floor jack safety valve adjustment in stock

An overload valve of a floor jack primarily exists so that the jack does not exceed the weight limit of the hydraulic press, which might cause it to break down. Overload valves stop the press from lifting further up if the weight limit is crossed.

The floor jack overload valve adjustment process is very straightforward and only requires you to follow a set of simple steps. However, if you’re trying to adjust the overload valve, chances are that your floor jack is having some trouble holding pressure. In that case, we have some solutions for that as well.

An overload valve is a safety measure to protect the hydraulic press from unwanted damage due to excessive pressure. It works by loosening the connection between the jack handle and the hydraulic press.

When we’re talking about adjusting the overload valve, we’re mainly changing the max weight capacity of the floor jack. To do that, you just need the right screwdriver. It varies from model to model, some use Philips heads while others use binding heads.

Once you’ve got the right screwdriver, find the location of the safety valve. There will be a shield on top of it that you’ll have to remove with the screwdriver. Spot the screws and turn them counterclockwise to release the shield.

After you’ve done that, the valve should be exposed to you. There are mainly two types of valves used on floor jacks. The handle valve and the screw valve. Handle valves have a handle, while screw valves have a hole for the screw to go through.

For a handle valve, you just have to hold on to the handle and rotate it to adjust the weight overload on the floor jack. Rotate it clockwise to increase the maximum weight capacity and counterclockwise to decrease it.

These valves are typically very sensitive so a small turn could drastically change the output. So, try it in small amounts and figure out the correct amount for you.

For a screw valve, you will need a corresponding screwdriver. Typically it is the same as the shield’s screws, but according to your model, it could be different.

Safety Note: Before attempting to put pressure after adjustments, check the instruction manual of the floor jack for the maximum supported weight capacity. Normally, the valve will be set to 90% of that max capacity. So, you can at best increase it to 100%. Going beyond that will be very risky as it can damage both the floor jack and your vehicle.

This is a very common issue for which people consider adjusting the overload valve. A loose valve can indeed cause your floor jack to suffer such problems. However, that’s not the only cause.

The hydraulic press will fail to operate if the oil levels are above or below the given margins. Also, if the oil is of low quality, it might cause friction which can also prevent it from working properly. To maintain the proper hydraulic level, you should fill your jack with oil correctly and safely.

To know exactly what types of fluid are used in a floor jack, check out this article where we have explained and recommended the hydraulic fluid to use in your jack.

Hydraulics work by using highly pressurized compressed air. After long-term use, some of that air can leak into other parts of the machine causing havoc. The air mostly gets trapped in the oil chamber. To remove air from the floor jack, you just need to bleed it.

The final most obvious consideration would be that the floor jack is damaged. In most cases, it’s the hydraulic press. Repairing a broken floor jack is not worth the effort and the money. You’re better off getting a new floor jack.

Keep in mind that the overload valve is a safety measurement. So, a floor jack overload valve adjustment should only be done under your own circumstances. To be on the safe side, never exceed the given weight limit of your floor jack.

Sorry sir but not this one, please check out the Omega 26030 3 ton aluminum jack owners manual. This is exactly the same as mine. I know my pic is lousy, The only slight difference is mine has a screw instead of a clip per pic. And that"s the only difference, the rest is exactly the same including, YES 2 balls on the overload.

I should of mentioned the one I found first. Then just pure luck would have it I remember reading you recommending Hein Werner and Omega would be good jacks to purchase. So I was looking at the Omega aluminum jacks because I must have Speedy or Magic lift along with a light unit. And the plugger release knob for the handle is a must. I could not believe it when I saw the parts break down that showed 2 balls on the overload, and the same exact diagram that my Craftsman 50239 uses. I saw this all the time as a ASE mechanic, mid production changes that drove us bonkers. Now retired I dabble. But mark my words, 2 balls on this unit. Proof is how every lifting test passes.

A hydraulic jack serves one fundamental goal: the lifting of heavy loads. Jacks are designed to provide force multiplication to enable a worker to amplify their strength through the jack"s hydraulics or mechanics to accomplish this goal.

There are two main types of jacks commonly in use; one type uses hydraulic pressure for lifting (hydraulic jacks), while the other uses a screw thread to achieve lift (mechanical jacks). Of the two, hydraulic jacks usually provide higher lift capacity and are more reliable.

Hydraulic jacks are available in two varieties: floor jacks and bottle jacks. Floor jacks have a horizontal shaft that pushes on a crank. The crank connects to a lifting pad that rises vertically. These jacks are capable of lifting several tons.

Bottle jacks have been around longer, and their name derives from their resemblance to an old-fashioned milk bottle. Bottle jacks have a vertical shaft that raises a platform called a bearing pad. They can lift up to several hundred tons, depending on the specific capabilities of the model being used. However, these jacks typically cannot lift the load to the same height as with a floor jack.

Both types of jacks operate under the same basic principle: In a closed container, the pressure is the same in all directions. In the case of a hydraulic jack, this container is a cylinder, and it holds incompressible hydraulic fluid. Hydraulic fluid is forced into the cylinder through a check valve that prevents the fluid"s backflow. The check valve keeps the cylinder pressurized so the load does not drop. As pressure builds in the cylinder, the force pushes upward on the plate of the jack and lifts the load resting on it. The weight of the load lowers the plate when the check valve is released, allowing the hydraulic fluid a path to exit.

There are some issues that are common to all types of hydraulic jacks which can impact their operation and safety. At some point, users will likely encounter leaks, rams that won’t lift, safety valves that get tripped, damage to the frames, and jack handles that kick back. While many hydraulic jack repairs are easy to accomplish, others might require the assistance of a professional.

Leaks, in particular, are extremely common, and result from a failed or dislodged seal or O-ring. Repair involves draining the hydraulic fluid, disassembling the jack, and inspecting the seals. Be sure to look carefully for cuts, tears, seals that are out of place, degradation, scratches, and so on. These issues are an indication that the seals or O-rings need to be replaced.

