very simple step in preventing accidents to shut off the gas supply on your grill or burner AND on your cylinder supply valve. Keep your tank plugged or capped when it is not connected to your grill. Remember that quick connect cylinder valves have two check valves so they do not require a plug but capping a quick connect cylinder will protect it from dust and moisture.

Always use your cylinder in an upright position— your gas grill is designed to burn propane vapor, not liquid propane. If your propane tank is laying on it’s side liquid propane can escape from the cylinder valve. Liquid propane cannot escape from the valve of an upright propane tank.

Never use a gas grill indoors— your gas grill is consuming oxygen and propane as it burns. The use of a propane gas grill, propane gas camp stove or propane gas burner indoors can result in carbon monoxide poisoning, asphyxiation and death. Carbon monoxide is colorless, odorless and lethal. Do not use a propane gas grill indoors.

Keep your gas grill away from your house— in the event that your grill suffers from a flare-up or a propane leak. You can’t imagine how quickly a small flare-up can lead to a big disaster when your grill is too close to a carport, home or shed.

Keep your spare tank away from the grill – you may have a storage area underneath or beside your grill. Use if for cooking tools or whatever else suits you but never store an extra propane cylinder under or beside your grill.

Safety check and clean your grill regularly — look at the entire grill from the ground up. Check for rust that could lead to a structural failure. Look at the condition of the hoses, burner assemblies and ignition system. Clean it out and replace the grills if necessary. Your grill can easily last twice as long if you spend two hours a year keeping it in top condition.

Buy a quality cover for your grill— the corrosive impact of weather is as bad for your grill as the intense heat of your hottest fire. The low cost of a good cover will pay for itself many times over—especially if you invested in a quality gas grill!

Nothing tastes quite as good as food cooked on the grill in the summer months! Some are purists who believe that only food cooked over hot coals qualifies as “barbequed,” but for many of us, the convenience of a gas grill is hard to beat. However, it’s important to remember that the propane tank in your trusty grill needs to be regularly maintained and properly stored in order to ensure a safe grilling season for you and your family. Here are our top tips for making sure that your summer cookout never results in fire damage to your home or other buildings that might result in a loss of personal property requiring the help of a fire restoration company.Keep it outside. Propane is a highly flammable gas. If you store a tank in your garage and it has even the smallest leak, the spark of starting a car or lawn mower could cause a fire that results in a need for fire damage restoration.

Keep it in the shade. While your tank should not be stored indoors, it should also not be stored in direct sunlight. On a hot sunny day, the temperature of a tank that’s not properly stored could quickly go above 120°F. The hotter your tank gets, the greater the pressure will be inside the tank. Portable propane tanks are equipped with a relief valve that activates when internal pressure builds up. Once the valve releases, the gas will slowly dissipate through the valve into the air and could ignite.

Keep it upright.If the valve on the top of the tank is at all compromised, gas can leak out if the tank is left on its side for any length of time. Keeping your tank stored in a safe place where it won’t get knocked over will help ensure that spilled gas won’t accidentally ignite, causing fire damage to your home that might require the services of a fire restoration company.

Store at a safe distance. If you have backup tanks, don’t store them adjacent to each other or right next to the grill. A distance of at least ten feet should be maintained between propane tanks as well as any other potentially flammable or spark-causing object.

Keep the valve closed. Make sure the valve is tightly closed when you’re not using the grill. It’s always best to close the valve first and then turn the burners off, to allow excess gas to clear the lines. If you smell gas when you approach your grill, don’t use it until you’ve had your tank checked.

Don’t use a damaged tank.If your tank has dents, peeling paint or rust, don’t use it. The integrity of the tank may be compromised, and gas could potentially be leaking. Take care when you’re transporting your tanks to and from the store. They should be kept upright and stable. By placing them in crates, they won’t roll around or collide.

