do propane tanks have a safety valve free sample

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

It’s hard to find anyone who doesn’t use propane as part of their RV experience. Propane gets used in RVs for cooking, refrigeration, and heating. Outside of the RV, propane has a host of other uses like firing up the barbecue or propane fireplace. The use of propane is so common, it’s easy for RVers to take propane safety for granted.

Propane is a colorless, odorless gas that is compressed into a liquid. Since propane is a highly noxious gas that can kill quickly if a leak goes undetected, gas companies add a rotten egg smell to it. This smell helps us detect propane leaks before they can poison us. When handled correctly, propane is a stable, safe, and convenient fuel.

Be aware that propane is heavier than the air we breathe. Being closer to the ground, children and pets are more vulnerable to propane’s toxic effects than adults.

In its compressed liquid state, propane is stored in metal propane cylinders. All propane cylinders are designed with a safety relief valve that will cause propane to leak out if the liquid propane inside comes into contact with the valve. This leaked propane vaporizes immediately and the resulting vapors could either ignite or cause propane toxicity.

Secure your tanks for use and transport them using the harnesses that come with your rig. If you need to take portable tanks in for a fill-up, secure them in the back of your pick-up truck using a milk crate, tie-downs, or a propane stabilizer.

Don’t store or transport propane tanks inside your RV or your vehicle. If you have to take them for a refill, transport your propane tanks secured in the back of a pickup truck. This is for two reasons:

If you are in an accident and firefighters attend, they will be focused on getting you and your family out of your vehicle. They’ll be using all the tools they need to do that. If they don’t suspect there is a propane tank inside your vehicle, a spark from a metal cutting tool could be disastrous.

Propane-related accidents can be catastrophic and are avoidable. Make sure you are on a safe route by planning your travels with RV LIFE Trip Wizard; you can simply select propane and RV-friendly routing options under the Routing & Driving tab to be automatically routed around tunnels that prohibit propane.

One of the most hotly contested topics among RVers is whether you should run the fridge on propane during travel. On one side, there are RVers who passionately say they do it all the time without issue. On the other side, there are some RVers who don’t want to risk it all for keeping their food and beverages cold.

The fact is, when we are traveling on highways and gravel roads with our rigs, they are subjected to shaking that can be equivalent to that of an earthquake. The parts of the propane system that make it function can theoretically be damaged during movement. All it takes is a small spark or your RV refrigerator’s flame and you could be standing by the side of a highway, inhaling the carcinogenic fumes of your burning RV or worse.

The trick to avoiding this ugly and unexpected scene is to simply keep your propane valves turned off during travel. Your RV fridge is designed to keep its contents cold for a few hours even if it’s off. For longer trips, you can always store cold food and beverages in a cooler, and then store them in the RV fridge when you get where you are going.

On really hot days, it won’t hurt to use Reflectix, aluminum shade cloth, or even ice to help keep your propane tanks cool. Given the high flammability of propane, it’s a good idea to always keep propane cylinders away from flames.

Propane cylinders have a useful lifespan of 10 years in Canada or 12 years in the USA. There is a stamp on the collar of the tank that will give you the date of manufacture so you can tell how old it is.

In addition, propane cylinders should be carefully checked for excessive rust, corrosion, and wear and tear. Out of date or worn out propane cylinders can often be returned to anywhere that sells propane.

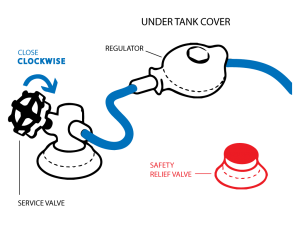

Your entire propane system should be inspected at least once per year. It’s best to get a certified RV technician to do this, but there are a few components close to the cylinder that you can easily check yourself and swap out if necessary. You can easily check them by spraying soapy water on them and watching for bubbles.

One of the best parts about RVing is engaging with the community of traveling enthusiasts.iRV2 forumsallow folks to chat with other RVers online, and get other perspectives on everything RVing, including products, destinations, RV mods, and more.

Lynne lives, travels, and works full-time in a Forest-River R-Pod 180 with her 2-pointers, Jolene and Annabelle. Lynne has been an enthusiastic RVer for over 35 years. And then one day in 2019, she began full-time RVing as a lifestyle experiment. She quickly fell in love with the convenience, freedom and minimalist lifestyle offered by full-time RV living. Lynne is a professional writer and has been a professional dog trainer since 1995. You can read about her travel adventures on her R-Pod Adventure blog, R-podyssey at: http://www.rpodaventure.com

One feature you need to learn more about is the tank’s safety relief valve. All propane tanks, including the cylinders you use for your grill, are required by law to have pressure relief devices that allow for the release of excess pressure inside the tank.

The safety relief valve is designed to protect your propane tank from rupturing in case excess pressure builds up in the tank. It is also called a pop-off valve, pressure-venting valve, or a relief valve.

The safety relief valve is kept closed by a very strong spring as long as the pressure inside the tank is at a safe level. If the pressure in the tank reaches the same amount of pressure of the spring, the safety relief valve is opened. If that happens, you’ll hear a hissing sound coming from the tank as pressure is dissipated. In instances where the pressure in the tank is much higher than that of the spring, the valve will fully open. You’ll hear a pop if that occurs.

Once the pressure is down below the pressure of the spring, the valve closes on its own. If the valve pops open, it may need to be replaced. DO NOT attempt to repair or replace this on your own. This job requires a professional. Contact us to help.

That’s why, when we deliver your propane, we fill your tank to 80% full. You may have noticed that and wondered if it was a mistake. It’s intentional. That remaining 20% of space in your tank remains empty so the propane has space to safely expand in warm or hot conditions.

For safe, expert propane tank installation, Boehlke Bottled Gas can’t be beat! Contact us today for your new propane tank. And don’t forget to ask about our reliable propane delivery!

As fall rolls along and some RVers are thinking about winterizing and storing their rigs for the winter, we thought this would be a good time to address the question, “Does propane go bad?”

