floor jack safety valve adjustment brands

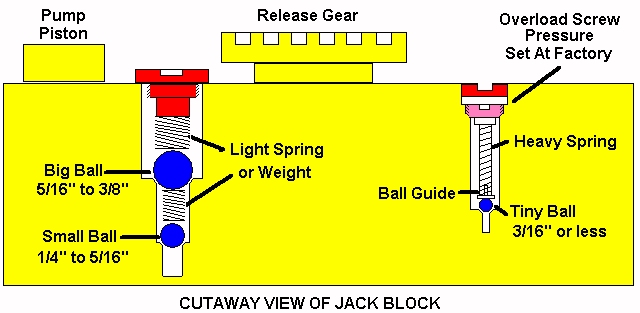

Sorry sir but not this one, please check out the Omega 26030 3 ton aluminum jack owners manual. This is exactly the same as mine. I know my pic is lousy, The only slight difference is mine has a screw instead of a clip per pic. And that"s the only difference, the rest is exactly the same including, YES 2 balls on the overload.

I should of mentioned the one I found first. Then just pure luck would have it I remember reading you recommending Hein Werner and Omega would be good jacks to purchase. So I was looking at the Omega aluminum jacks because I must have Speedy or Magic lift along with a light unit. And the plugger release knob for the handle is a must. I could not believe it when I saw the parts break down that showed 2 balls on the overload, and the same exact diagram that my Craftsman 50239 uses. I saw this all the time as a ASE mechanic, mid production changes that drove us bonkers. Now retired I dabble. But mark my words, 2 balls on this unit. Proof is how every lifting test passes.

An overload valve of a floor jack primarily exists so that the jack does not exceed the weight limit of the hydraulic press, which might cause it to break down. Overload valves stop the press from lifting further up if the weight limit is crossed.

The floor jack overload valve adjustment process is very straightforward and only requires you to follow a set of simple steps. However, if you’re trying to adjust the overload valve, chances are that your floor jack is having some trouble holding pressure. In that case, we have some solutions for that as well.

An overload valve is a safety measure to protect the hydraulic press from unwanted damage due to excessive pressure. It works by loosening the connection between the jack handle and the hydraulic press.

When we’re talking about adjusting the overload valve, we’re mainly changing the max weight capacity of the floor jack. To do that, you just need the right screwdriver. It varies from model to model, some use Philips heads while others use binding heads.

Once you’ve got the right screwdriver, find the location of the safety valve. There will be a shield on top of it that you’ll have to remove with the screwdriver. Spot the screws and turn them counterclockwise to release the shield.

After you’ve done that, the valve should be exposed to you. There are mainly two types of valves used on floor jacks. The handle valve and the screw valve. Handle valves have a handle, while screw valves have a hole for the screw to go through.

For a handle valve, you just have to hold on to the handle and rotate it to adjust the weight overload on the floor jack. Rotate it clockwise to increase the maximum weight capacity and counterclockwise to decrease it.

These valves are typically very sensitive so a small turn could drastically change the output. So, try it in small amounts and figure out the correct amount for you.

For a screw valve, you will need a corresponding screwdriver. Typically it is the same as the shield’s screws, but according to your model, it could be different.

Safety Note: Before attempting to put pressure after adjustments, check the instruction manual of the floor jack for the maximum supported weight capacity. Normally, the valve will be set to 90% of that max capacity. So, you can at best increase it to 100%. Going beyond that will be very risky as it can damage both the floor jack and your vehicle.

This is a very common issue for which people consider adjusting the overload valve. A loose valve can indeed cause your floor jack to suffer such problems. However, that’s not the only cause.

The hydraulic press will fail to operate if the oil levels are above or below the given margins. Also, if the oil is of low quality, it might cause friction which can also prevent it from working properly. To maintain the proper hydraulic level, you should fill your jack with oil correctly and safely.

To know exactly what types of fluid are used in a floor jack, check out this article where we have explained and recommended the hydraulic fluid to use in your jack.

Hydraulics work by using highly pressurized compressed air. After long-term use, some of that air can leak into other parts of the machine causing havoc. The air mostly gets trapped in the oil chamber. To remove air from the floor jack, you just need to bleed it.

The final most obvious consideration would be that the floor jack is damaged. In most cases, it’s the hydraulic press. Repairing a broken floor jack is not worth the effort and the money. You’re better off getting a new floor jack.

Keep in mind that the overload valve is a safety measurement. So, a floor jack overload valve adjustment should only be done under your own circumstances. To be on the safe side, never exceed the given weight limit of your floor jack.

Whether you need a tool for roadside tire changes or you plan to work on your car’s undercarriage, investing in one of the best car jacks is a good idea. The standard scissor jack or lift jack included in most tire replacement kits can get the job done, but they’re difficult to use and often less safe than alternatives.

If you perform any kind of at-home car repairs or tune-ups, you’ll want to invest in a quality floor jack. These recommendations are a good place to start your search. We’ve made an effort to suggest car jacks with various clearances, ton capacity, and price points.

The Torin Blackjack is a low-profile floor jack that is made with heavy-duty steel. A built-in safety overload system prevents lifting beyond load capacity. We like this floor jack because it is very easy to use, rolls nicely on its casters, and is simple to assemble.

While the instructions included with the Blackjack are practically useless, it isn’t too difficult to figure out how to assemble and operate this floor jack. The handle has a comfortable grip, and the low-profile jack easily slid under our test vehicle.

The release valve is integrated into the handle, which you twist when it’s time to lower the pump’s hydraulics. Among the car jacks that we tested, the Blackjack stood out as the strongest, lifting our vehicle with the least effort on our part.

Those who like the Blackjack appreciate its heavy-duty construction and low-profile design. Many are impressed with the value given the relatively low cost of this car jack. It is easy to maneuver with a long handle.

Some people received the Blackjack with parts missing or with broken swivel casters. While this isn’t common, there are multiple complaints on Amazon about this specific issue. There are also reports that customer service is slow and difficult to contact.

This low-cost, low-profile floor jack has a lifting range up to 14.0 inches. It has a 3.5-inch clearance, making it suitable for low-riding vehicles. A built-in safety valve prevents over-pumping and overloading this car jack. We like it for the price and ease of operation.

The F-767 is not as ruggedly built as the Torin Blackjack. However, it is made from alloy steel construction and is generally easy to use. The lever design offers an easy way to raise your vehicle, and this device is ultra low profile (just under 4.0 inches).

