do propane tanks have a safety valve supplier

A certified pressure relief valve testing contractor must perform all inspections. That’s where Foster Fuels comes in. Our inspectors can advise when testing is necessary and when a replacement would be a more cost-effective option. We also offer comprehensive preventative maintenance programs that can extend the life of your pressure relief valves and related safety equipment, saving you money over the long term with services such as:

Reminding you valves over 10 years old must be tested or replaced prior to the following scheduled inspection, which is two years from the current inspection.

Virginia has its own set of requirements for pressure relief valve testing and certification. These are primarily based on NFPA 58 and the Virginia Department of Labor and Industry. State requirements establish a propane pressure relief valve testing frequency of once every 10 years for most equipment. The state code also sets a compliance schedule of two years from the initial inspection date. For more information, contact Foster Fuels directly.

State and NBIC requirements present several challenges for businesses that rely on propane in their facilities. Organizations with multiple tanks may find the time and money required for pressure relief valve testing—including downtime and flaring of vapor, if necessary—to be overly burdensome. The limited time allotted to ensure all tanks are inspected and tested is an additional difficulty.

One thing you should pay attention to is the propane tank’s safety relief valve. All propane tanks, including the cylinders you use for your BBQ grill, are required by law to have pressure relief devices to allow for the release of excess pressure in the tank.

A spring keeps the safety relief valve closed as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear pop if that occurs.

Your propane tank needs to have room for the propane inside it to expand. That is why your propane tank is filled to 80% of its capacity. The 20% of the tank that is empty space allows the propane to safely expand.

That expansion is why propane tanks are white or beige. Light colors reflect heat to minimize expansion. Dark colors retain heat and can cause the propane inside your tank to expand to dangerous levels. So, even if your propane tank doesn’t go with the color of your siding, leave it alone.

Houses or buildings utilizing gas energy require a gas piping system to power heaters, ovens, and other heating appliances. One of the most important elements of a gas piping system is the propane service valve, which controls propane gas flow in and out of a building. While there may be many other valves within gas plumbing, this valve functions as an on/off switch and serves as the main point of control for cutting off or allowing for the flow of gas into a piping system.

Propane valves are simply used to turn gas on or off. Similar to that of a water faucet, propane valves consist of a handwheel that controls propane gas flow when turned. When the wheel is turned, a stem and seat mechanism located within the valve opens or closes to prevent or allow gas flow from the tank.

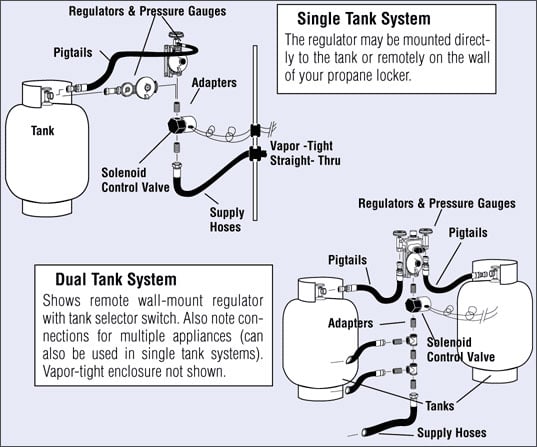

Using propane gas requires an LP gas regulator, which decreases the amount of pressure released into the gas line, keeping it at an acceptable and safe level while still meeting the needs of the application.

There are multiple different valves in any propane system, each of which has a particular job. At IPS Equipment, we provide some of the most common types of valves for propane systems, including:

A pressure or safety relief valve is a safety mechanism that every propane system needs. It allows excess pressure in the tank to be slowly and safely released. Without this valve, pressure can build up and cause the tank to crack or rupture.

The relief valve has a pressurized spring. If the pressure levels within the tank grow too high, the spring forces the valve open just enough to return the pressure levels to acceptable levels. Once the pressure decreases, the spring relaxes, and the valve automatically closes.

This valve is where gas delivery personnel add new gas to a propane tank. Propane delivery trucks have hoses that can be attached to the filler valve so propane can be pumped into the tank. This valve is also pressure-activated, and it opens automatically in response to the pressure in the hose.

Filler valves have gaskets that operators can push the hose end against to avoid propane leaks. They also only allow for unidirectional fluid movement, meaning that once the tank is full, there is no risk of propane escaping when the hose is withdrawn.

This shut-off valve prevents gas from entering the building and any attached appliances. You can use this central point of control like an on/off switch to completely halt the path of gas in the system.

This valve is also called a vapor return valve or vapor eliminator valve. It ensures that propane is delivered at the proper pressure levels from the propane delivery truck to a personal tank and returns any excess propane back to the delivery truck. This is similar to a safety valve, except the vapor equalizing valve ensures the propane is delivered at proper pressures for optimum use, not safety. This is especially crucial during hot weather or in warm environments, as that can increase the pressure.

This specialized valve is meant for use by propane companies only. It allows operators with the proper tools to drain liquid propane from the tank. Propane tanks must be drained to <5% capacity levels before they can legally be moved.

IPS Equipment specializes in supplying propane marketers with reliable valves, fittings, regulators, and more for propane systems. Contact us today to learn more about our comprehensive products or services, or browse through our catalog to start your order.

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

MISSISSIPPI STATE -- People trying to refill their propane tanks for summer grilling may encounter an extra expense as they find they must buy a new safety valve.