We’ve previously investigated gasoline and diesel in our posts entitled “Does Gasoline Go Bad?” and “Does Diesel Go Bad?” But we’ve never written a post about the shelf life of propane.

Not only do some RVers store their rigs for the winter (often with partially full propane tanks), but lots of people store partially full portable propane gas tanks used for summer barbequeing.

Many RVers rely on propane for heating, cooking, and hot water. As the fall nights get chilly, some are getting ready to bring out their portable propane-powered heaters for winter camping. But, they’ve been stored away for a long time.

For all of these people, it’s important to know whether propane degrades over time. More important, however, is whether a stored propane tank presents a risk. Can propane tanks explode in the cold, for example?

Propane, (LPG or liquefied petroleum gas), is a component of natural gas that is compressed and stored as a liquid. And, it has a very long shelf life.

When you see an expiration date on a propane tank or gauge, what you’re actually seeing is the date when the tank’s safety inspection expires. Essentially, the date on the tank is a reminder to get the tank itself inspected because it’s the tank that needs to be replaced – not the propane.

In the United States, PORTABLE propane tanks/cylinders with a capacity of 100 pounds or less will have an expiration date 12 years out from the manufacturing date, as required by the DOT standard they are certified to. (They have a 10-year expiry in Canada.)

After that date, you’ll need to have the tank inspected to determine if it needs to be replaced or requalified/recertified. Requalified/recertified tanks will receive a new expiration date of 5, 7, or 12 years out, depending on the type of recertification and the method.

Brand new, larger, BUILT-IN RV propane tanks are manufactured with thicker walls and are certified by ASME (just like permanently installed propane cylinders for residential use), not the DOT, and don’t need to be recertified. However, it’s still a good to check regularly them for signs of rust and leaks.

Propane tanks can rust and leak. Since a gas leak is never a good thing, it’s important to prevent rust and to monitor tanks for the development of rust. It’s also why propane tanks have an “expiry” date – a reminder that it’s time to get the tank inspected.

There are safety mechanisms built into propane tanks. As long as you maintain your tanks and respect the propane as you use it, your propane tank exploding (or imploding) is highly unlikely.

Leaks can develop around valves, of course, but if rust penetrates the tank, you’ve got a real problem on your hands. The important thing is to make sure your tank never gets to that point!

It’s also important to make sure that a propane tank isn’t exposed to extreme heat for long periods of time. If temperatures outside the tank are so high that they cause the temperature inside to rise excessively, the tank can explode if the built-in safety release systems fail.

However, this is an unusual situation and would require the liquid propane inside a faulty tank to come to a boil and expand. That expansion could cause the tank to explode. For this to happen, your tank would need to be stored in a place with temperatures of 120℉ or higher for an extended period.

It’s always best to store a propane tank (or a rig with a built-in propane tank!) in a place that is cool and dry. Lower storage temperatures ensure the tank, and the LP inside it, remain at a safe, low temperature. Again, it’s best to store propane at temps below 120 degrees Fahrenheit.

When storing a propane tank (or an RV with a propane tank onboard) be sure to shut the valve off prior to storing. You don’t want a gas leak developing.

Yes, you can! If you don’t have a working gauge on your propane tank, the best way to check the level of propane in the tank is actually quite simple.

Join our newsletter to learn about all things RV-related. Every week we offer free tips, tricks, product reviews, and more to our online community of RVers. So, whether this is your first time on the road or you’re a seasoned expert, we’d love for you to geek out with us!

Container assembly - An assembly consisting essentially of the container and fittings for all container openings, including shutoff valves, excess flow valves, liquid-level gaging devices, safety relief devices, and protective housing.

“Liquified petroleum gases” - “LPG” and “LP-Gas” - Any material which is composed predominantly of any of the following hydrocarbons, or mixtures of them; propane, propylene, butanes (normal butane or iso-butane), and butylenes.

Movable fuel storage tenders or farm carts - Containers not in excess of 1,200 gallons water capacity, equipped with wheels to be towed from one location of usage to another. They are basically nonhighway vehicles, but may occasionally be moved over public roads or highways. They are used as a fuel supply for farm tractors, construction machinery and similar equipment.

Systems - an assembly of equipment consisting essentially of the container or containers, major devices such as vaporizers, safety relief valves, excess flow valves, regulators, and piping connecting such parts.

Vaporizer-burner - an integral vaporizer-burner unit, dependent upon the heat generated by the burner as the source of heat to vaporize the liquid used for dehydrators or dryers.

Ventilation, adequate - when specified for the prevention of fire during normal operation, ventilation shall be considered adequate when the concentration of the gas in a gas-air mixture does not exceed 25 percent of the lower flammable limit.

Approved - unless otherwise indicated, listing or approval by a nationally recognized testing laboratory. Refer to § 1910.7 for definition of nationally recognized testing laboratory.

All liquefied petroleum gases shall be effectively odorized by an approved agent of such character as to indicate positively, by distinct odor, the presence of gas down to concentration in air of not over one-fifth the lower limit of flammability. Odorization, however, is not required if harmful in the use of further processing of the liquefied petroleum gas, or if odorization will serve no useful purpose as a warning agent in such use or further processing.

The odorization requirement of paragraph (b)(1)(i) of this section shall be considered to be met by the use of 1.0 pounds of ethyl mercaptan, 1.0 pounds of thiophane or 1.4 pounds of amyl mercaptan per 10,000 gallons of LP-Gas. However, this listing of odorants and quantities shall not exclude the use of other odorants that meet the odorization requirements of paragraph (b)(1)(i) of this section.

Each system utilizing DOT containers in accordance with 49 CFR part 178 shall have its container valves, connectors, manifold valve assemblies, and regulators approved.

Each system for domestic or commercial use utilizing containers of 2,000 gallons or less water capacity, other than those constructed in accordance with 49 CFR part 178, shall consist of a container assembly and one or more regulators, and may include other parts. The system as a unit or the container assembly as a unit, and the regulator or regulators, shall be individually listed.