Users with low-riding cars especially seem to appreciate this car jack, which is able to neatly slide under such vehicles. The majority of reviews are comments from those who were happy to report that the jack works as advertised with no issues.

There are reviewers who say that they were shipped jacks with missing parts. This appears to be rare, but it can be very annoying if it happens to you. Some also say that it is a little short, and would prefer a jack able to raise their car higher.

The Blackhawk B6350 is a beefy car jack with a weight limit of 3.5 tons for larger vehicles. This steel floor jack has a lifting range of 5.5 to 22.0 inches and built-in safety valves for overload protection. It features an extra-long handle for greater leverage and is the most powerful car jack that we tested.

Operating this hydraulic jack is similar to the other floor jacks that we tested – insert the handle, tighten the release valve, and pump. The included instructions are easy to follow. Generally, we were impressed with the construction and material quality of this car jack. The handle is very long which makes operation easier, and it is covered in a comfortable foam. It has a fast lift speed and is made of high-quality materials.

Though quite heavy, this jack isn’t difficult to maneuver on its wheels. It does take two people to lift, however. This is the least portable jack we tested.

Most are impressed with the high load weight offered by this relatively inexpensive car jack. According to customer reviews, this is a long-lasting jack.

Some have reported poor welds on the handle, which broke for a handful of customers. Aside from that item, the jack is well-constructed. It may ship low on hydraulic fluid (and need to be topped off), but most are satisfied with a jack that can lift 3.5-ton vehicles at this price. The Blackhawk seems to be an especially popular jack for DIY mechanics.

This tiny bottle jack has a 10.0-ton lift capacity (6.0-, 8.0-, 12.0-, 30.0-, and 50.0-ton versions are also available). It can lift vehicles up to 18.13 inches and comes with a one-year warranty. This bottle jack’s small size makes it highly portable, but the design means that it won’t fit under vehicles with low clearance. It did not fit under our first test vehicle (a sedan), so we tested it on an SUV with a higher chassis.

The Big Red hydraulic bottle jack is easy to carry and position, weighing only around 10.7 pounds in total. When first using this jack you must follow the instructions to remove excess air and possibly top up the hydraulic fluid.

The lever is shorter than with floor jacks and doesn’t include a comfortable handle. It also fits together awkwardly – one part slides into the pinched end of the other, and rests that way, somewhat wobbly.

Besides positioning, this jack is harder to use than the standard floor jack, but still not difficult. It has a very high load capacity (10.0 tons) and easily raised the test vehicle.

Many write that this is an excellent option for high-clearance, heavy vehicles. It has a high weight capacity and its portability makes it a popular choice for changing spares. Be sure that it is stored upright, however, as bottle jacks can leak fluid otherwise.

Some have complained about receiving jacks that leak fluid. In the worst case, a few people got packages wet with hydraulic fluid. It’s annoying to need to clean and maintain your new product, but given the shipping distances, this isn’t entirely unreasonable.

The Big Red floor jack is a good low-cost option for a strong car jack. This jack has a maximum lift height of 20.88 inches. It uses a single-piston quick lift pump and is designed with a safety bypass system to prevent overloading.

This car jack comes with an extra-long saddle neck which can save you some pumping when lifting raised vehicles. The neck extension can be removed for lower-clearance vehicles. We found this car jack easy to use if not quite as well-constructed as our other top picks.

What most distinguishes the Big Red floor jack from the other jacks in this review is the neck extension. This positions the jack saddle higher to begin with, meaning less pumping to lift a car. This is helpful if you have a raised car, though is not necessary for low-profile vehicles like our test car.

This car jack is as easy to operate as any well-designed floor jack. However, the handle design doesn’t seem as sturdy or as comfortable as the Blackjack or F-767. Still, we were able to raise and lower our test vehicle with ease using this floor jack.

Happy reviewers like how this jack works, and many mention the extended saddle neck as an appreciated convenience. Several report years of reliable use from this car jack, which is easy to maneuver and pump.

There are some comments about faulty welding on the wheels. Though uncommon, more than one reviewer posted complaints about the wheels failing. Another typical criticism is that the jack lowers too quickly. Some write that when the pressure valve is released the jack falls down very quickly. We did not experience this when we tested the Big Red floor jack, but this issue may be more common with heavier vehicles.

Scissor jacks are accordion-looking contraptions found with many spare tire kits. These jacks use a screw mechanism to raise your vehicle. They are slow and can be difficult to use.

Floor jacks are large and heavy, but stable and easy to use (if more difficult to maneuver). These are the most common type of jack for a garage or workshop.

Bottle jacks are small and bottle-shaped. These often operate with a lever and are easy to use, but can’t lift as high as a floor jack. A bottle jack is a good option for a portable jack but a poor choice for a car with low clearance.

When selecting a jack, you need to pick something that will fit underneath your vehicle before you begin to lift it. Some sports cars and luxury vehicles have especially low clearances, so require a low-profile jack to elevate. When purchasing a jack, consider your vehicle’s clearance compared to the jack’s.

Also, consider a car jack’s maximum lift height. If you have an especially high vehicle like an SUV, smaller jacks may not raise high enough to hoist your car off the ground.

Any car jack is rated to lift a certain tonnage. If you’re buying a car jack to lift your vehicle for repairs, pick something with a weight rating to match the vehicle you’re trying to lift. Keep in mind that to change a tire, you’ll only need to lift half the weight of the vehicle. You should be able to find your vehicle’s weight on the door panel or owner’s manual. The typical sedan weighs around 3,000.0 pounds, while trucks can weigh around 8,000.0 pounds.

How you plan to use your car jack should determine which type of jack you get. If you want to raise your car so you can get under the body to tinker around, you’ll most likely want a floor jack. These are the most stable and provide the best lifting power.

Floor jacks can be large and heavy, so they aren’t reasonable to carry in your trunk at all times, should you get a flat. If you need a car jack for spare tires, a scissor jack or bottle jack will serve you better (keep in mind vehicle clearance if you get a bottle jack, which may not fit under your car unless you have a truck or SUV).

If you need to jack up your vehicle, a floor jack is typically the universal choice for its ability to lift vehicles higher than a bottle jack. Most vehicles also come with a scissor jack that can support the weight of your vehicle but may not be compatible with other car models.

You don’t need to be a professional mechanic to use a car jack, and many jacks are simple to operate. However, there are some steps you’ll want to consider to keep yourself and your car safe. Additionally, drivingtests.org has a detailed guide should our instructions here not suffice.