Repairing leaking seals can be a significant undertaking, especially for those not experienced in jack repair. Novices might want to leave this type of issue to a professional with the requisite experience. Also, if the leaked fluid is cloudy or foamy, that indicates the presence of water or air in the hydraulic system and could mean that the hydraulic fluid needs to be replaced and the potential source of the intrusion investigated.

Jacks may also be overloaded, causing the safety valve to trip. The purpose of this safety feature is to prevent the jack from being loaded beyond its rated operating pressure, typically measured in pounds- force per square inch (psi). A jack will not behave the same way after the safety valve has been tripped. The ideal way to address this issue will vary by manufacturer, so always consult the service manual when this occurs. Professional service is recommended in these instances to restore safe operation of the jack.

In other cases, rams may stop lifting, which is usually the result of insufficient hydraulic fluid in the reservoir. Luckily, this is a repair that even beginners can handle. When there isn’t enough hydraulic fluid present, air may become trapped inside of the system. The solution here is to add the appropriate amount of hydraulic fluid, then turn the jack to its release position. Next, pump a few times to purge out the trapped air. Then, refill the reservoir and place the seal cap back on. Be careful to avoid introducing contamination (such as dirt and dust) to the hydraulic system while adding fluid, and never mix two different types of fluid.

Hydraulic jacks are powerful devices for lifting, but like any other mechanical or hydraulic system, they will inevitably require maintenance and occasional repairs. While someone with fundamental mechanical skills may accomplish some repairs, others are best handled by a hydraulic professional. Be sure to consider the options carefully before deciding on a course of action.

If you want to work under a garden tractor or any other automobile, you need to raise it. This applies if you want to change the tires as well. For this, you can use a hydraulic floor jack. Many people seem to dread this floor jack because they do not know how to use it properly or to adjust it to the desired height. This floor jack operates through a simple mechanism. The jack has a cylinder into which fluids are pumped in small additions. This has the resultant effect of raising the actuator arm. The cylinder then continues to provide the lifting effort because it is hard to compress fluids. This lifting is sustained as long as the fluid keeps being pumped or until the arm extends completely. However, you can still lift beyond the extent of the actuator arm if you adjust a threaded saddle.

On the side opposite the wheels you are raising, place the wheel chocks on either side. Ensure that the vehicle is in first gear if it has a standard transmission or in “Park” if it has automatic transmission. Do not forget to set the emergency hand brake and to remove the key from the ignition. Now, put the floor jack under the vehicle you are planning to lift. The saddle should be aligned with this firm part of the car. Ensure that you pick the most stable part of the car’s body. Before you start operating the floor jack, you should ensure that the fluid bleed screw is closed. This screw is found at the base of the hydraulic jack cylinder. After this, turn the saddle in an anticlockwise manner until you get the height that you are looking for. Different jack manufacturers have different height limits for their saddles. After this is done, pump the handle up and down to raise the floor jack and the saddle, by extension.

Now, to adjust the extension of the hydraulic floor jack, you need to pump fluid into the cylinder so that you can raise the car up to the height that you are looking for. Now, tighten the bleed screw further if you plan on raising your vehicle or garden tractor. The bled screw usually has a horizontal pin. This pin fits perfectly into the base of the pump. To lower the load, you need to turn the bleed screw anticlockwise.

To lower the jack, you will need to turn the floor jack handle anticlockwise at a half turn. You will then notice that the jack collapses a little. This should be enough to allow you to remove the jack from under the vehicle. You then have to step on the floor jack to lower it further and all the way back to its original positions.

In those simple steps, you have now learnt how to adjust a floor jack. This is one of the simplest devices to use and people need to stop thinking that it is a difficult process. You can then teach others how to use the floor jack and become a local hero. There are more info about the best floor jacks.

It’s frustrating when you need to lift something with your trusty floor jack, but discover that your previously reliable jack will only lift part-way, or not at all. Othertimes, the jack might be stuck in a lifted position and won’t lower.

For those encountering a stuck jack for the first time, having your jack stuck in the up or down position can elicit the kind of choice language that generally upsets our mothers, and ruins your plans to work on your car or truck.

The good news is that it’s usually* a fast and easy fix, and our friends at Sunex have made a short and accessible video for floor-jack maintenance which should help you solve your trapped-air problem as well as show you how to lubriate your floor jack properly to keep it in tip-top shape for the next time you need it.

The most-common reason a floorjack would be stuck in the up or down position would be because of air trapped within the hydraulic pump, preventing the jack from having full range or lifting/lowering capabilities.

The symptoms of a failing jack are that when you pump the handle up, the jack raises, but it doesn’t stay up, or it cannot hold weight. Here are some ways to diagnose and repair a jack that leaks down or won’t lift. In most cases, the jack will need hydraulic fluid added. It may also need some seals replaced. In this article, we will show you how to do both.

When I was a kid, we had a wide assortment of bottle jacks and cheap Harbor Freight floor jacks. They never worked for more than a couple of years, so dad would buy another one. One day, he had an old-timer show him how to add hydraulic fluid. We spent an afternoon topping off our jacks and instantly had a large, working collection of jacks.

In all cases, a failing floor jack is a result of a lack of hydraulic pressure. This could be from low levels of hydraulic fluid or an internal or external seal leak. This guide will help you find and fix common leakage points.

Hydraulic floor jacks offer a lifting capacity from 2 tons up to 15 tons. The larger the jack, the more you can lift. You can lift a tiny hybrid car with a larger floor jack, but you should not try to lift a large truck with a tiny, undersized jack.

Check the weight limit on each jack and compare that with the weight of the vehicle being lifted. A Ford F150 weighs about 2 tons. It is rare that you would need to lift the entire car, so any jack with a lifting capacity of 1 ton or greater should be able to lift that truck.