In systems utilizing containers of over 2,000 gallons water capacity, each regulator, container valve, excess flow valve, gaging device, and relief valve installed on or at the container, shall have its correctness as to design, construction, and performance determined by listing by a nationally recognized testing laboratory. Refer to § 1910.7 for definition of nationally recognized testing laboratory.

Containers used with systems embodied in paragraphs (d), (e), (g), and (h) of this section, except as provided in paragraphs (e)(3)(iii) and (g)(2)(i) of this section, shall be designed, constructed, and tested in accordance with the Rules for Construction of Unfired Pressure Vessels, section VIII, Division 1, American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, 1968 edition, which is incorporated by reference as specified in § 1910.6.

Containers constructed according to the 1949 and earlier editions of the ASME Code do not have to comply with paragraphs U-2 through U-10 and U-19 thereof. Containers constructed according to paragraph U-70 in the 1949 and earlier editions are not authorized.

Containers designed, constructed, and tested prior to July 1, 1961, according to the Code for Unfired Pressure Vessels for Petroleum Liquids and Gases, 1951 edition with 1954 Addenda, of the American Petroleum Institute and the American Society of Mechanical Engineers, which is incorporated by reference as specified in § 1910.6, shall be considered in conformance. Containers constructed according to API-ASME Code do not have to comply with section I or with appendix to section I. Paragraphs W-601 to W-606 inclusive in the 1943 and earlier editions do not apply.

The provisions of paragraph (b)(3)(i) of this section shall not be construed as prohibiting the continued use or reinstallation of containers constructed and maintained in accordance with the standard for the Storage and Handling of Liquefied Petroleum Gases NFPA No. 58 in effect at the time of fabrication.

Containers used with systems embodied in paragraph (b), (d)(3)(iii), and (f) of this section, shall be constructed, tested, and stamped in accordance with DOT specifications effective at the date of their manufacture.

Welding to the shell, head, or any other part of the container subject to internal pressure, shall be done in compliance with the code under which the tank was fabricated. Other welding is permitted only on saddle plates, lugs, or brackets attached to the container by the tank manufacturer.

Where repair or modification involving welding of DOT containers is required, the container shall be returned to a qualified manufacturer making containers of the same type, and the repair or modification made in compliance with DOT regulations.

Each container covered in paragraph (b)(3)(i) of this section, except as provided in paragraph (b)(3)(iv) of this section shall be marked as specified in the following:

With a marking identifying compliance with, and other markings required by, the rules of the reference under which the container is constructed; or with the stamp and other markings required by the National Board of Boiler and Pressure Vessel Inspectors.

With notation as to whether the container is designed for underground or aboveground installation or both. If intended for both and different style hoods are provided, the marking shall indicate the proper hood for each type of installation.

With the wording “This container shall not contain a product having a vapor pressure in excess of __ p.s.i.g. at 100 °F.,” see subparagraph (14)(viii) of this paragraph.

With marking indicating the maximum level to which the container may be filled with liquid at temperatures between 20 °F. and 130 °F., except on containers provided with fixed maximum level indicators or which are filled by weighing. Markings shall be increments of not more than 20 °F. This marking may be located on the liquid level gaging device.

Markings specified shall be on a metal nameplate attached to the container and located in such a manner as to remain visible after the container is installed.

When LP-Gas and one or more other gases are stored or used in the same area, the containers shall be marked to identify their content. Marking shall conform to the marking requirements set forth in § 1910.253(b)(1)(ii).

In the case of buildings devoted exclusively to gas manufacturing and distributing operations, the distances required by Table H-23 may be reduced provided that in no case shall containers of water capacity exceeding 500 gallons be located closer than 10 feet to such gas manufacturing and distributing buildings.

The minimum separation between liquefied petroleum gas containers and flammable liquid tanks shall be 20 feet, and the minimum separation between a container and the centerline of the dike shall be 10 feet. The foregoing provision shall not apply when LP-Gas containers of 125 gallons or less capacity are installed adjacent to Class III flammable liquid tanks of 275 gallons or less capacity.

Suitable means shall be taken to prevent the accumulation of flammable liquids under adjacent liquified petroleum gas containers, such as by diking, diversion curbs, or grading.

Valves, fittings, and accessories connected directly to the container including primary shutoff valves, shall have a rated working pressure of at least 250 p.s.i.g. and shall be of material and design suitable for LP-Gas service. Cast iron shall not be used for container valves, fittings, and accessories. This does not prohibit the use of container valves made of malleable or nodular iron.

Connections to containers, except safety relief connections, liquid level gaging devices, and plugged openings, shall have shutoff valves located as close to the container as practicable.

Excess flow valves, where required shall close automatically at the rated flows of vapor or liquid as specified by the manufacturer. The connections or line including valves, fittings, etc., being protected by an excess flow valve shall have a greater capacity than the rated flow of the excess flow valve.

Liquid level gaging devices which are so constructed that outward flow of container contents shall not exceed that passed by a No. 54 drill size opening, need not be equipped with excess flow valves.

Openings from container or through fittings attached directly on container to which pressure gage connection is made, need not be equipped with shutoff or excess flow valves if such openings are restricted to not larger than No. 54 drill size opening.

Except as provided in paragraph (c)(5)(i)(b) of this section, excess flow and back pressure check valves where required by this section shall be located inside of the container or at a point outside where the line enters the container; in the latter case, installation shall be made in such manner that any undue strain beyond the excess flow or back pressure check valve will not cause breakage between the container and such valve.

Containers of more than 30 gallons water capacity and less than 2,000 gallons water capacity, filled on a volumetric basis, and manufactured after December 1, 1963, shall be equipped for filling into the vapor space.