Before raising your car, you should also have jack stands and wheel chocks. Jack stands support and stabilize your car after it’s been lifted. They are a crucial safety component if you plan to work under your car while it is elevated. Any jack, especially a hydraulic jack, can fail and if that happens jack stands will prevent you from being crushed. Wheel chocks stop your car from rolling while it is elevated.

Before lifting your car from the ground with a car jack, make sure that it is on a level surface, in park, with the engine off, and the emergency brake engaged. If you have wheel chocks, place those behind your wheels.

You don’t want to place the jack just anywhere before lifting your car. If you put it in the wrong spot it can damage your trim or undercarriage. Consult your owner’s manual to find the jack points – typically a reinforced metal plate just behind each front wheel and just in front of each back wheel.

Slide the car jack under your vehicle and start lifting. If you’re using jack stands, set those up once your car has been raised and before you get to work.

Hydraulic floor jacks often need maintenance, sometimes even when new. Before using your jack, be sure to inspect the welds and bolts. Make sure there are no cracks and that every screw is fully tightened. If your car jack isn’t lifting properly it may need bleeding, a fluid top-off, or both.

New car jacks typically don’t need oil replacement for at least a year. However, if the screw or cap covering the oil chamber is loosened or damaged during shipping, your car jack could arrive low on hydraulic fluid.

To determine if your jack is low on fluid, open the oil chamber and inspect the fluid levels. Hydraulic fluid should come up to 1/8 of an inch from the top of the chamber. If you can’t see any oil, you’ll need to add more.

A floor jack like the Torin Blackjack will offer the fastest lifting speed and most stability. However, these jacks are heavy and not something you can store in your trunk for emergencies. For changing a tire, you’ll need a bottle jack like the Big Red Bottle Jack or a scissor jack.

Regardless of which car jack you have, be sure to also use safety equipment like wheel chocks and jack stands. You may not need jack stands just to change a tire, but you should certainly use them if you plan on sliding underneath a raised vehicle.

The automotive jacks in this article went through two rounds of reviews. We started by searching Amazon for top products, looking at customer ratings, Amazon superlatives, and prices. We combed through customer reviews to find a variety of jacks that are consistently rated for quality, durability, and value.

The car jacks that best met these standards were ordered by our team for testing. A team member assembled and tested each jack on a car, lifting it several inches off the ground. Each car jack was given a rating out of 5 stars based on ease of use, durability, and value.

To test each car jack, we unboxed and assembled the jacks according to the instructions (if any were included). We placed each jack under the test vehicle and lifted it several inches off the ground. Our tester was able to note the quality of materials, ease of use, and overall performance.

Based on our testing, we think that Torin, Pro-Lift, Blackhawk, and Big Red are all excellent brands for car jacks. Many car jacks are sold by different companies but manufactured by the same factory, so in some cases, it may be worth buying whichever is cheapest.

Never get under a car that is supported exclusively by a car jack. Even the safest car jack isn’t safe enough to hold a car on its own. While all of the car jacks we recommend (Torin Blackjack, Pro-Lift F-767 Blackhawk B6350, Big Red floor jack, and Big Red bottle jack) are excellent car jacks, you should always place your car on jack stands when working underneath.

Car jacks are reliable for lifting your vehicle, changing tires, or doing work under the chassis. However, no car jack is reliable enough that you should trust it with your life. Whenever working underneath a car be sure to support the vehicle with jack stands and not your jack’s lift arm alone.

A 3.0-ton jack can safely lift up to around 3,500.0 pounds. If the thing you’re lifting is significantly lighter than that, you may not need a 3.0-ton jack. If the thing you’re lifting weighs more than 3,500.0 pounds, you’ll need a stronger jack.

If you’re lifting a car, keep in mind you may only need to lift one side of the vehicle, so if your car weighs 7,000.0 pounds, a 3.0-ton floor jack can raise it enough to change a flat tire or perform oil changes.

A 2.0-ton floor jack can lift vehicles up to around 2,400.0 pounds. This will lift some SUVs, but the typical mid-size SUV can weigh up to 5,000.0 pounds. However, when using a jack, you’re likely only lifting one side of the vehicle, and not the entire car’s weight.

Professional mechanics generally use hydraulic jacks since they can bear the entire weight of a vehicle and allow greater access to work on a variety of issues.

The best car jack stands are best suited for specific maintenance tasks like replacing tires, changing brakes, or working on the underbelly of the vehicle. In other cases, ramps are cheaper and typically safer.

... & soft rubber pad on the saddle plateTurning handle for easy release of loadLow profile construction Low noise & smooth to floor tiles due to oil and acid resistant plastic wheelsThis product is not marketed yet in North ...

Air hydraulic jacks designed for heavy, intensive and professional applications. Easy to use, they present a hand-operated dead man’s control for optimum safety while lifting and lowering.

UGJ trolley jacks feature polyamide swivel castors for smooth and quiet operations. All models are fitted with a foot pedal for fast approach to the load. In addition all models are fitted with a safety valve and stroke ...

The DP LIFT jacks line offers its customers an easy and safe usage, both for automotive and industrial applications. The jacks consist of a highly resistant diaphragm and internal telescopic guide. They ...

A hydraulic jack serves one fundamental goal: the lifting of heavy loads. Jacks are designed to provide force multiplication to enable a worker to amplify their strength through the jack"s hydraulics or mechanics to accomplish this goal.

There are two main types of jacks commonly in use; one type uses hydraulic pressure for lifting (hydraulic jacks), while the other uses a screw thread to achieve lift (mechanical jacks). Of the two, hydraulic jacks usually provide higher lift capacity and are more reliable.

Hydraulic jacks are available in two varieties: floor jacks and bottle jacks. Floor jacks have a horizontal shaft that pushes on a crank. The crank connects to a lifting pad that rises vertically. These jacks are capable of lifting several tons.

Bottle jacks have been around longer, and their name derives from their resemblance to an old-fashioned milk bottle. Bottle jacks have a vertical shaft that raises a platform called a bearing pad. They can lift up to several hundred tons, depending on the specific capabilities of the model being used. However, these jacks typically cannot lift the load to the same height as with a floor jack.

Both types of jacks operate under the same basic principle: In a closed container, the pressure is the same in all directions. In the case of a hydraulic jack, this container is a cylinder, and it holds incompressible hydraulic fluid. Hydraulic fluid is forced into the cylinder through a check valve that prevents the fluid"s backflow. The check valve keeps the cylinder pressurized so the load does not drop. As pressure builds in the cylinder, the force pushes upward on the plate of the jack and lifts the load resting on it. The weight of the load lowers the plate when the check valve is released, allowing the hydraulic fluid a path to exit.