Fire safety, both indoors and outdoors, is a priority in every season. Your entire family should be familiar with fire safety practices and know what to do in the case of an unexpected fire. And, it only takes a few minutes to implement these quick fire safety tips to ensure that your summer cookout season is filled with only happy memories of delicious food, great company and family fun. Happy grilling!

For more than 38 years, Hays + Sons has been the property restoration company that families, businesses and schools trust. We’re committed to helping you be prepared when the unexpected strikes, and whether you just want tips for fire and smoke damage prevention or currently have fire damage, Hays + Sons has the capacity and expertise to help you get back to normal ASAP.

The compassionate, experienced, and trusted residential restoration experts at Hays + Sons are just a phone call away, 24 hours a day, 7 days a week, 365 days a year.

MISSISSIPPI STATE -- People trying to refill their propane tanks for summer grilling may encounter an extra expense as they find they must buy a new safety valve.

As of April 1, all four- to 40-pound propane tanks must be equipped with an Overfill Protection Device. This is a new valve that replaces the one on existing tanks. The new valves are marked with "OPD" to designate their compliance with the state law and have three-lobed valve handles, rather than the five-lobe type found on older propane tanks.

"The device will not allow the tank to be filled more than 80 percent full, leaving some room for the gas to expand," said Herb Willcutt, safety specialist with Mississippi State University"s Extension Service.

A typical grill"s 20-pound cylinder holds five gallons of propane. The propane is filled in the bottle as a liquid, and the new valves have a float that rises as the bottle is filled to lock off the opening once the tank has reached 80 percent full.

Willcutt said when a propane tank gets hot, the pressure rises dramatically. Both old and new valves have a relief valve that allows gas to escape if too much pressure builds up. At a temperature of 70 degrees, an 80 percent-full propane tank has a vapor pressure of 124 pounds per square inch.

"This is a safe, workable pressure," Willcutt said. "Overfilling contributes to much higher pressure, especially when the tank warms. When pressure rises beyond about 325 psi, the tanks are designed to release gas into the atmosphere. In an enclosed area, this creates an explosion and fire potential."

If a propane tank overheats as it is venting, Willcutt said to get it out of enclosed areas and away from sources of fire, lay it on its side and cool it with a water hose. Even if the tank is burning from the relief valve, cooling with a water hose can reduce the risk of fire to surrounding structures and allow the relief valve to shut itself off when the tank reaches a safe internal pressure.

"Laying a non-burning tank on its side allows the liquid to escape faster and relieves pressure more quickly. The water hose cooling it will reduce the pressure enough that it will quit relieving itself," Willcutt said.

Owners of propane tanks with the old valve can replace these at most locations that refill tanks. Either exchange the tank for a new one with the correct valve or place the new valve on a structurally sound existing tank.

"If you"re replacing the tank and don"t want the old one, the best option is to leave it with the dealer and let them make sure it is properly disposed of," Willcutt said.

State law does not allow propane tanks to be transported in the passenger compartment of a vehicle. This means they can"t be carried in sport utility vehicles, hatchbacks or similar passenger vehicles. Transport them upright in the trunk of a car or bed of a truck and secured so they can"t roll around.

Propane gas is highly flammable. Each year, hundreds of gas grill fires/explosions occur nationally. The new safety standard for propane gas tanks requires that an "over-fill prevention device" be installed in new gas tanks. The new propane gas tanks have valve handles with three "lobes" (prongs) while older tanks have valve handles with five prongs. People with older propane gas tanks should trade them in for the new, safer tanks.

Never keep a filled container in a hot car or car trunk. Heat will cause the gas pressure to increase, which may open the relief valve and allow gas to escape.

Never burn charcoal inside of homes, vehicles, tents, or campers. Each year dozens of people die nationally as a result of CO fumes from charcoal being burned inside. Charcoal produces carbon monoxide (CO) when it is burned. CO is a colorless, odorless gas that can accumulate to toxic levels in closed environments.

8613371530291

8613371530291