Pipe, except as provided in paragraphs (e)(6)(i) and (g)(10)(iii), of this section shall be wrought iron or steel (black or galvanized), brass, copper, or aluminum alloy. Aluminum alloy pipe shall be at least Schedule 40 in accordance with the specifications for Aluminum Alloy Pipe, American National Standards Institute (ANSI) H38.7-1969 (ASTM, B241-69), which is incorporated by reference as specified in § 1910.6, except that the use of alloy 5456 is prohibited and shall be suitably marked at each end of each length indicating compliance with American National Standard Institute Specifications. Aluminum Alloy pipe shall be protected against external corrosion when it is in contact with dissimilar metals other than galvanized steel, or its location is subject to repeated wetting by such liquids as water (except rain water), detergents, sewage, or leaking from other piping, or it passes through flooring, plaster, masonry, or insulation. Galvanized sheet steel or pipe, galvanized inside and out, may be considered suitable protection. The maximum nominal pipe size for aluminum pipe shall be three-fourths inch and shall not be used for pressures exceeding 20 p.s.i.g. Aluminum alloy pipe shall not be installed within 6 inches of the ground.

Vapor piping with operating pressures not exceeding 125 p.s.i.g. shall be suitable for a working pressure of at least 125 p.s.i.g. Pipe shall be at least Schedule 40 (ASTM A-53-69, Grade B Electric Resistance Welded and Electric Flash Welded Pipe, which is incorporated by reference as specified in § 1910.6, or equal).

Vapor piping with operating pressures over 125 p.s.i.g. and all liquid piping shall be suitable for a working pressure of at least 250 p.s.i.g. Pipe shall be at least Schedule 80 if joints are threaded or threaded and back welded. At least Schedule 40 (ASTM A-53-69 Grade B Electric Resistance Welded and Electric Flash Welded Pipe or equal) shall be used if joints are welded, or welded and flanged.

Tubing shall be seamless and of copper, brass, steel, or aluminum alloy. Copper tubing shall be of type K or L or equivalent as covered in the Specification for Seamless Copper Water Tube, ANSI H23.1-1970 (ASTM B88-69), which is incorporated by reference as specified in § 1910.6. Aluminum alloy tubing shall be of Type A or B or equivalent as covered in Specification ASTM B210-68 (which is incorporated by reference as specified in § 1910.6) and shall be suitably marked every 18 inches indicating compliance with ASTM Specifications. The minimum nominal wall thickness of copper tubing and aluminum alloy tubing shall be as specified in Table H-24 and Table H-25.

Aluminum alloy tubing shall be protected against external corrosion when it is in contact with dissimilar metals other than galvanized steel, or its location is subject to repeated wetting by liquids such as water (except rainwater), detergents, sewage, or leakage from other piping, or it passes through flooring, plaster, masonry, or insulation. Galvanized sheet steel or pipe, galvanized inside and out, may be considered suitable protection. The maximum outside diameter for aluminum alloy tubing shall be three-fourths inch and shall not be used for pressures exceeding 20 p.s.i.g. Aluminum alloy tubing shall not be installed within 6 inches of the ground.

In systems where the gas in liquid form without pressure reduction enters the building, only heavy walled seamless brass or copper tubing with an internal diameter not greater than three thirty-seconds inch, and a wall thickness of not less than three sixty-fourths inch shall be used. This requirement shall not apply to research and experimental laboratories, buildings, or separate fire divisions of buildings used exclusively for housing internal combustion engines, and to commercial gas plants or bulk stations where containers are charged, nor to industrial vaporizer buildings, nor to buildings, structures, or equipment under construction or undergoing major renovation.

Pipe joints may be screwed, flanged, welded, soldered, or brazed with a material having a melting point exceeding 1,000 °F. Joints on seamless copper, brass, steel, or aluminum alloy gas tubing shall be made by means of approved gas tubing fittings, or soldered or brazed with a material having a melting point exceeding 1,000 °F.

For operating pressures of 125 p.s.i.g. or less, fittings shall be designed for a pressure of at least 125 p.s.i.g. For operating pressures above 125 p.s.i.g., fittings shall be designed for a minimum of 250 p.s.i.g.

The use of threaded cast iron pipe fittings such as ells, tees, crosses, couplings, and unions is prohibited. Aluminum alloy fittings shall be used with aluminum alloy pipe and tubing. Insulated fittings shall be used where aluminum alloy pipe or tubing connects with a dissimilar metal.

Strainers, regulators, meters, compressors, pumps, etc., are not to be considered as pipe fittings. This does not prohibit the use of malleable, nodular, or higher strength gray iron for such equipment.

All materials such as valve seats, packing, gaskets, diaphragms, etc., shall be of such quality as to be resistant to the action of liquefied petroleum gas under the service conditions to which they are subjected.

All piping, tubing, or hose shall be tested after assembly and proved free from leaks at not less than normal operating pressures. After installation, piping and tubing of all domestic and commercial systems shall be tested and proved free of leaks using a manometer or equivalent device that will indicate a drop in pressure. Test shall not be made with a flame.

Provision shall be made to compensate for expansion, contraction, jarring, and vibration, and for settling. This may be accomplished by flexible connections.

Piping outside buildings may be buried, above ground, or both, but shall be well supported and protected against physical damage. Where soil conditions warrant, all piping shall be protected against corrosion. Where condensation may occur, the piping shall be pitched back to the container, or suitable means shall be provided for revaporization of the condensate.

Hose shall be fabricated of materials that are resistant to the action of LP-Gas in the liquid and vapor phases. If wire braid is used for reinforcing the hose, it shall be of corrosion-resistant material such as stainless steel.

Hose subject to container pressure shall have its correctness as to design construction and performance determined by being listed (see § 1910.110(a)(15)).

Hose and hose connections on the low-pressure side of the regulator or reducing valve shall be designed for a bursting pressure of not less than 125 p.s.i.g. or five times the set pressure of the relief devices protecting that portion of the system, whichever is higher.

Hose may be used on the low-pressure side of regulators to connect to other than domestic and commercial gas appliances under the following conditions:

For use inside buildings the hose shall be of minimum practical length, but shall not exceed 6 feet except as provided in paragraph (c)(5)(i)(g) of this section and shall not extend from one room to another, nor pass through any walls, partitions, ceilings, or floors. Such hose shall not be concealed from view or used in a concealed location. For use outside of buildings, the hose may exceed this length but shall be kept as short as practical.

The hose shall be approved and shall not be used where it is likely to be subjected to temperatures above 125 °F. The hose shall be securely connected to the appliance and the use of rubber slip ends shall not be permitted.