There are some issues that are common to all types of hydraulic jacks which can impact their operation and safety. At some point, users will likely encounter leaks, rams that won’t lift, safety valves that get tripped, damage to the frames, and jack handles that kick back. While many hydraulic jack repairs are easy to accomplish, others might require the assistance of a professional.

Leaks, in particular, are extremely common, and result from a failed or dislodged seal or O-ring. Repair involves draining the hydraulic fluid, disassembling the jack, and inspecting the seals. Be sure to look carefully for cuts, tears, seals that are out of place, degradation, scratches, and so on. These issues are an indication that the seals or O-rings need to be replaced.

Repairing leaking seals can be a significant undertaking, especially for those not experienced in jack repair. Novices might want to leave this type of issue to a professional with the requisite experience. Also, if the leaked fluid is cloudy or foamy, that indicates the presence of water or air in the hydraulic system and could mean that the hydraulic fluid needs to be replaced and the potential source of the intrusion investigated.

Jacks may also be overloaded, causing the safety valve to trip. The purpose of this safety feature is to prevent the jack from being loaded beyond its rated operating pressure, typically measured in pounds- force per square inch (psi). A jack will not behave the same way after the safety valve has been tripped. The ideal way to address this issue will vary by manufacturer, so always consult the service manual when this occurs. Professional service is recommended in these instances to restore safe operation of the jack.

In other cases, rams may stop lifting, which is usually the result of insufficient hydraulic fluid in the reservoir. Luckily, this is a repair that even beginners can handle. When there isn’t enough hydraulic fluid present, air may become trapped inside of the system. The solution here is to add the appropriate amount of hydraulic fluid, then turn the jack to its release position. Next, pump a few times to purge out the trapped air. Then, refill the reservoir and place the seal cap back on. Be careful to avoid introducing contamination (such as dirt and dust) to the hydraulic system while adding fluid, and never mix two different types of fluid.

Hydraulic jacks are powerful devices for lifting, but like any other mechanical or hydraulic system, they will inevitably require maintenance and occasional repairs. While someone with fundamental mechanical skills may accomplish some repairs, others are best handled by a hydraulic professional. Be sure to consider the options carefully before deciding on a course of action.

It’s big, it’s red, and it lifts your vehicle in a matter of minutes. The Torin Big Red Car Jack is a simple scissor jack that’s compact enough to fit under your seats and strong enough to lift a compact SUV for an emergency tire change.

We chose the Torin Big Red Car Jack as the best portable car jack lift because it’s suitable for most vehicles, costs less than a tank of gas, and weighs less than a bag of groceries. A simple car jack like this and an emergency roadside kit can get you out of a spot of roadside trouble.

While the Big Red jack does require manual cranking, its oversized base adds stability, making it a little safer to work with when you need to change a tire or work on your vehicle.

The Torin Big Red Car Jack is storable, affordable, and powerful. It fits the price and durability needs for most drivers, making it our pick for the best portable car jack.

Like all scissor jacks, the Big Red jack fits under your vehicle and lifts as you crank the tension rod. Its extra-wide base and heavy-duty steel construction keep the jack and your vehicle stable while you work.

This car jack is suitable for vehicles of most heights, so it will work with your low-profile sports car or compact SUV. Its weight capacity is 3,000 pounds, so we don’t recommend it for heavy-duty trucks and large SUVs.

The Pro-Lift is a floor jack, so it’s best for garages and paved surfaces. It’s made of heavy-duty steel, includes a lever for lifting, and has a safety valve to prevent overloading the jack.

We focused on the six-ton jack because it covers most passenger vehicles, even those with trailers on them. This Torin bottle jack is small enough to fit in your truck, toolbox, or under the seat without rearranging anything. And it costs just under $20.

This Powerbuilt jack can lift 6,000 pounds 17 inches off the ground (21 inches, if you raise it manually first), but it’s best for specialty vehicles.

Specially designed for Jeeps and off-roading vehicles, it has an extra-wide base for better support on uneven ground. It also has a safety valve to prevent slipping while you’re working on your rig.

For roadside maintenance, look for scissor lifts with extra-wide bases and floor jacks that can withstand unpaved surfaces (if you go off-road). Jacks you’ll use in your garage don’t have to be as portable and work better with jack stands or ramps for extra support.

Whether you rock a low rider or sit high up, you’ll need a portable car jack that can reach your vehicle and raise it high enough for you to start working.

Most jacks can lift your vehicle a little over a foot off the ground. That’s enough room to change a tire, but not enough for you to slip under the car.

It depends on your car’s weight. It’s best to find jacks that can lift a little more than what your car weighs. If your car weighs 2,500 pounds, a two-ton jack would be suitable.

Floor and trolley jacks are similar but have a few key differences. Floor jacks and trolley jacks both lie flat and roll under your vehicle. They’re also both better for garages and serious maintenance.

Trolley jacks are generally heavier lifters and less portable. Floor jacks cost less and are easier to set up, making them useful for roadside help for larger vehicles.

No. Look for a jack that’s strong enough to support your car. A two-ton jack is generally enough for a small car or sedan but not enough for a heavy-duty truck.

We wanted to find a portable car jack that works best for the most people. We considered factors like price, weight capacity, lift height, and the portability of the jack itself. So while the Torin Big Red Car Jack doesn’t lift the most weight, it checks the most boxes for the most drivers.

To find the best portable car jacks, we checked firsthand customer reviews to hear about real experiences with each product. The products with the highest ratings and most reviews made our list.

We also watched instructional videos about roadside emergencies, car jacks, and how to find the right fit for your car. Read our full methodology to learn how we wrote this and other articles on SafeWise.

As a renter, pet-owner, and woman living alone, Katie McEntire takes safety seriously. She’s tested devices like pet cameras, home security systems, and GPS trackers in her own home and devices in the name of safety. In addition to testing, writing, and reviewing for SafeWise, she also makes videos for the site’s YouTube channel.

1. As soon as the box was opened, I noticed that the jack had a stupid pressure release turn dial rather the much more common, easier, and safer design of the turn handle hydraulic pressure release. Not only is this super annoying as hell to drop your car down with ease, it is super unsafe as you can over turn in the slightest and literally DROP your car down putting way too much pressure quickly onto your suspension and possibly you jack stands when trying to get everything ready for work to be done on your vehicle.

3. Within 6 months of light and gentle common and quick use the jack started to show extensive rust with very little to no water exposure even with its painted finish much around the wheels.