If a jack has been overloaded, the jack may no longer be safe to use. Sometimes the seal will be permanently damaged by overload and will need to be replaced.

The fluid level should be within the manufacturer’s guidelines. All floor jacks are designed with the fill hole on the side of the jack — not at the very top. This prevents overfilling of the jack. Because of this design, it is more likely that jack will deal with a low fluid level problem than with an overfilling problem.

The low fluid level may prevent a jack from fully raising. It may also cause the jack not to lift, as the fluid is unable to build sufficient pressure.

Because a hydraulic jack works as a closed loop system, the only way for a jack to have low fluid is if there is a leak. It is common for jacks to lose fluid past their seals with use and age. This fluid loss will increase as the jack ages until it reaches the point that it needs all of the seals replaced in a full rebuild.

Checking the oil level in a jack should be simple: remove the oil fill screw and add oil until it reaches the bottom edge of the fill plug. Replacing low hydraulic fluid will fix most hydraulic jack problems.

However, on most floor jacks, this fill plug is underneath the arm of the jack. This means that the jack needs to be raised, and then a long, skinny funnel is used to reach the fill port. In a lot of cases, the jack needs to be disassembled, and the inner pump needs to be removed so you can access the fill plug.

When working with your jack, it is helpful to have an owner’s manual. In most cases, you can search for one by searching your jack model and the phrase “pdf” in Google. This will give you vital information on the manufacturer’s specifications for fluid type and viscosity.

Hydraulic jacks need ISO 22 oil. It can easily be purchased over the counter at Autozone, your local farm supply store, or online on Amazon. In most cases, you will only need a couple of ounces, but you will most likely be sold a large bottle of it.

Keep in mind that air compressors use an ISO 100 hydraulic fluid, which is not suitable for floor jacks. Some YouTubers have talked about using transmission fluid. If you are going through the hassle of filling your jack, it makes sense to invest the extra 15 minutes in ordering the right jack.

Too much trapped air in the hydraulic line will prevent the hydraulic fluid from building pressure and will cause the jack to leak down and lose its lifting ability.

If you add fluid, but the jack is still not jacking up or holding pressure –especially if it drops a little when pressure is applied and then stops — it might have trapped air that needs to be bled out.

Bleeding air out of a jack is simple; add fluid and then raise and lower it a few times, adding fluid after every time until you have added enough fluid to work the air bubbles out of the jack.

More commonly, however, is the situation where the relief seal (the one you turn to lower the jack) is not seating well and is allowing hydraulic fluid to slip by. This is especially common in slow overnight leaks, where the jack slowly lowers itself overnight.

Many floor jacks have an overload valve that prevents them from lifting a load that is too heavy for their rating. This bypass valve or safety valve allows the jack to release the additional pressure and prevent injury.

There is a screw head near the back of the jack where the handle inserts. Normally there is a warning sign to not mess with this screw head and a plastic cap covering it. This screw head controls a ball bearing and a spring that regulates the max lifting capacity of the jack.

Before removing this overload screw, tighten it all the way and count the number of turns it takes to tighten the screw head. This will let you know how many turns it will take to recalibrate this overload valve when you remove it.

To inspect the jack’s release valve, you simply unscrew the release valve all the way. As it threads out, there will be a small ball bearing down in the bottom. Additionally, when you flip it over to get the ball bearing out, all of the hydraulic oil will drain out, and you will need a catch can to capture this oil.

When you repair or rebuild your floor jack, you are accepting the risks of repairing a jack. Most people use their jack to lift heavy cars, and a jack should always be paired with jack stands to protect the user when they are under a vehicle.

If your jack is still not holding pressure, you might decide to give it a full rebuild. In our throw-away society, it is rare to repair an item instead of just buying a new jack. However, my blog tends to attract people like myself who like to fix things for the joy of fixing them.

Physically pull or pump the floor jack up, and prop it in the raised position with a block of wood to allow you room to work underneath it. There is a spring attached to the hydraulic pump that helps bring it back down when releasing pressure. Start by taking a pair of pliers and disconnecting that spring.

There are two bolts, one on each side of the handle at its base. Start by removing this handle and setting it to the side so that you can more easily maneuver the jack as you work on it. We do this in the second step since your jack may have enough pressure to allow you to raise it by pumping the handle.

Once you have lowered the jack arm again and laid it on its side, you are able to access the full pump and begin removing the wheel bolts. The Wheel bolts go through the frame, the wheel casters, and then hold the jack pump into place. Depending on the model, there may still be two smaller bolts on the inside that need to be loosened. Generally, the jack portion will be attached to the pivot points with cotter pins or c clips.

It is handy to have a vise to hold the jack in for this as you disassemble it. The large nut at the “top” of the jack needs to be removed and will require a large crescent wrench.

Once the seals are accessible, it is only a matter of replacing each seal carefully. The entire process is straightforward. Once Reassembled, the jack needs to be refilled with hydraulic oil and tested.

Even when fully repaired, a jack should never be used for long periods of time and should always be used alongside a jack stand. Jack stands are an essential safety item that protects the user in the event of jack failure. A jack is a lifting device only and should not be used to hold heavy weight.

Starting out a wrenching session by discovering your floor jack won’t lift can be a frustrating situation. Maybe it worked fine last time, or maybe it is new out of the box. Regardless of how things were before, the reality now is that your vehicle is staying on the ground. Before you give up and head to the store for a new jack, there’s a few quick simple steps that may just get you lifting again.

Your floor jack only has one job: lifting heavy things. It is actually quite amazing that your floor jack can transform the action of pumping the handle up and down into lifting a several ton vehicle. But what if your floor jack is experiencing the following problems:It won’t lift the rated weight load.