The shutoff valve for an appliance connected by hose shall be in the metal pipe or tubing and not at the appliance end of the hose. When shutoff valves are installed close to each other, precautions shall be taken to prevent operation of the wrong valve.

Every container except those constructed in accordance with DOT specifications and every vaporizer (except motor fuel vaporizers and except vaporizers described in paragraph (b)(11)(ii)(c) of this section and paragraph (d)(4)(v)(a) of this section) whether heated by artificial means or not, shall be provided with one or more safety relief valves of spring-loaded or equivalent type. These valves shall be arranged to afford free vent to the outer air with discharge not less than 5 feet horizontally away from any opening into the building which is below such discharge. The rate of discharge shall be in accordance with the requirements of paragraph (b)(10)(ii) or (b)(10)(iii) of this section in the case of vaporizers.

Minimum required rate of discharge in cubic feet per minute of air at 120 percent of the maximum permitted start to discharge pressure for safety relief valves to be used on containers other than those constructed in accordance with DOT specification shall be as follows:

When the surface area is not stamped on the nameplate or when the marking is not legible, the area can be calculated by using one of the following formulas:

The rate of discharge may be interpolated for intermediate values of surface area. For containers with total outside surface area greater than 2,000 square feet, the required flow rate can be calculated using the formula, Flow Rate-CFM Air = 53.632 A0.82.

Valves not marked “Air” have flow rate marking in cubic feet per minute of liquefied petroleum gas. These can be converted to ratings in cubic feet per minute of air by multiplying the liquefied petroleum gas ratings by factors listed below. Air flow ratings can be converted to ratings in cubic feet per minute of liquefied petroleum gas by dividing the air ratings by the factors listed below.

Obtain the total surface area by adding the surface area of vaporizer shell in square feet directly in contact with LP-Gas and the heat exchanged surface area in square feet directly in contact with LP-Gas.

Obtain the minimum required rate of discharge in cubic feet of air per minute, at 60 °F. and 14.7 p.s.i.a. from paragraph (b)(10)(ii) of this section, for this total surface area.

Container and vaporizer safety relief valves shall be set to start-to-discharge, with relation to the design pressure of the container, in accordance with Table H-26.

Safety relief devices used with systems employing containers other than those constructed according to DOT specifications shall be so constructed as to discharge at not less than the rates shown in paragraph (b)(10)(ii) of this section, before the pressure is in excess of 120 percent of the maximum (not including the 10 percent referred to in paragraph (b)(10)(iv) of this section) permitted start to discharge pressure setting of the device.

In certain locations sufficiently sustained high temperatures prevail which require the use of a lower vapor pressure product to be stored or the use of a higher designed pressure vessel in order to prevent the safety valves opening as the result of these temperatures. As an alternative the tanks may be protected by cooling devices such as by spraying, by shading, or other effective means.

Safety relief valves shall be arranged so that the possibility of tampering will be minimized. If pressure setting or adjustment is external, the relief valves shall be provided with approved means for sealing adjustment.

Shutoff valves shall not be installed between the safety relief devices and the container, or the equipment or piping to which the safety relief device is connected except that a shutoff valve may be used where the arrangement of this valve is such that full required capacity flow through the safety relief device is always afforded.

Each container safety relief valve used with systems covered by paragraphs (d), (e), (g), and (h) of this section, except as provided in paragraph (e)(3)(iii) of this section shall be plainly and permanently marked with the following: “Container Type” of the pressure vessel on which the valve is designed to be installed; the pressure in p.s.i.g. at which the valve is set to discharge; the actual rate of discharge of the valve in cubic feet per minute of air at 60 °F. and 14.7 p.s.i.a.; and the manufacturer"s name and catalog number, for example: T200-250-4050 AIR - indicating that the valve is suitable for use on a Type 200 container, that it is set to start to discharge at 250 p.s.i.g.; and that its rate of discharge is 4,050 cubic feet per minute of air as determined in subdivision (ii) of this subparagraph.

Safety relief valve assemblies, including their connections, shall be of sufficient size so as to provide the rate of flow required for the container on which they are installed.

A hydrostatic relief valve shall be installed between each pair of shut-off valves on liquefied petroleum gas liquid piping so as to relieve into a safe atmosphere. The start-to-discharge pressure setting of such relief valves shall not be in excess of 500 p.s.i.g. The minimum setting on relief valves installed in piping connected to other than DOT containers shall not be lower than 140 percent of the container relief valve setting and in piping connected to DOT containers not lower than 400 p.s.i.g. The start-to-discharge pressure setting of such a relief valve, if installed on the discharge side of a pump, shall be greater than the maximum pressure permitted by the recirculation device in the system.

The discharge from any safety relief device shall not terminate in or beneath any building, except relief devices covered by paragraphs (b)(6)(i) (a) through (e) of this section, or paragraphs (c) (4)(i) or (5) of this section.

Container safety relief devices and regulator relief vents shall be located not less than five (5) feet in any direction from air openings into sealed combustion system appliances or mechanical ventilation air intakes.

Vaporizers shall be constructed in accordance with the requirements of paragraph (b)(3) (i)-(iii) of this section and shall be permanently marked as follows:

Vaporizers having an inside diameter of 6 inches or less exempted by the ASME Unfired Pressure Vessel Code, Section VIII of the ASME Boiler and Pressure Vessel Code - 1968 shall have a design pressure not less than 250 p.s.i.g. and need not be permanently marked.

Vaporizers may be installed in buildings, rooms, sheds, or lean-tos used exclusively for gas manufacturing or distribution, or in other structures of light, noncombustible construction or equivalent, well ventilated near the floor line and roof.

When vaporizing and/or mixing equipment is located in a structure or building not used exclusively for gas manufacturing or distribution, either attached to or within such a building, such structure or room shall be separated from the remainder of the building by a wall designed to withstand a static pressure of at least 100 pounds per square foot. This wall shall have no openings or pipe or conduit passing through it. Such structure or room shall be provided with adequate ventilation and shall have a roof or at least one exterior wall of lightweight construction.