4. Within the same 6 months the Jack started failing making it extremely dangerous to use...I just experienced my 3rd jack failure and that"s it for me this last one was extremely dangerous and happened before I could even get my safety Jack Stands on each side to do some front brake work. wheel was off and it was luck I took the precaution to put it underneath the from middle or I"d be replacing my right front side brake system and possibly suspension. That"s hundreds of dollars worth of parts replacement and super dangerous consequences if you"re underneath there. I had to let some of the weight on the tire potentially throwing of its balance just to run and search the trunk quick to grab my scissor jack in order to save the vehicle from damage and save my wheel.(Luckily I was fast or I would have damaged my wheel as well)

5. Handle design and attachment positioning is stupid. The Handle has a small protrusion that has to click into the jack arm in order to lift it and of course, it doesn"t even stay locked in so again, another safety issue as you can be jacking up and slip out of the arm or even trying to re position the jack or pull it around on the ground can ALL BE A HUUUUGE HASSLE when trying to be quick and safe!

6. The instruction manual says the Oil Plug is located under the black cover as its not so removal of this is a complete waste of time and a pain to replace but if you"re wondering the oil plug is located on the right side in front of the cap kind of hidden rather then their own manual clearly states. Upon checking the Hydraulic Oil Level Upon opening it was way under par and I can tell you right now you"re supposed to be able to go right to work with a new floor jack; not have to worry about whether they topped off the hydraulic fluid or not. So if you"re crazy enough to buy this thing like I did thinking that its such a great deal(which it is) remember all these cons. Btw the tank is now basically empty so not even 6 months before needing a complete refill of fluid and common to minimal very light use on on a 1,6L small sedan....UNACCEPTABLE. MAKE SURE YOU HAVE ENOUGH HYDRAULIC FLUID IN THERE BEFORE USING, IF YOU"RE GOING TO BUY THIS!!!!

7. That"s right there"s still more negatives if you still haven"t moved onto another safe jack...There is a stupid locking pin that falls out almost every usage and every 3-5 pumps of the jack unless you hold it in while pumping now deeming you all in with both hands operating something and I can"t stand that. This is just another one of many bad operational designs and of course eventually lead to it breaking down and having the pin get stuck in between the holding brackets underneath the jack arm which keeps the whole unit functional and allows pressure to be applied properly. This is one of the multiple issues that almost caused my car to crush to the ground before even getting the stand in with the wheel already off very dangerous indeed. - I had to force the pin into the other side of the brackets after this ordeal just to buy myself time to grab the other jack from the trunk and even then it was slowly constantly losing pressure. I noticed that the pressure and weight lifting ability were some of the previous buyers" complaints and I"m not surprised because it ended up becoming its overall downfall... Normally I would try to fix this thing myself but NO it"s LUCKILY got a 2 yr warranty so I"ll just send it back for a new 1 from them and deal with it until I can afford a replacement. High hopes were crushed...literally with this jack and almost more....

You can have the best-equipped garage with the best tools in the world, but none of it will matter if you can’t get to the components of your vehicle that need to be fixed or replaced. A floor jack should be in your toolbox if you need to change your oil, replace a flat tire, or make other repairs to your car or truck.

Unfortunately, no matter which floor jack you choose, there might be a time when it doesn’t work like intended, and you’ll need to do some troubleshooting.

Locate the Gross Vehicle Weight (GVW) on the sticker in your driver’s door jamb to find out the right tonnage capacity for your vehicle. The weight of most vehicles is also divided into front and rear weights. Make sure that the jack you purchase can lift more than the heavier of the two weights. For example, if you need 3100 pounds in the front (just over 1-1/2 tons), get a floor jack that can bear at least 2 or 2-1/2 tons.

One of the most common reasons a jack won’t lift is incorrect fluid levels. First, remove the oil plug and look into the chamber to check the oil level. The suggested level for most floor jacks is 3/16 to a quarter above the reservoir. If you need to replenish, make sure you have the highest-grade oil possible.

If the jack’s oil level is higher than the required level, you will need to drain it. When a jack has more fluid than necessary, it risks blowing out seals, producing internal leaks, and causing the jack to lose pressure.

A jack with a low oil level will generally work correctly, but the low fluid level will significantly reduce the jack’s height. Hydraulic systems are closed-loop, which means the fluid level should never fall below zero. If it does, there’s most likely a leak someplace, which you’ll need to rectify before using your jack.

A jack can be tilted during shipping, allowing air to enter the cylinders. As a result, when you first pull a new jack out of the box, it’s critical to bleed out the air before using it.

Additionally, it would be best to repeat this practice monthly or whenever you notice any lapses in lifting capacity. Bleeding the jack every month will help your jack perform at its best. To bleed your lift, follow the steps below:

Most of the time, this will completely bleed the jack. If not, gently pull the oil fill plug on the side after the cylinder has been freed and lowered to help remove any trapped air.

Check the valve for leaks and make sure it’s airtight. If it isn’t, it will let the pressure out and allow air back into the system when you try to raise something.

You should look for cracked welds, destroyed parts, oil leaks, and anything else that isn’t in working order. You should also check the jack’s ram by flipping it on both sides. Always inspect it in both the retracted and extended states. If the floor jack has rusty pistons, this could indicate a problem.

Regular inspections are necessary for your lift. For example, examine where the jack was stored for any fluid leaks and inspect the housing for any cracking or rust and the piston rod for scoring or other damage. You should also look to determine if excessive wear in any areas could cause problems. Finally, keep an eye out for any foreign things (metal shards, dirt, rocks, etc.) that could harm the device.

It’s also essential to clean the hydraulic jack after each use before storing it. Wash the jack’s exterior using a gentle soap solution. Make sure that you do NOT CLEAN the hydraulic components that move. Oil your parts regularly to avoid premature wear. It would be best to grease the caster wheels, the front axle, the elevator arm, handle base pivot bolts, and the release mechanism with a general-purpose lubricant. After each use, inspect the seals for possible oil leakage and replace them as soon as possible.

Hopefully, this guide has helped you understand how to fix a jack that won’t lift. Regular maintenance is, once again, the most straightforward approach to avoiding malfunctions and future difficulties. Maintain your jack as much as possible by regularly keeping it clean and dry and lubricating it.Should you need parts for your lift or a new jack altogether, SVI is here to help you. We have everything that you might need for a safe and reliable floor jack. Contact us today at (800) 321-8173 and we can offer you same-day shipping on in-stock parts!