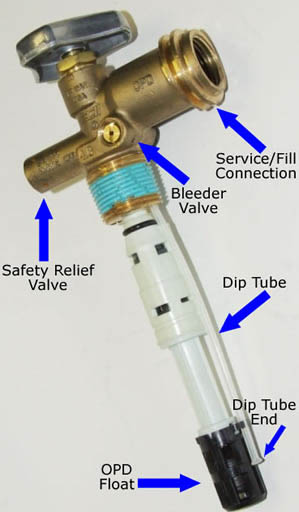

As of April 1, all four- to 40-pound propane tanks must be equipped with an Overfill Protection Device. This is a new valve that replaces the one on existing tanks. The new valves are marked with "OPD" to designate their compliance with the state law and have three-lobed valve handles, rather than the five-lobe type found on older propane tanks.

"The device will not allow the tank to be filled more than 80 percent full, leaving some room for the gas to expand," said Herb Willcutt, safety specialist with Mississippi State University"s Extension Service.

A typical grill"s 20-pound cylinder holds five gallons of propane. The propane is filled in the bottle as a liquid, and the new valves have a float that rises as the bottle is filled to lock off the opening once the tank has reached 80 percent full.

Willcutt said when a propane tank gets hot, the pressure rises dramatically. Both old and new valves have a relief valve that allows gas to escape if too much pressure builds up. At a temperature of 70 degrees, an 80 percent-full propane tank has a vapor pressure of 124 pounds per square inch.

"This is a safe, workable pressure," Willcutt said. "Overfilling contributes to much higher pressure, especially when the tank warms. When pressure rises beyond about 325 psi, the tanks are designed to release gas into the atmosphere. In an enclosed area, this creates an explosion and fire potential."

If a propane tank overheats as it is venting, Willcutt said to get it out of enclosed areas and away from sources of fire, lay it on its side and cool it with a water hose. Even if the tank is burning from the relief valve, cooling with a water hose can reduce the risk of fire to surrounding structures and allow the relief valve to shut itself off when the tank reaches a safe internal pressure.

"Laying a non-burning tank on its side allows the liquid to escape faster and relieves pressure more quickly. The water hose cooling it will reduce the pressure enough that it will quit relieving itself," Willcutt said.

Owners of propane tanks with the old valve can replace these at most locations that refill tanks. Either exchange the tank for a new one with the correct valve or place the new valve on a structurally sound existing tank.

"If you"re replacing the tank and don"t want the old one, the best option is to leave it with the dealer and let them make sure it is properly disposed of," Willcutt said.

State law does not allow propane tanks to be transported in the passenger compartment of a vehicle. This means they can"t be carried in sport utility vehicles, hatchbacks or similar passenger vehicles. Transport them upright in the trunk of a car or bed of a truck and secured so they can"t roll around.

This information has been developed to create a better understanding relative to the introduction of a new safety device designed to markedly increase the safe use of

small propane cylinders While an occasional inconvenience may occur during the transition to a higher level of propane safety for gas grill tanks, etc., it is the

Here then is a listing of answers to consumer"s most commonly asked questions. The propane industry hopes that this information will be helpful relative to the

At Smart Touch Energy, we prioritize propane tank safety. Let"s take a closer look at some of the key questions surrounding propane tank safety and how you can minimize propane tank dangers.

Propane, also referred to as liquefied gas, is a popular fuel choice for individuals and businesses. It is delivered as a liquid and pumped into a storage tank, and it will not ignite with air until the ignition source reaches at least 920°F.

Furthermore, propane is 270 times more compact as a liquid than as a gas. As such, propane is easier to transport and store as a liquid than as a gas.

According to the National Propane Gas Association (NPGA), roughly 90 percent of the U.S. propane supply is produced domestically. The NPGA points out that propane serves many purposes, including:

The U.S. Energy Information Administration reported U.S. propane and propylene inventories hit 97.7 million barrels in September 2015 — their highest level in 22 years. This indicates the demand for propane is on the rise in the United States, a trend that may continue in the foreseeable future.

On its own, propane gas is non-toxic. It produces minimal emissions and is not harmful to soil or groundwater. It also is colorless and odorless, but many propane suppliers will add a chemical compound to give propane an unpleasant smell. By doing so, propane suppliers help alert customers if a propane tank leaks — which can be a major safety hazard.

A residential propane tank that leaks may emit gas quickly. Fortunately, the following steps will ensure you are fully prepared to handle this scenario:

When it comes to propane tank safety, it is always better to err on the side of caution. Thus, if you smell gas, you"ll want to act fast to minimize this danger. Otherwise, you may put yourself and others at risk.

In addition, it is important to note that some smell sensitivities or medical conditions could make it difficult to detect propane. In these cases, a gas detector for propane may prove to be valuable, as it will provide an additional layer of security.

Another element to keep in mind when it comes to propane tank safety is odor fade, or the unintentional reduction of propane odor concentration. One reason odor fade may occur is due to water, rust or air inside a propane tank. Additionally, odor fade may happen because the odor can stick to areas such as distribution and piping systems, as well as simply to the inside of the tank. Although this problem is rare, it may affect propane tanks that have been sitting too long before being filled.

Apply a layer of soapy water or a leak detector solution to the connection between the residential propane tank"s cylinder valve and regulator outlet.

