drill string safety valve in stock

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale drill pipe safety valve on Alibaba.com. When you search for drill pipe safety valve and related items, you will be able to find many types of drill pipe safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of drill pipe safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

The revolutionary new Sentinel Drilling Safety Float Valve is the first major improvement for drilling float equipment in decades. It was designed to replace outdated equipment that cannot consistently seal after prolonged use. Using Drilling Innovative Solutions’ field-proven flapper actuated ball valve technology, The Sentinel is able to withstand the most extreme downhole drilling conditions and ensure proper sealing time after time.

All Drilling Safety Float Valves are manufactured to the highest API and ISO 9000 standards ensuring the highest quality tools. The Sentinel is available in a broad range of valve sizes, to accommodate most drilling operations.

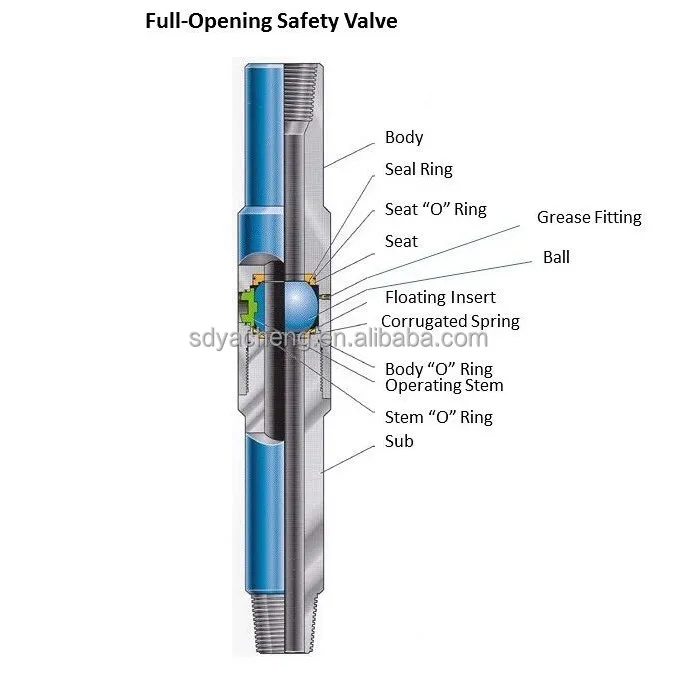

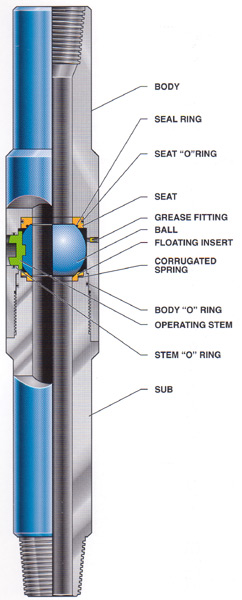

Kelly Valve/Drill Pipe Safety Valve is a full opening valve that provides positive pressure control of the fluids in the drill string. These valves can be used as a drill pipe safety valve or upper kelly valve to control blowout pressures, or as a lower kelly valve to prevent loss of drilling fluid when the kelly is disconnected.

The valve seals in both directions with metal to metal seals. Available in 10,000 psi working pressure as standard, 15,000 psi working pressure is available in certain sizes upon request. The valve uses a hexagon socket on the operating stem and has positive stops in the open and closed positions.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

M&M International is an original equipment manufacturer (OEM) of drill string and well control valves along with inside blowout preventers (IBOPs), crossover subs, swivels and other oilfield equipment.

M&M designs and manufactures the most efficient and user friendly drill string and well control valves on the market today. M&M incorporated their patented Canister Guard™ and Lite-Torc™ technology into the design making M&M Products the most reliable valve in the business.

Lite-Torc™ – improves the ability of valve so fitted to be closed under heavy flow at torque values manageable by one person with a standard 12” valve wrench. As well, once closed, well bore pressure can slowly be balanced by pump pressure to allow the valve to reopen with less than 30 ft lbs of torque.

M&M Internationals has been API licensed since 1992 and quality management system is well established and continually monitored for potential improvements. M&M is licensed under API Q1, and API Spec 7-1 and 7-2 for the monogramming of Upper and Lower Kelly Valves.

An essentially full-opening valve located on the rig floor with threads to match the drill pipe connections or other tubulars in use. NOTE: This valve is used to close off the drill pipe to prevent flow and may be crossed over to fit other connections and sizes of tubulars being installed in the well.

An essentially full-opening valve located on the rig floor with threads to match the drill pipe in use. This valve is used to close off the drill pipe to prevent flow.

An essentially full-opening valve located on the rig floor with threads to match the drill pipe in use. This valve is used to close off the drill pipe to prevent flow.

M&M International is an original equipment manufacturer (OEM) of drill string and well control valves along with inside blowout preventers (IBOPs), crossover subs, swivels and other oilfield equipment.