After a ratchet-and-socket set, box-end wrenches, and screwdrivers, the most commonly used automotive DIY tools are probably a floor jack and a set of jack stands. Whether you’re changing a flat tire, replacing brake pads and rotors, or performing work under the vehicle that requires it to be raised for clearance or comfort, it’s important to understand that the functions of floor jack and jack stands are tightly intertwined.

That is, you use a floor jack to lift the nose or tail of a car (or, possibly, just one wheel), then you set it on jack stands to keepit safely in the air.

Last year, low-priced tool giant Harbor Freight recalled several of its jack stands due to instances of the stands slipping under a shifting load. It pushed the issue of jack stand safety to the automotive media’s front burner, which is certainly a positive thing. I thought I’d give you my common-sense perspective on floor jack and jack stand safety.

Before I delve into the mechanics of the slippage of the Harbor Freight stands, we need to jump into the Wayback Machine. If you wrenched 30 years ago, the jack stands you likely used had a design consisting of two sliding stamped metal tubes like the ones pictured below. The bottom of the outer tube was slit in three places, and the resulting sections were bent outward to create three legs which had metal bands welded to the bottoms to secure them against splaying apart further under load.

The inner height-adjustable tube had a cradle on the top to hold whatever part of the car it was under, as well as several holes that could be aligned with a hole in the outer tube and locked with a metal pin that was the diameter of a pencil. Stands like this were inexpensive and lightweight, but the stamped metal was fairly thin, the increment of height adjustment with the holes was usually pretty coarse, and using the stands meant putting them under your jacked-up car, raising the inner tubes, lowering them until one hole aligned with the hole in the outer tubes, and manually sliding the pins through. The pins actually performed three separate functions—selecting a height, locking that height in place, and supporting the weight of the car—but this wasn’t really trumpeted as an advantage.

The stamped metal-pinned tubular jack stand was gradually replaced by a welded ratcheting design. Instead of having two sliding stamped-metal tubes with their location fixed by a pin, the ratcheting design has a post with teeth, which slides up and out of the middle. This ratchet works like the familiar ratchet in a wrench, except it’s linear instead of circular. Teeth on the post are a right-triangle sawtooth shape with the short edge parallel to the ground. As the post is lifted up, a “pawl”—a curved eyebrow-shaped bar—has one end that pivots, and another end that slides under the part of the tooth that’s parallel to the ground, making it so the post can be pulled upward but can’t be lowered without flipping the release bracket. It’s a bit quicker to deploy beneath a jacked-up car than a pinned stand.

In addition to the ratchet itself, the construction of a ratcheting stand is heavier and thicker than the pinned stamped-metal tubular one. Typically, a thick metal plate is bent into a four-legged shape, welded onto itself at a seam, and welded at the top to the central body that receives the toothed post. If you accidentally run over a stamped-metal tubular stand, odds are you’ll flatten it, or at least bend the legs. In contrast, if you accidentally run over a ratcheting jack stand, odds are you’ll damage the undercarriage of the car.

In May 2020, low-priced tool giant Harbor Freight recalled 1.7 million of its Pittsburg-brand three-ton jack stands (items 56371) and six-ton stands (items 61196 and 61197) due to reported instances of the stands slipping while under load. You can find videos on YouTube where people demonstrate this under controlled conditions. This video of a disassembled jack stand does a pretty good job of showing the mechanics of the problem—the end of the pawl not fitting as securely under the teeth as it should. And on this website, you can see photos in which someone put white paint on the pawl, and a surprisingly small amount of paint transferred onto one of the teeth on the shaft, which demonstrates the small amount of overlap of the pawl under the teeth.

The root cause of the problem was reportedly traced to aging tooling at one factory run by the manufacturer, the Jiaxang Golden Roc Tool Company, affecting reportedly about 5 percent of the jack stands manufactured there. There were reportedly 11 injuries caused by the problem, none of them life threatening.

Unfortunately, Harbor Freight’s replacements for the recalled three-ton stands (item 56373) had a different problem—instances of the seam weld cracking when under load. These were recalled as well. You can find videos of this “zipper failure” of the seam weld on YouTube. Together, the recalls created the impression that any Harbor Freight jack stand was going to kill you.

An unintended but completely reasonable response to the Harbor Freight jack stand debacle was a sharp resurgence in interest in tubular jack stands, where a thick and plainly-visible pin is used to set the height, lock the stand, and support the car’s weight. Although the cheap lightweight stamped metal design is a thing of the past (and rightly so), sales of pinned-design jack stands such as this Torin T43004, with two sliding aluminum tubes and a screw-on aluminum base, soared. In addition to having a locking pin instead of a pawl, the screw-on base means that this particular design is even free of the kind of weld that failed in the second Harbor Freight recall.

Ratcheting jack stands, however, have not gone away. Far from it. In fact, many if not most new ratcheting stands have had a makeover, receiving a manually-insertable safety pin that provides redundant load bearing to the ratchet pawl. If you want to buy new ratcheting stands, you’d probably need to go out of your way to find one that doesn’thave this “double-locking” feature.

Obviously, the Harbor Freight jack stand recalls are a very serious issue, and if you have Harbor Freight jack stands from one of the recalled batches, you should return them. But should you toss your current ratcheting jack stands in the recycle bin and pony up for one of the newer pinned-tubular stands or a ratcheting stand with a redundant pin? If you’ll never feel safe working under a car unless you do, sure. But if that’s allyou do, you still won’t be as safe as you could be.

With that said, I’ve been wrenching on my own cars for 40 years and writing about it for 35, and in my Hack Mechanic opinion, the dominant safety issues working under a car are these, and they remainthese, even after you’ve exchanged your Harbor Freight jack stands:

Always, always,“double-jack” the car. I can’t write this often enough or say it strongly enough. The single most important thing you can do to make working beneath a car as safe as possible is that, after you’ve used your floor jack to raise the car and set it down on jack stands, leave the floor jack in place as a back-up.This is literally zero extra work, and it costs you nothing. I realize that, at times, the floor jack may then be in the way, but consider approaching the part you need to work on from another angle.

Always jack up the car on a level surface, never on an incline.You’d think you need to be suicidal or an idiot or both to jack up a car on a hill, but people sometimes make poor choices in the heat of the moment. I was a physics major in college and had a mechanics professor—that’s “mechanics” as in the study of the forces on moving and stationary objects—who died when his car fell on him. Months after it happened, I looked at his driveway and was astonished at its steepness. What caused him to do it, I don’t know. The best, smoothest, most level, safest place to jack up a car is usually your concrete garage floor. Maybe there was already a car in his garage and all he wanted was a quick oil change. Who knows. That a mechanics professor could get this wrong enough to get himself killed haunts me to this day.