Vaporizers shall have, at or near the discharge, a safety relief valve providing an effective rate of discharge in accordance with paragraph (b)(10)(iii) of this section, except as provided in paragraph (d)(4)(v)(a), of this section.

The heating medium lines into and leaving the vaporizer shall be provided with suitable means for preventing the flow of gas into the heat systems in the event of tube rupture in the vaporizer. Vaporizers shall be provided with suitable automatic means to prevent liquid passing through the vaporizers to the gas discharge piping.

The device that supplies the necessary heat for producing steam, hot water, or other heating medium may be installed in a building, compartment, room, or lean-to which shall be ventilated near the floorline and roof to the outside. The device location shall be separated from all compartments or rooms containing liquefied petroleum gas vaporizers, pumps, and central gas mixing devices by a wall designed to withstand a static pressure of at least 100 pounds per square foot. This wall shall have no openings or pipes or conduit passing through it. This requirement does not apply to the domestic water heaters which may supply heat for a vaporizer in a domestic system.

Gas-fired heating systems supplying heat exclusively for vaporization purposes shall be equipped with automatic safety devices to shut off the flow of gas to main burners, if the pilot light should fail.

Vaporizers of less than 1 quart capacity heated by the ground or surrounding air, need not be equipped with safety relief valves provided that adequate tests demonstrate that the assembly is safe without safety relief valves.

In accordance with the requirements of the American Society of Mechanical Engineers Boiler and Pressure Vessel Code - 1968 that are applicable to the maximum working conditions for which the vaporizer is designed.

With the name of the manufacturer; rated BTU input to the burner; the area of the heat exchange surface in square feet; the outside surface of the vaporizer in square feet; and the maximum vaporizing capacity in gallons per hour.

Vaporizers may be connected to the liquid section or the gas section of the storage container, or both; but in any case there shall be at the container a manually operated valve in each connection to permit completely shutting off when desired, of all flow of gas or liquid from container to vaporizer.

Vaporizers with capacity not exceeding 35 gallons per hour shall be located at least 5 feet from container shutoff valves. Vaporizers having capacity of more than 35 gallons but not exceeding 100 gallons per hour shall be located at least 10 feet from the container shutoff valves. Vaporizers having a capacity greater than 100 gallons per hour shall be located at least 15 feet from container shutoff valves.

Vaporizers may be installed in buildings, rooms, housings, sheds, or lean-tos used exclusively for vaporizing or mixing of liquefied petroleum gas. Vaporizing housing structures shall be of noncombustible construction, well ventilated near the floorline and the highest point of the roof. When vaporizer and/or mixing equipment is located in a structure or room attached to or within a building, such structure or room shall be separated from the remainder of the building by a wall designed to withstand a static pressure of at least 100 pounds per square foot. This wall shall have no openings or pipes or conduit passing through it. Such structure or room shall be provided with adequate ventilation, and shall have a roof or at least one exterior wall of lightweight construction.

Vaporizers shall have at or near the discharge, a safety relief valve providing an effective rate of discharge in accordance with paragraph (b)(10)(iii) of this section. The relief valve shall be so located as not to be subjected to temperatures in excess of 140 °F.

Vaporizers shall be equipped with automatic safety devices to shut off the flow of gas to main burners if the pilot light should fail. When the flow through the pilot exceeds 2,000 B.t.u. per hour, the pilot also shall be equipped with an automatic safety device to shut off the flow of gas to the pilot should the pilot flame be extinguished.

Pressure regulating and pressure reducing equipment if located within 10 feet of a direct fire vaporizer shall be separated from the open flame by a substantially airtight noncombustible partition or partitions.

Except as provided in (c) of this subdivision, the following minimum distances shall be maintained between direct fired vaporizers and the nearest important building or group of buildings:

Direct fired vaporizers shall not raise the product pressure above the design pressure of the vaporizer equipment nor shall they raise the product pressure within the storage container above the pressure shown in the second column of Table H-31.

Tank heaters shall be permanently marked with the name of the manufacturer, the rated B.t.u. input to the burner, and the maximum vaporizing capacity in gallons per hour.

Tank heaters shall be equipped with an automatic safety device to shut off the flow of gas to main burners, if the pilot light should fail. When flow through pilot exceeds 2,000 B.t.u. per hour, the pilot also shall be equipped with an automatic safety device to shut off the flow of gas to the pilot should the pilot flame be extinguished.

Pressure regulating and pressure reducing equipment if located within 10 feet of a direct fired tank heater shall be separated from the open flame by a substantially airtight noncombustible partition.

The following minimum distances shall be maintained between a storage tank heated by a direct fired tank heater and the nearest important building or group of buildings:

No direct fired tank heater shall raise the product pressure within the storage container over 75 percent of the pressure set out in the second column of Table H-31.

The vaporizer section of vaporizer-burners used for dehydrators or dryers shall be located outside of buildings; they shall be constructed and installed as follows:

The vaporizer section of vaporizer-burners shall be protected by a hydrostatic relief valve. The relief valve shall be located so as not to be subjected to temperatures in excess of 140 °F. The start-to-discharge pressure setting shall be such as to protect the components involved, but not less than 250 p.s.i.g. The discharge shall be directed upward and away from component parts of the equipment and away from operating personnel.

Vaporizer-burners shall be equipped with automatic safety devices to shut off the flow of gas to the main burner and pilot in the event the pilot is extinguished.

Pressure regulating and control equipment shall be located or protected so that the temperatures surrounding this equipment shall not exceed 140 °F. except that equipment components may be used at higher temperatures if designed to withstand such temperatures.

Pressure regulating and control equipment when located downstream of the vaporizer shall be designed to withstand the maximum discharge temperature of the vapor.

Equipment utilizing vaporizer-burners shall be equipped with automatic shutoff devices upstream and downstream of the vaporizer section connected so as to operate in the event of excessive temperature, flame failure, and, if applicable, insufficient airflow.