If you discover bubbles, close the cylinder valve, tighten the connection and repeat the testing process. If bubbles continue to appear, it means there is a leak in the propane tank.

Avoid Space Heating Propane Grills or Ovens: Although space heating propane grills and ovens may seem like viable options at first, they can be dangerous.

Work With a Qualified Propane Service Technician: A qualified propane service technician can connect an appliance to a propane tank and perform the necessary assessments to ensure you can maximize the value of your appliance.

If you are ever uncertain about how to take care of a propane gas appliance, you can contact the appliance provider for extra assistance. This company will be able to address any of your concerns and questions and help you use your appliance safely.

Inspect Old Appliance Connectors:If an appliance is more than 20 years old, have a qualified service technician assess the appliance connector. If you try to do this on your own, you risk damaging the connector and causing a propane gas leak. If you work with a service technician, however, you may be able to avoid risk and bolster your appliance"s performance for years to come.

Check the Appliance Vents: Let the vents on your appliance breathe and ensure flue gases can flow easily to the outdoors. Remove any insects, bird nests or other debris from the vents. Clear the area around the appliance to ensure plenty of air can reach the burner for proper combustion.

Don"t Repair or Modify the Appliance on Your Own: If you attempt to modify, repair or replace an appliance connector, control, regulator or valve on your own, you risk causing a gas leak.

Propane tank safety extends beyond the tank itself, and those who focus on finding ways to take care of their propane gas appliances can manage risk like never before.

Of course, working with a qualified propane appliance service technician can help you keep your appliance in working order. This technician possesses the training and know-how needed to fix or upgrade an appliance safely.

A propane tank is complex, and you should never modify a propane tank on your own. If you believe your propane tank is defective, don"t try to modify or repair regulators, valves or other propane tank parts if you lack the proper training and expertise.

On the other hand, you may believe your outdoor appliance is problematic. Like propane tanks, outdoor appliances are intricate, so you may want to get expert help with appliance repairs.

Sometimes, the pilot light on an outdoor appliance may go out. If the pilot light goes out periodically, you should follow the appliance manufacturer"s instructions to reignite it correctly. Follow the instructions closely and review any safety warnings before you attempt to reignite the pilot light.

If an outdoor appliance"s pilot light goes out frequently, it likely indicates there is an issue with the appliance, and you should avoid the temptation to reignite the pilot light on your own. In this case, you should get expert help to reignite the pilot light.

If you try to reignite the pilot light on your own, you risk fire or explosion. Comparatively, a qualified propane service technician will do everything possible to fix the pilot light on your appliance and ensure the problem does not occur again.

Any time you have concerns or questions about a propane tankand/or outdoor appliance, reach out to your propane supplier and/or a qualified gas service technician for support. This will allow you to get the expert assistance you need and avoid putting yourself or others in danger.

If you find a propane tank leaks, you should never refill it. You’ll need to get the tank inspected by a qualified propane gas technician before it can be refilled.

It is against the law to refill a tank if it’s out of date. The most recent inspection date of a propane tank is printed on the side of the tank, and you should review this information before you try to have your tank refilled.

The law requires periodic inspection of propane tanks, and you should evaluate a propane tank at least once a month to identify any leaks. Remember, a diligent approach to propane tank safety can make a world of difference. If you allocate even a few minutes each month to inspect your propane tank, you can manage propane tank safety risks effectively.

You should never throw a propane tank away. Conversely, many municipal programs offer propane tank collection in cities and towns nationwide. Or, your propane supplier should be able to offer additional support so you can dispose of your propane tank properly.

How you store your residential propane tank is paramount. If you store your propane tank correctly, you will be able to reduce the risk of causing a leak.

Avoid Excess Heat: Heat builds up inside of a propane tank, and when this happens, the tank"s pressure relief valve may release propane. Therefore, you"ll want to keep your residential propane tank away from areas where temperatures reach 120°F or higher.

Disconnect the Propane Tank When Not in Use:A common scenario you might see is a propane tank connected to a barbecue. However, when the propane tank is not in use, ensure it’s disconnected from the barbecue or other appliance.

You should always store your propane tank outdoors and keep it in an upright position away from heat and direct sunlight. If you intend to use a propane tank that has been stored for a long time, be sure to look for signs of aging on the rubber tubing that links the propane tank to an appliance. If the rubber tubing is broken or cracked, you can replace it by purchasing new rubber tubing from a hardware store.

You should always move a propane tank in standing position. Ultimately, you"ll want to secure the propane tank with rope — not a metal chain. A metal chain could move around against the metal propane tank, creating sparks that could be disastrous. Meanwhile, rope is strong and sturdy and will help you keep the propane tank in place consistently.

When you travel, keep the windows of your vehicle open for added safety. You also will want to ensure the propane tank valve is locked and covered with a dust cap. And if the propane tank needs to be refilled, visit a filling station before you reach your final destination.

Believe it or not, running out of gas in your propane tank can be dangerous. Some of the most common problems that may arise due to an empty propane tank include:

Leaks:If the appliance valve or gas line of a propane tank remains open after the propane supply runs out, a leak may occur when the tank is refilled.

Rust Build-Up:Air and moisture can accumulate inside of an empty propane tank. This can result in rust build-up inside the propane tank, lowering the concentration of the odor of propane and making the gas more difficult to smell.