M&M designs and manufactures the most efficient and user friendly drill string and well control valves on the market today. M&M incorporated their patented Canister Guard™ and Lite-Torc™ technology into the design making M&M Products the most reliable valve in the business.

Lite-Torc™ – improves the ability of valve so fitted to be closed under heavy flow at torque values manageable by one person with a standard 12” valve wrench. As well, once closed, well bore pressure can slowly be balanced by pump pressure to allow the valve to reopen with less than 30 ft lbs of torque.

M&M Internationals has been API licensed since 1992 and quality management system is well established and continually monitored for potential improvements. M&M is licensed under API Q1, and API Spec 7-1 and 7-2 for the monogramming of Upper and Lower Kelly Valves.

The M&M International CANISTER GUARD® encapsulates its internal spring loading within the canister itself, which is a significant feature that cannot be overstated. During disassembly of one-piece valves made by other manufacturers, the internal spring must be compressed prior to removal of the locking mechanism. Considering the application, it is typical for mud, cement, debris, and/or corrosion to accumulate in this area. This makes it difficult or even impossible to compress the spring enough to remove the locking mechanism from valves of this kind, even when using the special tools required by the competitor manufacturer. These and other issues can make field dressing impractical and shop dressing a much longer and more expensive process than necessary. M&M International’s CANISTER GUARD® technology completely eliminates these issues, saving both time and money.

M&M International’s CANISTER GUARD® reduces the need for customer locations to keep large spare valve parts inventories on hand. In most cases, CANISTER GUARD® valves utilize identical parts within each size range. This low inventory ability allows a customer to operate with one spare canister and one or two spare operating stems in inventory, if necessary.

Drillstring valves and IBOPS are one of the most critical well control equipment on the rig. This VDO training will teach you about drillstring valves and iBOPs. After watching this, you will fully understand several of the valves and their applications. Additionally, we also have full VDO transcript to help anyone who are unable to fully understand the English speaking in the VDO. We wish you would enjoy watching it.

Drill string valves stop fluid from flowing up the drill string often if the drill kicks with the bit off bottom. Formation fluids flow from the annulus and up the drill string. Crewmembers close of the drill string valves. The flow is in the string, If the Kelly is made up the can close the upper or lower Kelly cock. If the Kelly is not made up then they can install the full opening safety valve in the top of the drill string.

An inside blowout preventer or IBOP is a one-way valve, a check valve that they can install in the drill string. One type of IBOP is a float valve that is sometimes made up in the drill string near the bit. It prevents backflow up the drill string.

Another type of IBOP is the drop in valve or D.I.V. It is dropped into the drill string and falls to a special landing sub that is usually located near to the top drill collar in the drill string. It allows the driller to pump mud down the string but the check valve will not allow influx fluid to flow up the string.

Another type of inside BOP is the heavy-duty check valve or a gray type valve named after the company that makes it. It is a plunger check that crew stab into the drill pipe at the surface. It is usually used during stripping operations.

Here is a full opening safety valve. If the Kelly is not made up in the drill string and flow occurs, crewmembers can insert this safety valve into the drill string. This procedure is called stabbing.

A full opening valves has as large an inside opening as possible. When fully open flow from the drill pipe passes through the valve with no additional restriction. This relatively large opening allows the crew to stab the valve against pressure coming out of the drill string. The cruel picks up this safety valve by its lifting handles. They make sure it is fully opened and stab it into the drill pipe then they screw it into the pipe. Finally, the you was a special operating wrench to close the valve and shut off flow. Driller’s should make sure that valves have the right to cross over subs handy on the rig floor. Crewmembers should be able to make up the safety valve in any drill string member coming out of the Rotary. For example if a drill collar is in the Rotary, these safety valves threads may not match the drill collars threads. They will need the right cross over sub to make it work.

Float valves also prevent flow of the drill string. Crewmembers place a float valve in a string, a special drill string fitting just above the bit. One type allows mud to be pumped down but shuts against upward flow. Under normal conditions pump pressure moves drilling mud through the open one-way valve. An influx of formation fluids from below causes of the float valve to close. This prevents further flow of the drill string.

Packard safety valves are designed to either stab into the drill pipe or tubing at the rig floor or are used as part of the drill string to shut off a well kick. Use of these valves in the drill string enhances rig safety.

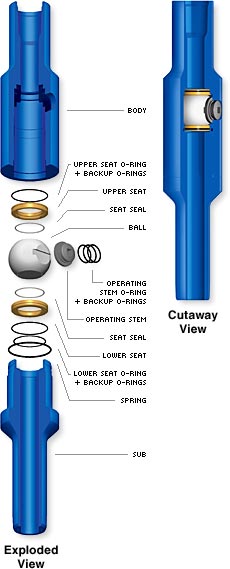

The Packard two-piece safety valve offers the convenience of a two-piece body for easy maintenance. Its full bore also allows the unrestricted flow of drilling fluid � reducing wear on critical parts while providing unrestricted access for downhole tools.

Packard International�s safety valves are built with enough length on each end to allow fully recutting the connections in the event of damage to the threads or shoulders where sealing takes place.