Don’t jack up a car on asphalt, especially on a hot day. Asphalt is never as hard as concrete, and as its temperature increases, it can get soft enough that a floor jack and jack stands can sink right in, causing a car to topple. Combine it with a surface that isn’t laser level and things can go sideways very quickly. I’ll never forget checking out a car I was thinking about buying. I met the seller in a CVS parking lot in July. I’d brought an aluminum floor jack and used it to put the nose of the car in the air to quickly wiggle the front wheels and check for front-end play. I didn’t “double-jack” the car because I wasn’t even pulling the wheels. I didn’t perceive the parking lot as slanted, but it was, and the slant was at a right angle to both the car and the jack, and that—combined with the hot temperature and the soft asphalt—caused the jack to sink and the car to topple, with the nose abruptly jumping one foot toward me. My body was never under the car, but it scared the bejesus out of both me and the seller, and I’ve never forgotten it. If you have no place other than asphalt to jack up a car and have absolutely no other choice, I strongly advise making sure it’s dead flat and putting metal plates beneath the floor jack and all jack stands.

Once settled, check the jack stands. Once you’ve released pressure on the floor jack and let the car down on the jack stands, check the stands both top and bottom. Make sure that the part of the car the cradle (at the top of the stand) is touching is in the middle and is sitting flat, and verify that all four legs of the base of the jack stands are sitting securely on the ground. This is especially crucial if you’re trying to put all four wheels of the car in the air, as the act of jacking up one end of a car can easily cause stands already at the other end to tip forward.

Don’t overload the jack or the stands. I’ll talk about load ratings below, but basically, don’t be an idiot and jack up a truck with a little jack and then set it on little stands.

Don’t rock the cradle.Once the car is up on stands, give it a few good shoves from all four sides. Any motion should be barely perceptible. It certainly shouldn’t sway. (Note, however, that some owners of pinned jack stands report that, due to that circular pin, they do sway more than ratcheting stands, where the pawl rests on a squared-off tooth). However, once you’re under the car, do notrock it. It can be surprisingly easy to set up a resonant harmonic motion if you’re doing a lot of shoving, such as while installing a transmission and trying to line up the splines and seat the input shaft in the pilot bearing.

Jack stands manufactured after 2015 should be rated in pairs. That is, a pair of three-ton jack stands should together safely support 6000 pounds. The ratings come from the American National Standards Institute (ANSI) and American Society of Mechanical Engineers (ASME). You may see the standards referred to as ASME PALD (Portable Automotive Lifting Devices) and ANSI PASE (Portable Automotive Service Equipment). Stands manufactured to these standards are tested to 200 percent of their rated load for 10 minutes and experience less than 1/8-inch of deformation. However, note that testing is by the manufacturer, not by ANSI or SAME, and merely allows the manufacturer to claim certification of the product line. It is not assembly-line testing of each set of stands.

If you look up your vehicle’s weight in the owner’s manual or online and divide that by two, in theory that’s the minimum load rating you need for a pair of jack stands to support the front or rear of the vehicle. However: 1) for both safety and peace of mind, you probably don’t want to use the minimum, and 2) weight is just one factor. Jack stands also need to reach the underside of the vehicle and support the load in a stable manner, and the higher the stands are extended, the more the vehicle can rock. For example, half the weight of a 6000-pound truck is 3000 pounds, and on paper, even a little pair of two-ton (4000-pound) jack stands exceeds that, but two-ton jack stands are typically short and may not reach the frame rails of the truck even when fully extended.

So, apply some common sense and use the little two-ton jack stands for small passenger cars, three-ton stands for medium to large cars or mid-sized SUVs, and real five- or six-ton truck jack stands for a full-sized truck or SUV.

There are a few ways to think about floor jack load ratings. A floor jack that is ASME PASE 2014-certified should have been tested by the manufacturer to 150 percent of its rating, so as with jack stands, there is a built-in safety factor. It also should have a bypass valve that prevents you from continuing to lift if it’s overloaded. (Safety tip: If it’s getting really hardto keep pumping up the jack, you’re probably close to overloading it.) However, as is the case with jack stands, if you look at the load ratings the wrong way, you can fool yourself into doing things that aren’t safe. It’s important to understand that the physical size of the jack is probably just as important as the numerical load rating, since a big jack is simply more stable than a small one.

Case in point: If you’re only ever using a jack to lift one wheel to change a flat and want to factor in that the wheel could be on the heavy end of the car where the engine is, assume the jack has to safely lift 33 percent of the weight of the car. For a big vehicle like a 6000-pound truck, one-third the weight is 2000 pounds, so, on paper, even the smallest 1.5-ton (3000-pound) trolley jack has an adequate rating. But, as with the jack stand calculation above, this is so misleading that it’s unsafe, as the jack needs to reach the lift point, get the vehicle high enough in the air to lift the tire off the ground and allow a stand to be put under the frame, and do all this in a stable fashion. I simply don’t believe that a little trolley jack with a narrow base can do that repeatably and safely on a big vehicle, no matter what the load rating says.

For this reason, an oft-quoted rule of thumb, cited by Tom and Ray Magliozzi (“Click and Clack” of Car Talkfame) is that a right-sized floor jack should be rated to at least 75 percent of the vehicle’s weight. So, 6000-pound vehicle à 4500-pound (2 1/4-ton) jack. That still feels a little light to me, but the recommendation does say “at least.”

My option is that, as with jack stands, you should use a good dose of common sense and only ever use a narrow little trolley jack to lift one wheel of a small car, use at least a two-ton jack for repeated in-garage lifting of most cars, use at least a three-ton jack for SUVs, and use a real truck jack to lift a real truck.

This could be a whole column in and of itself. Consulting an owner’s manual doesn’t always help, as it’ll probably only tell you where the factory jack points are for the flimsy little jack that comes with the car. An enthusiast web forum is probably the best place to look. The nose of an older car is typically lifted from the middle of the front subframe, and jack stands are typically placed either under the subframe or the frame rails, but on a newer car, these locations may be hidden under cladding, and the plastic jack pads on or under the rocker panels may be best. Be hyper-aware of the rust situation on your car, as the car world is filled with stories of jacks puncturing rusty frame rails.

To a certain extent, with both floor jacks and stands, bigger is better, as bigger generally means a larger load rating, more stability, and higher lift, but it also means heavier, and that’s at odds with portability. If you’re looking for just-in-case floor jack and stands to have in the trunk for a road trip, you want them light and right-sized.