If the fuel level on your propane tank falls below 20 percent, you shouldcontact your fuel supplier for a refill. Setting up regular propane deliveries also may provide immediate and long-lasting benefits. The deliveries will ensure you"ll always have a full supply of propane on hand, so you"ll be able to use propane any time you choose.

An OPD prevents a propane tank from being overfilled. If a propane tank is overfilled, the tank won"t have sufficient space if liquefied gas expands in warm temperatures. As a result, a propane tank"s cylinder pressure will increase, which can create dangerous conditions.

Smart Touch Energy empowers customers with propane tank safety knowledge and insights. We also take the hassle out of ordering propane and help customers purchase energy products in an easy, convenient and cost-effective way.

Gauges, regulators, valves … welcome to your propane tank! If you’ve only used propane to power a gas grill in the past, the larger tanks may be intimidating. It can seem like a whole new world at first, especially if you’re used to powering your home using other fuel sources like natural gas, whose components may not be as visible. And while your propane supplier often handles a lot of the periodic propane tank maintenance and refilling, it’s a great idea to know the basics — especially if you own your own tank. No worries — we’ll make it easy for you. So you can feel confident and secure managing the day-to-day operations of living with propane.

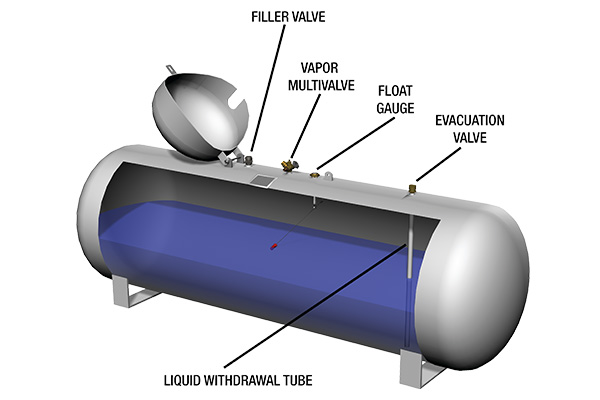

Here’s a quick glossary ofpropane tank parts along with their functions — plus a few tips for making sure your propane tank stays in good working order.

PropaneFill Valve: When your propane is delivered, this is the valve that the technician attaches to the fuel hose. The hose from the truck connects to this valve. The hose end coupling screws into the valve with a gasket to create a reliable seal that prevents gas from escaping.

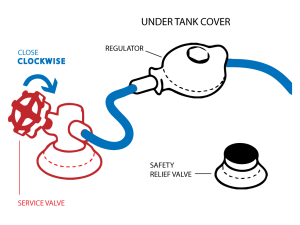

Service (Shut Off) Valve: Essentially the master switch to the propane supply, the service valve is the point at which propane gas enters the piping system to supply all the appliances that connect to it.

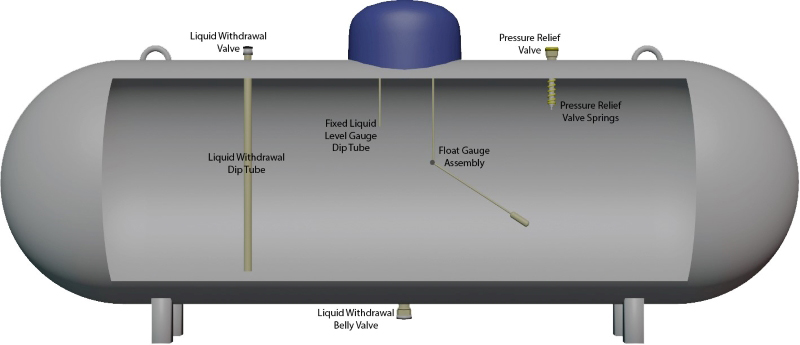

Float Gauge Assembly:The float gauge shows the volume of propane in the tank. Sometimes called a dial gauge, the float gauge is made of several parts: a mechanical float that lives inside the tank (much like the float you’d see if you lift the lid off your toilet’s water tank) connected to a reader on the outside of the tank that displays the liquid level (this may be a numeric gauge or a visual one color coding for safe, under-, and over-fill levels). It doesn’t show the exact amount of liquid in the tank, but it is reliable for everyday monitoring of your tank’s propane level.

To check the approximate propane level in your tank, look at the float gauge. It will be a round (or roundish) device on the tank (see image above) with a needle over a range of numbers or graphic indicators. The numbers will range from 5 to 95—indicating a percentage of volume, not the number of gallons remaining. If you see a level below 30, it means that your tank is getting low and needs to be refilled.

If you’re an AmeriGas customer, you may also have a remote tank monitor that automatically transmits the tank’s percentage to us every day. You can check your tank’s current status—without looking at your tank—by logging into your AmeriGas account.Learn more about our online services.

Relief Valve: This is the safety relief mechanism designed to vent propane in the event that pressure builds — for example, if the heat rises very suddenly to an extreme temperature (as might happen in a forest fire or other emergency situation). A spring inside the valve is designed to release if the pressure inside the tank builds to a certain level, at which point the valve will open slightly and start to hiss. If pressure rises excessively, the valve will open completely. The relief valve allows pressure to be released quickly and safely. All propane tanks are required by law to have a relief valve. You may also hear it called a pop-off valve or a pressure-venting valve.