High and low pressure sealing is assured by the Teflon and metal sealing system of the ball and seats. The ball and lower seat float while the upper seat is fixed in the body. This floating/fixed design aids in low pressure sealing and enables the operator to pressure balance the valve under full rated working pressure.

Packard International�s safetyvalves are designed for even the harshest drilling conditions; however, it is suggested that parts most subject to wear and tear be replaced regularly.

For complete maintenance instructions and valve specifications, please phone 281-399-8771, e-mail support@packardint.com, or click the link below to download a PDF.

In 2006, Forum purchased the Baker SPD product line. Forum continues to manufacture the products formerly known as Baker SPD under the SPD name and offers a complete line of float valves, repair kits, and puller assemblies for a wide range of drilling situations and operating conditions. We are the premier provider of “Certified” drill pipe float valves that includes high- and low-pressure testing, serialization, and full material traceability, providing improved reliability and failure prevention.

High-performance drill pipe float valves are essential for consistent fluid control throughout drilling. Also known as non-return valves, this type of downhole safety valve prevents undesirable fluids from backing up into the drill string any time your crew is modifying connections.

Maintaining safe operating conditions can be challenging in deep-set or deepwater, high-pressure/high-temperature (HP/HT) wells. The REACH™ subsurface safety valve from Baker Hughes provides an answer, with fail-safe operation in a wide range of deep-set completions that require low operating pressures due to control system limitations.

REACH safety valves are designed to provide reliable sealing in deep, HP/HT wells. They can be set up to 20,000 ft (6,096 m) below sea level and withstand temperatures up to 400°F (205°C) and pressures up to 20,000 psi (1,379 bar).

REACH safety valves are V1 validated and have undergone the stringent prototype testing per API SPEC 14A, Specification for Subsurface Safety Valve Equipment, Twelfth Edition. Our safety valve specialists have continuously modified the design to accommodate the new V1 validation specifications while progressively exceeding the requirements set forth by API.

REACH valves rely on field-proven, heavy-sprung closure technology to ensure fail-safe-closed operation. Because tubing pressure is isolated from the control system, the valve can open at much lower operating pressures, reducing the cost of umbilicals in some applications.

The valve’s unique activation system requires lower valve operating pressures than previous safety valve designs by eliminating the need to overcome tubing pressure, making the valve ideal for applications with opening pressure limitations including: subsea completions, high-pressure wells, and fields where the rig site and other control facilities may have supply pressure limitations.

REACH valves incorporate several proven features from other safety valve designs, including flapper closure technology, RBT housing thread technology, dynamic seal technology, and debris exclusion geometries—all of which help deliver integrated functionality and dependability.

To ensure long term reliability, the valve is also offered with a reinforced dynamic seal configuration, upgraded dynamic seal materials, internal alignment enhancements, and an enhanced scraper ring to minimize debris. Because the REACH valve does not utilize gas springs, the operating seals and gland do not experience pressure reversals, making them ideal for your critical deepwater HP/HT applications

As a rental company we inspect, clean and test the valves every time they are returned to us from a rig. Before the next job, we need to make sure that the valve is in optimal condition. Just a few words about the valve before we start ...

The valve is placed in the top of drill string, right below the top drive. When abnormal situations occur and the pressure limit is exceeded, the driller can close the valve to stabilize the pressure and avert a potential kick.

The device is named after the kelly drive, which was turning the drill string. As a side note, the "Dictionary of Petroleum Exploration, Drilling and Production" states that the kelly was named after Michael J. Kelly, a Chicago baseball player from the 1880s. He was known for his base running and long slides.

They even made a song about the baseball player called "Slide Kelly, Slide!". As you probably know, "sliding" is what you do when you pass the kelly through the kelly bushing when you drill.

When we receive the valve in the yard we first high pressure clean it. Then we start disassembling it, while inspecting and cleaning each part by hand. We typically look for things like:

All the internal parts are visually inspected and measured. We also replace all seals with a complete new seal-kit before re-assembling. If, for instance, the valve is going to be used in a Sour Gas Well, we insert gaskets that are resistant to H2S (Hydrogen Sulphide).

After that, we perform functional test and leak tests (a kind of pressure test) according to its class. The class is specified in the data book that comes with the valve:

These valves are only tested upstream. That means you test it in the closed position from below (the pin-end) to verify that it holds pressure. The valve is tested at a low pressure (250 PSI) and at the maximum working pressure.

Class 2 valves are tested with the same procedures as class 1 valves, but both upstream and downstream. First by testing low pressure and working pressure upstream, and then testing downstream in the same manner.

*In some HPHT (High Pressure, High Temperature) wells valves are also placed in the part of the string that is down hole. The challenge here is that you can"t access the valve while down hole. This is usually solved by placing a valve in each stand, so the driller can operate the valve while tripping out.

After the leak test, the valve is dried with air and preserved (with light oil) to avoid corrosion while lying on stock in the yard or on the rig. That"s it! Now you know how a kelly-valve is maintained and serviced.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

8613371530291

8613371530291