Unlike hydraulic oil, air can be compressed. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. So you need to get the air out of the hydraulic oil. Luckily it is just takes a few easy steps:Turn the jack handle clockwise direction until it is tight. Then turn the handle counterclockwise two complete revolutions so the lift arm won’t raise.

That’s it! If you go through this process and still find that your floor jack won’t lift, it may be time for a rebuild or to pick up a new floor jack. And remember a floor jack is purely a lifting device and NOT a holding device, so ALWAYS use jack stands.

Check out all the tools & equipment available on NAPA Online or trust one of our 17,000 NAPA AutoCare locations for routine maintenance and repairs. For more information on what to do when your floor jack won’t lift, chat with a knowledgeable expert at yourlocal NAPA AUTO PARTS store.

This is a 1 1/4 ton hydraulic floor jack my father passed on to me. He bought it new during the 1970s. It began to leak down a little a few months ago. The lift arm no longer rises when the handle is pumped up and down. (I was able to pull the lift arm up by hand and it settled slowly enough that I could make a photo with the arm partially raised.)

I checked to be sure it was adequately filled with fluid, but that was not the problem. A few months before this problem, there were bubbles coming up through the vents at the filler plug. At that time I raised the lift arm with the handle, released the jack"s valve, and let the arm fall slowly several times to purge air from the system. Finally, one day, the lift arm would not rise at all. If filling with fluid and purging air from the system do not restore function, there is probably internal leakage, even though fluid is not leaking from the jack. From what I have read, forty years of service is a reasonable time for a hydraulic jack to operate before it needs a rebuild.

A word of caution: Rebuilding this jack presented several challenges that seemed almost insurmountable at the occurrence of each. Rebuilding this jack was much more difficult than simply replacing a few "O" rings, and it required more than the very few hours some say are required for rebuilding a jack. Further, I had to make several special tools to get the job done. If you want to attempt rebuilding a jack and you are not a member of Instructables, I would encourage you to pick a password and a screenname, and join. Doing that will allow you to download a PDF of this Instructable for printing, or to view at any time later on your computer, assuming you wish to consult what I have done as a guide.

When putting fluid into a jack never use anything other than hydraulic jack fluid. Do not use motor oil or brake fluid. Brake fluid makes the seals swell.

At this link you will find one man"s description of how he rejuvenated his twenty-five year old jack by flushing its insides with a solvent, letting it dry completely, and filling it with fresh hydraulic jack fluid. It could be worth a try. I did find one manual for a floor jack that said the fluid should be changed every year. The procedure is to place the jack over a large pan, remove the filler plug, turn the jack on its side and let it drain. Then fill it again.

Several firms sell rebuild kits for hydraulic jacks. I found Blackhawk Parts and ordered parts on-line. My jack came with the Fleet brand name. It was sold through NAPA Auto Parts. It should have been easy to find my jack among the listings for Fleet jacks on the Blackhawk Parts web page and order the appropriate rebuild kit, but it was not. So, I sent an e-mail to Blackhawk Parts with the name of the manufacturer and the model number. It is good that I did. The kit I need is not the one I would have thought, but is actually for a Lincoln/Walker jack. Although my jack has the Fleet name, it was actually made by someone else. I paid about $45 for the parts kit, plus $11 shipping. That is a fairly typical price for a rebuild kit.

I decided not to open the parts kit until I was certain the parts it contains match what I see on my jack as I dismantle it. I will have less difficulty exchanging an unopened parts kit than I would have trying to exchange a kit I had opened, in case the wrong one was shipped to me. In the photo you can also see the paperwork that came with the parts kit. It will help, too, if an exchange were necessary. And, I do not want to risk losing any parts by opening the bag early and having something roll out.

The rebuild kit does not include any instructions. The Blackhawk Parts web page offers a few cautionary and a few safety notes, but no helps on the rebuild procedure for the Saturday mechanic. e-How does offer a step-by-step procedure for rebuilding a hydraulic jack in text, but it is quite general. There is avery helpful link at the e-How page that takes you to a set of photos and some useful notes on critical stages for doing work on a low price imported hydraulic floor jack. Some of these things would be very helpful for the proper assembly, too. Floor jacks are remarkably similar, despite small differences. See the next step for information on helpful videos on-line.

The graphic for this step is an exploded diagram of a hydraulic jack and a list of parts. This one is from aHarbor Freight jack. Diagrams like this one are easy to find on the Internet. Just search for "hydraulic jack manual." Diagrams like this one help with the names of parts and with a visual understanding of how the parts fit together. You can enlarge images in your browser to see more detail, or save them in PDF and do the same. But, if you are able to watch the videos linked in step 3, you will see how the parts fit together, too. (The day may come when those videos are no longer available on the Internet.)

There are many videos related to hydraulic jacks at YouTube, but most of those are not really very helpful for a rebuild, even though their titles are enticing. A floor jack is a really a bottle jack laid over onto its side and installed inside a frame equipped with casters, a handle, and a lift arm. This video shows how to remove the bottle jack unit from the frame. The floor jack in the video is my Fleet jack with a different name and paint color on it. Some jacks are the least bit different. You may also want to view this video.

If you do not want to rebuild the bottle jack unit yourself, you can use either of these videos to remove the bottle jack unit from the frame of the jack and simply take it to a repair shop near you. The cost of a rebuild at a shop is said to be around $150 to $200 plus parts. The e-How article linked in step 2 contains a word of caution. If your jack is a cheap import, it may not be worth a rebuild. The machining is not always as good as on the older models made in the USA. Further, the correct parts kit may be impossible to get. You may find it more economical simply to buy a new jack. Classic jacks made in the USA are generally considered worth the expense and effort of a rebuild.

First photo--The halves of the jack frame will need to be spread to get the bottle jack unit out for repair. Loosen the nuts on the axle for the lift arm considerably, but do not remove them. There is one on each side of the jack frame. The nuts on my jack are 15/16 inch in size.