FixedLiquid Level Gauge: Also known simply as a fixed liquid level gauge or the bleeder valve, this is the only tank component that gives a precise measure of how much liquid propane is in the tank. It’s used only by certified propane service providers when filling the tank — and even then, it’s used only to monitor, not to refill (propane goes into the tank through the fill valve).

Vapor Return Valve: Also known as the vapor equalizing connection or vapor equalization valve, this feature is required on all ASME propane tanks. They are usually deployed in the event that the liquid in the container becomes very overheated and must be evacuated from the container.

Liquid Withdrawal Valve: Used by technicians to withdraw liquid propane from the tank so it can be moved or disposed of. Note: Never attempt to remove liquid propane from a tank on your own. This should only be done by a professional using specialized equipment.

PropaneRegulator:Though they come in many shapes and sizes, the function of all propane regulators is the same — they maintain a safe and effective level of pressure on propane within the tank. This helps keep the flow steady and usable. These components make a persistent humming noise when operating — don’t worry, it’s normal.

You’re aware of what your tank should look like when it’s “all systems go” — as well as some important warning signs that will tell you it’s time to contact a professional. Armed with these basic terms and tips, you’re set up for propane success.

Safety Note: We do not recommend attempting any propane system adjustments, repairs, or maintenance on your own. Only certified propane professionals are equipped with the gear and knowledge to properly assess and address propane systems safely.Please contact us for more information and service.

It’s summertime, folks, and that means it’s the grilling season. Sure, we all love grilling year round but there’s nothing quite like a summer barbecue. Before you fire up that grill I allow me to engage you in a quick discussion about our ‘propane bottles.’

Grilling cylinders are technically known as 20 lb. DOT cylinders because they are built to DOT specifications. DOT specifications include rules that deal with metal thickness, pressure capabilities, and longevity of the tank. These cylinders can only legally contain 20 lbs. of propane. Propane weighs 4.24 lbs. per gallon. That means there is approximately 4.7 gallons of propane in your grilling cylinder when it’s full.

Grilling cylinders can be refilled or exchanged at a cylinder exchange cage. Refilling stations must refill the cylinder by weight. That’s why when you get your grilling cylinder refilled, the attendant will place it on a set of scales before they start the pump. Sometimes the attendant even uses a screwdriver and opens a small hole in the valve. You’ll hear a hissing noise as the bottle fills. When the grilling cylinder reaches 80% capacity, a white mist will shoot out of the small hole indicating that the cylinder is full. ‘Full’ in the propane industry, when regarding tanks and cylinders, is actually 80% of the water capacity of the tank or cylinder being filled. Propane is very susceptible to temperature changes and will expand or contract greatly with changes in the outside temperatures. To compensate for this possible dangerous expansion, we never completely fill up a tank or cylinder. We always stop at the 80% level.

Grilling cylinders are equipped with all kinds of safety features. One such feature is the OPD valve. The OPD valve ensures that your grilling cylinder isn’t over filled. All cylinders that hold less than 100 lbs. of propane are required by law to have this type of valve installed. OPD stands for Overfill Protection Device and that is exactly what it is designed to do. As the cylinder is being filled and the liquid level rises, it also raises a small float attached to the bottom of the valve. As this float rises to approximately 809% of the volume of the tank, the valve will shut and stop propane from being allowed into the cylinder. Despite the OPD being required by law to be on your grilling cylinder, the law also says it must still be filled by weight. The OPD is a safety backup.

Your grilling cylinder is rated to be used for a period of 12 years from the date of manufacture. On the cylinder collar you will ding the date of manufacture in a month-year format, stamped into the metal. Each time that your cylinder is filled it must be visually inspected and looking at the date of manufacture is usually one of the first items that the refilling agent will look for. A cylinder may be re-qualified by doing a visual inspection by a properly trained agent and will require a new date followed by the letter E stamped into the collar. This will allow the cylinder to be filled for another 5 years. Some companies do this re-qualification for their customers but most do not.

Many customers find that the cylinder exchange cages are the way that they prefer to get a full cylinder of propane for their grill. The customer brings an empty cylinder to the cage location, leaves the empty, and gets a full cylinder. The price for exchange is generally higher than having your cylinder refilled yourself but the exchange cage locations are generally open when a cylinder filing station may be closed. When using the exchange cages, the customer is assured that the cylinder has benen inspected and filled by a professional. Another drawback of the exchange process is that some companies will, by policy, not put a full 20 lbs. of propane in the exchange cylinder. Be sure to check the cage before purchasing to ensure that you are getting a full 20 lb. cylinder.

Another safety measure installed in grilling cylinders is an excess flow valve. The excess flow will engage and stop the full flow of propane through the valve if it sense that the gas line may have been broken or installed incorrectly. Over the years, I have seen customers open the valve swiftly, allowing gas to fill unpressurized gas hose so quickly that the excess flow ‘thinks’ that there is a problem and will shut the gas. It will release a small amount of gas to pressurize the hose on the downstream side of the valve in order to reset itself. For an unknowing customer, this small amount of gas being released is just enough to light a very small flame in their grill. This usually lends to the assumption that there’s something wrong with the grill. If this happens to you, simply turn off the burners on the grill and turn the cylinders valve to the off position and the excess flow will reset itself. You may even hear a small click when the reset occurs. After being reset, open the valve slowly (very slowly). Once the hose is pressurized, full gas flow will occur.