One wildcard is that, if you have a very low car with a jacking point that is far underneath and difficult to reach, you need a low-rise, long-reach floor jack, but the quirky tradeoff is that even though these are big and heavy to have the structural rigidity necessary to achieve the long reach, that very design means they don’t have as high a load rating as an equally-heavy truck jack would have.

I currently own four floor jacks. The biggest is an AC Hydraulics DK13HLQ, which was and still is the cream-of-the-crop of low-rise long-reach floor jacks and has an insanely low 3.15-inch profile. They’re very expensive, but about 10 years back I found a used one locally and treated myself. For reaching the jack point of my BMW M Coupe or playing limbo with the front sway bar of my lowered Lotus Europa, nothing else I own will work. However, due to its long reach, it’s only rated at 2900 pounds. The Harbor Freight 2 1/4-ton jack has been kicking around the garage since it was still called “Harbor Freight and Salvage.” The Pittsburgh 1.5-ton aluminum floor jack gets thrown in the trunk for road trips. It’s a little bigger than the little yellow trolley jack that used to perform that function, but that makes it more stable. I don’t currently have a real truck jack, but then again, I don’t currently have a real truck.

Stand-wise, there are three sets, all of which are ratcheting stands. There’s a set of tall six-ton truck stands that I bought nearly 20 years ago when I needed to put the back of the Porsche 911SC way up in the air to drop the engine. There’s an old set of Harbor Freight three-ton stands that still see the most use. And there’s a set of aluminum stands that get thrown in the trunk along with the aluminum floor jack for road trips. These are all old enough that none have the new “double-locking” redundant safety pin, but since I always “double-jack” the car, I don’t lose sleep over it. I do check the welds on all three sets for any signs of cracking.

If you won’t feel safe working under a car until you have the best most expensive jack stands available, by all means have a look at the D41609 from US Jacks or the ESCO 10498 stands. But once you have them, please remember everything I said above—always double-jack the car, work only on a level concrete surface, do not overload the stands, and do not rock the car.

Every vehicle owner deserves a dependable hydraulic jack to lift automobiles to change a flat tire or fix issues underneath the car. Although most people pick a bottle jack because it’s compact, lightweight, and affordable, I prefer a floor jack because it’s more stable and effortless to position under the automobile. Unfortunately, there are many floor jack choices.

For me, the ideal trolley jack must have an impressive lifting height range, allowing me to raise any vehicle from a road-hugging convertible to a terrain-conquering lifted truck. Only the best low profile floor jack fits this requirement to the tee. If you’re also looking for such a floor jack, I’ve reviewed ten of the market’s best options to help you determine the best low-profile trolley jack to use in your vehicle.

One disadvantage of low-profile jacks is their price compared to conventional bottle hydraulic lifts. This trolley jack won’t hurt your budget while giving you commendable vehicle lifting performance.

Any automobile with a 2.75-ton maximum gross weight should be compatible with this 2-ton floor jack. Owners of sedans, small-sized pickup trucks, and SUVs will find this service jack more than capable of lifting their vehicles 13 inches off the ground.

It’s comforting to know that underneath its shiny blue paint is a solid steel alloy construction, allaying any fears about this trolley jack failing after only several uses. Each component is as robust as high-end brands, adding to the confidence in this device.

Positioning this service jack under the car is a breeze because it has oversized front wheels and the rear casters never snag. Its lever is long enough to facilitate precision maneuvering, while the saddle is adequately broad to guarantee correct lift point alignment.

I’m also impressed with this service jack’s quick-start technology. Most floor jacks require at least 20 pumps to raise the lifting arm. This product’s proprietary system ensures three times faster lift arm elevation, allowing operators to finish faster.

Although this trolley jack has an admirable lifting performance, its minimum lifting height might be insufficient for low-clearance cars. At 5.125 inches, you’ll find it challenging to slide this floor jack under a Porsche, Ferrari, or other ground-hugging, ultra-low cars.

It’s not as low-profile as most people would want, but its lifting performance and affordability make this hydraulic floor jack a good option for average vehicle owners.

I call it thebest low profile floor jack for the moneybecause of its unbeatable lifting performance, exceptional craftsmanship, and sweat-free maneuverability.

Sliding this three-ton floor jack under a Ferrari, Porsche, Mustang, or other low-clearance sports cars is a cinch with its 3.125-inch minimum lifting height.

Raising trucks, vans, SUVs, 4x4s, ATVs, and trailers 20 inches off the floor is also never a problem, making this floor jack as handy in the home garage as it is in professional auto shops.

Its lifting height range isn’t this trolley jack’s only admirable attribute. Its load capacity also deserves mention. Capable of lifting any 4-ton vehicle, this floor jack is the last device you’ll buy if you have a thriving auto repair shop.

The extra-wide saddle facilitates precise lift point positioning and guarantees a non-marring surface for the vehicle’s under-chassis. Maneuvering this service jack is sweat-free, thanks to its swivel casters and two-foot jack lever.

Torin never fails to impress with its thoughtfully designed products. This low-profile trolley jack continues the brand’s untarnished reputation in cutting-edge vehicle-lifting technologies.

This 4-ton hydraulic jack delivers exceptional vehicle-lifting performance like any other Torin device. It’s like the Torin TCE ATZ830026XU but with a higher load capacity.

This floor jack is also perfect for SUVs, trucks, vans, and trailers, raising them 20 inches off the floor. Any automobile with a 5.35-ton maximum gross weight should be compatible with this vehicle-lifting device.

Maneuvering and operating this floor jack is hassle-free because of the carefully designed wheels, handle, safety valve, and lifting arm. Its steel alloy frame offers confidence in its use, while its dual piston pump guarantees more effortless pumping.

Although this low-profile floor jack is impressive, it’s hefty. At 100.8 pounds, I wouldn’t dare put this in my trunk. The truck bed should be more suitable for this device, although leaving it at home sounds more reasonable.

You can still buy this low-profile floor jack if you don’t mind its heft. It should make roadside emergencies more manageable with its superior lifting performance.

Its heft is the only thing preventing this low-profile floor jack from earning five stars. You should still give it a thumbs up if weight isn’t an issue.

With an impressive 15.75-inch lifting range from 3.5 to 19.25 inches, this floor jack can accommodate a power-hungry Ford F150, a road-hugging Mustang, and every high-performance machine in between.

Four-ton vehicles will sit nicely on this floor jack’s extra-wide saddle, relying on its robustly

8613371530291

8613371530291