Second photo--Two bolts on each side hold the body of the bottle jack unit to the frame. Remove all four. (One is partially backed out already.) Although the man in the video from step 3 removed the casters, that is not really necessary to access the bolts on this jack. I did fine without removing the casters.

Fourth photo--A universal joint twists to open and close the release valve. The upper end of the universal joint is a piece of hex stock. It fits into a hex socket in the bottom of the handle.

Fifth photo--Lift the jack frame and the bottle jack unit remains on the work surface, even though attached to the lift arm by hinged extensions. Use a pair of pliers to remove the end of the return spring from the pin.

Sixth photo--The rams from the jacks shown in the videos attach to the frame with a cotter pin. On this jack a pin both holds the end of the spring and secures the block in the photo to the top end of the ram. Flip the bottle jack unit over and drive the pin most of the way out with a hammer and a punch.

Place the bottle jack unit into a pan and drain the oil as best you can. On the bottle jack unit in one of the videos it was easy to work the plunger in order to extract more of the oil. The spring on the plunger is too strong for that on this jack. Be aware that additional oil will pour out of the jack in coming steps. Have a pan or newspaper available to catch it and minimize the mess.

The first photo shows the ram and ram nut (or tank nut, also top nut) at the end of the bottle jack. Most ram nuts are hexagonal. This one has two slots for a special spanner wrench. In the video from step 3 showing a man taking the ram nut off of a bottle jack, the ram nut came loose quite easily. On my jack the nut was stuck on very hard. I placed the bottle jack unit into my vise and tried to loosen the ram nut with a very large pipe wrench. I only did a little cosmetic damage to the nut. It would not loosen. I soon realized that my workbench and vise were not equal to the task, either.

The third photo shows the tool in use. Check the yellow text boxes. My vise did not have enough leverage to hold the bottle jack unit, so I bolted it upright into the jack frame and used the jack frame as my own long bar for leverage. In order to make that work, I planted my foot against the end of the frame that is not shown in the photo. I had to strike very hard with a 16 ounce ball peen hammer, but after about five or six strikes, the ram nut began to move. My tool worked and I was able to loosen the ram nut with the ram for removal from the bottle jack unit.

First photo--Unscrew the ram nut until it and the ram can be pulled from the bottle jack unit. The ram nut simply pulls off of the top end of the ram.

The outer shell of the oil tank appears to be securely fastened to the base of the bottle jack unit, but it is not. Press against its side and it tips off to one side immediately. There will be some oil that runs out onto the work surface. Put down some newspaper or a pan to catch it.

Third photo--Unscrew the universal joint assembly for the release valve. Insert a magnetic tool and pull out the cone-shaped plug. The hole from which it came is visible behind the magnet tool.

Fourth photo--Place the bottle jack unit in a vise and use a wrench to remove the plunger mechanism. I had to tap on the end of the wrench with a hammer to loosen it. On my jack a 1 inch wrench was required.

Move your cursor over the text boxes in the first photo. for part names, etc. The cylinder would normally be removed for a rebuild. But, this one is stuck very tightly. Remember how much difficulty there was in removing the ram nut in step 6. It screws to the cylinder, so the cylinder should be difficult to remove, too. It is not as easy as the video linked in step 3. I tried, but could not get it to loosen. There actually are no "O" rings or seals below the cylinder on this jack. Removing it does not give access to any removable parts. I did notice some oil at the bottom of the cylinder appears dirty.

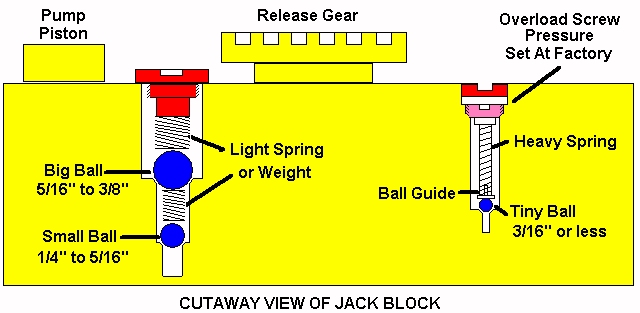

There are two metal plugs in the body of the bottle jack unit. Two large screws are below them. See the text boxes again. This site warns NEVER EVER to open these. It also has a diagram of what is inside. (Scroll down to the middle of the web page.) The author"s concern is that the small balls in the valves can be lost, and the jack would become useless. Get a shallow cardboard box with no holes in the bottom or a large pan and work inside of either one. If any balls roll away, they will be contained inside the box or the pan. Also, extra balls are included in my kit. Even if the balls were not included in the kit, precision steel balls can be purchased at a bicycle shop in a series of sizes. Check the link in this paragraph for the sizes normally used. The ball sizes in my jack are: 5/16 inch (7.94mm), 7/32 inch (5.55mm), and 5/32 inch (3.96mm). I measured them with a caliper through the plastic parts bag. I want to do as complete a rebuild as possible. Dirt may have found its way into the passageways where the balls are. The balls could also have rough surfaces through years of use.

If I turn the jack body back and forth I can hear metal balls rolling inside passageways. I drilled a hole in the center of each of the metal plugs. Then I inserted a slightly larger sheet metal screw into the hole until the threads bound against the hole I drilled. I placed a pair of pliers under the head of the screw and pounded against the pliers with a hammer to pull the metal plug out of the jack"s body. I repeated the process with the other plug. New plugs are included in the parts kit.