One last thing to be aware of when handling your grilling cylinder is a hissing sound coming from the back side of the valve. This is the pressure relief valve. It is designed to relive excess pressure that may build up inside of the cylinder. If you discover the valve is hissing or leaking, move the cylinder away from people and buildings in a cool place and away from any source of ignition. Call the person that filled the cylinder and follow their directions.

It"s time to fire up the propane grill for National Grill Month. There is nothing better than grilling in the summertime whether at the lake or at your home as long as you do it safely. Safety should always be a top concern when operating propane grills or any other propane equipment.

Have you ever went home with your full propane cylinder and hooked it to your grill and you can"t get propane to come out. The cylinder has an OPD (Overfill Protective Device) Valve and if too much propane tries to go through it at once, it will shut off. Here are some steps to reset the valve:

Carefully read the manufacturer"s instructions before turning on and lighting your propane grill for the first time. Always follow the manufacturer"s instructions, which supersede any guidelines shown here!

Ignite the burners that are closest to the gas flow first (if your ignition source is to the far right of the grill, for example, turn on the burner that is farther to the right first).

If you plan to store a spare tank for emergencies, choose a well-ventilated outdoor location. Do not store extra propane tanks in your home, garage, or shed

Choose a flat, low-traffic location with a solid, non-flammable surface (like concrete). Avoid storing tanks on surfaces that gather moisture (such as grass or dirt) to prevent tank rust

If you cook using a gas grill fueled by propane, you may have noticed a change in how the valve on the propane tank looks. Also, if you bought a gas grill in the last couple of years, the tank that came with the grill and the connection on the grill probably look different from what you are accustomed to seeing.

A safety note for you: Propane tanks of any design must be transported and stored in an upright position so the pressure relief device will function properly. Laying the tank on its side in the trunk of your car is a potentially very dangerous situation.

What happens if you have an older grill and have to replace the tank and get one with the Acme valve? Use it. They are compatible, as the left-hand-thread fitting on your older grill will screw into the internal threads on the Acme valve.

Also, there is another type of valve not widely available yet. This one is a quick disconnect, somewhat like a fitting that attaches an air hose to a pneumatic tool. This fitting will be covered later in this article.

All new cylinders from 4 pounds up to 40 pounds propane capacity must have the OPD valve. All cylinders from 4 pounds up to 40 pounds will have to have an OPD valve by April 1, 2002, or it will be illegal to fill them. It will not be illegal to use or transport them, only to fill them.

Now that you know how to make the connection between the grill and the tank, you need to know what the difference is in getting your tank refilled. If you take it to a place that fills your tank, you will notice no difference in filling the tank. The same piece of equipment that fills tanks with the POL valve will also fill through the Acme valves or OPD valves because of those internal threads. But there is a difference you need to recognize after you get your tank filled. As you get ready to travel with your newly-filled tank, instead of screwing a plug into the internal threads, you may press the optional dust cap over the external threads. The Acme valves and OPD valves have some built-in safeguards that prevent the escape of gas when the tank is not attached to the grill, even if the valve is open. This is the reason for the valve body being slightly larger. However, if you screw a plug into the valve, you defeat these safeguards. So be sure to leave the plug out of the Acme valves and OPD valves!

There are some other safeguards in the valve and connector combination that stop the gas flow if the tank is involved in a fire, even if the tank is still attached to the grill and even if the valve is wide open. Another safeguard limits the flow of gas from the tank should the hose break or leak.

The safety devices require you to open the valve on the tank before you open the burner valve. Otherwise, all you will get is enough gas to run a pilot light. If your grill will not light, try this:

You need to be attentive if you go to a cylinder exchange cabinet to turn in your empty tank for a filled one. If you have the old-style connector on your grill, you can use both of the widely-available screw-on valves. However, if you have a new grill with the connector that needs the new external threads, be sure to get a tank with the new Acme valve. Some of the exchange cabinets offer many tank styles. Get the one you need. Remember, the Acme valve will work on both styles of grill connectors discussed so far.

You may still see some non-OPD-equipped cylinders after April 1, 2002. This is legal. As mentioned earlier, you may use and transport non-OPD cylinders after this date. But you cannot have them filled.

As mentioned earlier, there is also a quick-disconnect valve and fitting combination available. (Some Weber gas grills use this fitting.) To make the connection with this combination, you simply pull back slightly on the collar ring on the valve and press the fitting firmly into the hole in the valve until it "clicks" into place. It will remain in place until you slide back the collar on the end of the valve. This valve and connector combination also has the safeguards mentioned earlier for the Acme valve. Your refueling choices are more restricted with this combination. These are rarely stocked in exchange cabinets. When you bought the tank with the quick-disconnect valve, you probably received a special fitting to be used to fill the tank. The fitting has the internal POL threads that allows the refiller to attach his equipment to your tank. Your refiller may or may not have this fitting. Be sure you have the fitting with you when you go to the refiller and when you leave with your full tank.

Propane tanks make grilling easy and convenient. In most cases, grilling is a pleasant way to spend a summer evening or weekend outdoors with family and friends. There have been few problems with propane tanks in these situations, but the potential for problems exists, as it does with any source of energy. To reduce the possibility of these problems, follow these steps:

If the tank becomes corroded or looses its collar ring (the carrying handle) or its foot ring (the support ring on the bottom), replace the tank immediately.