The “filling density” is defined as the percent ratio of the weight of the gas in a container to the weight of water the container will hold at 60 °F. All containers shall be filled according to the filling densities shown in Table H-27.

Except as provided in paragraph (b)(12)(iii) of this section, any container including mobile cargo tanks and portable tank containers regardless of size or construction, shipped under DOT jurisdiction or constructed in accordance with 49 CFR chapter I Specifications shall be charged according to 49 CFR chapter I requirements.

Portable containers not subject to DOT jurisdiction (such as, but not limited to, motor fuel containers on industrial and lift trucks, and farm tractors covered in paragraph (e) of this section, or containers recharged at the installation) may be filled either by weight, or by volume using a fixed length dip tube gaging device.

are used excusively to house equipment for vaporization, pressure reduction, gas mixing, gas manufacturing, or distribution, or to house internal combustion engines, industrial processes, research and experimental laboratories, or equipment and processes using such gas and having similar hazard;

Buildings, or separate areas of buildings, used exclusively to house equipment for vaporization, pressure reduction, gas mixing, gas manufacturing, or distribution, or to house internal combustion engines, industrial processes, research and experimental laboratories, or equipment and processes using such gas and having similar hazard; and when such buildings, or separate areas thereof are constructed in accordance with this section.

Liquid piping inside the building shall conform to the requirements of paragraph (b)(8) of this section, and shall not exceed three-fourths iron pipe size. Copper tubing with an outside diameter of three-fourths inch or less may be used provided it conforms to Type K of Specifications for Seamless Water Tube, ANSI H23.1-1970 (ASTM B88-69) (see Table H-24). All such piping shall be protected against construction hazards. Liquid piping inside buildings shall be kept to a minimum. Such piping shall be securely fastened to walls or other surfaces so as to provide adequate protection from breakage and so located as to subject the liquid line to lowest ambient temperatures.

A shutoff valve shall be installed in each intermediate branch line where it takes off the main line and shall be readily accessible. A shutoff valve shall also be placed at the appliance end of the intermediate branch line. Such shutoff valve shall be upstream of any flexible connector used with the appliance.

Suitable excess flow valves shall be installed in the container outlet line supplying liquid LP-Gas to the building. A suitable excess flow valve shall be installed immediately downstream of each shutoff valve. Suitable excess flow valves shall be installed where piping size is reduced and shall be sized for the reduced size piping.

The use of hose to carry liquid between the container and the building or at any point in the liquid line, except at the appliance connector, shall be prohibited.

Where flexible connectors are necessary for appliance installation, such connectors shall be as short as practicable and shall comply with paragraph (b)(8)(ii) or (9) of this section.

at least one attendant shall remain close to the transfer connection from the time the connections are first made until they are finally disconnected, during the transfer of the product.

Containers manufactured in accordance with specifications of 49 CFR part 178 and authorized by 49 CFR chapter 1 as a "single trip" or "nonrefillable container" shall not be refilled or reused in LP-Gas service.

Gas or liquid shall not be vented to the atmosphere to assist in transferring contents of one container to another, except as provided in paragraph (e)(5)(iv) of this section and except that this shall not preclude the use of listed pump utilizing LP-Gas in the vapor phase as a source of energy and venting such gas to the atmosphere at a rate not to exceed that from a No. 31 drill size opening and provided that such venting and liquid transfer shall be located not less than 50 feet from the nearest important building.

Filling of fuel containers for industrial trucks or motor vehicles from industrial bulk storage containers shall be performed not less than 10 feet from the nearest important masonry-walled building or not less than 25 feet from the nearest important building or other construction and, in any event, not less than 25 feet from any building opening.

Filling of portable containers, containers mounted on skids, fuel containers on farm tractors, or similar applications, from storage containers used in domestic or commercial service, shall be performed not less than 50 feet from the nearest important building.

The filling connection and the vent from the liquid level gages in containers, filled at point of installation, shall not be less than 10 feet in any direction from air openings into sealed combustion system appliances or mechanical ventilation air intakes.

The maximum vapor pressure of the product at 100 °F. which may be transferred into a container shall be in accordance with paragraphs (d)(2) and (e)(3) of this section. (For DOT containers use DOT requirements.)

Marketers and users shall exercise precaution to assure that only those gases for which the system is designed, examined, and listed, are employed in its operation, particularly with regard to pressures.

Pumps or compressors shall be designed for use with LP-Gas. When compressors are used they shall normally take suction from the vapor space of the container being filled and discharge to the vapor space of the container being emptied.

Pumping systems, when equipped with a positive displacement pump, shall include a recirculating device which shall limit the differential pressure on the pump under normal operating conditions to the maximum differential pressure rating of the pump. The discharge of the pumping system shall be protected so that pressure does not exceed 350 p.s.i.g. If a recirculation system discharges into the supply tank and contains a manual shutoff valve, an adequate secondary safety recirculation system shall be incorporated which shall have no means of rendering it inoperative. Manual shutoff valves in recirculation systems shall be kept open except during an emergency or when repairs are being made to the system.

Agricultural air moving equipment, including crop dryers, shall be shut down when supply containers are being filled unless the air intakes and sources of ignition on the equipment are located 50 feet or more from the container.

Agricultural equipment employing open flames or equipment with integral containers, such as flame cultivators, weed burners, and, in addition, tractors, shall be shut down during refueling.

A backflow check valve, excess-flow valve, or a shutoff valve with means of remote closing, to protect against uncontrolled discharge of LP-Gas from storage tank piping shall be installed close to the point where the liquid piping and hose or swing joint pipe is connected.

Electrical equipment and wiring shall be of a type specified by and shall be installed in accordance with subpart S of this part, for ordinary locations except that fixed electrical equipment in classified areas shall comply with subparagraph (18) of this paragraph.

Open flames or other sources of ignition shall not be permitted in vaporizer rooms (except those housing direct-fired vaporizers), pumphouses, container charging rooms or other similar locations. Direct-fired vaporizers shall not be permitted in pumphouses or container charging rooms.

Since liquefied petroleum gas is contained in a closed system of piping and equipment, the system need not be electrically conductive or electrically bonded for protection against static electricity.