The second photo shows the bottle jack unit"s body, but inverted so it was easier to hold while operating the camera. The metal plugs have been removed. Both holes have a large screw inside them. The one on the right is recessed so far that it is not visible. It is the safety overload valve. This valve protects the jack"s seals from failing under a load heavier than the jack"s rating. When the safe range of the jack is exceeded, the safety overload valve opens like a pressure regulator to allow oil to return to the tank rather than entering the chamber for the ram. This screw has to be set so the safe level of pressure is not exceeded. In order to do that at home, I carefully turned this screw and counted by half-turns until it bottomed out. My screw was set to 1 3/4 turns above or looser than the bottoming out point. When it is time for reassembly, I will turn the screw gently until it bottoms out, then I will back it off 1 3/4 turns. The safety overload valve should then be set very close to the original factory calibration. One author noted that some jacks fail because the safety overload screw unscrews itself, which sets the jack"s lifting ability to a much lower threshold, and the arm may not lift what you want to jack. I found this screw turned with enough resistance that it is not likely to shift its position by itself. That same author also said most safety overload screws are about two turns looser than the bottoming out point.

The fourth photoshows another special tool I made. The screw for the check valves is quite tight. I tried the largest screwdriver I had (3/8 inch wide blade) with a wrench on its square shank. The blade on the screwdriver broke! The screw slot is 1/2 inch across the diameter of the screw and almost 1/8 inch wide. I bought a short bolt 5/8 inch in diameter. It is #8 on the hardness scale. Near the end I ground the diameter down until it fit nicely inside the recess for the screw. I kept a cup of cold water near my grinding wheel to avoid softening the bolt with heat. I ground a rough profile by sight. I moved the bolt to a vise and finished cutting the profile of the screw slot by means of a hand file. I checked the dimensions with a digital caliper. When my improvised screwdriver fit the screw and its slot, I tapped on the bolt"s head to be certain it had fully seated in the slot. I used a wrench on the bolt head and the screw came out with no difficulty, at all. I had tried to buy a large screwdriver, but could find none this large. This improvised solution cost me $1.65 for the bolt and a few minutes of time.

The first photo shows a paper towel I pressed into the cylinder and rotated with a screwdriver without letting the screwdriver touch the sides of the cylinder. (Be careful not to scratch the inside of the cylinder. A 1/2 inch dowel pin would have been a safer tool to use.) Jack fluid is clear. The towel shows how much dirt was in my jack"s oil. In addition to sopping up some dirty oil still in the cylinder, I poured a little clean jack oil into the openings and passageways. Most of it collected in the opening for the plunger. At first this oil was cloudy. After a few tries, it was clear. I think this should adequately clean the jack so that it can be reassembled.

Inspect the seats in the bottle jack unit"s body for signs of rust and pitting. The seats need to be clean and smooth. When I let sunlight shine into the recesses where there are seats, I saw more dirt. I used a wooden dowel rod to scrape and break loose any dirt I could find. I poured some jack oil into the holes to flush the dirt away.

Second photo--Clean the groove that receives the tank"s outer shell. It has some brown dried oil residue. Something brass would be ideal. It would be tough enough to remove the residue, but would not scratch the machined surface. Someone said jack oil is a vegetable oil. The oil residue is certainly like what I have seen in the kitchen from vegetable oils.

I kept the bag of parts inside the same shallow pan in which I assembled the bottle jack unit. This is so I am less likely to lose parts, especially the steel balls.

First photo--This shows the plunger body and the plunger parts. At the left three leather seals are shown. My jack does not use these. Several different parts came in more than one version. I think the same parts kit is sold for several similar, but different jacks. I have some parts I will not use on my jack. In the center area of the parts are the steel washer and the locking nut. The other two parts at the right are the old seal I removed. It has an oily sheen. Just below it is the replacement part my jack requires.

Second photo--Coat the new neoprene seal with fresh jack oil. During the installation of all parts, double check for any grit or dirt sticking to the oily parts and remove it before the installation of that part. Install the new neoprene seal, rounded end first. Install the steel washer and the locking nut. I will discuss how tight to tighten the locking nut after treating how to install the spring assembly onto the plunger body. I made a special tool for putting the plunger assembly back together. It is made from steel wire about 1/8 inch in diameter. The wire came from stubs of concrete reinforcement wire broken off from a friend"s foundation for his new garage.

The third photo shows how this special tool is used. I chucked this tool in my small drill press. The circle of wire at the end of the tool fits over the top of the cap for the plunger assembly. The two straight pieces welded crosswise allow the quill of the drill press to exert pressure downward and to collapse the spring so the "C" ring can be attached. Notice that the bottom end of the plunger body presses against wood so the smooth machined surface is not scratched. I used an adjustable pliers to close the "C" ring. My drill press has limited adjustment. I used a couple of pieces of wood on the drill"s base in order to achieve the desired distance between the chuck and the surface supporting the smooth end of the plunger.

Check the plunger for dust and particles of wood. Thread the plunger into the base of the bottle jack unit. Tighten with a wrench and hit the wrench several times with a hammer to make a good seal, since there is no "O" ring or copper washer to make the seal.

First photo--I have a dental pick I can use to remove old seals. This "O" ring shows cracks from age when stretched a little. Match the new "O" ring from the parts kit to the old "O" ring. Coat it with jack oil. Install the new "O" ring.

Second photo--Install the conical metal seal in the hole for the release valve. The pointed end goes in first. Tamp on it with a small screwdriver to make sure it seats at the bottom of the hole. Thread the release valve into the hole.

First photo--The hole for the check valves has a copper sealing washer inside it. The old washer is barely visible in the hole. Note its color. A new copper washer is supplied in the parts kit. The old washer has compressed to fit very tightly. There is no good way to remove it. I did not want to fill the passageways in my jack with copper shavings from digging it out in pieces. I decided simply to place the new washer on top of what is left of the old washer. (This photo was made before the plunger and the release valve were installed.)

Second photo--Install the parts in the order shown in this photo from step 8. (The release valve and the plunger are not shown in this photo.) Use the new balls from the parts kit. Do all of this inside a pan or shallow cardboard box so none of the balls are lost if one gets away from you. Tamp the parts down with a small screwdriver so they settle down as far as possible in their hole. Carefully start the screw plug with a screwdriver. It is easy to crossthread. Use the special screwdriver made from a hardened bolt to tighten the screw plug with a wrench.