If you have questions about propane containers or propane use, contact your propane dealer or Richard Fredenburg, LP-Gas Engineer with the Standards Division, North Carolina Department of Agriculture and Consumer Services. Our address is 1050 Mail Service Center, Raleigh, NC 27699-1050. Our telephone number is (919) 733-3313.

Did you knowthat bringing a propane tank to the point of explosions is actually quite difficult? It is not as simple as many people believe. An operational propane tank under normal circumstances will not explode or leak, as there are safety valves and other mechanisms in place to prevent ruptures, leaks, and yes - explosions. Human error is actually the main cause of propane related accidents and explosions, so it’s important to understand how to safely handle propane.

ABLEVE, or, aBoiling Liquid Expanding Vapour Explosion, is a term that describes a situation where the safety valve on a tank of combustible material such as propane, cannot vent the excess pressure in the tank as the vapours inside start to heat causing the gas to expand. Under normal circumstances, this safety valve can effectively vent the excess pressure. If the pressure builds up faster than the valve can release it, the tank can rupture. If flames are present to ignite the leaking fumes, this can cause an explosion. In order for this to happen the conditions have to be just right. The tank has to be exposed to excessive heat for a long period of time and a source of ignition has to be present. Propane won’t ignite when combined with air unless the source of ignition reaches at least 940 degrees Fahrenheit. In contrast, gasoline will ignite when the source of ignition reaches only 430 to 500 degrees Fahrenheit. These types of explosions are rare with propane and if proper safety precautions are taken, can be avoided altogether

Propane tanks are subject to strict manufacturing standards that ensure they are durable and safe to use. Regulations state that tanks/cylinders must be equipped with pressure relief valves to prevent excessive pressure in abnormal conditions. Tanks are also stamped with information about the date of manufacture and subsequent service and testing dates. It is also required by law that personnel dealing with filling propane tanks have a record of training. You can read more about the regulations here. Propane tanks are also 20 times more puncture resistant that tanks filled with ethanol, methanol or gasoline.

One of the biggest misconceptions surrounding propane as a fuel source for your home or cottage is safety. But the reality is, the characteristics and regulations applied to propane use make it one of the safest fuels when compared to other fuels such as gasoline, diesel and compressed natural gas.

If you have any questions about our delivery services or products callBudget Propane Ontarioat 1 888 405.7777 . We offer affordable propane solutions for home, business, and industrial use and Smart Tank remote-monitoring technology to save you time and money.

Always keep flammable and combustible materials (e.g., paper, clothing, wood, gasoline, solvents) away from any open flames that originate from your appliances.

Never place your head near or directly over the valves on your storage tank. A sudden release of product from the safety relief valve could result in serious injury.

If you think you smell propane in your home, camper, RV or the area around any gas equipment, or if a gas alarm signals the presence of propane, you should IMMEDIATELY follow these suggestions:

Even if you do not continue to smell propane, do not open or turn on the propane supply valve. Do not re-enter the building, vehicle or area. Let a qualified propane service technician and/or emergency personnel check for escaped propane.

Have a properly trained propane service technician repair the leak. The propane service technician or emergency responder needs to determine that the leak situation has been fully resolved. The propane service technician should check all of your gas appliances and re-light any appliance pilots.

All lines not attached to appliances must be closed and terminated with threaded caps or plugs. If you have any questions, please call your propane supplier.

Propane expands when heated. That increases the pressure in the tank. Above a certain pressure, the relief valve opens to release a small amount of vapor. That release keeps the pressure from building up too much inside the tank. Once excess pressure has been released, the relief valve closes automatically.

It’s important to keep your tank painted with a white, aluminum or other reflective color. A rusty, unpainted or dark-colored tank may cause pressure build-up resulting in a safety relief valve discharge.

All appliances should be installed and repaired only by qualified technicians. Improper ventilation can starve the combustion process in the appliance and create a situation that could produce toxic carbon monoxide gas. Carbon monoxide is an odorless and colorless gas that, in sufficient amounts, may be deadly to humans. Usually, headaches and/or flu-like systems are initial signs of carbon monoxide poisoning. If you suspect that any of your appliances have been improperly vented, you should discontinue using them and contact your propane supplier or local fire department immediately for an inspection.

An appliance gas control is a precision mechanism that may malfunction if it is exposed to water from flooding, storms, or any other damaging environments. A flooded gas control must be replaced by a qualified gas appliance technician. Damaged gas control valves must be replaced.

If you continue to smell gas, even after lighting a pilot, turn off the gas valve immediately upstream of the appliance to stop the flow of gas. Contact your propane supplier immediately to investigate the situation.

If an appliance or any other component of your propane system has been tagged “out-of-service,” do not attempt to enable it. The tag indicates a serious unsafe condition.

Ask your propane supplier to conduct a regular gas safety check to inspect your system for leaks and ensure it meets all applicable safety standards. The technician will also check your tank, piping, regulators, gauges, connectors, valves, vents, thermostats, pilots, burners and appliance controls to make sure they are in good working condition.

Do not use a propane gas cylinder if it shows signs of external damage, such as dents, gouges, bulges, fire damage, corrosion, leakage or excessive rust.

To see how much propane is left in your cylinder, run a wet finger down the side. The wet streak will evaporate faster over the empty part of the cylinder.