Open flames (except as provided for in paragraph (b)(11) of this section), cutting or welding, portable electric tools, and extension lights capable of igniting LP-Gas, shall not be permitted within classified areas specified in Table H-28 unless the LP-Gas facilities have been freed of all liquid and vapor, or special precautions observed under carefully controlled conditions.

Fixed electrical equipment in classified areas.Fixed electrical equipment and wiring installed within classified areas specified in Table H-28 shall comply with Table H-28 and shall be installed in accordance with subpart S of this part. This provision does not apply to fixed electrical equipment at residential or commercial installations of LP-Gas systems or to systems covered by paragraph (e) or (g) of this section.

Each container manufactured after December 31, 1965, and filled on a volumetric basis shall be equipped with a fixed liquid-level gage to indicate the maximum permitted filling level as provided in paragraph (b)(19)(v) of this section. Each container manufactured after December 31, 1969, shall have permanently attached to the container adjacent to the fixed level gage a marking showing the percentage full that will be shown by that gage. When a variable liquid-level gage is also provided, the fixed liquid-level gage will also serve as a means for checking the variable gage. These gages shall be used in charging containers as required in paragraph (b)(12) of this section.

All variable gaging devices shall be arranged so that the maximum liquid level for butane, for a 50-50 mixture of butane and propane, and for propane, to which the container may be charged is readily determinable. The markings indicating the various liquid levels from empty to full shall be on the system nameplate or gaging device or part may be on the system nameplate and part on the gaging device. Dials of magnetic or rotary gages shall show whether they are for cylindrical or spherical containers and whether for aboveground or underground service. The dials of gages intended for use only on aboveground containers of over 1,200 gallons water capacity shall be so marked.

Gaging devices that require bleeding of the product to the atmosphere, such as the rotary tube, fixed tube, and slip tube, shall be designed so that the bleed valve maximum opening is not larger than a No. 54 drill size, unless provided with excess flow valve.

Length of tube or position of fixed liquid-level gage shall be designed to indicate the maximum level to which the container may be filled for the product contained. This level shall be based on the volume of the product at 40 °F. at its maximum permitted filling density for aboveground containers and at 50 °F. for underground containers. The employer shall calculate the filling point for which the fixed liquid level gage shall be designed according to the method in this subdivision.

It is impossible to set out in a table the length of a fixed dip tube for various capacity tanks because of the varying tank diameters and lengths and because the tank may be installed either in a vertical or horizontal position. Knowing the maximum permitted filling volume in gallons, however, the length of the fixed tube can be determined by the use of a strapping table obtained from the container manufacturer. The length of the fixed tube should be such that when its lower end touches the surface of the liquid in the container, the contents of the container will be the maximum permitted volume as determined by the following formula:

The maximum volume of LP-Gas which can be placed in a container when determining the length of the dip tube expressed as a percentage of total water content of the container is calculated by the following formula.

The maximum weight of LP-Gas which may be placed in a container for determining the length of a fixed dip tube is determined by multiplying the maximum volume of liquefied petroleum gas obtained by the formula in paragraph (b)(19)(b) of this section by the pounds of liquefied petroleum gas in a gallon at 40 °F. for abovegound and at 50 °F. for underground containers. For example, typical pounds per gallon are specified below:

[(100 (gals.) × 42 (filling density from subparagraph (12) of this paragraph)) ÷ (0.510 × 1.031 (correction factor from Table H-29) × 100)] = (4200 ÷ 52.6)

(4200 ÷ 52.6) = 79.8 gallons propane, the maximum amount permitted to be placed in a 100-gallon total water capacity aboveground container equipped with a fixed dip tube.

[(Maximum volume of LP-Gas (from formula in subdivision (b) of this subdivision) × 100) ÷ Total water content of container in gallons] = Maximum percent of LP-Gas

Fixed liquid-level gages used on containers other than DOT containers shall be stamped on the exterior of the gage with the letters "DT" followed by the vertical distance (expressed in inches and carried out to one decimal place) from the top of container to the end of the dip tube or to the centerline of the gage when it is located at the maximum permitted filling level. For portable containers that may be filled in the horizontal and/or vertical position the letters "DT" shall be followed by "V" with the vertical distance from the top of the container to the end of the dip tube for vertical filling and with "H" followed by the proper distance for horizontal filling. For DOT containers the stamping shall be placed both on the exterior of the gage and on the container. On above-ground or cargo containers where the gages are positioned at specific levels, the marking may be specified in percent of total tank contents and the marking shall be stamped on the container.

Gage glasses of the columnar type shall be restricted to charging plants where the fuel is withdrawn in the liquid phase only. They shall be equipped with valves having metallic handwheels, with excess flow valves, and with extra-heavy glass adequately protected with a metal housing applied by the gage manufacturer. They shall be shielded against the direct rays of the sun. Gage glasses of the columnar type are prohibited on tank trucks, and on motor fuel tanks, and on containers used in domestic, commercial, and industrial installations.

Gaging devices of the float, or equivalent type which do not require flow for their operation and having connections extending to a point outside the container do not have to be equipped with excess flow valves provided the piping and fittings are adequately designed to withstand the container pressure and are properly protected against physical damage and breakage.

Any appliance that was originally manufactured for operation with a gaseous fuel other than LP-Gas and is in good condition may be used with LP-Gas only after it is properly converted, adapted, and tested for performance with LP-Gas before the appliance is placed in use.

Unattended heaters used inside buildings for the purpose of animal or poultry production or care shall be equipped with an approved automatic device designed to shut off the flow of gas to the main burners, and pilot if used, in the event of flame extinguishment.

All commercial, industrial, and agricultural appliances or equipment shall be installed in accordance with the requirements of this section and in accordance with the following NFPA consensus standards, which are incorporated by reference as specified in § 1910.6:

Industrial appliances - NFPA 54A-1969, Standard for the Installation of Gas Piping and Gas Equipment on Industrial Premises and Certain Other Premises.

Application. This paragraph applies specifically to systems utilizi

8613371530291

8613371530291