Third photo--Install the parts shown in this photo from step 8. Drop the new ball into the hole. Insert the spring into the open end of the cap and drop both into the hole. Insert the screw plug. Carefully turn the screw plug until the valve assembly bottoms out. Back it off 1 3/4 turns.

I chose not to install the metal plugs that close the valve holes yet in case I would need to open one of the valves during testing of the jack to correct a problem.

Coat the inside of the cylinder with jack oil before inserting the ram. You should be able to pull the ram up and push it down with your hand. A seal too large in size makes the ram very difficult to install and to move.

Second photo--Clean the tank shell, both on the edges that mate to make a seal and inside. I found quite a bit of dirt inside mine. The dirt had not entered the jack from the outside, but appeared to be residue that had formed from changes in the oil. I applied some jack oil to the inside of the tank and wiped it with a clean paper towel. I did this several times until I could no longer feel anything gritty with my fingertips.

Retrace what you did in step 4, but in reverse, to bolt the bottle jack unit back into the jack"s frame. (The photo is from that step.) While the bolts are still loose, put the handle"s yoke in place.

I used about 20 ounces of jack fluid. Around 12 ounces was used to fill the jack. The rest was used for cleaning and flushing the bottle jack unit. The fill hole is 1/4 inch in diameter. Even though the bottles for the jack oil have a pointed end, some spurts out while trying to get the bottle end to the hole, and it makes a mess. Get a funnel with a very narrow end. This is one I made specifically for this job from some sheet metal.

I filled the reservoir in small steps. The jack"s release valve was open. Occasionally I pumped the yoke for the handle. When oil was at the level below the plug hole, I pulled the lift arm up and let it fall two or three times. This is to draw oil through the jack. I pumped the yoke between five and ten times to remove any air lock in the check valves. I checked the oil level again a couple of times. Then I returned the reservoir cap. The reservoir cap appears to be open, but actually has a small felt filter inside it.

Update: After using my jack a few times, it tends to throw off extra oil through the felt filter in the reservoir cap. I do not have the original instructions for this jack, so I do not know exactly what the recommended fill level is for it. From what I have read, some jacks are to be filled to the bottom of the hole while the floor jack is level on a floor. Others vary between just covering the cylinder with oil to slightly below the fill hole. At first I thought I might have a leak, but it was just the jack throwing off extra oil. This extra oil may also be due to the jack evacuating air trapped inside the jack. There are bubbles in the oil vented. One source suggested raising the jack fully and lowering it slowly twenty or so times to remove all air that might be trapped inside the jack"s passageways. Check the oil level to keep it at the desired level.

My jack worked as it should immediately. The real test is to lift something heavy with the jack. I left the jack in this position for a few minutes. It did not leak down that I could see. Now I can use a hammer to tap the metal caps into the holes for the safety overload valve and for the check valves. I will check the fluid level again after I have used the jack several times. I will also watch for signs of leakage. It is also a good idea to oil or grease all moving parts on the jack now and regularly in the future.

Troubleshooting--What do you do if you have rebuilt your jack, but it still does not work under load? Be certain the oil level is correct. Here are instructionson properly filling a floor jack. The jack could be air locked. This site says to open the release valve and pump the handle rapidly 10 to 15 times in that case. Here is a link to a document on troubleshooting hydraulic systems, like a jack. If necessary, check to be certain all check valve balls were installed properly. Check for leaks.

Conclusions--I did not find any clearly damaged seals in my jack, other than cracks in an "O" ring on part of the release valve, but it was a non-critical part. I did find dirt in the oil. I expect the seals were just old and less efficient. It feels good to have my jack working again, especially since it once belonged to my father. Rebuilding a hydraulic floor jack was much more difficult and a lot more work than I expected from information I had gathered before I began. I found some parts were not as easy to remove as I expected from videos and other helps that I linked earlier in this Instructable, and I had to make several special tools. I first had to develop those in my mind. Then I had to design them and build them with materials I already had. Fortunately, I have a welder and was able to do that without too much difficulty.

I can easily understand why many suggest a person ought simply buy a cheap jack and replace it with another when it fails. I have a hard time doing that, no matter how much financial sense it might make, That seems like the waste of a good tool containing numerous carefully machined parts. An imported floor jack comparable in capacity to mine lists for around twice the cost of the parts kit I bought, sometimes even less than twice the cost of the parts kit. I do not know if my Fleet jack will last longer than an import jack.

Knowing all I know now, I might suggest flushing out old jack oil every decade and replacing it with fresh, clean fluid. Even then, I am not sure draining the old fluid and refilling the jack with new fluid would have removed all of the dirt I found. Some of it was in places that seemed to hold the dirty oil in that particular place. The oil in the reservoir had always appeared clear and clean. Still, neoprene seals used in hydraulic jacks do harden or crack and will fail to seal properly in time.

Owning and using a hydraulic jack is often a necessity. But, it has costs over time. Those costs mean the eventual repair or replacement of a jack. If you choose to repair your jack, you have the option of doing it yourself or of taking it to a shop. If you choose to do it yourself, you will learn a lot, but it may require more of your time and be more difficult than you expected. If you take it to a shop, there will be a cash outlay that will likely be a fair amount greater than the cost of a new imported jack.

Several times I feared I had ruined a vital part on my jack, or was about to do so, simply because I was without knowledge and experience related to rebuilding a floor jack. It is my hope that this Instructable will enable others who wish to do so to rebuild a hydraulic jack with confidence and without some of the near mishaps I experienced. I wish someone had published this before I began to rebuild my jack. It would have saved me time and trouble.