This article is a consolidation of information and experience gained over the years. It is provided to assist the reader in having an understanding of the propane industry’s experience with pressure relief valves (PRVs) in propane tank service.

In Ontario, a formal inspection of the PRV is conducted on a “maximum” of a three-year frequency with a record of the inspection being maintained by the propane distributor. At bulk plants and propane dispensing facilities, inspections including the PRVs are conducted annually.

As each province adopts the 2014 version of the B51 code into regulation, an implementation plan will be prescribed in order to provide tank owners appropriate time to come into compliance with the new requirements.

Larger capacity tanks (10,000 USWG and larger) are normally equipped with single or multiple external spring type pressure relief valves. Tanks equipped with multiple external spring type pressure relief valves do not have to be taken out of service to replace the PRVs.

PRVs used in propane service are constructed of corrosion-resistant materials and are installed so as to be protected against the weather. The variations of temperature and pressure due to atmospheric conditions are not sufficient to cause any permanent set in the valve springs.

PRVs are visually inspected each time a propane tank is filled as part of the filler’s responsibility to ensure the tank and all of the visibly attached components are in acceptable condition. PRV inspection programs ensure that the pressure relief valves found in unacceptable condition due to damage, corrosion or weeping are replaced so as not to create a potential safety hazard.

Persons conducting the inspection of pressure relief valves on propane tanks are trained on how to inspect PRVs and tanks. The Fuels Learning Centre offers a training program to instruct bulk truck drivers, service technicians, and plant operators how to inspect PRVs and tanks –

As previously stated the majority 95% of the PRVs in domestic service are PRVs with “internal springs” sitting within the propane vapour space, and are, therefore, not subject to corrosion or contamination. The external components are protected from the elements by the use of protective caps, designed to keep moisture and debris out of the valve. The protective cap is an item that a delivery driver checks to ensure it is in place and in good condition each time a delivery is made. Missing or damaged caps are replaced by the delivery driver.

There are approximately 750, 000 propane tanks in Canada. All of these propane tanks, regardless of size, are equipped with one or more PRVs. The majority of the propane tanks are located at residences, farms, and commercial establishments. Tanks are either owned by the propane consumer or leased from the propane company supplying the fuel.

We classify a pressure relief valve failure to be when the pressure relief valve failed to activate in an over-pressure situation or opened or partially opened in a non-overpressure situation. The mechanical components of the valve failed to operate as designed.

Industry experience in Canada and the United States is an indicator that PRVs in propane service have experienced very minimal failure rates and should not be grouped or treated legislatively with PRVs in service with gases or fluids that may have an adverse effect and documented life expectancy on the PRV.

The propane industry is aware of only one reported failure on a stationary propane tank in which a used “external spring” pressure relief valve was reinstalled in a 2,000 USWG propane tank at a plant north of Kingston, Ontario in the mid-1990s. The pressure relief valve partially opened when the propane tank was being filled. This is one incident, in 25 years, that involved a type of PRV designed with an external spring, which represents approximately 5% of the PRVs currently in use.

As a result of this failure, a Directors Order was issued by the Technical Standards and Safety Authority (TSSA) instructing all propane marketers to inspect and replace as required pressure relief valves equipped with “external springs”.

Information received from the Ontario Fire Marshal’s Office (OFM) indicated the OFM was not aware of any specific cases involving propane PRVs. Fire Marshall Office (FMO) statistics are gathered through fire and explosion reports received from the fire services and FMO investigators. A propane release without fire would not be reported to the FMO.

The National Propane Gas Association (NPGA) in the United States has no statistics on PRV failures in stationary propane tanks. NPGA staff are not aware of any incidents of this nature. The National Board of Boilers and Pressure Vessel Inspectors in Columbus, Ohio was also not aware of any incidents involving the failure of PRVs in propane service.

The NPGA did, however, commission a study examining relief valve performance in cylinders. These valves are smaller and more susceptible to damage. Cylinders, unlike tanks, are meant to be portable and readily transported by the general public. The study found there was broad scatter and inconsistency in relief valve performance regardless of valve age, manufacturer or source location.

There are three manufacturers of pressure relief valves currently used in Canada; Engineered Controls (Rego), Fisher Controls and Sherwood. A review of the literature published by the three manufacturers shows that Fisher recommends a 15-year replacement cycle, while Rego and Sherwood recommend a 10-year replacement cycle.

Of the three manufacturers of pressure relief valves, one of them currently provides replacement parts for servicing PRVs in propane service. Replacement of the pressure relief valve’s components still requires removal of the pressure relief valve from the tank so the components are accessible and can be replaced in a facility equipped with the proper tools and trained personnel.

Pressure relief valves are required to function under widely varying conditions. Corrosion, aging of the resilient seat disk, and friction, all proceed at different rates depending upon the nature of the specific environment and application.

Predicting the safe useful life of pressure relief valves is obviously not an exact science. The conditions to which the valve is subjected will vary widely and will determine its useful life.

The majority (95%) of the PRVs in domestic propane service are PRVs with internal springs situated within the vapour space and not subject to corrosion, contamination, or dam-age.

There are no industry statistics (from Canada or the USA ) confirming that failure of PRV’s in propane service are a safety issue – only one documented incident in Ontario in the last 25 years.

8613371530291

8613371530291