Thank you. That is what I expected you have. I suppose you could also try to collect names of jacks using those gesrs and inquire of them to see if the gears are available as replacement parts.0

My CRAFTSMAN floor jack has 3 ports (valves)..... could you tell me what each one is and how to set them ? It was made around 2005...... (MADE IN CHINA) model #214.50145

I rebuilt this with new parts no problem...... I just did NOT check the turns for the check valve and safety overload valve and a 3rd one ??? ( factory settings) Any help would be greatly appreciated !

Thank you for your gracious comment. I hoped someone like you might see this and comment, especially in case I might have given totally false information, and you would correct me. This is my first intrusion into hydraulics, other than replacing a couple of brake lines on a previous family automobile and bleeding air from the system afterward. As I mentioned in the Instructable and in response to a previous comment, I needed to rebuild my jack; but, could not find all of the information I felt I needed. I wanted to document what I did, should I ever need it again, and also make it available to anyone else in the situation in which I found myself.

What would be your recommendation on the type of solvent to use and how long would let it soak inside the jack prior to rebuilding the 45+ year old hydraulic floor jack:

Ajack does not get hot and accumulate burned residue. Most parts will wipe clean with a rag. Sometimes there was residue where oil dried out. A wooden popsicle stick cut off square makes a good tool for removing oil residue without scratching the steel.0

There is one thing I learned that is worth knowing. Rebuild kits for hydraulic devices, even pneumatic devices, sometimes include two nearly identical O-rings, but one is slightly larger. One works, but the other does not. If an O-ring does not seem to fit, or the device does not seem to work, check for a nearly identical O-ring. A couple of years ago, my son-in-law rebuilt a nail gun. It did not work after rebuilding. He asked me to look at it. I replaced an O-ring with a nearly identical O-ring that was just a little different, and suddenly the nail gun worked just fine. I ran into something similar on rebuilding my jack.0

Very very good posting on rebuild of floor jack.Will be helpful with much detail for anyone wanting to complete a jack rebuild Thanks for all your suggestions, KneeWalker0

I understand. My life situation has changed. I am retired with a car that gets about all of its service at the dealership. We moved across the country and I left my floor jack with a brother-in-law. Here there is a son-in-law who will lend me a floor jack when I need one, but that has not happened. But, it is something you can check on your bucket list.More CommentsPost Comment

You can have the best-equipped garage with the best tools in the world, but none of it will matter if you can’t get to the components of your vehicle that need to be fixed or replaced. A floor jack should be in your toolbox if you need to change your oil, replace a flat tire, or make other repairs to your car or truck.

Unfortunately, no matter which floor jack you choose, there might be a time when it doesn’t work like intended, and you’ll need to do some troubleshooting.

Locate the Gross Vehicle Weight (GVW) on the sticker in your driver’s door jamb to find out the right tonnage capacity for your vehicle. The weight of most vehicles is also divided into front and rear weights. Make sure that the jack you purchase can lift more than the heavier of the two weights. For example, if you need 3100 pounds in the front (just over 1-1/2 tons), get a floor jack that can bear at least 2 or 2-1/2 tons.

One of the most common reasons a jack won’t lift is incorrect fluid levels. First, remove the oil plug and look into the chamber to check the oil level. The suggested level for most floor jacks is 3/16 to a quarter above the reservoir. If you need to replenish, make sure you have the highest-grade oil possible.

If the jack’s oil level is higher than the required level, you will need to drain it. When a jack has more fluid than necessary, it risks blowing out seals, producing internal leaks, and causing the jack to lose pressure.

A jack with a low oil level will generally work correctly, but the low fluid level will significantly reduce the jack’s height. Hydraulic systems are closed-loop, which means the fluid level should never fall below zero. If it does, there’s most likely a leak someplace, which you’ll need to rectify before using your jack.

A jack can be tilted during shipping, allowing air to enter the cylinders. As a result, when you first pull a new jack out of the box, it’s critical to bleed out the air before using it.

Additionally, it would be best to repeat this practice monthly or whenever you notice any lapses in lifting capacity. Bleeding the jack every month will help your jack perform at its best. To bleed your lift, follow the steps below:

Most of the time, this will completely bleed the jack. If not, gently pull the oil fill plug on the side after the cylinder has been freed and lowered to help remove any trapped air.

Check the valve for leaks and make sure it’s airtight. If it isn’t, it will let the pressure out and allow air back into the system when you try to raise something.

You should look for cracked welds, destroyed parts, oil leaks, and anything else that isn’t in working order. You should also check the jack’s ram by flipping it on both sides. Always inspect it in both the retracted and extended states. If the floor jack has rusty pistons, this could indicate a problem.

Regular inspections are necessary for your lift. For example, examine where the jack was stored for any fluid leaks and inspect the housing for any cracking or rust and the piston rod for scoring or other damage. You should also look to determine if excessive wear in any areas could cause problems. Finally, keep an eye out for any foreign things (metal shards, dirt, rocks, etc.) that could harm the device.

It’s also essential to clean the hydraulic jack after each use before storing it. Wash the jack’s exterior using a gentle soap solution. Make sure that you do NOT CLEAN the hydraulic components that move. Oil your parts regularly to avoid premature wear. It would be best to grease the caster wheels, the front axle, the elevator arm, handle base pivot bolts, and the release mechanism with a general-purpose lubricant. After each use, inspect the seals for possible oil leakage and replace them as soon as possible.

Hopefully, this guide has helped you understand how to fix a jack that won’t lift. Regular maintenance is, once again, the most straightforward approach to avoiding malfunctions and future difficulties. Maintain your jack as much as possible by regularly keeping it clean and dry and lubricating it.Should you need parts for your lift or a new jack altogether, SVI is here to help you. We have everything that you might need for a safe and reliable floor jack. Contact us today at (800) 321-8173 and we can offer you same-day shipping on in-stock parts!

8613371530291

8613371530291